Do-it-yourself split-system repair: the main breakdowns and how to fix them

Split systems are becoming more and more popular every year. With their help, it is possible to maintain optimal air temperature in rooms of various sizes and purposes. They have an affordable cost, and a set of useful functions allows you to use them not only in summer, but also in winter, as an additional heating device.

Such equipment breaks down infrequently. In most cases, it can last much longer than the warranty period. But, in case of improper use and maintenance, breakdowns are inevitable. In some cases, you can repair a split system with your own hands, without using specific tools.

But how to find the cause of the malfunction and fix the breakdown? We will talk about this in our article. We also consider more rare malfunctions and methods of prevention.

The content of the article:

The main components of the equipment

It is not possible to repair the climate equipment on its own, without knowledge of all its elements.

We offer to understand what a split system consists of:

- condensing unit (outer);

- evaporation unit (indoor unit).

Each of the blocks contains specific details. The external part of the equipment includes: compressor, condenser, four-way valve, control board, fan, filter, housing.

The inside of the equipment is mounted indoors. A consists indoor unit from: front panel, filters (coarse and fine cleaning), evaporator, display panel, fan, condensate tray, control board.

Also in the equipment there is a system of copper tubes.Freon refrigerant moves along them. During the operation of the equipment, it is in two states: gaseous and liquid. Therefore, the tubes in differ in diameter.

Diagnostics of faults in a split system

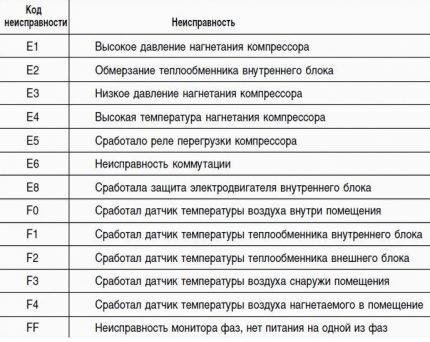

Before you fix a split system, you need to roughly understand where to look for a malfunction. To do this, there are error codes that are displayed on the display of modern technology. If the climate control unit is without a display, an error may be indicated by a flashing LED or sound signals will be heard.

Each manufacturer of equipment has its own codes that indicate malfunctions. To decrypt them, you can use the technical documentation for the equipment. Decryption can also be found on the Internet by entering a model of technology.

Knowing the error codes will help reduce the time to search for damage and try to cope with the repair on your own. But if we are talking about a serious malfunction, then it is advisable to turn to experienced specialists. They know safety precautions and they have instrumentation for diagnostics of equipment.

Failure number 1 - the system does not start

Most likely in this case there is damage to the electrical cable.

If there is voltage in the network, but the compressor, fans and indicators do not work, then you need to look for the problem in the following places:

- power outlet;

- cable and mains plug;

- power connectors on the control board.

Most often, the reason lies in the lack of voltage, but it happens that the voltage in the network is not enough for the correct operation of the device. Most often this happens due to overload of the house network. If the outlet voltage is about 220 V, then you should ring the power cord with a plug.

This can be done using a multimeter or a simple "dialing". The cable consists of three wires. Damage to one of them can lead to a power outage on the board and other organs of the split system. If the cable is intact, then you need to check the voltage at the point of its supply.

Also, the reason for the lack of power supply to the equipment can be the dead batteries in the remote control, the idle remote control or the power button.

Breakdown number 2 - dripping water

This unpleasant problem is faced by many owners of split systems. Most often, it indicates a blockage in the drainage pipeline.

The blockage can be of two types:

- mechanical - dirt is clogged in the tubes;

- climatic - it happens in the cold season, when some sections of the pipeline can freeze, as a result of which ice caps form.

Mechanical contamination is extremely rare. In this case, you will need to resort to manual cleaning of the dirt, but you can use a compressor. Access to the pipes of the drainage system is carried out at the place of fluid drainage.

In the second case, you just need to melt the frozen sections of the drainage pipeline. For this purpose, you can use industrial or soldering hair dryers, but in severe frosts this procedure is not recommended.

