Installing a hood with a non-return valve: the nuances of selection and installation with valuable tips

The presence of forced ventilation in the kitchen or in the bathroom is a common thing in a modern apartment. But with improperly organized air exchange, there is a risk of fogging of the windows, the appearance of mold, lack of oxygen and other undesirable moments. To avoid this, it is necessary to install a hood with a non-return valve or a similar technical solution.

This is not difficult to do, the main thing is to understand where and in what cases an obstacle is necessary for reverse traction. This will help knowledge of the norms of ventilation of premises and the fundamentals of the physical law of air movement.

From this article you will learn what designs of check valves exist, where they are best used and where to place the ventilation system. The installation itself is quite simple, but there are nuances that you should familiarize yourself with in advance, then self-installation will be easy and air exchange will be seamless.

The content of the article:

Ventilation in an apartment or house

On the one hand, the air exchange in an apartment or house must comply with the standards established for residential facilities, and on the other, it must obey the laws of physics. Therefore, it is not always possible to get by with trivial solutions, and sometimes you have to install a check valve designed to let the flow pass in one specific direction.

Standards and regulations

The main document that you need to focus on when designing ventilation both in an apartment and in a private house is SP 54.13330.2016. This is the updated edition of SNiP 31-01-2003 “Residential multi-apartment buildings”. The scheme of air movement through a residential facility of any layout should be drawn up based on the provisions of paragraphs. 9.6 and 9.7 of this set of rules.

Table 9.1 sets the air exchange rates for various types of rooms. Designers and commercial property owners are required to strictly follow these parameters.

Residents can install ventilation with less bandwidth, focusing on microclimate indicators:

- Humiditywhich can be measured with a hygrometer. Air saturated with water leads to the formation of fungus on the wallpaper and ceiling, as well as smudges on the windows.

- Carbon dioxidethe concentration of which can be measured by a gas analyzer. Without a device, the lack of oxygen can be felt right away when you enter the room from the street.

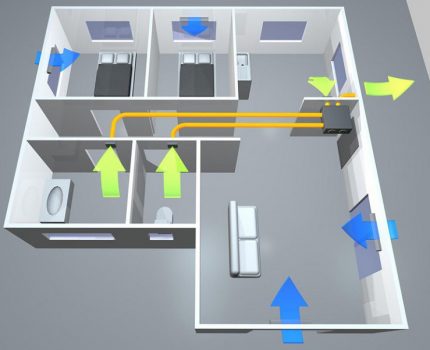

Air circulation can be natural or forced. It depends on many factors, including area, number of storeys, location of rooms and technical rooms.

Thus, in any dwelling there are points of inflow and removal of air, and the situation is unacceptable when outflow occurs through the air inlet, and air mass flows through the ventilation shaft.

This leads to a violation of sanitary, hygienic, fire and other standards and can seriously worsen living conditions.

Artificial and natural air exchange

Sometimes a situation arises when forced removal of air from the following rooms is necessary:

- Kitchen. When cooking, intense evaporation may occur. So that it does not spread throughout the kitchen and further through other rooms, an extractor hood is installed above the stove. Its operation allows directing contaminated air directly into the ventilation shaft.

- Bathroom. When taking a shower, air is saturated with water vapor. To quickly remove it, turn on the ventilation unit, since otherwise the appearance of mold or peeling of plastic and tiles will occur much more intensively.

- Workshop. When carpentry or other work, a suspension is often formed, which can harm human health. To do this, start the fans or hoods, which are located near the source of pollution.

The inclusion of forced ventilation is temporary, as it consumes a lot of electricity and creates noise during operation.

