Why do I need a proximity switch + marking and features of its connection

Innovative ideas make it possible to simplify many processes, add convenience when using household and industrial equipment, and automate work cycles.

Often, a contactless switch is taken to implement them, able to respond in a timely manner to a specific stimulus without the physical presence of a person.

Let's take a closer look at what kind of device it is and for what purpose it serves.

The content of the article:

What is a proximity switch for?

To perform a certain action, it is not necessary to take an active part yourself - go to the intended object and carry out any manipulations with it. Proposed by manufacturers of electrical equipment smart productable to partially replace a person.

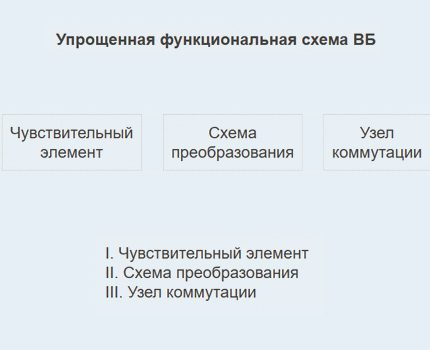

The principle of operation of the equipment

A device that stops the operation of certain equipment in a non-contact manner is called a switch or, in short, WB. It is also often called a sensor - but this concept also generalizes in itself devices with an analog output signal.

Such terminology, as well as the scope of use, resistance to various kinds of damage and technical characteristics are provided GOST R 50030.5.2-99. The document regulates the compliance of operating parameters, the timely operation of the protective mechanism during overload and other operational nuances of the device.

The product is a semiconductor element that controls the electrical circuit. When an irritant is detected or its presence in the zone of its action, it turns off the load current, which leads to an open circuit.

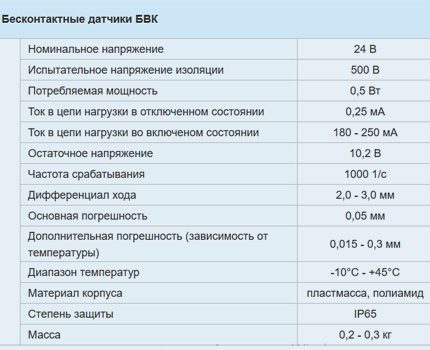

The device has a durable case made of polymer or nickel-plated brass. Inside such an enclosure is an electrical part that needs insulation. Many models have protection class IP65 or 67.

The device works without contact, and the sensitive element, also called a photodetector, can be located separately from the emitter or in the same housing with it. These 2 parts work in pairs.

As for the size, shape and appearance of the WB, these parameters depend on the purpose and scope of application, as well as operating conditions.

The standard provides for the manufacture of devices, the shape of the case of which is as follows:

- rectangular with a square or rectangular section, which is denoted as D or C, respectively;

- cylindrical with thread - A or without it - B.

Depending on the model and its intended use, the product can be additionally equipped with a double insulated wire.

To operate in difficult conditions, contactless devices are produced, the housing of which is filled with a compound. This is a polymer substance that provides reliable protection against moisture and other foreign matter getting on the working mechanisms.

According to the principle of functioning, the devices are divided into 4 large groups.

The capacitive and inductive detection method is more reliable, and the WB itself, operating in this way, are more durable than their counterparts. The first of them react to an item made of almost any material, and the second to metal.

Scope of contactless device

The unique property of controlling the operation of devices without contacting them directly opens up bright prospects for the use of this type of switch. It allows you to create original developments in various fields, improve living conditions in a house / apartment.

And for sound modifications, it is enough to clap your hands so that the device hidden inside the chandelier body opens the circuit.

In addition, proximity sensors are widely used to optimize production processes. It is they that allow you to control the quality of the implementation of complex cycles in mechanical engineering.

And also on automatic lines in the production of food products and textile products, in the manufacture of parts in foundries, and more.

What will the labeling say?