If your split system does not just drip, but flows into the room, we recommend that you familiarize yourself with more detailed information about remedies a similar problem.

Failure number 3 - bad smell

This indicates a clogged filter. When the air supplied by the fan of the indoor unit has an unpleasant odor, this indicates the beginning of the multiplication of various bacteria on the surface of the contaminated filter.It must be changed immediately so that it does not lead to the occurrence of diseases.

But replacing such a filter may not solve the bad smell problem. This is due to the fact that pollution can already be on other parts of the indoor module. Therefore, it is highly advisable to wash the main parts or order a comprehensive service.

Failure No. 4 - poor cooling

There are several varieties of such damage. Consider a poor cooling situation to which dripping water is added. In this case, the main reason lies not so much in the clogging of the drainage system as in the clogging of the filters (rough or fine cleaning).

Dust does not settle on the filter cloth, but is deposited on the surface of the evaporator. This prevents the return of cold, which is why the fan and supplies insufficiently cooled air. And water is dripping due to the fact that tubes freeze or dirt gets into drainage. The first case is the most frequent.

To fix this malfunction yourself, you need to clean the filters. So that the canvas does not deform, you need to wash it under a stream of cold or warm water, but not hot. You can use special detergents or disinfectants.

Dust from the pipeline can be blown off with a compressor or vacuum cleaner. More thoroughly, dirt can be removed if the unit is completely disassembled. But, it is not recommended to do this without the proper skills.

In the case where poor cooling is supplemented by turning off the compressor, the reason lies in outdoor unit pollution. If there is a lot of dust, fluff outside the room or is located near a highway, the radiator and condenser will quickly become covered with a layer of dirt. This causes the compressor to overheat, resulting in shutdown.

Inadequate cooling causes obstructed air exchange. This can be eliminated by removing all dirt from the fan, radiator and condenser. You can use soapy water and a brush, or you can use modern washing machines, steam generators.

The main thing is safety during the work. Since the compressor and condenser unit is located outside the room, for its cleaning most often you will have to use the services of industrial climbers.

If the compressor runs continuously or with occasional shutdowns, and the cooling is very weak, then this indicates lack of freon in the system. A small amount of refrigerant can be explained by two reasons: its leak due to mechanical damage to the pipeline or natural evaporation.

Since freon is a gas, it tends to evaporate even from inoperative equipment. Accordingly, the correct decision in this case would be to fill the split system with freon of the desired brand. You can find out the brand of refrigerant based on the information in the technical documentation for the equipment.

Freon is sold in special containers. But buying a refrigerant is half the battle. It still needs to be charged into the system, not exceeding the required volume. There are several ways to refuel and all require skills and special tools.

The easiest way is to fill the split system with freon, controlling the pressure in the pipeline. This is done using a manometer. We recommend that you familiarize yourself with self refueling rules freon.

When the pipeline is damagedthen you need to find the fault.Sometimes for this you will have to disassemble both blocks to find a crack or chip in the tubes. They can be sealed or replaced with new ones if there are a lot of damage and the tubes are in poor condition. After this, the climate device is refilled with freon.

Failure No. 5 - warm air supply

If the split does not cool, but vice versa - it supplies warm air, this indicates that freon boils off before it enters the evaporator. It boils off earlier due to clogging of capillary tubes. A pressure difference occurs, as a result of which the refrigerant gives off the cold to the fan, and the fan delivers warm air.

In this case, the compressor can operate for a longer time or without shutting down at all.

This problem can be solved by cleaning the blockage or replacing capillary tubes. It is easiest to clean the blockage with a compressor. But, the force of compressed air may not be enough, especially if the blockage is complete or they are multiple.

In this case, you can resort to hydraulic cleaning or flushing the pipeline with special solvents. This often helps, but takes a lot of time. It is easier to replace capillary tubes, but this is an expensive service.

Failure No. 6 - hot air supply

When the heating mode is on, when you select the cooling function, only one thing is said: four way valve defective. It is from him that the change of modes depends. Such a malfunction of the split system is rare, and its elimination is possible on its own. You will need to find the valve.

