How to make grounding for a gas boiler: grounding requirements and installation instructions

Installing a gas boiler will help to solve the problem of heating, warm water and optimizing the internal microclimate in housing at its discretion. But in order to avoid breakdowns and mitigate the risk of gas fire, the installation and further operation of such a powerful electrical appliance must be carried out in compliance with all the rules. Do you agree?

We will tell you how to make grounding for a gas boiler in accordance with building codes and recommendations of the PUE. In the article we proposed, the installation technology is examined in detail. Our advice on material selection and preliminary calculations will allow you to perfectly ground the equipment.

The content of the article:

Why do you need to ground the gas boiler?

A mandatory element of the device of any gas boiler is a metal casing, on the surface of which static charges are formed when the device is connected to the network.

And if you do not take care of the “waste routes” for electricity, at one unfavorable moment, the entire electronic component of the device or its individual elements may fail. For example, a board or control system.

To prevent this, the boiler is “insured” by grounding - a conductor that connects the appliance to the ground electrode, and the latter - directly to the ground. The earth has the property of "absorbing" electric current, so its environment will be a guarantee of safety against equipment failure in case of voltage drops or short circuits in the network.

Grounding is necessary so that:

- Reduce the explosion hazard of the device - Static electricity often causes spontaneous combustion of gas-powered devices, and even under pressure.

- Eliminate the probability of injury - the metal case sometimes “breaks through”, and when touched, a person can feel an electric shock from a slight tingling to a powerful charge, followed by death.

- Prevent damage to automation - gas boiler boards are sensitive to voltage surges, and their replacement will cost at least a third of the cost of the equipment itself.

In addition, there will be a lot of questions from the gas service inspectors for a boiler that works without grounding, which can result in significant fines and forced shutdown of the device. Therefore, it is worth equipping the ground loop in any case, because this is not only about economic nuances, but also about your safety.

Subtleties of the circuit device

The grounding system may be natural or artificial. The first option includes structures made of metal or reinforced concrete, which are in direct contact with the ground. This may be the foundation of a building, a pipeline or other underground utilities.

But for gas boiler Natural grounding provides for the presence of at least two contacts with separate parts of the housing, and sewer, heating and gas pipes in this case are excluded. Therefore, during installation, an artificial system is often used, the organization of which we will consider.

What material to choose for grounding?

For artificial grounding, rods or pipes that are interconnected by metal strips become conductive electrodes. They are installed vertically in the soil in order to ensure the operation of the system even in the winter season, when the top layer of soil freezes.

An important condition is that metal elements must not be protected from corrosion by an insulating material.

On sale you can find ready-made kits for the grounding system, which consist of steel rods (usually with a copper coating) and special pointed tips for soil of various densities.

The kit also includes anti-corrosion agent for processing the system before installation and connecting elements - brass couplings, clamps. The main advantage of such a solution is that it is possible to assemble a circuit without welding work and lengthy preparation.

To assemble a system from improvised materials, several important nuances should be taken into account:

- Metal structures intended for installation in the ground can be made of a profile pipe, an I-beam, a channel, a corner.

- The grounding metal must be protected from destruction by galvanizing, copper plating or, in extreme cases, anti-corrosion paste.

- The cross-sectional area of the wire connecting the zero phase of the shield to the ground loop depends on the type of metal from which it is made. The optimal value for copper is 1 cm2, for steel - 7.5 cm2, and for aluminum - 16 cm2.

- The grounding resistance for sandy soil should not exceed 50 Ohms, for clay soil - maximum 10 Ohms.

- Materials for the electrodes must be selected and taking into account the resistance of the circuit. The best option is two-inch pipes or corners with a length of 2 m and a cross-sectional area of 5 cm2.

- The grounding bar is made of copper or steel strip (aluminum is forbidden for this case).

Compliance with these requirements and correctly performed ground loop installation help to eliminate claims from gas inspectors, regardless of whether you used a ready-made modular system or assembled it yourself.

Calculation of circuit parameters

The list of requirements for grounding includes several indicators, the algorithm for obtaining which may not be clear to a novice in the business of electricians - for example, how many electrodes are required for the correct operation of the system or how to measure the loop resistance. Let's try to clarify the basic principles for determining these parameters.