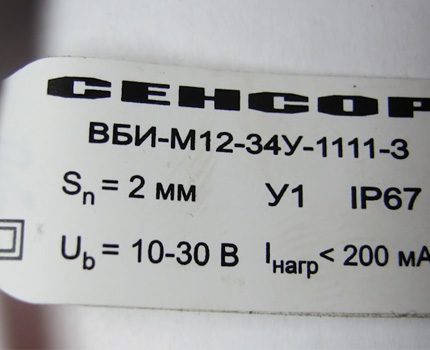

Non-contact type switches are supplied to the market by various manufacturers. Among them are Western, domestic and Chinese companies. It is important when buying to pay special attention to the quality of the units and the reputation of the manufacturer.

Due to the seriousness of the regulated processes, for the control of which various modifications of the sensors are used, you should only choose products that have accompanying documentation - instructions with installation diagrams, operating conditions and a list of technical parameters.

Not all indicators can fit in a small section of the switch. The rest, relevant to the consumer, are contained in the user manual.

If the model you like does not have instructions in the kit, then you should not buy it - it could be a fake. Moreover, some of the necessary parameters will remain unknown, but you cannot trust the seller’s word.

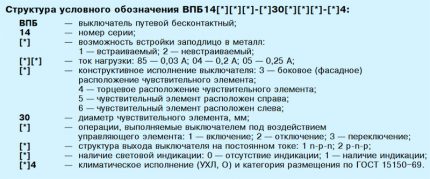

Each company engaged in the production of switching devices for controlling an electric circuit has its own notation system. Its decoding is given in the catalog, which also contains the range of products offered.

The need for marking arose by chance - the variety of circuit breakers is large. In addition, they can be classified according to various principles.

For example, depending on the function performed during switching, devices are divided into the following categories:

- inclusion (NO) - A;

- shutdown (NF) - B;

- switching - C;

- programmable option - P;

- another - S.

And according to the installation method, the sensors are recessed, unrecessed, and others.

If the company uses the labeling principle recommended by GOST, then the inscription on the switch will have, for example, the following form:

U3 A30 A D2

Where:

- U is an ultrasonic method for detecting an irritant. The rest correspond to other Latin letters: I - inductive, C - capacitive, D, R and T - photoelectric direct, reflective and barrier action, respectively;

- 3 - another installation method;

- A30 - shape and diameter, which in this case means cylindrical with a thread with a diameter of 30 mm;

- A is the switching function of the element, which means the inclusion of (NO);

- D is the number of wires for outputting direct or alternating current, which corresponds to two connectors for direct current;

- 2 - plug-in connection method.

In total, 4 matching options are provided, among which the unit corresponds to ribbon wires, the two were considered above, the three - clamp, and the four - another method.

Among bona fide manufacturers there are such companies as Sensor / Sesor, German company Fotoelektrik Pauly, NPK TEKO, PKF STRAUS, Meander, ZAO OVEN and SKB IS, NPP PRIZMA from Yekaterinburg and others.

Many of them offer a service for the manufacture of WB with the parameters necessary for the consumer - to order.

We also recommend reading our other article, where we described in detail the various types of light switches. Read more - read Further.

DIY connection features

It is possible to install a contact switch for domestic use, functioning non-contact. As for the models for controlling the load current in production, here only an employee who has access to specific equipment is allowed to carry out installation.

Before connecting, pay attention to the following points:

- for the functioning of the WB requires power, but it can not be connected directly if the product is a two-wire type;

- at the power source used for the proximity sensor, the voltage must correspond to the parameters specified in the switch passport;

- When tightening fasteners, it is important not to overtighten the nuts.

The manual should include a wiring diagram to be followed, as well as a method for installing a specific model.

First, a mechanical type of installation is performed - using fasteners, if necessary, lock nuts to connect the device.

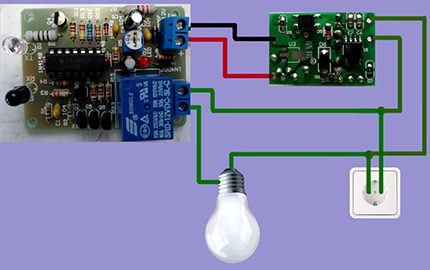

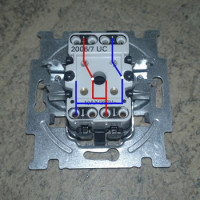

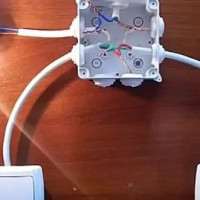

When everything is securely fixed, then it's time to proceed to the second stage - the electrical connection.

