How to replace a heated towel rail in a bathroom according to the rules

The counters of markets and construction stores are mesmerized by the splendor of new heated towel rails. Any domovy owner will not resist the opportunity to make functional and aesthetic changes in his home. After purchasing the selected device, you should find out how to install and connect it.

All about how to replace heated towel rail in the bathroom in accordance with regulatory requirements, you will find out by reading the article we presented. We have described in detail the technological steps, listed the subtleties of the process. To help independent masters attached schemes for connecting heated towel rails.

The content of the article:

Towel warmer replacement steps

Work on the replacement of the heated towel rail is carried out in stages. Each of the stages requires diligence, accuracy and attention from the performer, because it directly affects the final result.

To carry them out, you can call the plumbers or do everything yourself. The first option is simpler, but requires money and confidence in the literacy and responsibility of the hired builders.

For the implementation of the second, substantial knowledge and serious comprehensive training will be required.

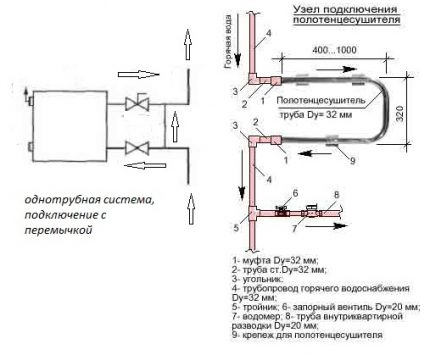

Water devices are connected to the DHW pipeline if the apartment is provided with hot water from a centralized system. They do the same if the house is equipped with a double-circuit boiler that produces hot water for autonomous water supply.

Connection to the heating network is made in apartments with a centralized water supply supplying only cold water, and in houses with single-circuit boilers.

Proper preparation is the key to success

Any independent activity requires an objective assessment of their own strengths and capabilities.

The home master needs:

- Assess your capabilities, knowledge in the field of plumbing and the amount of real skills.

- Stock up on the necessary set of tools.

- Assess the conditions of work.

The choice of the method of implementing the planned project and the list of means for its implementation will depend on a real assessment of their own capabilities.

If the owner heated towel rail If he does not have the skills of a welder, then any such work must be excluded and find a replacement for them. The same applies to working with different building materials.

Installation skills drywall or gluing tiles may be needed to finish the decoration of the laid communications and concealment of defects formed during the course of work. Ignorance of the features of working with electrical wiring will not allow to qualitatively connect the electrical part of equipment.

The availability of not only the basic tools for installation is important here. When welding, in addition to the equipment itself, liquefied substances may be necessary for the operation of a gas welding unit or high-load-resistant wiring for connecting an electrical apparatus.

Always consider:

- in which house (private or municipal) the actions will be performed;

- the condition of the heating system and the method of circulation of the coolant in it;

- the material composition of the walls, floors and ceilings surrounding the place of work.

With a centralized water supply, you need to wait until the heating season ends.

The presence of wooden supporting decorative structures may limit the use of open sources of fire. Stretch ceilings will not allow bending metal pipes to the angle necessary for threading them. Welding will also not be possible due to the risk of damage to heat-sensitive materials.

After an analysis of the listed parameters, a diagram should be drawn up, a list of the necessary connecting nodes should be determined, and the necessary set of tools should be formed, which must necessarily consist of

- level;

- pipe cutter;

- welding and soldering equipment (if necessary);

- angle grinders (grinders);

- thread cutter or dies of large diameter;

- punch;

- adjustable and pipe wrenches.

All assembled equipment must be laid out for ease of operation. The next step is to study the instructions for the purchased device. Although most of these devices have a similar structure, the manufacturer may declare in the accompanying documentation about any recommendations or conditions for proper installation. This should be known in advance.

Before installation, it is necessary to study the complete set of the device, check the compatibility of components, connections and fasteners. The generally accepted rule of professionals is that you need to hold a thing in your hands before work to get to know it. Tactile analysis gives a person a lot of information: about the mass, flexibility, size of the product.

After the arrangement of the future workplace with everything necessary, you can proceed to the next stage - the dismantling of old equipment. It is worth mentioning that heated towel rails there are water and electric.

If only planned transfer of the heated towel rail to an adjacent wall due to the redevelopment of the premises or the conversion, the work mainly consists in altering the pipeline and fixing the device on another surface.

Next, we will focus on the installation of the first type. Installation and connection of an electric variety differs only in the absence of the need to connect such a device to a water heating system. The power source is an ordinary household outlet.

