Why gas cylinders explode: root causes and preventive measures

Agree, the news that somewhere there was an explosion of a gas cylinder, which, unfortunately, we sometimes hear on TV or from friends, make us think about our own safety. And complacency that this will not happen to us is not the place in this situation.

The consequences of such an explosion and the fire caused by it can be the most sad, and not only for property, but also for the health and life of people who are nearby. We will help you understand why gas cylinders can explode, and how, without giving up the convenience of their use, to protect yourself from big trouble.

To do this, we conducted a study of the features of existing types of domestic gas vessels, analyzed the reasons for the explosions in a number of real cases, and studied the competent opinions of experienced users about this. The proposed article can be presented as a compilation of codes of rules set out in an understandable form that allows in practice the correct and safe use of gas in cylinders.

The content of the article:

The main thing about gas cylinders

The indispensability to date of gas cylinders in everyday life can confidently confirm a significant part of the Russian population.

At the state level, Rostekhnadzor identified common problems with the use of gas vessels, which you need to know about, since they are associated with their safe use:

- outdated fleet - about 90% of all cylinders are not protected from overfilling during refueling;

- the lack of clear state regulation in the field of circulation of cylinders in the market, which includes the presence of illegal gas stations;

- the need to improve and bring technical standards to international standards.

Non-compliance with these requirements and the recommendations of the European Commission imposes difficulties in ensuring the safety of imported and gas-filled products used in Russia.

In addition to knowing common problems, in order to make it easier to imagine the causes of the explosion, and the conditions that can contribute to this, it will be useful to know which cylinders exist, deal with the device, and understand some of the nuances from the physics of explosion and combustion of the mixture used in them.

Types of vessels for gas

Depending on the application, the filler used and the connection methods, gas vessels may vary both structurally and in the material of which the housing is made.

The most popular metal cylinders, both new and vessels of the old park. The main reason for the increased demand for tanks of this type is the relatively low price for them and a large number of offers on the market, including due to capacities made back in Soviet times.

But it is steel cylinders that are most at risk of explosion and, following safety principles, require compliance with a number of conditions during their storage and operation. Therefore, we will dwell on them in more detail.

How is the cylinder arranged?

By design, the gas vessel resembles an ordinary lighter, the capacity of which is also filled with a substance in two aggregate states. Part of the reservoir is gas in the liquid phase, the remaining free space is filled with the same substance, but in a gaseous (working) form. Through the locking device, gas enters the appropriate equipment for ignition and intended use.

The standard equipment for a gas cylinder includes:

- The vessel itself for gas or shell, cylindrical in shape and with a minimum wall thickness of 2 mm.

- Balloon valve with locking element and handwheel.

- Ring support (shoe), providing a stable vertical position of the tank with gas.

- A casing protecting the valve from damage and contamination during transportation, storage and operation.

A cap is attached to a special threaded part - the neck of the cylinder.

Its use allows to reduce, stabilize and maintain the pressure of the mixture in the values specified for a particular gas consumer. This adapter is easy to install on any type of bottle.

Gas mixture for household cylinders

The filling for the cylinders is hydrocarbon gas - a mixture of propane and butane, which is pumped into a vessel under pressure up to 15 MPa.

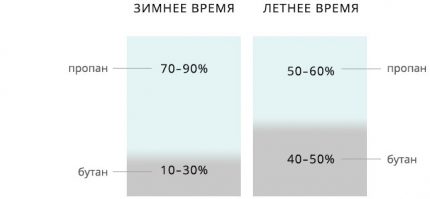

The ratio of these hydrocarbons determines the seasonality of the use of the mixture or a specific region. The fact is that with relatively identical basic properties, propane and butane have a significant difference in the values of evaporation temperatures: butane - 0.5 ° C, propane - 43 ° C (with a minus sign).

Knowledge of the principle of mixing the hydrocarbons used in gas tanks is essential not only in the possibility of cheapening fuel (butane is cheaper than propane), but also in reducing, due to less intensive evaporation of butane,the risk of high blood pressure with a significant increase in ambient temperature. A sharp increase in pressure in the tank can cause its depressurization and, accordingly, explosion or fire.

Explosion Prerequisites

Despite the increasing requirements for the safe handling of cylinders and their quality, annually in Russia more than 200 people become fatal victims of balloon gas explosions, injured - an order of magnitude more.

Summarizing the information of gas tank manufacturers, we present the pressure ranges at which the destruction of flasks is possible:

| Gas bottle volume | Pressure at which explosion is possible, MPa | Pressure at which explosion is possible, atm |

| 5 l | 15-16 | 120-160 |

| 27 l | 7,5-13 | 75-130 |

| 50 l | 7,5-12 | 75-120 |

With a decrease in the strength of the flask walls, the critical pressure value leading to its depressurization decreases to 5.3 MPa.

Gas explosion or burning

You need to understand that the explosion and ignition of a cylinder is not exactly the same thing. For example, when asked if a household gas cylinder that has received a fragmentation or bullet hole can explode, it is impossible to answer unequivocally “yes”.

A mixture of propane-butane with oxygen in the air explodes outside the cylinder or drawn inward after the pressure inside the flask equals atmospheric.

Why do gas cylinders explode or burn?

Fire cylinder

The explosiveness of the tank that has fallen into the combustion zone with the gas mixture under pressure in it is very high. According to GOST, the maximum safe temperature for a cylinder with a hydrocarbon is 45 ° C. It is clear that in the fire, it significantly exceeds the permissible.

The physics of the process is as follows. At a strong heating temperature, the mixture in the vessel boils and, accordingly, the pressure in it increases. In addition, uneven heating of the surface of the shell weakens its initial strength and leads to the destruction of the walls.

Rapidly evaporating and igniting, the hydrocarbon ejected from the cylinder in a liquid and vapor state has an additional thermal effect in the fire zone on everything around it.

Having understood why gas cylinders explode in houses during a fire, one should also know how they can behave when heated.

There are two options for rupturing the flask:

- By "hydraulic" mechanics.

- Strong twisting and the formation of a large crack on the bottom and the rim.

In the first case, the liquid phase with increasing temperature to 60 ° C will fill the volume of the vessel to the norm of 85% at a pressure of 1.5 - 2.5 MPa. The destruction of the shell will occur with a further increase in temperature in the room to 70 - 75 ° C.

The second option occurs when there is no liquid phase in the vessel, if, for example, the evaporation of the liquefied mixture occurred due to depressurization of the shut-off device, at elevated temperatures in a fire.

In any scenario, fragments of an exploding balloon can scatter in different directions with great speed, creating a threat to the person and damage to property.

Excessive gas filling

Often, filling tanks with liquefied gas overflows them. This happens due to negligence or deliberately, wanting to save on the utilization of the tank.

A part of the free volume should remain in the tank - a cushion, for the vapor phase of hydrocarbons. The safe volume of such a pillow is at least 15% of the total tank volume.In its absence, the pressure in the flask increases by 0.7 MPa with an increase in the temperature of the mixture by each degree, which is unacceptable by safety standards and can lead to overstrain of the shell and its rupture.

The amount of gas injected into the vessel is strictly regulated by pressure and mass, and should not exceed 0.425 kg per 1 liter of tank volume.

Even at the temperature specified by GOST +45 ° С, an overflowed flask poses a great danger of the probability of a longitudinal rupture along the weld.

We also recommend that you read our other article, where we talked in detail about the rules. gas tank refills.

Heating or cooling vessel walls

The propane-butane mixture, having a large expansion coefficient, even with a slight increase in its temperature, greatly increases in volume.

The danger of increasing the pressure of the mixture on the walls of the flask also exists in the cylinder installed next to the heat source.

In addition to heating, a number of dangers also conceals the negative effects of negative temperatures. The first is an increase in the fragility of the metal. And the second - it is necessary to remember forever that in no case can a vessel kept in the cold be brought into a warm room for a long time. A sharp increase in the temperature of the hydrocarbon mixture is unsafe.

Bumps and falls of cylinders

Sudden mechanical effects on its walls can provoke damage and ignition of a vessel with gas, especially when the tank is in conditions of low or, conversely, excessively high temperatures.

When using a cylinder in abnormally cold conditions, the mechanical properties of the metal change - the toughness of the steel decreases.

In the second case, an increase in temperature and heating of the gas contained in the flask, as was said, sharply increases its pressure, which, with additional shock effects on the vessel, can break it.

Foreign matter in the gas

Explosion hazard lurks when water and hydrogen sulfide enter a vessel with liquid gas. Their high content in the tank contributes to the appearance on the inner metal surface of the shell of delaminations and pouts.

Such vascular defects occur in the presence of hydrogen sulfide in propane from 0.3% or more, and can be observed after a two-year period of use of the balloon.

Weld Marriage

Less often, but there are problems associated with the depressurization of vessels with gas in the heat-affected zone.

The overall integrity of the shell at break of the defective weld can be maintained.

Explosion scenarios

The above causes of the explosion or ignition of gas vessels can, in various ways, provoke the following dangerous scenarios.

Tank burst and flame

Explosion of a cylinder and ignition of propane-butane are dangerous by the following factors:

- a column of strong flame, rapidly increasing the area of the fire;

- high temperature of the fire in the center of the explosion;

- toxicity of combustion products.

The defeat can also come from suffocation, due to a significant decrease in oxygen with a sharp concentration of harmful gases.

Typically, rupture of the vessel occurs along its lateral part.

Secondary blast effects

Secondary, but no less serious damaging effects in the explosion of a cylinder are:

- valve separation;

- exposure to a compression wave or shock wave;

- damage from fragments of shell elements.

The fragments from the balloon and its detached elements can fly very far, causing damage in a radius of up to 250 m, and rise to a height of thirty meters.

Gas leak hazard

The danger of propane leakage from a damaged tank is that the room is very quickly, and in large volumes, creates an explosive concentration of a mixture of hydrocarbon and oxygen - much faster than with leaks of liquid combustible substances.