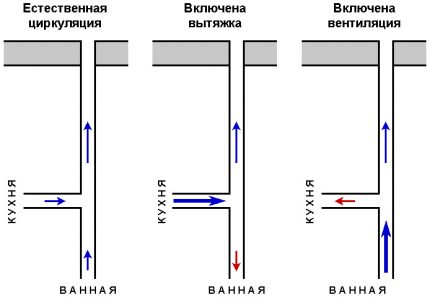

After the introduction of devices for forced ventilation, there is a problem with the natural circulation of air through the obstacle. If an ordinary paddle fan still somehow lets air flow through, then hoods, as a rule, minimize passage to unacceptably low rates.

Stopping natural circulation can cause local problems in the room. For example, in the kitchen there will be increased humidity and in the winter windows will “leak”. But even worse, the movement of air through the house will be disrupted, which will affect all rooms.

Installing a hood can have another negative effect if this device is integrated into the general duct ventilation. Air exchange obeys the law of balance: at any time, the amount of incoming and outgoing air is the same.

It follows that an increase in pressure at one of the points leads to a change in the readings in others. The main thing here is to exclude the possibility of reverse flow.

To solve both problems set check valve. Given the fact that modern air ducts for residential premises have standard dimensions, the independent installation of such an element is not very difficult.

Check Valve Installation

In order for the non-return valve to perform well the functions assigned to it, it is necessary to choose its type and location for installation, as well as to correctly install it. All this can be done independently without the involvement of paid installers.

Position in the ventilation system

Consider a situation where the inclusion of forced air exchange changes the direction of flow in the duct system. Take the frequently occurring case where extractor fan in the kitchen and a fan in the shower are connected to one ventilation shaft.

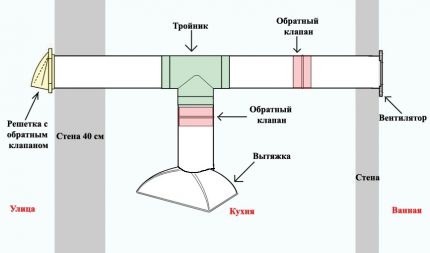

If the topology of the ventilation ducts is more complex, then the rule of placement of the non-return valve can be formulated as follows: the valve is installed after each air inlet point and to the nearest branch of the duct. The exact location is not critical, it is chosen based on the convenience of installation. This solution ensures that there is no reverse thrust for any combination of hoods and fans that are turned on.

In order to provide an opportunity for the outflow of air from the room when the hood is not working, a branch from the channel is made. It should function so that the flow passage is only towards the ventilation shaft, therefore it is equipped with a check valve.

Since the valve can be installed on the channel near the hood at different angles, it must be understood that the branch should not be an obstacle to the movement of air. A high flow rate combined with additional resistance will create a load on the fan motor and contribute to noise generation.

A layering with a valve can be installed anywhere from the hood - this is unprincipled. Most often, it is placed near the shaft, since you can replace the angle with a tee without changing the length of the remaining elements of the ventilation duct.

Principle of work and design

The non-return valve is designed for one-way air flow passage, during the reverse of which it must tightly close the live section of the channel.

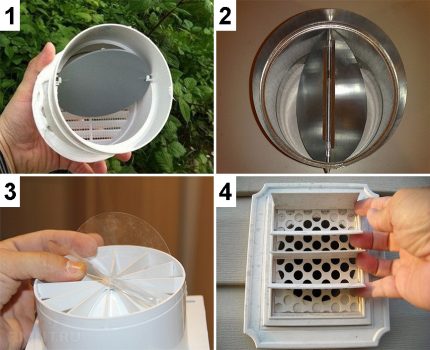

There are 4 common types of performance of such devices:

- Membrane A small force of air flow can change the position of the flexible membrane. This type is used for natural ventilation. Sometimes the cross-section near the membrane is reinforced with several stiffeners, which avoids the curvature of the plate with strong reverse traction from the hood.

- Single-leaf gravitational. Due to the flow, the rigid valve flap deviates. If a reverse occurs or air duct speed close to zero, then under the influence of gravity the sash closes. Such a system is also used for natural ventilation and inside the canal.