The specifics of the dismantling

The nature of the dismantling depends on what the new design will be. To choose the future arrangement of new equipment, you need to evaluate your professional skills in different areas of construction. It is worth calculating your material capabilities in advance. Most of the old communications are laid over the walls and have an unsightly appearance.

To give pipe wiring more aesthetics, you can:

- Hide them in the walls.

- Leave in place.

Hidden wiring required strobing brick or concrete surfaces. This process will require studying the contents of their entrails for the presence of fittings, wiring, and other factors that impede the achievement of the assigned task. Such a procedure will require large expenses, coordination with authorities and neighbors.

Covert piping looks much more attractive than external pipe branches, but it turns out to be the most problematic and expensive.

You can mask the laying of pipes through the construction of:

- plastic or drywall box;

- brick channel;

- concrete casing.

Decorative coated frame structures are the most practical and relatively inexpensive way to decorate old communications. This option will allow access to the compounds in case of leaks. Damage to the supporting structures, the formation of a large amount of debris and dust will be completely eliminated.

With a proper design approach, constructed communication channels can be effectively integrated into the bathroom interior. This will add unusualness to the final appearance of the room, save a lot of money and effort.

There are many ways to mask dots. heated towel rail to pipelines without destroying the walls and separating them. For example, it is convenient to close the coil connection section with a plasterboard box.

If there is a technological possibility, you can hide the connection points by installing a frame wall with drywall. Naturally, both of the options described require finishing.

Having decided on how the final finish will occur, you can proceed to the removal of the old heated towel rail. In most cases, it has a threaded connection, which you need to try to unscrew with an adjustable or pipe wrench (depends on the quality of the preserved faces of the fitting).

After incompletely unscrewing the connection, it is necessary to ensure the collection of the water remaining in the pipes, after substituting a container of sufficient volume under the lower connection. This will not be necessary if disassembly is carried out in a building with central heating. You just need to make sure that there is no water in the system.

If it is impossible to disconnect the structure with keys, a grinder is used. It is also used when dismantling metal pipes, if the path of future concealment of pipes in the walls is chosen.

Installation of new equipment

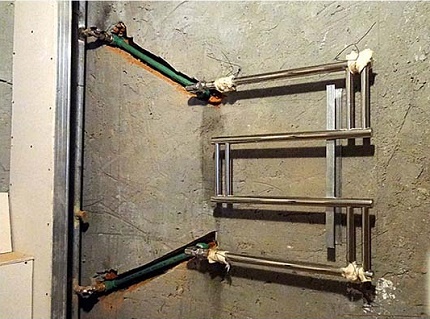

After removing the old heated towel rail the location of the new heater is determined. It is attached to the wall and marks not only the places of future attachment to the surface, but also the places where the connecting fittings will be located.

After that, you can install the new device on the wall, but to fix it unreasonably, since it may require adjustment of its position.

At the next stage, threading is performed on metal pipes. This is done if the old thread is not preserved. Cutting is carried out with a die of the desired diameter or thread cutter. During the procedure, it is necessary that the pipe is firmly fixed with a pipe wrench or other equipment.

This will prevent its possible damage. Two workers need to cut using a die, since the efforts of one person will not be enough to carry out the main action and effectively fix the pipe.

It is worth noting that some thread cutters have systems for fixing pipes. It is very convenient, but not every device has such a variant of equipment. An assistant may be needed even when working with thread cutter.

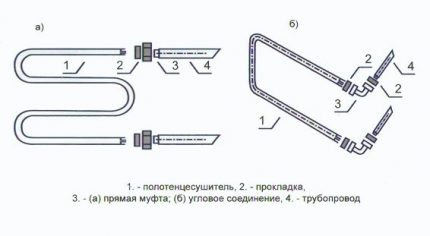

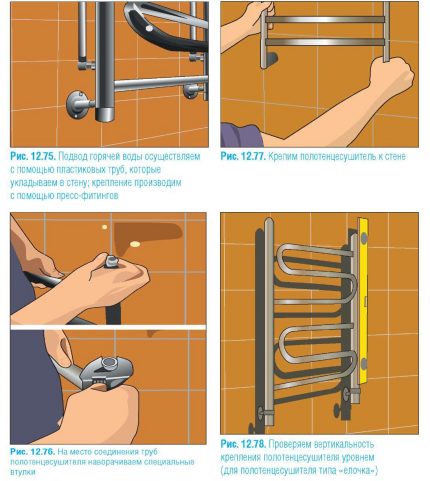

Adapters for plastic piping are installed on the finished seats or flexible hoses are screwed, which is also acceptable if further construction is planned drywall designs. Tow or FUM tape is pre-wound on the connections.

