DIY LED lamp: scheme, design nuances, self-assembly

LED-lamps are widely used in the organization of domestic, street, industrial lighting. Their important advantages are profitability, environmental friendliness, unpretentiousness in service.

A self-made LED lamp will certainly find its application in your home. Detailed manufacturing instructions, as well as assembly schemes, can be found in the article.

The content of the article:

- The principle of operation of the LED device

- Four varieties of LED devices

- LED lamp device

- Advantages and disadvantages of a homemade lamp

- Self-made issues

- LED lamp schemes

- Important element: LED driver

- LED Enclosures

- Materials for making homemade

- Putting a simple LED lamp

- Conclusions and useful video on the topic

The principle of operation of the LED device

The basis of the LED lamp is a one-sided semiconductor, the value of which is several millimeters. In it, the unidirectional movement of electrons occurs, which allows you to convert alternating current into direct current.

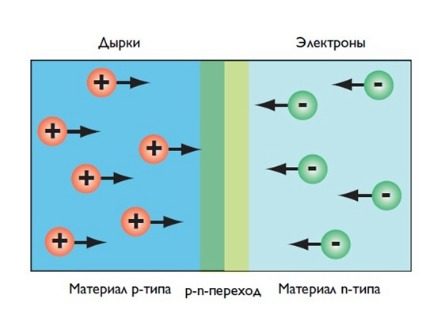

The LED crystal consisting of several layers is characterized by two types of electrical conductivity: positively and negatively charged particles.

The side where the minimum number of electrons is contained is called hole (p-type), while the other with a large number of these particles is called electronic (n-type).

When elements collide at the pn junction, they collide, generating photons of light particles. If the system is kept constant at this time, the LED will emit a steady stream of light. This effect is used in all LED lamp designs.

Four varieties of LED devices

Depending on the placement of LEDs, such models can be divided into the following categories:

- Dip. The crystal is arranged with two conductors over which the magnifier is located.The modification was widely used in the manufacture of signboards and garlands.

- "Piranha". Instruments are assembled similarly to the previous version, but provide four conclusions. Reliable and durable structures are most often used to equip cars.

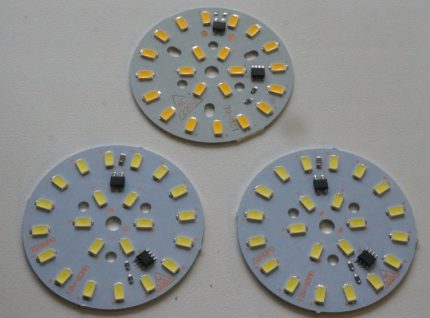

- SMD. The crystal is placed on top, which significantly improves heat dissipation, and also helps to reduce the size of the devices.

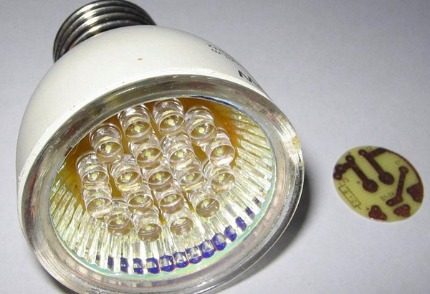

- OWL. In this case, the LED is soldered directly to the board, which contributes to an increase in the glow intensity and protection against overheating.

A significant drawback of COB devices is the impossibility of replacing individual elements, which is why it is necessary to acquire a new mechanism due to a single failed chip.

Chandeliers and other household lighting products typically use the SMD design.

LED lamp device

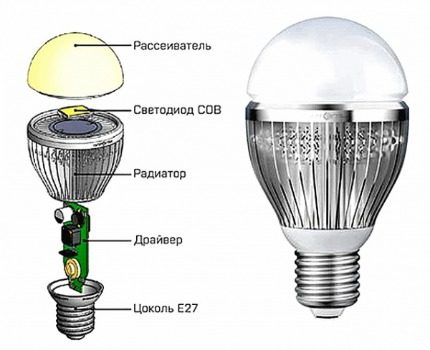

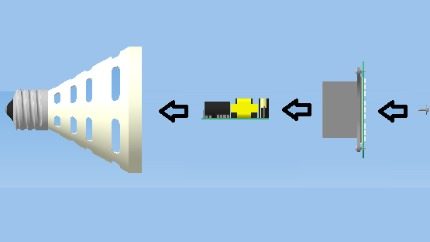

The LED lamp consists of the following six parts:

- Light-emitting diode;

- basement;

- driver;

- diffuser;

- radiator.

