Powerful do-it-yourself voltage regulator: circuit diagrams + step-by-step assembly instructions

Making homemade voltage stabilizers is a fairly common practice. However, for the most part, stabilizing electronic circuits are created that are designed for relatively small output voltages (5-36 volts) and relatively low power. Devices are used as part of household equipment, nothing more.

We will tell you how to make a powerful voltage regulator with your own hands. In our article, we describe the manufacturing process of a device for working with a network voltage of 220 volts. Based on our tips, you can easily cope with the assembly yourself.

The content of the article:

Voltage stabilization of a household network

The desire to provide a stabilized voltage of the household network is an obvious phenomenon. This approach ensures the safety of operating equipment, often expensive, constantly necessary in the household. And in general, the stabilization factor is the key to increased safety of the operation of electric networks.

For domestic purposes, they most often acquire gas boiler stabilizerwhose automation requires a power connection, for the refrigerator, pumping equipment, split systems and similar consumers.

There are many ways to solve this problem, the simplest of which is to buy a powerful voltage regulator manufactured in an industrial way.

Offers voltage stabilizers in the commercial market a lot. However, acquisition opportunities are often limited by the cost of devices or other points.Accordingly, an alternative to buying is the assembly of a voltage stabilizer with your own hands from available electronic components.

Provided that you have the appropriate skills and knowledge of electrical installation, the theory of electrical engineering (electronics), wiring circuits and soldering elements, a home-made voltage stabilizer can be implemented and successfully applied in practice. There are such examples.

220V power supply circuit stabilization solutions

Considering possible circuit solutions for voltage stabilization taking into account relatively high power (at least 1-2 kW), one should keep in mind the variety of technologies.

There are several circuit solutions that determine the technological capabilities of devices:

- ferroresonance;

- servo-driven;

- electronic;

- inverter.

Which option to choose depends on your preference, available materials for assembly and skills in working with electrical equipment.

Option # 1 - Ferroresonance Scheme

For self-manufacturing, the simplest version of the circuit is the first item on the list - a ferroresonant circuit. It works by using the effect of magnetic resonance.

The design of a sufficiently powerful ferroresonant stabilizer can be assembled on only three elements:

- Throttle 1.

- Throttle 2.

- Capacitor.

However, simplicity in this embodiment is accompanied by a lot of inconvenience. The design of a powerful stabilizer, assembled according to the ferroresonant circuit, turns out to be massive, bulky, and heavy.

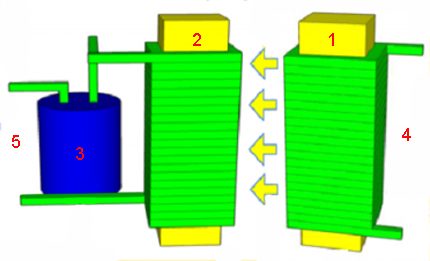

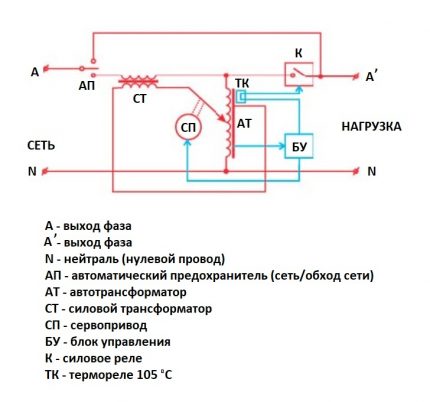

Option # 2 - autotransformer or servo drive

In fact, this is a scheme where the principle of an autotransformer is used. The voltage transformation is automatically carried out by controlling the rheostat, the slider of which moves the servo.

In turn, the servo drive is controlled by a signal received, for example, from a voltage level sensor.

Approximately in the same way a relay-type device operates, with the only difference being that the transformation ratio changes, if necessary, by connecting or disconnecting the corresponding windings using a relay.

Schemes of this kind already look more technically complicated, but at the same time they do not provide sufficient linearity of the voltage change. Manually assemble the relay device or on a servo drive is permissible. However, it is wiser to choose an electronic option. The cost of effort and money is almost the same.

Option # 3 - electronic circuit

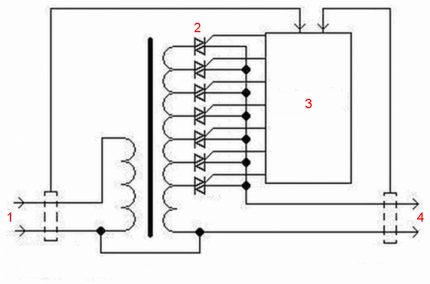

Assembling a powerful stabilizer according to the electronic control scheme with an extensive assortment of radio components for sale becomes quite possible. As a rule, such circuits are assembled on electronic components - triacs (thyristors, transistors).

