Wash-basin siphon: types, selection criteria + assembly rules

Self-assembly of the sink is necessarily accompanied by the purchase of a new siphon, its assembly and installation. Sink siphon for washbasin - the structure through which the liquid passes, and thanks to the water plug, sewer gases are blocked.

The selection criteria and the subsequent assembly of this plumbing fixture is simple, however, the implementation of all the rules can save you from further leaks, which will ensure uninterrupted operation of the drain.

In this material we will talk about the device and the types of drain systems for the washbasin, as well as what rules should be followed when choosing.

The content of the article:

Functions and working principle

The main purpose of the siphon is to organize timely outflow of liquid into the sewer. It also performs secondary functions: it prevents clogging of pipes and protects the room from unpleasant gases accumulated in the drain.

Structurally, the device consists of three elements:

- tank / container;

- a receiving branch pipe with a decorative grill made of metal;

- drain pipe, which is connected to the sewer.

One of the additional but important designs of the device is the overflow mechanism. It is made in the form of a tube and is responsible for protecting the washbasin from overfilling with water, by removing excess fluid.

The principle of operation of the drainage mechanism is based on the hydrostatic law of communicating vessels. Vessels with a common part filled with a resting liquid are called communicating. In the siphon, they are represented by a knee, with the opening of the inlet pipe located above and the lower part - the drain pipe hole.

Even after the shut-off valve and the cessation of water intake, part of it cannot pass through the bend, so the so-called sump is always filled with water. Thus in the knee is formed water seal, preventing odors from the sewer from entering the room.

Types of siphons for washbasins

Design features and characteristics of the material of manufacture are the main indicators that should be guided in the selection of plumbing fixtures.

They determine the time and labor costs for installing the mechanism. Therefore, a detailed review of the available siphon variations and their features during installation is required.

All models presented in stores may differ in shape, material and principle of operation.

However, there are several main groups:

- corrugated;

- bottle;

- trumpet.

In addition, hidden siphons are distinguished, and pipe siphons are divided into ordinary ones, when the pipe section is bent in the form of a semicircle, and flat - the bend is created by two vertical pipes and one horizontal, and the design eventually acquires a U-shape.

Convenience and simplicity of corrugation

This option is quite simple in structure. The receiving pipe, equipped with a metal grill, rubber seals and a bolt, passes into a flexible pressed pipe.

The last element is connected via the adapter to the sewage drain.

The corrugated model is quite convenient, especially in the case when there is not enough free space under the washbasin: because of the installed cabinet or when it is planned to place any objects.

The main difference between such a siphon is the possibility of independent modeling of bending for the arrangement of a water seal. There are models that are not equipped with a frame that fixes the fold.

Therefore, when installing the drain mechanism, the radius of the bend loop should be sufficient to create the required volume of water in the sump.

Despite the fact that this variation of siphons is the simplest, there are minor disadvantages in assembly and installation. For the most part, they relate to additional mechanisms, namely the inability to connect hoses for overflow and drainage from the washing machine.

The process of assembling a siphon-corrugation is not difficult. Parts are completed as follows:

- Using a screw, the inlet pipe is connected to the washbasin. In this case, rubber washers are placed on its outer and inner sides.

- The pipe tip through the adapter is connected to the sewage drain.

- The corrugated hose is then bent to create a bend forming a water seal.

- Fixing is performed using the bent frame included in the kit.

In this case, impregnation of the connection nodes with a sealed composition is not required. When it becomes necessary to clean the pipe from clogging, it will be enough to remove the corrugation hose from the adapter, level it and clean it of unnecessary accumulations.

Bottle siphon device

The main advantage of bottle designs in versatility. Their functionality is easily expanded by connecting one or two additional drain hoses.

Even in models where such connectors are not provided, it is possible to purchase an adapter with the desired number of outputs.Its installation is made between the so-called bottle and the inlet pipe.

The disadvantages of the bottle system include the stiffness of the components - the possibility of their bending during installation is excluded. Also, many are afraid of the presence of a large number of components.

Assuming that the assembly of such a node is difficult, many beginners opt for another model.

However, it is not difficult to assemble it, it is enough to familiarize yourself with the set of parts:

- protective grill, with several holes with a diameter of not more than 10 mm;

- large rubber gasket;

- connection to the washbasin;

- nut;

- coupling screw;

- siphon;

- drainage to the sewerage;

- cone-shaped gaskets;

- small and large flat gaskets;

- decorative overlay made of plastic;

- plastic coupling nut;

- plastic adapter.

