Classes of washing in washing machines: how to choose the appliances with the necessary functions

It is difficult to understand the wide variety of models of household equipment without an idea of the technical capabilities of a particular unit. It is hard to imagine what could give the potential owner the number of revolutions of the drum and the spin speed.

But the right hint will be the classes of washing in washing machines. This characteristic directly tells about the quality indicators of operations. We will talk about how the “coolness” of washing equipment is determined, and tell you how to correctly orientate on it.

The content of the article:

The principle and objectives of classification

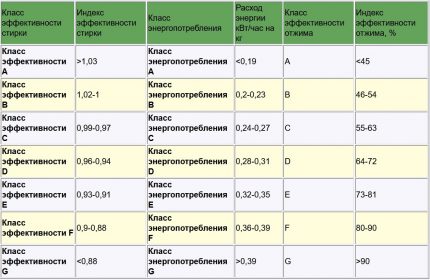

The division of washing units into classes greatly facilitates the choice of a machine with the necessary and sufficient capabilities. The higher they are, the better the washing, but the greater the amount the buyer will have to give the washing machine. Immediately, we note that to solve everyday problems, maximum quality indicators are optional.

The classification is also carried out according to the criteria of spinning and energy consumption, these criteria are no less interesting than the quality of the wash. By analogy, it’s worthwhile to decide in advance in order not to overpay for super-high performance, as well as for those that have not found application for the function.

In the 90s of the last century, information stickers were developed to alert potential owners of washing machines about the effectiveness of the appliance.

Classes on them are depicted by color marking stripes and Latin letters from "AND"assigned to equipment with maximum performance, up to "G"marking the unit with the lowest rating.

Letters and their corresponding gradation are valid in all classification options carried out for each brand and model of a washing machine by a manufacturer that adheres to international rules of testing and control.

Note that the vast majority of washing machines offered for sale in terms of washing quality are marked with letters "AND" or "AT". Manufacturers themselves do not see the point of producing and selling inefficient devices. However, with the nuances of the aforementioned division, one should understand the smallest details.

The process of determining the class of washing

To determine the qualitative characteristics of the washing operation, a technology is developed and adopted, regulated by a standard of European importance EN 60456-A11.

Preparatory activities before the test

Before testing, washing of cotton linen is carried out. Cotton sheets and other bedding, kitchen tablecloths, waffle towels are suitable.

Control tests for a class of washing are carried out in several stages:

- Preparation of linen. Those. washing in water without detergents and drying under the conditions specified by the standard.

- Processing in a washing machine. It is carried out five times, includes washing itself, followed by rinsing and spinning with drying. Wash at 60 ° C.

- Assessment of studies on an average. As a rule, do not evaluate the initial wash, because it gives the highest result. The determination is carried out on one of the four remaining experimental washes.

To accurately determine the effectiveness of washing, 20 different criteria are applied. The analysis is carried out according to organoleptic and physico-chemical indicators.

Cotton linen is prepared in a special way for the upcoming cotton testing. It is divided into four parts of equal weight, each of which weighs at least 5 kg.

The first part is left completely new, the second goes through 20 washing cycles. A third of things are washed 40 times. The fourth batch is the most "long-suffering" - it is loaded 60 times into the typewriter.

Preparatory washing is carried out in clean water. Before further experimental work, things are stored indoors at 20 ° C, the humidity level in it during this period should be equal to 65%. After completing the washing and drying under strict observance of the described conditions, proceed to testing the washing unit.

Test Detergent

Control tests are carried out using a detergent produced by the concern. "Henkel". In the composition of the product intended for testing, at least 77% of the detergent directly The proportion of enzymes is exactly 20%, the proportion of bleach is 3%. It has no flavoring and conditioning agents.

The above detergent does not go on free sale, where it was hardly in demand. It is purposefully produced for manufacturers of washers and deliver to enterprises engaged in their production.

The test tool does not come in a mixed format, but in the form of the individual components listed above. They immediately before the control wash must be mixed in precisely measured proportions, 180 g should be loaded.

Until testing, the ingredients are stored separately in a sealed container allocated for each of them.

Strips for testing the operation of the machine

In addition to a specific detergent for reference studies, standards are needed. This is also a product not intended for the ordinary consumer. They are produced in laboratories in Germany (WFK) and Switzerland (EMPA) specifically for manufacturers of washing machines.

The standard for testing is a strip of five pieces of fabric sewn together with a variety of contaminants. Pollution options are selected from those that are most often found in the conditions characteristic of everyday life. These are strips - squares of cotton fabric with a side of 15 cm.

One of the flaps is perfectly clean. All the other four pieces are stained with difficult to remove substances and products: red wine, cocoa with milk, mineral oil with soot, pork blood.