Grounding is done after gas boiler installations in a country house. The physical parameters of the grounding loop are selected mainly empirically. This practical method is suitable for those who are afraid to get caught up in complex theoretical calculations.

The execution algorithm is as follows:

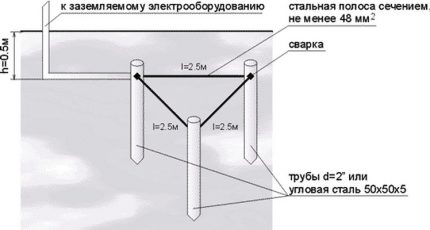

- We take as a basis a contour in the form of an isosceles triangle of three metal rods 3 meters long.

- We connect the conductors.

- We take an ohmmeter (a device for measuring resistance) and measure the performance for the circuit. The ideal value is 4 ohms.

- If the result obtained significantly exceeds the optimal indicator, we add one more element to the circuit and check the resistance again. We continue until we get the ideal indicator or at least the maximum allowable value for the boiler circuit of 10 ohms.

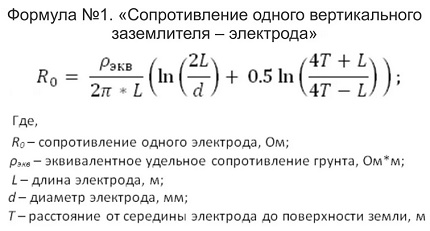

But you can determine the required number of electrodes using formulas, choosing the appropriate options for your case.

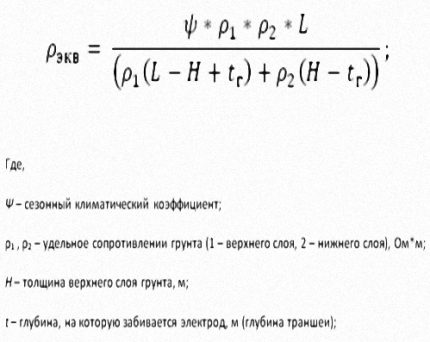

In the formula, you need to substitute the average value of the resistivity, depending on the type of soil in which the ground electrode will be located:

- wet sand - 500 Ohm * m;

- solid sandy loam - 300 Ohm * m;

- clay-sand mixture - 150 Ohm * m;

- loam - 100 Ohm * m;

- semi-solid clay and chernozem - 60 Ohm * m;

- garden land - 40 Ohm * m;

- refractory loam - 30 Ohm * m;

- peat - 25 Ohm * m;

- plastic clay and salt marsh - 20 Ohm * m.

The least suitable for the installation of the grounding circuit is stone and rocky soil. In this case, an artificial embankment will have to be erected.

The value of the seasonal climatic coefficient of soil resistance depends on the area where your home is located. They are conditionally divided into 4 groups.

There are also more complex algorithms for accurately determining the parameters of the electrodes and even special programs for their calculations. But for the correct operation of the gas boiler, it will be enough to follow the general recommendations for arranging a standard ground loop.

The use of copper-bonded grounding conductors allows you to build systems in soils with any physical and mechanical properties:

Installation of a grounding system for the boiler

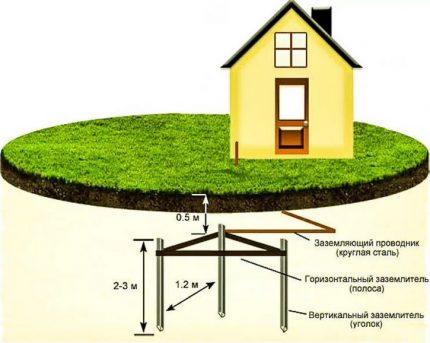

To install the circuit, you need to allocate free space, which is located at a distance no closer than one, but no further than 5 meters from the house foundation.

This site can not be used in the future for the construction of various extensions, landing work, and indeed a person is not safe to be on it, because if it is triggered it can be fatal. Therefore, it is worth fencing the contour with a border and ennoble the place with some composition of stone or decorate it with a garden sculpture.

