Do-it-yourself pool waterproofing: technology overview + step-by-step example of work

The construction of a concrete bowl, despite the emergence of new designs, is the most common option for the construction of stationary pools. However, this material has the ability to absorb moisture, which subsequently destroys the structure.

Agree, I would not want, having spent a lot of money on the construction of an artificial reservoir, to find cracks in a couple of years. Timely waterproofing of the pool will help prevent defects on the concrete bowl.

We will tell you about the most effective methods of protection against moisture, and we will also describe in stages the technology for equipping the hydrobarrier.

The content of the article:

Why waterproof the pool?

Concrete is a strong and durable material, but it is characterized by increased porosity. Water that has leaked into the thickness of the material is easily absorbed and retained for a long time, becoming a favorable environment for the development of mold.

When exposed to subzero temperatures, such a wall becomes a conductor of cold, and freezing of the liquid leads to cracks and mechanical destruction of the structure.

The device of reliable waterproofing of the inner surface of the pool bowl is not in doubt, since it is filled with water. However, destruction can also occur from the outside.

Concrete is characterized by the so-called “capillary suction” of a liquid when moisture is drawn in from the environment - soil, air with high humidity, and atmospheric precipitation. In this regard, the outside of the pool bowl is also subject to waterproofing measures.

Often the walls of the pool are erected from separate blocks. In this case, the joints are dangerous. The strength of the bonding solution is significantly lower than the strength of concrete slabs. Therefore, if water begins to seep in such a place, then under the influence of the pressure of the mass of liquid, the material quickly collapses.

First, drip seepage appears, then a small leak, which washes out the particles of the solution and turns into a decent leak.

Moisture protection methods for concrete structures

Waterproofing can be superficial, internal or combined.

To ensure moisture protection of structures made of monolithic concrete or concrete blocks, the following tools are used:

- Deep Penetration Compounds - even microscopic cracks are clogged, working at the level of capillaries.

- Additives for sand-cement mixture - increase the hydrophobicity of concrete.

- Liquid glass - a composition that, after hardening, forms a solid, moisture-proof layer on the surface.

- Liquid and viscous compounds - the so-called liquid rubbers and coating waterproofing, forming a strong elastic membrane.

- Roll film coatingsglued to the surface of concrete.

Each tool has its own characteristics, which determine the scope and method of application.

Penetrating waterproofing compounds

Penetrating materials are cement-sand mixtures with active chemical additives. Diluted with water and applied to a well-moistened surface.

Active substances in the presence of water begin to react with particles of concrete mix - free lime. As a result, insoluble crystals of calcium hydrosilicates and hydroaluminates are formed.

Thus, the concrete is compacted deep - the active components of the waterproofing penetrate even the smallest cracks due to capillary suction. A moisture barrier is formed.

When all water molecules have reacted, the process of crystal formation stops. The resumption of contact with the liquid starts it again, causing even greater compaction and waterproofing.

The thickness of the formed layer can reach 10-20 cm. Protection is not afraid of mechanical damage, increases the frost resistance of concrete and the durability of the entire structure.

However, the penetrating waterproofing does not give 100% protection against moisture in constant contact with the liquid.Therefore, it is used as a preliminary treatment before applying the main protective layer.

Hydrophobic concrete additives

The principle of action of waterproofing additives is the same as that of penetrating compounds. Only in this case, not only the layer near the surface is protected - the entire mass of the material becomes hydrophobic.

Calcium hydroxide, or free lime, is washed out in ordinary concrete over time, leaving a large number of microscopic capillaries and cavities.

The active additives added to the mixture already at the stage of concrete hardening interact with calcium hydroxide and water molecules. Growing in solution, they fill the resulting microcavities and pores.

Cast concrete construction or individual blocks acquire the properties of a stone monolith. With further exposure to water, the surface of the structure becomes even more compacted.

A construction made of such concrete has not only moisture resistance - it is characterized by increased strength, frost and heat resistance, and resistance to aggressive effects of environmental chemical compounds.