The assembly and installation of such a unit is designed for 3 main stages: connecting to the wash basin, completing the main part of the bottle siphon and connecting to the sewer. If the parts are not tight enough to each other, use plumbing flax for sealing.

At the first stage An o-ring and a protective grill fit into the drain hole of the appropriate diameter. Further, the thickest rubber gasket is placed on board the receiving pipe.

The upper section is pressed against the sink, and the coupling screw is inserted into the protective net and screwed into the nut, which is located on the body. When tightening the fasteners, it is necessary to monitor the gasket flange - they must not rotate.

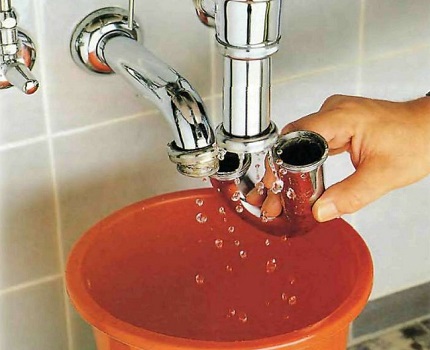

Second phase due to siphon assembly. A tightening nut and conical gasket are put on the pipe draining the liquid into the sewer.

Now, a receiving pipe is inserted into the upper section of the “bottle” case and is fixed at the desired height by means of a coupling nut. A large flat seal is placed in the glass, and in the final, the lid on the body is screwed.

In the third stage direct connection to the sewer system. To do this, a gasket is applied to the drain pipe and a siphon drain pipe is inserted into it.

If necessary, you can use an adapter. The last node uses sealants. This completes the assembly and installation process. Now you need to check the operation of the drainage system.

You can read more about installing a siphon on a sink in this stuff.

Features of pipe sanitary units

There are two types of pipe siphons - ordinary and flat. The former have a stylish design, so they do not require camouflage, and the latter are more used with limited space under the sink.

These models are more difficult to care than previous ones. For cleaning, you will need to unscrew the bent part of the pipe from the receiver, and then from the drain.

The device of the pipe siphon is simple - it is the bent part of the pipe, on both sides connected to the inlet and outlet pipes. The whole structure is rigid and cannot be adjusted during installation.The installation process of such a mechanism differs from the bottle only one point - instead of a "bottle" a curved pipe is screwed.

Some models have a small hydraulic seal. Nevertheless, to counteract the pressure of gases from the sewage system, this depth will be sufficient.

But with a long absence, for example, when leaving, the water in the sump can evaporate and at the time of return a characteristic smell of sewage will be heard. To avoid this situation, it is recommended to close the drain with a stopper.

When installing this plumbing device, you should pay attention to the height of the sewer entrance. Its level should correspond to the horizontal section of the drain on the siphon.

Pipe models with overflow are quite common, which is very convenient for small sinks, where there is a likelihood of liquid leaving the washbasin.

Concealed Type Drain Unit

The hidden variation of the siphons is partially installed in the wall, namely the bottle device. Only the horizontal pipe remains visible.

The advantages include a completely hidden plumbing unit. The disadvantages are the complexity of the installation, as well as problematic access for maintenance and repair.

What materials are siphons made of?

Materials used for casting siphons must comply with all technical standards. Their service life and quality of performance of the functions declared by the manufacturer depend on this.

The requirements for materials of stock devices are as follows:

- practicality in service;

- invulnerability to high temperature conditions;

- resistance to corrosion;

- low susceptibility to accumulation of deposits due to constant contact with water.

For the most part, sink drains are made of plastic, cast iron, nickel, brass, an alloy of brass and bronze, steel, and more.

The most practical and economical option is the design of the plastic drain. It can be a standard white or color option. The material is easy to install, has a tight adhesion of parts and in most cases does not require sealing joints - instead, a coupling is used.

Also, the models are not susceptible to rust, resistant to passing processes of decay and corrosion. Easy maintenance even with chlorine-containing compounds allows you to maintain maximum purity of the device.

Bronze and brass drain installations are considered more durable. Models undergo little corrosion and rust, but still oxidize.

Through these chemical processes, dirt particles trapped in running water are trapped in uneven areas. So there is a gradual clogging. In this regard, plastic is much more practical.

The drainage installation made of metal annually expands the circle of its fans. Literally in the last ten years, popularity has more than doubled. All thanks to the excellent characteristics of metal devices: strength, aesthetically attractive appearance and hygiene of the alloy.

For such models, steel can be used both in pure form and in alloys. The price category of a metal device is an order of magnitude higher than the previous options, which indicates excellent quality and a high service life.

Most buyers, based on low cost and practicality, opt for plastic structures. Nevertheless, the metal is not too inferior in position. After all, it is possible to emphasize the sophistication of the interior, to focus on the necessary details only with stainless steel elements.