The active element of such a device is an LED that generates a stream of light waves.

The base, which can have a different look and size, is also used for other types of lamps - fluorescent, halogen, incandescent. At the same time, some LED devices, such as LED strips, can do without this part.

An important design element is the driver, which converts the mains voltage into the current on which the crystal operates.

The effective operation of the lamp largely depends on this unit, in addition, high-quality driverhaving a good galvanic isolation, provides a bright constant light stream without a hint of blinking.

A conventional LED produces a directional beam of light. To change the angle of its distribution and provide high-quality lighting, a diffuser is used. Another function of this component is to protect the circuit from mechanical and environmental influences.

The radiator is designed to remove heat, excess of which can damage the device. Reliable operation of the radiator allows you to optimize the lamp and extend its life.

The smaller this part, the greater heat load the LED will have to withstand, which will affect the speed of its burnout.

Advantages and disadvantages of a homemade lamp

Specialized stores offer a large selection of LED devices. However, sometimes in the assortment it is impossible to find a device that meets the necessary parameters. In addition, LED devices are traditionally of high cost.

Meanwhile, it is quite possible to save money and get the perfect lamp by completing the assembly yourself. To do this is simple and it will be enough basic technical knowledge and practical skills.

A self-made LED device has a number of significant advantages over an analogue purchased in a store. They are economical: with careful assembly and use of high-quality parts, the operation period reaches 100 thousand hours.

Such devices show a high degree of energy efficiency, which is determined by the ratio of power consumption and brightness of the generated light. Finally, their cost is an order of magnitude lower than that of factory counterparts.

Self-made issues

The main issues that have to be addressed in the manufacture of LED lamps are the conversion of alternating electric current to pulsating and its equalization to constant. In addition, it is necessary to limit the strength of the electric current to 12 volts, which is necessary to power the diode.

Thinking through the device, you should also solve a number of design problems, namely:

- How to arrange the circuit and LEDs;

- how to isolate the system;

- how to provide heat transfer in the device.

Before assembling, it is advisable to think through all these problems, taking into account the requirements that apply to a home-made light source.

LED lamp schemes

First of all, you should work out an assembly option. There are two main ways, each of which has its own pros and cons. Below we will consider them in more detail.

Diode Bridge Option

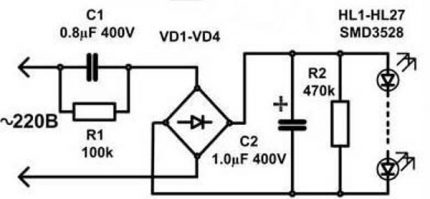

The circuit includes four diodes that are connected in different directions. Thanks to this, the bridge gains the opportunity to transform the mains current of 220 V into pulsating.

This happens as follows: when passing through two diodes of sinusoidal half-waves, they change, which causes a loss of polarity.

During assembly, a capacitor is connected to the positive output in front of the bridge; in front of the negative terminal - 100 Ohm resistance. Another capacitor is installed behind the bridge: it will be needed to smooth out voltage drops.

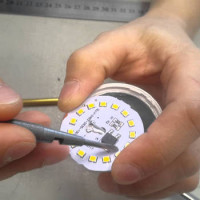

LED element fabrication

The easiest way to create an LED luminaire is to make a light source based on a broken luminaire. It is necessary to check the operability of the detected parts, which can be done using a 12 V battery.

Defective items must be replaced. To do this, you should unsolder the contacts, removing the burnt out elements, put in their place new ones. It is important to observe the alternation of anodes and cathodes, which are mounted in series.

If you want to change only 2-3 pieces of the chip, just solder them to areas where previously failed components were located.

With complete self-assembly, it is necessary to connect 10 diodes in a row, observing the rules of polarity. Several completed circuits are soldered to the wires.

When assembling the circuits, it is important to ensure that the soldered ends do not touch each other, since this can lead to a short circuit of the device and failure of the system.

Accessories for softer light

To avoid the flicker inherent in LED lamps, the scheme described above can be supplemented with several details. Thus, it should consist of a diode bridge, 100 and 230 Ohm resistors, 400 nF and 10 uF capacitors.