Since after washing all the standard flaps become almost white, the organoleptic technique gives only a superficial idea of the quality of the washing process.

In-depth information is obtained using high-precision equipment - a spectrophotometer, which allows with extreme clarity to evaluate the effectiveness in quantitative measurement.

The main testing method is to determine the percentage of light reflection, based on the ability of white to fully reflect light rays, and black to absorb them entirely.

To obtain the value, find the percentage of light intensity reflected from different test flaps. Then, the obtained value is compared with the linen washed by the next standard.

Research reference unit

At this stage, laundry that has been washed in a reference washing machine is used as a test benchmark. "Wascator". It serves as monitoring equipment on demand. DIN EN 60456.

The specified unit is used solely to determine the quality characteristics of washing machines manufactured by manufacturers from different countries in recent years.

This is the most ordinary car, not giving out more than 800 revolutions per minute. The technical potential is not taken into account here - the stability of operations is important.

Each time, the reference device erases the things loaded into it with exactly the same quality, which is why it is used in the form of a measure to determine the performance of other machines.

The standard unit takes exactly 5 kg of laundry, and weighs it yourself, becausethe model has a built-in device. Washing in it lasts exactly 79 minutes at a temperature of 60 ° C. Activate it with a magnetic card with a programmed washing process that meets the requirements of the EU.

Test Steps

The reference and test machine are launched simultaneously. Laundry in the drums of equipment loaded in a special way. For example, if one thing fits in with the fold outward from the bottom of the tank, then the next one should be placed with the fold inward.

Together with the laundry, strips with standard rags are laid in the drum. If 6 kg of laundry is loaded into the tested equipment, for example, then an additional strip is attached to it. During operation of the washing unit, its energy consumption is also evaluated.

At the end of the cycle, laundry is removed from the washing machines and reference flaps are separated from it. Laundry items are dried and purely visually determine the quality of the rinse.

In the classification, the characteristic of rinsing usually does not appear, but for allergy sufferers and small children it is of no small importance. After all, in direct contact with their skin sensitive to irritants, the powder remaining in the fibers of the tissue can cause real harm.

Further, the laboratory staff begin to study the flaps. They are dried and ironed, then examined with a spectrophotometer to determine the degree of reflection. The spectrophotometer data is transmitted to a computer with software designed for their processing.

In fact, as a result of research, a quantitative value of the effectiveness of the washing machine is obtained. Literature "AND" the unit undergoing testing will be able to receive if it removes the contaminated tissue pieces 3% better than the reference machine did, "G" appropriate to the one that managed to remove 12% worse than the reference technique.

The influence of the energy efficiency class on the choice

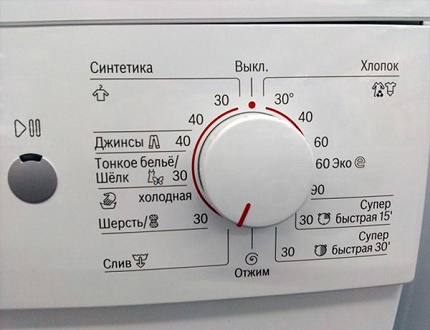

Electronically controlled washing machines differ significantly from their historical predecessors. The owner of the unit can at his own discretion set the temperature regime, select or deactivate the rinse or spin functions, set the activation delay, etc.

Note that the more operations the laundry machine performs, the more energy it consumes. In the same way, the spin option and the washing temperature influence the electricity consumption: the higher it is, the more you will have to pay.

Due to the introduction of numerous functions produced in different modes, the electronic command apparatus has become unnecessarily complicated. In order not to “clog the head” of the owners washing units redundant information, many manufacturers have switched to a new scheme - Fuzzy Logic, which in translation into our language means "fuzzy logic."

Thanks to the new control principle, it is enough to select the type of fabric on the panel. The machine will determine all other washing parameters and related procedures by analyzing the situation. The unit itself will select the optimal, most economical mode of energy consumption.

Washing machines with the described basic system are more expensive than conventional analogues by about $ 150. However, overpayment is more than covered by savings if the unit is actively operated. Costs are reduced by as much as 20%.In addition, units of this category also save water consumption.

Therefore, you have to decide in advance on the amount you plan to spend on the purchase best washing machine and compare with the potential resource savings that your favorite model will provide as a result of several years of operation.

It is not always advisable to overpay for a higher class a few thousand. After all, it will not affect the quality of the washing in any way. It is difficult for the average user, and even “by eye”, to distinguish the difference without technical equipment. Without appliances, the quality of washes corresponding to classes “A” and “B” cannot be ascertained.