A number of voltage stabilizer circuits have also been developed, where power field-effect transistors are used as keys.

It is quite difficult to make a powerful device completely electronically controlled by a non-specialist, better buy a finished device. In this matter, experience and knowledge in the field of electrical engineering is indispensable.

Under independent production, it is advisable to consider this option if there is a strong desire to build a stabilizer, plus the accumulated experience of an electronics engineer. Further in the article, we will consider a design of electronic design suitable for DIY manufacturing.

Detailed assembly instructions

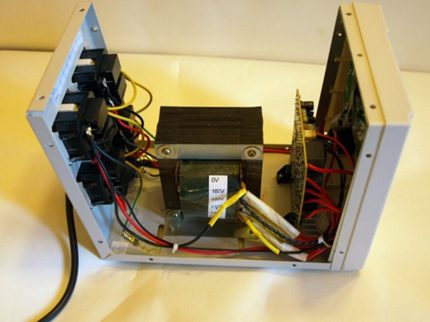

Considered as an independent manufacture, the circuit is more likely a hybrid option, since it involves the use of a power transformer in conjunction with electronics. The transformer in this case is used from among those that were installed in TVs of old models.

True, in TV receivers, as a rule, TS-180 transformers were installed, while a stabilizer requires at least TS-320 to provide an output load of up to 2 kW.

Step # 1 - making the stabilizer body

Any suitable box based on an insulating material such as plastic, textolite, etc. The main criterion is the sufficiency of space for the placement of a power transformer, an electronic board and other components.

Also, the housing can be made of fiberglass sheet by bonding individual sheets using corners or otherwise.

The stabilizer box must be equipped with slots for installing the switch, input and output interfaces, as well as other accessories provided by the circuit as control or switching elements.

Under the manufactured case, you need a base plate, on which the electronic board will “lie” and the transformer will be fixed. The plate can be made of aluminum, but insulators should be provided for mounting the electronic board.

Step # 2 - making a circuit board

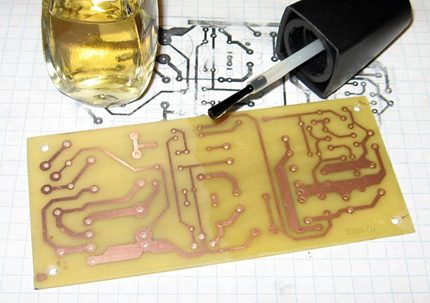

Here, you will need to initially design a layout for the placement and bundle of all electronic parts according to the circuit diagram, except for the transformer. Then, a sheet of foiled textolite is marked on the layout and the created trace is drawn (printed) on the side of the foil.

Next, the board is etched using the appropriate solution (for electronic engineers, the method of etching the boards should be familiar).

The printed copy of the wiring obtained in this way is cleaned, tin-coated and all the radio components of the circuit are assembled, followed by soldering. This is how the electronic circuit board of a powerful voltage regulator is manufactured.

In principle, you can use third-party services for etching printed circuit boards. This service is quite affordable, and the manufacturing quality of the “signet” is significantly higher than in the home version.

Step # 3 - voltage stabilizer assembly

A board equipped with radio components is prepared for external wiring. In particular, external communication lines (conductors) with other elements, such as a transformer, switch, interfaces, etc., are output from the board.

A transformer is installed on the base plate of the case, the circuit of the electronic board is connected to the transformer, the board is fixed on the insulators.

It remains only to connect external elements mounted on the housing to the circuit, install the key transistor on the radiator, after which the assembled electronic structure is closed by the housing. The voltage regulator is ready. You can begin to configure with further tests.

The principle of operation and homemade test

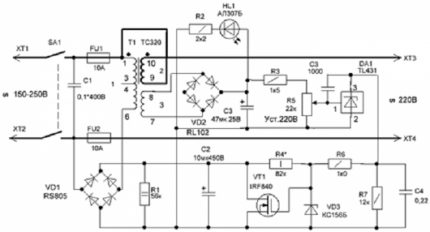

The regulating element of the electronic stabilization circuit is a powerful field effect transistor type IRF840. The voltage for processing (220-250V) passes through the primary winding of the power transformer, is rectified by the diode bridge VD1, and enters the drain of the IRF840 transistor. The source of the same component is connected to the negative potential of the diode bridge.

The part of the circuit, which includes one of the two secondary windings of the transformer, is formed by a diode rectifier (VD2), a potentiometer (R5) and other elements of the electronic controller. This part of the circuit generates a control signal, which is fed to the gate of the IRF840 field effect transistor.

In case of increasing the supply voltage, the control signal decreases the gate voltage of the field-effect transistor, which leads to the closure of the key. Accordingly, at the load connection contacts (XT3, XT4), a possible increase in voltage is limited. The reverse option is a circuit in case of a decrease in the mains voltage.

Setting up the device is not particularly difficult. Here you will need a conventional incandescent lamp (200-250 W), which should be connected to the output terminals of the device (X3, X4). Further, by rotating the potentiometer (R5), the voltage at the marked terminals is brought to the level of 220-225 volts.

Turn off the stabilizer, turn off the incandescent lamp and turn on the device already with a full load (not higher than 2 kW).

After 15-20 minutes of operation, the device is turned off again and the temperature of the radiator of the key transistor (IRF840) is monitored. If the heating of the radiator is significant (more than 75º), you should choose a more powerful heat sink radiator.

If the manufacturing process of the stabilizer seemed too complicated and irrational from a practical point of view, without any problems you can find and purchase a factory-made device. Rules and Criteria choosing a stabilizer for 220 V are given in our recommended article.

Conclusions and useful video on the topic

The video below discusses one of the possible homemade stabilizer designs.

In principle, you can take note of this version of the improvised stabilization apparatus:

Assembling a block that stabilizes the mains voltage with your own hands is possible. This is confirmed by numerous examples when radio amateurs with little experience quite successfully develop (or use an existing one), prepare and assemble an electronics circuit.

Difficulties with the purchase of parts for the manufacture of a stabilizer-homemade is usually not noted. The cost of production is low and naturally pays off when the stabilizer is put into operation.

Please leave comments, ask questions, publish photos on the topic of the article in the block below. Tell us about how to assemble a voltage regulator with your own hands. Share useful information that may come in handy for beginners visiting electrical engineering.

DIY electrical panel exclusion: current diagrams + detailed assembly instructions

DIY electrical panel exclusion: current diagrams + detailed assembly instructions  How to connect a differential machine: possible connection schemes + step-by-step instructions

How to connect a differential machine: possible connection schemes + step-by-step instructions  DIY assembly of the electrical panel: the main stages of electrical work

DIY assembly of the electrical panel: the main stages of electrical work  Rating of voltage stabilizers for the home: a popular ten among buyers + the nuances of choice

Rating of voltage stabilizers for the home: a popular ten among buyers + the nuances of choice  How to connect an RCD in an apartment without grounding: analysis of schemes and step-by-step instructions

How to connect an RCD in an apartment without grounding: analysis of schemes and step-by-step instructions  Fire RCD: selection recommendations, rules and installation diagrams

Fire RCD: selection recommendations, rules and installation diagrams  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Regarding the transformer used in the stabilizer. Finding a TC-320 is not so easy; less powerful specimens are more often found. But you can combine several less powerful transformers for this purpose, for example, TS-180, TS-200 or others. Important - transformers must be of the same type, with very close parameters. Yes, the device will add a little in size, but there will be a margin of power.

Good afternoon, Gleb.

If you look for exactly the TS-320, used in old TVs, then there will be difficulties. True, the model range of dry single-phase devices is not limited to these models. For example, Promelectrica produces OSM-1 analogues - a power line - 0.063 ~ 4 kW. By the way, the analogue of TS-320 implements Elementavia, promising to deliver anywhere in the world.

Regarding the unification of less powerful ones - this is called "parallel operation of transformers" - here, of course, it is easier to buy, but more difficult to choose. The "store" does not deal with such things. Let me remind you, among the coinciding technical characteristics of PUE 2.1.19 regulates:

- coincidence of groups of connections of the windings;

- power ratio ≤ 1: 3;

- scissors of transformation ratios ≤ "+/- 0.5%";

- short-circuit voltage rise ≤ "+/- 10%";

- phasing.

For our option, the observance of the conditions on 2, 3, 4 points is essential. This is enough to bury your idea. Stock power, I note, will be limited by the "bandwidth" of the least powerful transformer.

And where is the transformer winding data? Wire diameter?

The circuit does NOT WORK! Polevik crashes - 5 pcs. Burned out. It seems to me that the scheme is a scam! The primary winding of the transformer is an inductive load. The fieldman in this circuit cannot work at all inductive load. Once again, this is a scam! Prove that this is not so.

Hello. It can not, therefore, it is divided by the capacitor C1 in the circuit. So, call him first of all on your invention.

If divided by capacitor C1 then an error in the circuit diagram.

This point should not be.

It seems to me that a power element is better to use solid-state relays on simstor. I have been working without problems for several years. I do schemes on arduino plus 155 id3 for management. Penny price.

He composed the program himself. The autotransformer ordered 10 kW, 14 steps. The harness is standard, an industrial machine type B at 45A, two voltmeters from China to the input and output, and an ammeter to the panel with the function of short-circuit protection and overload + a powerful bypass switch. Solid state relays are mounted on a radiator. Only 14 pieces.

In the circuit, the error is in the switching of the diode bridge vd2, the negative output is not connected anywhere, but should be connected to the minus vd1. The capacitor and the point have nothing to do with it.