To protect the device from voltage surges, a 100 Ohm resistor is placed at the beginning of the circuit, followed by a 400 nF capacitor, a diode bridge and another 230 Ohm resistor are installed after it, followed by an assembled LED circuit.

Resistive devices

A similar scheme is also quite accessible to the novice master. It requires two 12k resistors and two chains of the same number of LEDs, which are soldered sequentially taking into account the polarity. In this case, one strip from the side of R1 is connected by the cathode, and the other from R2 by the anode.

The luminaires made according to this scheme have a softer light, since the active elements are lit in turn, so that the pulsation of the flashes is almost invisible to the naked eye.

Devices are successfully used as a table lamp and for other purposes. To create optimal lighting, experts recommend the use of ribbons of 20-40 diodes. A smaller amount gives a small luminous flux, the connection of a larger number of elements is technically quite difficult to perform.

Important element: LED driver

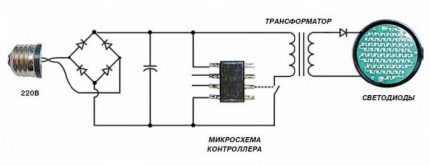

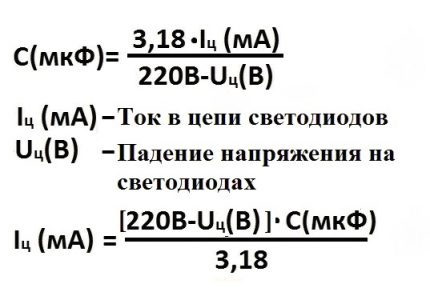

For the correct operation of the LED device, made by hand, you should solve the problem with the driver. The layout of this node is quite simple. The algorithm of operation consists in passing alternating current of 220V to the diode bridge through capacitor C1.

The rectified current passes to the series-connected LEDs HL1-HL27, the number of which can reach 80 pieces.

To avoid flickering and to achieve a consistently even color, it is desirable to use a capacitor C2, which should have the largest possible capacity.

LED Enclosures

Before assembly, it is important to decide where the assembled circuit will fit.

There are several options for solving this problem - you can use to place the device:

- lamp bases incandescent;

- cases from blown energy-saving or halogen lamps;

- DIY fixtures.

The first option has an important advantage. When using it, it is easy to screw the assembled LED device into the cartridge, thereby ensuring heat transfer.

It should be noted that in addition to the obvious plus, this method has obvious disadvantages. The assembled design has a not very aesthetic appearance, in addition, in this case it is difficult to make reliable insulation.

A convenient and practical option is to place a home-made device in the housing of an energy-saving lamp. To do this, it is first necessary to disassemble the burned-out device, removing the converter board from it.

The assembled circuit can be inserted using different methods:

- Diodes are placed in holes that are made in the lid under a glass flask.

- The circuit can be placed inside the base, which guarantees heat transfer. In this case, the LED elements are inserted and fixed into existing openings.

- The board can be hidden in the base. To perform the process, it is convenient to use a regular plastic bottle cap from a water bottle.

To place the LEDs, craftsmen often use a do-it-yourself circle made of plastic or cardboard, in which holes for diodes are drilled. With carefully executed work, such devices look quite aesthetically pleasing.

Another option is to use a halogen lamp housing. He did not receive wide distribution, since in this case there is no way to twist the lamp into the cartridge. Nevertheless, such a modification is used to make home-made indicators and other devices.

If you decide to use the light bulb housing for work, we recommend that you read our other article, where we described in detail how to disassemble various types of light bulbs. More details - go to the link.

Materials for making homemade

In addition to the housing, other elements will be required to create the lamp. These are, first of all, LEDs, which can be purchased in the form of LED strips or individual NK6 elements. The current strength of each part is 100-120 mA; voltage 3-3.3 V.

Rectifier diodes 1N4007 or a diode bridge, as well as fuses, which can be found in the base of the old device, are also required.

You will also need a capacitor, the capacitance and voltage of which must correspond to the used electrical circuit and the number of LED elements used in it.

If you do not use a finished board, you need to think about the frame to which the LEDs are attached. For its manufacture, a heat-resistant material that is not a metal and non-conductive electric current is suitable.

As a rule, such a part is made of durable plastics or thick cardboard. To attach the LED elements to the frame, you need liquid nails or superglue.

Putting a simple LED lamp

Consider the implementation of the lamp in a standard base from a fluorescent lamp. To do this, we will have to slightly modify the above list of materials.

In this case, we use:

- old base E27;

- LEDs NK6;

- RLD2-1 driver;

- a piece of plastic or thick cardboard;

- Super glue;

- electrical wiring;

- soldering iron, pliers, scissors.

Initially, it is required to disassemble the lamp. For fluorescent devices, the base is connected to the plate with tubes by means of latches. It is important to locate the fastener and pry the elements with a screwdriver, which makes it easy to detach the cartridge.

When disassembling the device, extreme care must be taken so as not to harm the tubes inside which the poisonous substance is located. At the same time, it is necessary to monitor the integrity of the electrical wiring connected to the base, and also to keep the details contained in it.

We use the upper part with the connected discharge tubes to make the plate necessary for connecting the LEDs. It is enough to remove the tubular elements and fix the LED parts into the remaining round holes.

For their reliable fastening, it is better to make an additional plastic or cardboard cover, which will serve to insulate the chips.

NK6 LEDs will be used in the lamp, each of which consists of 6 crystals with parallel connection. They allow you to create a fairly bright lighting device with a minimum of electricity consumed.

To connect each LED to the cover, two holes must be made. They should be punctured carefully in strict accordance with the scheme.

The plastic part allows you to firmly fix the LED elements, while the use of cardboard requires additional fastening of the LEDs to the base with liquid nails or superglue.

Since the device is designed to use six LEDs with a power of 0.5 watts each, it is necessary to provide for three parallel connected elements in the circuit.

In a design that will operate on a 220 V power supply network, the RLD2-1 driver must be provided, which must be purchased at the store or performed independently.

To avoid a short circuit, before assembling it is important to isolate the driver and the board from each other using plastic or cardboard. Since the lamp almost does not heat up, do not worry about overheating.

Having picked up all the components, you can assemble the structure according to the scheme, and then connect it to the mains to check the glow.

The device, powered by a standard 220 V cartridge, has low power consumption and a power of 3 watts. The latter indicator is 2-3 times less than that of luminescent devices and 10 times less than that of incandescent lamps.

Although the luminous flux is only 100-120 lumens, thanks to the dazzling white color, the lamp seems much brighter. The assembled lamp can be used as a table lamp or for lighting a compact room, for example, a corridor or a closet.

Conclusions and useful video on the topic

In the video below you can see a detailed story of a specialist about self-assembly of an LED-lamp:

LED lamps, made independently, have high technical characteristics. They are almost not inferior to factory models in such qualities as strength, reliability, durability.

The assembly of such devices is available to almost everyone: for its successful implementation it is only necessary to strictly follow the schemes and carefully carry out all the prescribed manipulations.

Perhaps you already had to assemble the LED lamp yourself and you can give valuable advice to visitors to our site? Or after reading the article have questions? Please leave your comments in the box below.

LED lamp E40: device, characteristics, scope

LED lamp E40: device, characteristics, scope  Assembly and installation of the chandelier: detailed instructions for installing and connecting with your own hands

Assembly and installation of the chandelier: detailed instructions for installing and connecting with your own hands  DIY LED lamp repair: the causes of breakdowns, when and how you can repair it yourself

DIY LED lamp repair: the causes of breakdowns, when and how you can repair it yourself  Lighting in the bathroom: DIY LED lighting

Lighting in the bathroom: DIY LED lighting  LED lamp layout: simple driver device

LED lamp layout: simple driver device  Bulbs for spotlights: types, characteristics, nuances of choice + best brands

Bulbs for spotlights: types, characteristics, nuances of choice + best brands  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

It is interesting to read, but I doubt that someone will make a home-made LED light bulb. Unless purely out of curiosity and academic interest, you can try to make it, with different schemes. In general, LED lamps have many advantages - they work for a long time, they require little electricity, they produce little heat, they offer a wide selection of colors.

Exactly. I read the material with interest, but I do not see the practical application of homemade LED dumps.

A good idea for those who like to hold a soldering iron in their hands, and also have a little time and desire. Given the widespread use of LED bulbs, the material costs of assembling them tend to zero, it is enough not to throw out lamps that have stopped working (including from friends). In some, the LEDs themselves “burn”, in others, a capacitor or a diode bridge fails, the cases almost always remain intact ... Unless you can buy drivers if you want to put things on stream.