Then you can do the following:

- to repair- in most cases, it simply jams and its work can be resumed;

- replace with new;

- remove from system- Descending it from the equipment will be able to resume the supply of cold air, but will have to sacrifice the heating mode.

In any case, it is not necessary to contact the master, with the exception of ignorance of safety precautions and the basic elements of split systems.

Failure number 7 - the compressor does not work

There are several reasons for this malfunction. This may be a failure of the compressor itself, a breakdown or loss of capacitance of a capacitor, or a breakdown of a thermal relay.

The most problematic case is failure exactly compressor. This is a rather complicated and expensive device that is very difficult to repair on your own. Even masters will not always be able to help. Repair is possible only when the motor shaft is jammed. It can be wedged and resume work.

Compressor diagnostic methods we reviewed in this publication.

But, more often motor windings burn out - from overheating, vibration, power surges or mechanical stresses. In this case, only replacing the compressor with a new one will help.

You will also have to re-fill the system with freon. The cost of a new compressor with delivery, installation and charge of refrigerant will not be much lower than the cost of a new air conditioner. Therefore, it is wiser to buy a split system.

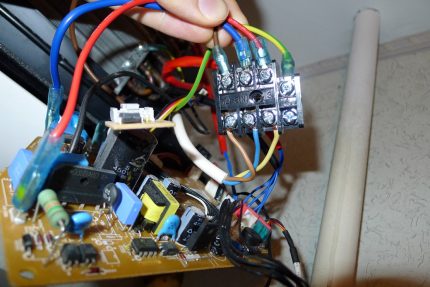

It happens that the cause of the breakdown is not in the compressor. Any of the capacitors may fail or thermal relaywhich can be replaced. These components are relatively cheap, and no special tools are needed to replace them. The main thing is to correctly identify a failed element and replace it with a similar one.

Capacitors and thermal relays may have “burns” due to poor contact or exposure to voltage surges. Also, capacitors may have traces of bloating or electrolyte leakage.

This is the first sign of a malfunction. If there are no visible signs of damage, then each capacitor check with a multimeter.

Failure number 8 - short duration

If the split system is working properly, but quickly turns off, not reaching the desired temperature in the room, then this indicates failure of one of the temperature sensors.

In the average design there are three of them: in the indoor unit there is a thermistor and one temperature sensor per evaporator and condenser. Failure of one of them leads to such a work of technology. They are easy to check with a multimeter. They are cheap, and only a soldering iron is needed to replace them.

More rare malfunctions

Among these stand out: loss of communication between the blocks, “glitches” of the display panel, failure of one of the fans, breakdown of the control board or inverter module.

Each such malfunction is also solvable. But, they are extremely rare, especially with the proper use of climate equipment. If maintenance is carried out regularly, breakdowns can be avoided for a very long time.

The average operating life of HVAC equipment without breakdowns is 7 years. A competent maintenance of the equipment allows you to extend this time to 15 years.

How to avoid equipment breakdowns?

Climatic equipment is a complex equipment that needs regular maintenance of technical condition.

To avoid frequent breakdowns, you must follow the basic rules for operating split systems:

- Clean the filters regularly.

- Do not switch to heating mode when the air temperature in the street is lower than specified by the manufacturer.

- Once a year, check the pressure of the freon in the system and, if necessary, refuel.

- Once a year carry out a full cleaning of two system units. For industrial premises, clean at least twice a year.

If it is not possible to carry out comprehensive maintenance of equipment, then you need to conduct an independent cleaning of the heat exchanger, which is located in the indoor unit, at least once a year.

To familiarize yourself with the features of self-service split systems, please go to this link.

Another important aspect that affects the duration of trouble-free operation of HVAC equipment is its installation. Installation should only be done by specialists. If the installation was not carried out correctly, it may cause unacceptable vibrations and mechanical damage.

Conclusions and useful video on the topic

We recommend that you find out the comments of the indoor unit cleaning specialist from the following video:

Self-repair of HVAC equipment is quite real. The main thing is that this does not harm the health and does not damage the equipment even more.