Connection by flexible hoses is the simplest and most convenient in all respects. These components can do without complex equipment and time-consuming operations.

In schemes with natural movement of the coolant through pipelines, the supply pipe (feed) should have a slight bias towards heated towel rail, and outlet (return) - to be directed in the opposite direction.

A slope of the order of 2-3 mm per linear meter is needed to enable the cooled water, the movement of which is not stimulated by the pump, to flow freely from the heating equipment, and to flow into the device when heated.

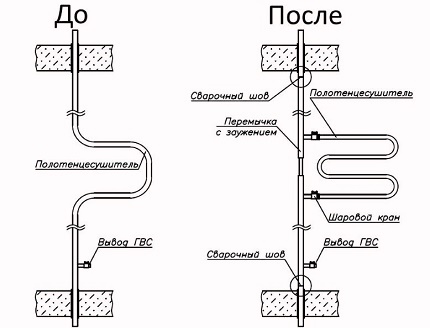

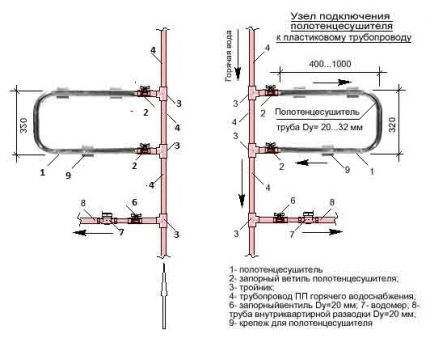

Using bypass in wiring diagram

To ensure efficient and convenient operation of the system, a bypass arrangement is required. This is a spare channel to which any equipment involved in heating is connected. Its task is to ensure the operation of the system in case of emergencies in the components connected to it.

Most homegrown needlewomen do not think about possible leaks and fix heated towel rails directly to the main pipes without mounting to wall surface and installation of valves. Such installation during operation can lead to a violation of the tightness of the connection and subsequent flooding of the room.

This will especially have negative consequences if the room is located in a multi-storey building with central heating. In an emergency, it may take a long time before the coolant is completely cut off. Subsequent restoration or blocking work will leave part of the house without heat for several days.

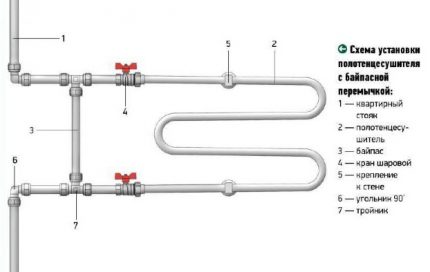

Simple and effective bypass construction and shutoff valves, which are shown in the picture below, will give confidence in any situation and allow you not to worry about the health of the installed equipment.

To create it, tees are installed at the ends of metal pipes. Two outlets directed to each other are connected by a straight pipe. Side outlets are used to install locking elements, to which pipes leading to heated towel rail.

If the structure is assembled from ready-made flexible connecting components, then when installing it, you should forget about the use of sealing materials. When creating a plastic pipe, a special soldering iron for plastic pipes is used. In this case, the master may need the help of a second person.

The image below shows how two workers solder. The soldering iron has elements for its installation in the working position, but only those elements that are not fixed to the common system can be connected in this way. Otherwise, without an assistant will not do.

If rigid connections are used to connect the heater, it is necessary to monitor their compliance with the vertical and horizontal levels. Otherwise, established heated towel rail it will not be possible to fix it evenly. The crooked position will spoil the whole impression of the repair.

For achievement tier matching is very convenient to use laser devices.They give additional freedom to the specialist, allowing you to work with two hands.

Connectivity Test

An important element of any construction is the test of the finished system. This procedure may have some differences, depending on whether the heating system was reworked - centralized or autonomous.

In houses with central heating

It is necessary to take a number of measures before the start of the heating season. If the installed equipment was mounted with the construction of a bypass and shut-off valves, then you need to shut off the latter before starting the water supply. You can open the taps when the system is fully warmed up. Such actions will save the owner of the new heated towel rail from flooding of neighbors and their own housing.

During the supply of water to the pipes, it is necessary to monitor the state of the entire network, waiting for the connections to completely warm up. Expansion fittings during a temperature change, it can cause a coolant leak, which can be eliminated by using the blocking of the shutoff valves.

If the bypass is not installed, then at the time of the test water supply, about which the administration warns the residents of multi-storey housing, you need to be at home. Their neighbors should be informed of the work done so that they are ready for possible flooding.