Additives not only contribute to the filling of micropores - larger cavities are lined with a layer of insoluble crystals. Due to this, the wettability of the surface is minimized, and the effect of capillary retraction is removed.

However, in addition to its positive properties, this characteristic also has a drawback. The formation of a waterproof layer leads to low adhesion with adhesives and plaster. Therefore, before applying the finish coatings, measures are required to increase the surface roughness of the material.

Liquid glass is an effective tool

Water glass is a solution of potassium or sodium silicates. The composition is a transparent liquid mass, which when solidified forms a solid glass-like layer. The principle of operation of such a waterproofing is based on the ability of the solution to harden spontaneously.

Due to its fluid texture, liquid glass fills the pores and cracks of the surface to be protected. Due to this, possible paths for the passage of fluid are completely blocked. The composition makes the treated concrete surface waterproof and increases its strength.

The composition is characterized by good adhesion and is easy to apply - with a roller, brush or spray method. Processing is carried out in two or three layers, waiting for the complete hardening of the applied solution.

It should be borne in mind that liquid glass sets very quickly. Therefore, some skill is needed to carry out the work. This creates difficulties with independent waterproofing of the tank.

The solidified layer is close to glass in its properties - it is hard and quite fragile.For processing surfaces that are constantly in contact with water, it is used only as a basis for gluing with polymer films.

Liquid and viscous waterproofing

Easy to apply and effective liquid products are becoming more common. These are compositions based on bitumen, latex, silicone, polymers. They are applied to the surface with a conventional brush, spray or roller.

The compositions are characterized by good adhesion to the surface - they fill in microroughnesses, pores and cracks, forming a dense moisture-proof membrane.

Liquid insulators are divided into two types:

- Water emulsions. Almost no smell, hardening occurs only due to polymerization processes.

- Organic Solvent Compounds. When applied and hardening, toxic substances are released, therefore they are not recommended for indoor use. After application, the solvent evaporates, an elastic hydrophobic base remains on the surface.

Means most often do not require preliminary surface treatment. Apply in several layers. The result is a strong and flexible membrane that does not have joints and seams.

Such a waterproof barrier is not afraid of any water hammer system, neither the pressure of the liquid, nor the shrinkage of the concrete structure and the appearance of small cracks in it. The film will remain intact.

The following compositions of liquid and coating waterproofing:

- Bitumen. This is a traditional waterproofing - a viscous organic compound of a deep black color. It is applied in a hot way, which makes the technology fire hazardous. In addition, the coating does not withstand low temperatures and lasts only 6-7 years.

- Bitumen-polymer. The composition does not require heating before application. The addition of polymers makes the composition more elastic and frost-resistant. Adhesion to the treated surface increases. It is used outdoors or in ventilated areas.

- Bitumen-latex, or liquid rubber. Latex is harmless and odorless, so the tool can be used for internal work.

- Water based acrylic solutions. They contain mineral fillers and pigments. They can be white or colored. These are used for a finishing layer that does not require additional staining or lining.

Colored polymer mastics are often used on their own, without any topcoat. In this case, in order to increase the wear resistance and strength of the coating, a reinforcing fiberglass mesh is recessed into the first layer of the applied mass. They are waiting for complete polymerization and coated with a second layer.

Such a protective barrier is able to withstand even severe mechanical stress.

The disadvantage of almost all such compositions is that the ultraviolet has a negative effect on the finished coating, up to the loss of elasticity and cracking. Therefore, outdoor pools are additionally covered with a protective agent.

Polymer coating

Coating a concrete surface with PVC film is one of the most economical ways to waterproof a pool. The film is a finished membrane with a thickness of 1-1.5 mm, supplied in rolls. It is a lightweight, resistant to aggressive chemical attack, completely waterproof material.

Membranes can be smooth - for easy cleaning, and with a rough surface - for covering ladders and the bottom of children's pools. Fiberglass reinforced mesh are more durable and last longer. Unreinforced is cheaper, but their service life is only 5-6 years. After that, the polymer film must be replaced.

The waterproofing of concrete with polymer membranes requires a professional approach, and it is quite difficult to do it yourself. Surface pretreatment with penetrating waterproofing or water glass is required.