When working with the mains, it is important not to forget to turn off the power to housing shieldto protect yourself. Then the WB wire is connected in one of the ways provided by GOST. Its type depends on the modification.

Most often for home use, a sensor is used to control the operation of the chandelier. Therefore, the last stage is the placement of the fixture in the body of the lighting product. If necessary, adjust and configure the response time, the active distance at which the device will operate.

Assembling the device at home

You can make a switch yourself. Although at first glance, this venture seems complicated and incomprehensible to the average consumer, but if desired, everything will work out if you choose a simple method.

The best part is that a person who does not have much experience in assembling electrical appliances, but is keenly interested in such units, will be able to cope with the task.

Of course, if you do not aim at creating a device capable of performing programmable switching of an element, when complex response options are implemented.

The product should be able to turn off the light bulb if the user's hand falls into the coverage area for a couple of seconds.

First, you have to prepare the working elements for the assembly of the device. It will be a board, microcircuit, transistors, relays, capacitors, LEDs, photocells and other accessories.

After soldering, it is necessary to check the quality of the joints made so that each structural element is securely fixed.

The lifetime depends on this, because the product will be placed inside the fan housing, hand dryers or chandeliers.

It remains to verify the operability of the assembled device. To do this, carry out several tests for operation, holding the palm next to the sensor.

When the result is not satisfied, it is up to the adapter - a screw for adjustment - to set the necessary parameters for the response.

The assembled circuit breaker can be further modified by adding the desired functions if there is experience in conducting electrical work and the desire to create something original.

Conclusions and useful video on the topic

Why do we need non-contact switching devices, their types, connection and marking:

An infrared switch helps turn on the light without touching the actual keys of the switching device. Assembly and demonstration of his work in the video:

For automatic drying, you can use a smart device of a non-contact type. About this in the video:

On capacitive switches operating without direct contact with an object:

Having dealt with the intricacies of marking and the scope of application of specific types of sensors, you can choose the optimal model for switching electrical circuits. Or even make a contactless assembly with your own hands, having acquired a set of necessary elements with a scheme for their location. Such a switch will make your home a little “smarter”.

Want to ask a question about mounting a proximity switch? Please leave comments in the block below. Here you also have the opportunity to report an interesting fact on the topic of the article.

Rocker switch: marking, types, connection features

Rocker switch: marking, types, connection features  Float switch: what is needed and what to consider when choosing and installing

Float switch: what is needed and what to consider when choosing and installing  Card switch: what is it for, how to choose it and connect it correctly

Card switch: what is it for, how to choose it and connect it correctly  Touch light switch: why is it needed, types, marking, selection and connection

Touch light switch: why is it needed, types, marking, selection and connection  How to choose a passage switch: device and purpose of various types + marking

How to choose a passage switch: device and purpose of various types + marking  How to connect an LED switch: rules for connecting a backlit switch

How to connect an LED switch: rules for connecting a backlit switch  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

In general, I believe that in everyday life all switches should become exclusively contactless. It is not even a matter of fashion, namely, convenience. Moreover, such switches will not spoil the design of the room. But more complex designs should clearly correlate with the given functions. Therefore, it is better to take programmable options. By the way, special attention should be paid to the quality of the sensors.

I agree, Igor, convenience and practicality above all. Therefore, proximity switches are becoming increasingly popular. Although, I must say that the independent connection of such a proximity switch is somewhat more complicated than usual, and requires a preliminary study of the manuals. But most importantly, the desire to understand is quite real, even having skills at the level of labor lessons at school.

You yourself can easily make an ordinary switch, but for this you will have to call a specialist every time. Excessive over-complication of technology is also not a plus.