Autonomous heating system

It can be turned on immediately after work. As in the first case in autonomous heating system it is necessary to wait for the complete heating of the pipes and connectors. After turning off the boiler, wait until the system cools completely and perform additional tightening of the threaded connections.

Decoration of the installed device

After completing all installation work on the installation of a new device for drying towels, you can begin to seal the defects formed during dismantling wall surface. All finishing work is not related to the topic of this article. There are several points worth paying attention to.

If you plan to build drywall or plastic frame construction, it is worth observing some rules:

- to leave small inconspicuous channels at the junction of the box and the floor, which will perform the function of drainage and indication in case of possible future leaks of the system;

- to provide for the future design the presence of an opening small door opposite the locking elements.

Convenient and aesthetic door will provide instant access to faucets, allowing to shut off the flow of coolant to emergency heating devices.

Additional information for independent installers

The article describes the method mounting heated towel rail to the main heating pipes, which are not planned to be hidden in the strob. When choosing a method of fastening equipment with the subsequent immersion of the main pipelines in the channels cut into the walls, it is necessary to take into account some of the nuances of such work related directly to the installation of pipes.

Features of concealed piping

With a complete cut of the old metal pipes within the repaired room, at least 70 mm of their length should be left on each side. This condition will help to work with equipment to create threads on the remaining pipe pieces. If this condition is not met, the possibility of a threaded connection may be difficult or excluded. This will require welding.

Welding connections

When using electric welding equipment, two important conditions must be met:

- Reliable engagement and contact with metal clips crocodiles.The absence of such a contact or its unreliability can lead to the transmission of current through the heating pipes and personal injury.

- The connection of any electrical appliance, and in particular the welding machine, must be made only to high-quality grounded voltage sources.

Simultaneous contact of the master with metal pipes and damaged sections of the wire often becomes a cause of fatal electric shock.

Electric installation heated towel rails

Their installation also requires the dismantling of old equipment. The absence of the need to connect new devices to the water circulation system does not save the builder from operations related to the installation of pipes, unless the old heating devices were connected via bypass.

In the absence of such an arrangement, the pipes of the old system should be interconnected to allow water to circulate through the common system.

Here it is worth taking into account the fact that electrical equipment has its own shelf life and may fail at any moment. The next selected drying element may be water.

In order to avoid time-consuming operations in the future, it will be rational to install tees with stopcocks installed on them in the places where the connecting pipe is installed. This will allow seamless installation of the next element of the heating system without costs and dirt.

Conclusions and useful video on the topic

A clip about the final stages of replacing a heated towel rail:

Video about installing the device and connecting to a copper pipe:

Connection process using bypass:

Apparently with replacement heated towel rail even a novice master can handle it. The main thing is that he react to the upcoming work responsibly and do not forget about the safety rules.

Tell us about how the heated towel rail was changed in your house / apartment. Please write comments in the block below. Ask questions, share useful information, post pictures on the topic of the article.

Transfer the heated towel rail to another wall in the bathroom: installation instructions

Transfer the heated towel rail to another wall in the bathroom: installation instructions  Installing a heated towel rail in the bathroom: DIY installation guide

Installing a heated towel rail in the bathroom: DIY installation guide  Connecting an electric heated towel rail: step-by-step installation instructions

Connecting an electric heated towel rail: step-by-step installation instructions  Repairing an electric heated towel rail: an overview of popular breakdowns and how to fix them

Repairing an electric heated towel rail: an overview of popular breakdowns and how to fix them  How to choose a heated towel rail for the bathroom: what to look at before buying + an overview of popular brands

How to choose a heated towel rail for the bathroom: what to look at before buying + an overview of popular brands  How to choose an electric heated towel rail for the bathroom: selection tips and best options

How to choose an electric heated towel rail for the bathroom: selection tips and best options  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I believe that a heated towel rail should definitely be in the bathroom, especially if there is a small child, it is very convenient to quickly dry panties, socks, tights. In our new bathroom, we chose the simplest option - electric. We plug it into the outlet if necessary, only when you need to dry something. We chose a small, 4 pipe, and are satisfied.

I thought about the electric heated towel rail, but decided to just change the old water one to the new one. All the same, he constantly warms the bathroom, and unlike the electric one.

I myself changed, it did not require any skills at all, except for physical strength. We have paneled walls, pipes out. I just shut off the water, took off the old one and put in a new heated towel rail. Since everything had dried up at the junction points, we had to cut the pipe and cut the thread on it. I knew that it would be so, and got the necessary tool (borrowed).But if the pipes were hidden under the tile or the heated towel rail was of an irregular shape, then the master would have to call.