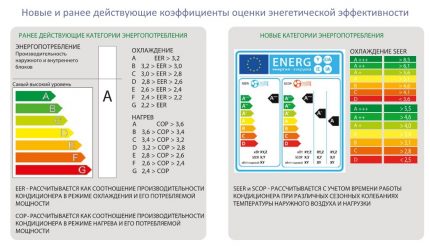

The energy consumption of conventional machines that do not have a designated function is determined by the electricity consumption during a standard wash at 60 ° C. The less the unit spent energy, the higher its class.

If the future owner is not too demanding of a not-too-large, at first glance, cost reduction, and in the case of energy consumption there is no particular need to pay purely for "class."

To assign a class, the assessment is carried out during the washing process in different modes with different degrees of load. It is believed that in a year the machine must work out at least 220 full cycles. On average, the reference unit spends 1.52 kW / h on an hourly wash. At the same time, annual consumption is estimated at 334 kW.

Starting from 2010, the energy efficiency index is indicated in the data sheets of washing machines. This value Energy efficiency index abbreviated Eei. That greatly facilitates the buyer the choice of a model that meets his wishes in terms of energy efficiency.

To calculate the index, the reference annual consumption is multiplied by a coefficient corresponding to the energy class, then divided by 100.

The most economical units are assigned the class "A +" ... "A +++". Cost reduction is an important parameter, but it will be justified only if the machine is actively exploited. In the case of infrequent use, chasing the pluses does not make sense, because an impressive amount will also have to be paid for them.

Conclusions and useful video on the topic

The creators of the video share with potential buyers valuable recommendations on choosing a washing machine:

The plot discusses the main characteristics that affect the choice of a washing machine:

These are the difficult ways to experimentally find the parameters for the classification of washing machines, and the buyer presented only the designations that greatly facilitate the choice of model.

The main task of the user is to determine for himself the importance of the class of the future assistant before the purchase, comparing the potential savings in the future with the amount of the overpayment for “class”.

Please leave comments in the block form below, ask questions and post photos on the topic of the article. Tell us what class of washing machine you prefer to buy. Share why you purchased this particular option.

5 interesting facts about washing machines

5 interesting facts about washing machines  Rating of washing machines by reliability and quality: TOP-15 of the highest quality models

Rating of washing machines by reliability and quality: TOP-15 of the highest quality models  Dimensions of automatic washing machines and other parameters affecting the choice of equipment

Dimensions of automatic washing machines and other parameters affecting the choice of equipment  Indesit washing machines: how to choose the best technique + TOP-5 of the best models

Indesit washing machines: how to choose the best technique + TOP-5 of the best models  Rating of the best top-loading washing machines: TOP-13 models on the market

Rating of the best top-loading washing machines: TOP-13 models on the market  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I read with interest about how washing machines are tested for their compliance with one or another class. The question arose: these units are produced in many countries, some brands are well-known, some are quite the opposite. Do all manufacturers adhere to such testing methods and standards? Or, having bought a typewriter of an unknown brand, you should not believe stickers about the class?

The question, of course, is a good one. It is especially relevant for Chinese and domestic models, since I, and many other people, are very sensitive to the choice of household appliances and naturally pay attention to the class of washing machines. Everyone wants to buy cheaper, but higher class. And there is a maneuver for deception. However, I am sure that in most cases this examination is mandatory for all manufacturers, and to everything else, it is also independent.

Hello. Having bought any machine of dubious production, which has not proven itself, you can run into a fake, the lack of a standard and dishonest fake certificates. As well as a branded device, when buying, it is best to check for authenticity through individual serial numbers and a call to the support service of the manufacturer.

For me, as a mother, it is very important that the washing machine has a "Children's" mode, as well as the ability to start the enhanced rinse function. Because my son is allergic, and I need to rinse the laundry well so that there is not the slightest residue of detergent. It is also better that the machine is equipped with a “Fast” mode, when things are washed less time, that is, they do not need a thorough wash, but only refreshment.

I worked at a home appliance store, and they gave us workshops on selling washers. I advised everyone when buying a washer, at the first start of the machine, just to drive away with a powder and a bad rag, in order to wash the factory oils from the drum, no additional special powders should be added. Spin set 1000 revolutions, more and less does not make sense.

I needed the “fast wash” mode the most. Otherwise, without any additional requirements. I took an indesit, with a top load, like my mother. Serves three years already.

I chose from those with the largest load. As a result, a hotpoint. Already 10 kg! From useful - self-cleaning. Really necessary function.

Virlpool well erases and wringes. With the last washer, she was afraid to set high speeds - she often tore her clothes. But there is no such thing. I set the maximum speed and the clothes are not very wrinkled, whole and not long to dry.

Great informative article, thanks to the author! We personally took Hotpoint for 16 programs and 6 kg of download. There were always enough functions and modes and did not think about how many there were.