The film should be laid on a geotextile layer to avoid condensation and to prevent friction of the membrane on a rough surface.

In this case, it is necessary to ensure good adhesion of the film to the surface in order to prevent peeling. Welding of seams is carried out by special equipment. The connection must be airtight - the slightest inaccuracy will lead to the penetration of liquid under the waterproofing layer.

Internal and external waterproofing of the pool

Measures for moisture protection of the structural elements of the tank should be carried out on both sides at the stage pool construction. Distinguish between internal and external waterproofing of the pool. External waterproofing is arranged to protect the structure from the penetration of groundwater.

Internal - protects the structure from exposure to liquid, which presses on the surface of the bowl with its mass.

The choice of waterproofing methods depends on the installation location of the pool - outdoors or indoors, air humidity, height of the aquifer, type of soil.

Groundwater tank protection

Protect the pool from groundwater penetration even at the construction stage - before the construction of the bowl. Under the construction, a sand cushion is arranged, on which overlap canvases of roofing material or other dense waterproof material are laid.

With close groundwater, a waterproofing screen made of clay or loam with a thickness of at least 30 cm will also be required.

To harden concrete and increase its hydrophobic properties, special additives or water glass are added to the sand-cement mixture. However, this requires strict adherence to the recipes and proportions.

With independent construction of the pool, this is quite difficult. At home, it is easier to process an already finished structure from the outside with liquid glass or penetrating waterproofing.

When installing a pool in a house, penetrating waterproofing will become a protection against water seeping from the pool bowl.In this case, the concrete will begin to harden inward - towards the movement of the liquid, not letting it out and excluding flooding of the space surrounding the pool.

On stationary soils (rocky, semi-rocky rocks, low-moisture sands with a low-lying aquifer), penetrating treatment is sufficient.

But clay soils are subject to frost heaving and seasonal shifts. In such areas, microcracks may appear, into which moisture begins to be drawn. A surface coating, especially liquid glass, in this case will not save.

Therefore, before constructing a concrete bowl, unstable soils are removed from the foundation pit during frosty periods. Mandatory peeling and extraction of loess loam and sandy loam is mandatory.

Reliable moisture protection is provided by applying a waterproofing coating or liquid rubber. The strong film formed after polymerization withstands aggressive effects and soil pressure and is not damaged by shrinkage of the concrete structure

Waterproofing the inner surface of the bowl

Work to protect the inner surface from water should be carried out especially carefully. Errors in the waterproofing device lead to leaks and / or wetting of concrete, which you may not even notice. As a result, the material is destroyed, mold appears. Repair work in the end is very expensive.

Therefore, it is better not to save on internal waterproofing. To increase efficiency, several different methods are used at once.

The protective coating of the bowl must meet the following requirements:

- absolute moisture resistance;

- elasticity along with strength;

- ability to withstand hydrostatic and dynamic loads;

- good adhesion to the surface;

- resistance to biological destruction by microorganisms, aggressive effects of water and the antimicrobial additives contained in it (chlorine-containing preparations);

The material for the internal waterproofing of the pool bowl must be environmentally friendly and resistant to ultraviolet radiation, temperature extremes.

These requirements are met by the following types of waterproofing:

- liquid rubber and polymer compositions based on water;

- deep penetration materials;

- protection with polymer membranes.

You can use a combination of three tools at once, or limit yourself to two.

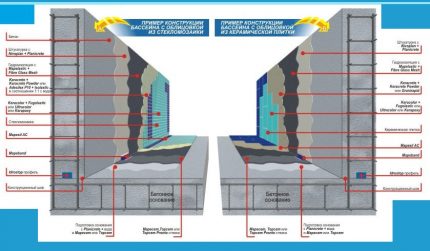

Lining the surface of the tank’s bowl with ceramic tiles or mosaics does not lose its relevance. Such a coating is durable - it is resistant to any impact, is well washed and quietly withstands water pressure.

Separate elements are absolutely waterproof. Dangers are seams. Even the use of waterproof grout does not guarantee the penetration of liquids.