If you have the skills, experience and tools, then you can fix most of the existing failures. But in case of complex malfunctions, it is recommended to contact specialized specialists.

You have a problem with the split system, but you just can not figure out the cause of its occurrence? Ask your questions to our experts and other visitors to the site - we will try to help you deal with the cause of the malfunction.

If you want to supplement the above list of malfunctions or add recommendations for their elimination, please write this information in the comments section.

Humidifier repair: typical breakdowns and effective solutions

Humidifier repair: typical breakdowns and effective solutions  How to disassemble a split system with your own hands: features and procedures

How to disassemble a split system with your own hands: features and procedures  Common causes of air conditioning noise and how to resolve them yourself

Common causes of air conditioning noise and how to resolve them yourself  Shuft split systems: ranking of the best brand models + basic selection criteria

Shuft split systems: ranking of the best brand models + basic selection criteria  Ballu air conditioner error codes: what kind of breakdowns are encountered and how to repair them on your own

Ballu air conditioner error codes: what kind of breakdowns are encountered and how to repair them on your own  Inverter split systems: ranking of the best models in today's market

Inverter split systems: ranking of the best models in today's market  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I had a case with a split system, it's hard to call a breakdown. The indoor unit is partially above the bed. I woke up from a cold shower - water from the block dripped on me in large such streams. I ran to see what's outside.

And there the wife decided to collect water for some purpose, and stuck the outlet pipe in the can, the can was filled, and the water partially plugged the tube. Then you understand. In general, escaped with a slight fright.

My air conditioner began to cool much worse, plus frost began to appear. I read so - it looks like symptoms of a lack of freon. How realistic is it to independently refuel the refrigerant? Somewhere they write that it’s not worthwhile to climb it yourself and you must definitely call a specialist, but, as it seems to me, the masters and companies who earn money from it write it themselves.

I also asked this question, but I came to the conclusion that there are too many nuances, and it is not so much to invite a specialist, given that refueling is not needed every year.

Hello. Other causes of the air conditioner's malfunction may also be caused, for example, non-compliance with temperature conditions, high humidity.

In addition, if your appliance starts to cool poorly, ice falls out or builds up, a slight crack is heard during operation, the unit could become dirty, filters, fan, and evaporator clogged. In this case, it is recommended to perform a comprehensive cleaning of the indoor unit.

Contamination of the outdoor unit could also give a similar reaction, especially since just June, poplar fluff flies in full swing, constantly clogging the air conditioners.

If you noted that with all the symptoms, the compressor almost does not turn off - the pressure is reduced, while water starts to flow from the indoor unit or ice falls - this is a freon leak. It is difficult to say how difficult the repair is, depends on the causes of the leak. This may be a natural exit or damage to the tubes. But in general, repairs are not so expensive as to refuse the services of a master, especially since the required set of tools and materials is required.

If the capillary is clogged in non-inverter models of air conditioners, nitrogen purging, hydraulic cleaning, or replacing the tube itself is required. Symptoms are similar to a leak.

Problems with poor cooling and freezing syndrome can also be caused by problems with the control module of inverter models, a breakdown of the temperature sensor or a malfunction of the fan.

In any case, it is very difficult to determine the “disease” of the device from your comment. Nevertheless, we recommend calling a specialist for the first time.

Hello. The air conditioner turns off and on (when it always turns on at 24 degrees auto). Even when I turn it off from the remote control, sometimes it turns on itself and again in auto mode, and the remote control at the same time stands for heating, 30 degrees. He reset the settings, took off the batteries, the timer is also turned off ... I think that this is definitely something in the control board. I want to fix it myself, help?

Split system Samsung. I turn it on, the light comes on, the relay clicks. After a few minutes, it turns off, the light starts blinking. Called the wizard - changed the temperature sensor on the radiator.

She worked for several hours and turned off again, and began to blink in the heat and cold in the same way. What to do, where to look for a reason, the master said that he could not do it. Money back. “If we continue to change everything, the compressor will fly,” his words.