A strong leakage of a mixture from a flask or a faulty shutoff valve can be detected by smell or by ear - the sound is similar to what we hear when the balloon is quickly deflated.

If there is a gas leak, then it is necessary to cover the place of depressurization with a wet rag, carefully take the vessel out into the street and call the gas workers.

Since 2016, the technical rules provide for the mandatory installation of gas detectors in new homes. For previously built housing, this norm has a recommendatory nature, but the benefit of this device, especially in homes where bottled gas is used, is undeniable.

The fact is that the density of the hydrocarbon mixture is greater than the density of air. In case of violation of the sealing of the flask, shut-off equipment or connecting hose, gas begins to accumulate at the bottom, and its smell can not be immediately detected. That is why, a mixture with propane, which got into the air from a damaged gas cylinder, often explodes in houses from any spark without being noticed.

Fundamentals of safe handling of cylinders

Before installing the bottle and connecting it to gas appliances the first thing to do is make sure that there is no damage, rust on the body and the valve is in good condition.

The main technical requirements that must be observed when operating cylinders include:

- All cylinders, with the exception of one (five-liter for connecting to a gas stove), must be installed in extensions outside buildings and at a distance not closer than 5 m from the entrance to them.

- Exclude storage of cylinders in living rooms, basements and attics.

- Do not place cylinders closer than 1 m from heaters and 5 m from open flames.

The obvious, but often forgotten safety measures when using vessels with gas should be attributed and taken to the strict execution of the following:

- Do not bring a lit match or lighter to the bottle to check for gas leakage.

- Categorically exclude the use of open flame to heat the gearbox or valve. For these purposes, only hot water is allowed.

- If gas is detected in the room, do not turn on any electrical appliances, including light, and do not turn them off. The temperature of a spark in a socket or switch can go up to a thousand degrees.

- Do not try to repair shut-off valves and other structural elements of the cylinder yourself.

In addition, it is necessary to strictly follow the time limits for the use of cylinders prescribed by the manufacturer. Vessels released before December 2014 can be operated for 40 years.

In the absence of information on the permitted period of use of gas cylinders produced after this date and not having accompanying documentation for them, Rostekhnadzor recommends taking the cylinder for a shelf life of 20 years.

A safer alternative to steel gas cylinders are more modern polymer-composite vessels - Euro-cylinders. Their flasks are protected by a plastic casing, do not accumulate static electricity. The explosion safety of composite cylinders is ensured by equipping them with safety devices of a new generation - a fuse-link and an overpressure relief valve.

Conclusions and useful video on the topic

The reasons for the explosions of gas cylinders are examples of real facts, and what can and should not be categorically done with their use:

How to use gas cylinders in everyday life, and what requirements they must meet:

For all the risk factors that accompany the operation of gas equipment, there is no reason to succumb to fear and abandon the convenience of using them in everyday life.

Theoretical knowledge of the causes and conditions associated with the explosion of domestic gas tanks are designed to help overcome this fear. And compliance with the set of standards for their safe use will serve as reliable insurance against the severe consequences of a gas explosion and fire.

If you have valuable information that can complement our material, please share it with other visitors to the site - leave your comments in the block below. There you can ask questions of interest on the topic of the article.

Why does the gas pipe in the apartment vibrate and buzz: causes of noise and solutions to the problem

Why does the gas pipe in the apartment vibrate and buzz: causes of noise and solutions to the problem  Why a gas pipe is shocking: causes and ways to cope with a problem

Why a gas pipe is shocking: causes and ways to cope with a problem  Why a gas stove is shocking: popular reasons and recommendations for their elimination

Why a gas stove is shocking: popular reasons and recommendations for their elimination  How gas explodes in an apartment: causes of explosions and tips for safe use of gas

How gas explodes in an apartment: causes of explosions and tips for safe use of gas  Why the gas burner is noisy: analysis of the causes + valuable recommendations for resolving the problem

Why the gas burner is noisy: analysis of the causes + valuable recommendations for resolving the problem  Rules for the operation of gas equipment in residential buildings: measures and standards for safe use

Rules for the operation of gas equipment in residential buildings: measures and standards for safe use  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Unfortunately, not everyone understands the increased danger of gas. Although it would seem that somewhere constantly something explodes, people die and are injured. Maybe they were right in the USSR, where it was impossible to recharge the cylinder on their own, only exchanged at the station?

To be honest, I think this approach is very correct and safe. No self-refueling, only exchange for another cylinder. The bottom line is that the cylinders are subject to wear, corrosion, microcracks appear inside the gas cylinder over the years. It is the latter that pose the greatest danger. With self-refueling, it is impossible to detect such defects. In addition, many tankers sin by trying to refuel to the maximum in order to sell more fuel, and this is already excessive pressure on the walls of the gas cylinder.

Personally, I can name the three most important reasons that lead to explosions:

1. Violation of the rules for storing gas cylinders;

2. Depreciation of the cylinder (it is necessary to conduct a survey every two years);

3. Sudden changes in temperature (refers to the first paragraph, but I will highlight separately).

If you comply with TB, then gas will not be more dangerous than an electric stove.