Design and preparatory work

In order to ground the gas boiler, first a mock-up of the future circuit is drawn on the selected area. Most often, a scheme is used that involves the placement of grounding conductors on the sides of an isosceles triangle.

But the contour can also be in the form of a line, square or polygon - it all depends on the estimated number of electrodes and the location of the building itself.

To assemble a home-made design you will need such tools:

- welding machine for connecting metal elements of the system;

- grinder for cutting and sharpening pipes or rods;

- hammer drill or drill for home grounding cable plant.

And you also need to prepare a digging tool. The minimum set, which probably will be in stock at the owners of a private house - a bayonet shovel and a heavy sledgehammer. But if the site is hard soil, it is better to get a Yamobur or Motobur, which will greatly facilitate the "deep" stage of work.

Installation and connection of the circuit

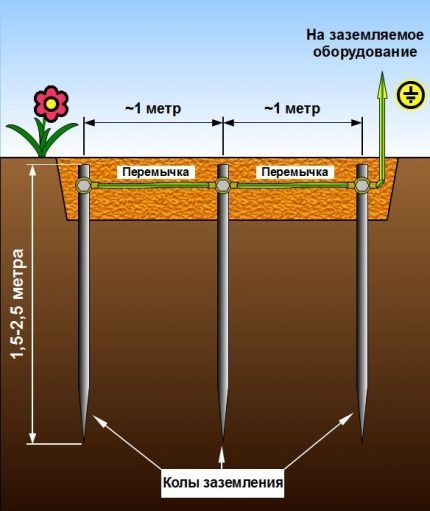

Now we will consider step by step how to make a triangular shape circuit for grounding a gas boiler. First you need to dig trenches along the lines of a previously drawn layout. The optimal width of each groove is 35–40 cm, and the depth is 50–70 cm. A direct trench is drawn from the nearest triangle top to the foundation.

With the help of a sledgehammer or a punch, the electrodes — steel conductors from pipes or corners — are vertically hammered along the vertices of the triangle. To facilitate this process, you can pre-grind the grinder the lower edge of each segment.

They need to be installed to such a depth that the distance from the bottom of the trench to the upper edge of the conductor is within 15-20 cm (that is, the entire structure will subsequently be covered with a soil layer of 30-55 cm).

Further, the electrodes must be interconnected. Lay along the trenches dug on the sides of the triangle a steel conductor with a cross section of 4.8-5 cm2 or a strip of width 4 cm and a thickness of at least 4 mm.

The entire grounding loop procedure involves a number of standard steps:

Ready-made grounding kits can be connected with the bolts provided in the kit. And for home-made designs, the best solution is spot welding.

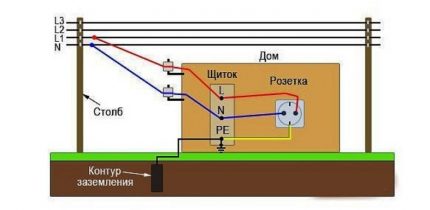

Then you need to weld a horizontal metal strip to the steel conductor, which will be led out of the trench to the planned location to enter the ground into the building itself. It rises above the blind area by about 50 cm (you can use a steel pin).

Now you need to make grounding in the house. To do this, using a punch in the wall, a hole is made through which a copper wire is passed. An M8 bolt is welded to the strip. The copper wire is fixed at one end to the terminal on the ground bus, and the other to the metal plate on the base.

Then the gas boiler is connected to the shield through an individual circuit breaker using a three-wire cable. Additionally, it is recommended to install a voltage stabilizer.

How to check the operation and get a grounding certificate?

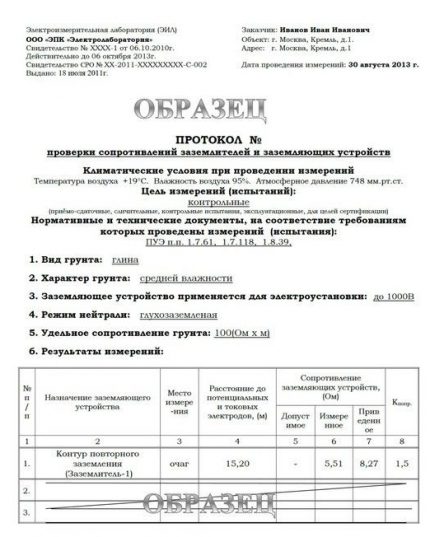

Using a measuring device, find out the current spreading resistance along the circuit. If the result earth resistance measurements does not exceed the maximum allowable figure of 10 ohms, you can dig trenches.