Therefore, before facing, the surface must be treated with moisture protective agents. The combination of the penetrating composition with a coating mastic is the most effective waterproofing of the pool bowl, applied under the tile.

For indoor pools, the correct role will be played in maintaining normal humidity. ventilation organization.

How to waterproof yourself

The simplest and most effective method for self-waterproofing the pool is the application of penetrating, and then viscous coating formulations. However, in order for the coating to be reliable, technology must be followed.

The ambient temperature during the work should not be lower than + 5 ° C. In hot sunny weather, mastic application areas shade or work in the morning and evening.

Mastic must be thoroughly mixed before use. For this, a belt mixer is used to exclude air entrainment in the coating mixture.

Stages of waterproofing work:

- The concrete base is cleaned. Chips, shells and cracks expand and cover. The surface of the walls and the bottom level.

- A layer of penetrating insulation is applied to a well-moistened base. Seams, cracks, places of entry of communications are processed especially carefully. They are waiting for drying.

- The surfaces are degreased with a weak acid solution, which is left for an hour. Then it is washed off with water and the residues are neutralized with a 4-5% solution of soda ash.

- Dry the treated substrate completely.

- Apply the first layer of mastic with a thickness of 2-3 mm. Vertical surfaces are treated with a roller or brush. Horizontal - using the bulk method, followed by distribution with a needle roller, which will help remove air bubbles from the mass.

- Reinforced in a slightly set layer of waterproofing reinforced fiberglass mesh and wait for the complete polymerization (hardening) of the composition.

- A second layer of mastic is applied, the thickness of which can be from 1 to 3 mm.

The waterproofing layer should dry for at least 3 days, on surfaces in contact with water - 14-15 days. At this time, you must not step on the walked surfaces and walk on them.

To avoid uneven drying and the formation of a strong and flexible membrane, the coating is periodically moistened with water during polymerization and covered with a film.

According to this technology, it is possible to carry out both internal and external waterproofing of the pool. Thus prepared surface is ready for finishing.You can tile the pool, cover with PVC film, or cover with colored liquid rubber.

Conclusions and useful video on the topic

How to apply penetrating waterproofing. An example of surface preparation and pool treatment with Vandex materials:

Waterproofing the pool with a polymer membrane:

Moisture protection of the bowl with liquid rubber. Spraying allows you to get a uniform layer of the same thickness:

Whatever the method of waterproofing the pool, the reliability of the coating should be checked for leaks. To do this, fill the tank with water and maintain it for about 10-15 days.

All this time, the area around the pool is periodically checked for leaks. And only in the absence of errors in the waterproofing proceed to the finish.

Have experience in waterproofing a concrete pool? Please share information with our readers, tell us about your method of resolving the issue. You can leave comments in the form below.

How to make a fountain pump yourself: a step-by-step workshop

How to make a fountain pump yourself: a step-by-step workshop  How to make a pool with your own hands: step-by-step instructions for the construction

How to make a pool with your own hands: step-by-step instructions for the construction  How to make a pool in the country with your own hands: the best options and master classes

How to make a pool in the country with your own hands: the best options and master classes  How to choose a pump for the pool: a comparative overview of different types of units

How to choose a pump for the pool: a comparative overview of different types of units  Materials for waterproofing pools: a comparative review

Materials for waterproofing pools: a comparative review  Pool heat pump: selection criteria and installation rules

Pool heat pump: selection criteria and installation rules  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Last year I made a small pool on my site. Waterproofing made with liquid glass. This is the best option when correlating reliability with ease of use. I myself coped with the application in a day - with the help of a roller I processed the entire surface of the bowl. The composition is good, does not spread and is not too thick, lays flat, fills all cracks, quickly sets.

There was a problem with the pool. Partial detachment of the mosaic occurred, depth to the reinforcing mesh. As far as I can understand, this is the top layer of waterproofing. There is a leak, that is, it does not. I suppose that this is because the foundation is “walking”. Is it possible in this situation to make some kind of patch of critical areas or will it be necessary to redo the entire pool?