If we talk about brass fixtures, then only the decorative component plays a role - the complexity of care and gradual oxidation are not positive characteristics.

Additional product features

In addition to draining and having an effective water trap between the room and the sewer pipe with all its fragrance, the device can be supplemented with the necessary elements - hoses. For example, for most washbasins manufactured with a top outlet, purchased overflow siphon.

Water is removed not only through the drain hole, but also through the outlet to which the hose is connected - so the mechanism prevents flooding.

A siphon can also include a nozzle with an additional input that helps simplify the drainage system in household appliances - for a compact organization of the drain of the washing machine. The outlet unit is located between the neck of the washbasin and the siphon bowl. Overflow and an additional connector can only be integrated into bottle-type drains.

Overflow assembly

Initially, the bottle is assembled. A suitable seal sits on the thread of the flask, which is built into the bottom of the washbasin. Next, the bottom cover is screwed tightly. The connection must be tightened manually to ensure a tight fit.

Now you need to take the upper pipe, which is responsible for the drain in the washbasin, put a nut on it, and then put on the cone gasket.

In this case, the seal must be tensioned with the wide side on the pipe. After that, the element is inserted into the upper part of the siphon. The next step is to tighten the nut.

A corrugated tube is connected to the overflow hole of the sink, and its second end to the docking nozzle. It is very easy to do this - the part in the form of a scapula is equipped with conical grooves that are easily included in the corrugation of the corrugation.

Installation of all pipes of the drainage unit - the bottom one, which ensures water drainage into the sewage system, the middle one for the drain of the washing machine and the upper one for overflowing, is performed similarly to the vertical pipe.

What to look for when choosing?

To make the right choice of siphon, it is necessary to take into account the device of the washbasin, the particularities of the assembly of the mechanism and the location of the sewer.

If you are replacing not only the drainage device, but also the washbasin, it is advisable to dwell on models of sinks that come with a siphon. The organization of the drainage system in this case will be simplified as much as possible, and all the details are perfectly adapted to the dimensions of the washbasin.

The presence in the design of an overflow and outlet for a washing machine is optional. However, it is worth considering that only a bottle type siphon can be additionally equipped with these elements.

The low located entrance to the sewage system involves the installation of any type of siphon, except the pipe one. For its installation, it will be necessary to raise the drain to the required level, which represents an additional cost of time and money.

When buying, it is also worth focusing on components - the parts must be integral and without chips. This is easy to do, because most manufacturers of sanitary fixtures make the packaging transparent.

Useful video on the topic

The problem of poor water flow from a plumbing fixture may be hidden inside the siphon. The presence of defects is not always obvious:

Connecting an additional pipe for organizing the drain from the washing machine:

The standard device of the siphon is not burdened with unnecessary parts, so it does not take much time to assemble the entire structure. It is important in this matter to take advice on choosing a suitable mechanism that adequately ensures the removal of waste fluid into the sewer system.

Have questions about the topic of the article, find flaws or is there any interesting information that you want to share with visitors to the site? Please leave comments in the block under the article.

Siphon for washing: design, purpose, do-it-yourself installation features

Siphon for washing: design, purpose, do-it-yourself installation features  Installing a siphon in the kitchen: how to assemble and install a device + circuits and installation example

Installing a siphon in the kitchen: how to assemble and install a device + circuits and installation example  Small washbasins: varieties, photo-selection of options and features of choice

Small washbasins: varieties, photo-selection of options and features of choice  Countertop washbasin: features of selection and installation

Countertop washbasin: features of selection and installation  How to install a sink in the kitchen: installation rules for mortise and freestanding models

How to install a sink in the kitchen: installation rules for mortise and freestanding models  Sink in the bathroom: types of washbasins + nuances of choosing the best design

Sink in the bathroom: types of washbasins + nuances of choosing the best design  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I always put bottle-type siphons in the bathroom, and they have already helped out more than once, when something valuable got into the drain hole - an earring or a ring. You can always unscrew the siphon and find in it a valuable thing washed away by the jet, and in the corrugation it would have already gone into the sewer. Installing it is not much harder than the corrugation, just a little more fuss during assembly, but otherwise it’s the same.

Most of all I like corrugated siphons, and they are more convenient to install. I try only to buy them. You can simulate a pipe bend that will provide the necessary water seal. And if there is not enough space, then this is generally salvation. I did not notice any minuses. It is also convenient to clean if necessary, everything is easily disconnected. Well, yes, as noted above, if something valuable has fallen, it has sailed away forever, we have an additional lattice for this.