If deviations are found, add the required number of electrodes, make sure that the resistance is normal. Grounding is ready, you can dig in the circuit and call the inspection.

By the way, there is another way to check the health of the system. To do this, you need a simple light bulb with a power of 100 W (or more), which is screwed into a carrying cartridge. Then one end of the carrier is connected to one of the horizontal strips of steel mounted on the sides of the grounding triangle, and the other to the 220 volt phase.

Compare the result:

- The lamp burns brightly, as if plugged into a power outlet - the circuit is working.

- The lamp is on, but the light is dim or blinking - boil again the joints of the structure.

- The lamp is off - you need to check the integrity of the entire circuit, from the quality of welding to the connection to the shield.

Representatives of regulatory authorities are usually guided in checking the readiness of equipment for operation by the recommendations of the PUE specified in paragraphs 1.7-1.8. They determine the resistance of the soil and the ground loop, the correct connection to the shield of the gas boiler and other parameters.

If all indicators are normal, a grounding certificate is issued. It is a set of technical documentation from the test report showing the list of used measuring instruments, laboratory registration certificate, protocol for checking the circuit between the ground loop and the boiler, and a defective sheet.

With the features of the grounding bath in the apartment of a multi-storey building will acquaint next articlewhich we advise you to read.

Conclusions and useful video on the topic

And finally, we offer a selection of video materials where you can get a visual representation of how to safely ground a gas boiler in a private house.

In this video you can see the construction of the grounding circuit of 4 rods with the task of achieving a resistance of up to 7 Ohms:

Another option for arranging the gas boiler circuit for a private house connected from a pole:

The grounding system is an important step that should not be neglected when installing a gas boiler. And if you are not sure that you can correctly install and connect the circuit to the shield, it is better not to risk it and turn to the builders, because not only the safety of expensive equipment is at stake, but most importantly - your safety and even life.

Tell us about how you built the grounding system in your suburban area. It is possible that you have information that will be useful to future independent installers of grounding systems. Please write comments, post photos on the topic and ask questions in the block below.

How to make a ground loop in a private house with your own hands: grounding schemes and installation instruction

How to make a ground loop in a private house with your own hands: grounding schemes and installation instruction  Grounding the bath in the apartment: why and how to properly ground the bath

Grounding the bath in the apartment: why and how to properly ground the bath  Earth resistance measurement: a review of practical measurement methods

Earth resistance measurement: a review of practical measurement methods  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

So, grounding should be in every house, and not only for the boiler, but also for all electrical equipment. Such things are conceived at the stage of construction or overhaul, and the wiring is laid already three-core together with outlets. In principle, the boiler will work without grounding, but still for such a powerful consumer it makes sense to hammer the circuit into the ground.

I don’t know about you, but in Moscow Mosgaz’s order is in force and gas workers demand that the gas boiler be earthed.

And we bought a house without grounding. I didn’t think about him at once, and then, when the refrigerator and the boiler burned out after a thunderstorm, I, of course, was upset. Although there was a transformer on the house, which was supposed to save the equipment, but it did not work. The Chinese fake turned out to be, but after the battle they do not wave their fists. Now I’m reading a lot about this and am going to do grounding myself, I think I should handle it.

I understood correctly, Konstantin, that you have your own 10 / 0.4 kV step-down transformer? If so, then it does not save from lightning surges. It is necessary to put arresters on the high, low side, supplemented by RCD. The surge arresters “cut off the top of the wave”, the RCD will disconnect the home network while the charge flows to ground.

If the boiler does not have electrical mechanisms, does the pump on its side stand, which has grounding from the outlet, is it necessary to ground the boiler body in this case?