- Double wing spring. The butterfly type has two wings and is similar in principle to the gravitational model, only springs are responsible for closing the valve, not gravity. This type is used inside the channel, since it will be difficult for a weak flow to overcome the resistance force of the springs.

- Jalousie. This is a modification of the single-leaf gravity version, with only a few flaps. It is used as an external element of the ventilation system, since it has compact dimensions in the open state. Its device is more complex, so it is better to limit yourself to the previous three options.

The cost of the non-return valve is low, therefore, in the case of standard sizes of the ventilation system, it is better to buy a shaped element with the function of one-way air flow.

If the parameters of the ventilation duct are of non-standard proportions, then it is easier to independently manufacture for it a membrane valve or a single-leaf type. A rigid sash is usually made of plastic or metal.

In this case, two points must be taken into account:

- the plate should fit snugly against the walls of the casing or the locking protrusion to prevent air leakage;

- it is necessary to exclude the knock of the plate, so soft material, usually rubber, is glued to the edges of the body.

The membrane for a makeshift valve can be made of thick paper. If the product is made for a bathroom or shower room, it is better to use mylar film, as it will last longer in conditions of high humidity.

Mounting the device to the hood

If the ventilation duct is made independently, it is difficult to give general recommendations for installing a non-return valve, since its installation depends on the material and geometry of the air ducts.

But now they usually use standard rectangular or round solutions to create ventilation. In this case, there is no problem introducing an additional element into the system, since it is possible to correctly install a non-return valve on the channel near the hood using the method standard for all structural parts.

It is necessary to fasten the shaped element with a non-return valve in a place providing convenient access to it. The closing mechanism may lose tightness, then it will need to be cleaned of adhering dust and dirt. And for this it will need to be removed.

Joints between a tee or a piece with a non-return valve and other channel elements are coated with silicone sealant (for plastic boxes) or wrapped with aluminum tape (for metal structures).

The use of strong adhesives is undesirable, as this will make it difficult to disassemble the structure for carrying out maintenance work or changing the configuration of the ventilation system.

The grille is mounted on the ventilation shaft using self-tapping screws. The variant with liquid nails is less preferable due to the difficulty in removing this element.

Particular attention should be paid to sealing joints with foam rubber or rubber, otherwise there will be little point in installing a grille with a check valve.

Useful video on the topic and conclusions

The classic solution for mounting a non-return valve on a tee in front of the ventilation shaft:

Integrated butterfly valve and additional valve for natural ventilation:

How to make a homemade diaphragm valve type:

Installing a non-return valve is a necessary measure if there is a hood in the ventilation system. It can be used to prevent back draft or can be used to provide air circulation when the fan is off.

The place to install the valve in the ventilation duct must be selected taking into account the prospects of its removal for cleaning. The installation process itself is uncomplicated, but it is important to properly seal the joints to avoid air leakage.

Do you want to share your own experience in the selection and installation of a check valve on the exhaust duct? Do you have useful information on the topic of the article? Write comments, please, in the block below, post a photo and ask questions.

Check valve for ventilation: how to arrange ventilation with a check valve on the hood

Check valve for ventilation: how to arrange ventilation with a check valve on the hood  TOP-10 rating of silent fans for a bathroom with a non-return valve

TOP-10 rating of silent fans for a bathroom with a non-return valve  How to connect a fan with a humidity sensor: subtleties of connection and installation + selection rules

How to connect a fan with a humidity sensor: subtleties of connection and installation + selection rules  Plastic ducts for hoods: overview of types + installation rules

Plastic ducts for hoods: overview of types + installation rules  How to disassemble the exhaust fan in the bathroom: instructions for disassembling and cleaning the exhaust fan

How to disassemble the exhaust fan in the bathroom: instructions for disassembling and cleaning the exhaust fan  How to make ventilation in an animal shed: requirements and nuances of arranging ventilation

How to make ventilation in an animal shed: requirements and nuances of arranging ventilation  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements