Water pressure sensor in the water supply system: specifics of use and adjustment of the device

The well-functioning operation of the water supply system is one of the most important attributes of comfortable living both in a luxury cottage and in a modest summer house. Often, owners have to equip an individual water supply network. After all, far from all settlements there is a centralized water supply.

The water pressure sensor in the water supply system will automate its supply to the taps. A small-sized device will significantly increase the resource of pumping equipment, and at the same time prevent destructive water hammers for equipment.

You will learn about how the device works and how to choose it competently taking into account the operating characteristics of the water supply system, after reading the information provided by us. We described in detail the device and the principle of operation of the sensor. The information proposed for consideration was supplemented by photos and video materials.

The content of the article:

Appointment and scope of use of the device

Issues that many residents of large cities do not even suspect of become immediately relevant after acquiring suburban real estate. Among them - personal water supply, one of the important elements of which is a pressure sensor.

Living in the fresh air is doubly pleasant if you can take a bath, use the washing machine or turn on the automatic watering of beds planted with homemade vegetables, strawberries and herbs. To satisfy all the needs of residents of a particular private household, a well-functioning water supply system is required.

To automate the process of water intake, pressure sensors are installed in autonomous water pipes, the following selection introduces the specifics of their use:

The owners of cottages and cottages use water from wells and boreholes. For its fence, modern equipment is used, the heart of which is a pump. He, as necessary, pumps water. To extend the service life, install a special sensor that monitors the pressure of water in the pipeline.

The second name of this device is pressure switch. In some models of pumping stations, it is included. The sensor has the settings set by the manufacturer. Its purpose is to provide the optimal frequency for turning the pump on and off.

When 5-6 households permanently live in the house, they turn on taps to wash their hands, use the toilet, wash dishes, take a bath, use water to wash a car or water the garden. It is difficult to imagine how long a pump would have lasted, the operation of which is not controlled by the sensor. It would turn on every time users need water.

Classification of controller models

The market of equipment and spare parts for water supply systems replete with offers of domestic and foreign factories. Among the pressure sensors you can find both inexpensive and simple models of Russian manufacturers, as well as expensive multifunctional solutions.

All types of sensors can be divided into 2 main groups:

- electromechanical;

- electronic.

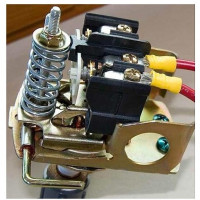

The first type of devices has a metal plate that responds to the pressure of the hydraulic tank membrane in the system, closing or breaking contacts. If its value is insufficient, then the pump is turned on, and otherwise - shutdown.

The electronic type of sensors sends a signal about the deformation of the membrane to the automatic control system.The received information is analyzed, a command to turn off / turn on the pump is received.

Such equipment is very sensitive to the slightest deviation from the set values, it has protection from the "dry" course. Depending on the model, it is possible to automatically start the system after an emergency shutdown, notifying the owner of problems by sending a message to a mobile phone and other additional functions.

For example, the Spanish regulator KIT 02, which acts as a pressure sensor, is able to maintain a constant pressure of a predetermined value, protects against dry running, has a reverse valve, a built-in pressure gauge, and dampens water hammer. But the cost of this model is far from 1000 rubles.

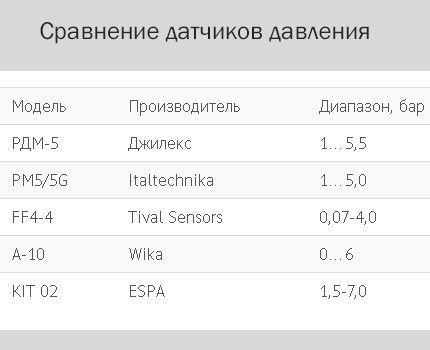

The most popular options for water pressure devices in a private water supply system:

- Russian - RDM-5 from Dzhileks;

- German - Grundfos FF 4-4, Tival FF 4-4, Condor MDR 5/5;

- Italian - PM / 5G, PM / 3W from ITALTECNICA, EASY SMALL from Pedrollo;

- Spanish - electronic regulator KIT 00, 01.02, 05 from ESPA.

One of the budget solutions can be a sensor from the company Dzhileks RDM-5. It has factory settings for the lower and upper limits of 1.4 and 2.8 atmospheres respectively. You can change the range yourself, given that the operating values of this device are from 1.0 to 4.6 atmospheres.

The device of the German company Grundfos model FF4-4 is distinguished by the ability to specify settings with an accuracy of 0.01 atm. Its working range is from 0.07 to 4 atmospheres, and FF4-8 - up to 8 atm. It has a transparent cover and a special scale inside the device.

All this greatly simplifies self-adjustment - no need to twist the nuts and wonder if it is enough. The scale immediately shows the result. The main negative quality of the device is the cost, which is almost 5 times higher than RDM-5.

The device and principle of operation of a typical sensor

Most often, owners use mechanical type sensors. Their main advantage is independence from electricity. They do not require a dedicated outlet to turn the device on.

These devices are designed to turn the pump on and off when the set pressure indicators are reached. Therefore, the pump is connected to the network through a sensor.

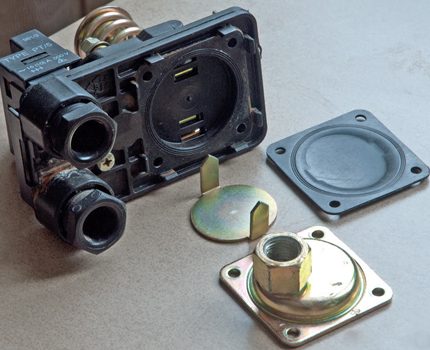

The simplest and most popular mechanical sensor is the RDM-5. It consists of the following elements:

- metal platform;

- membrane;

- piston;

- springs;

- adjusting bolts with nuts;

- plastic case;

- electrical contacts.

More expensive models of foreign manufacturers may have a scale for adjustment, a built-in pressure gauge and other components that allow you to perform a wide variety of functions.

By the number of possibilities and cost, the following pressure sensor groups can be distinguished:

- simple pressure switch;

- additional sensor for protection against dry running. It is paired with a simple relay, for example, from the company Aquatica;

- water pressure controller is a complex device with a sensor, pressure gauge, many other functions and a fairly high price.

The installation of electronic controllers with an integrated pressure switch and pressure gauge is more complicated than mechanical ones. Such devices, depending on the model, have an additional regulator that prevents pressure drops in the system.This ensures always uniform pressure, regardless of whether the pump is operating at a particular moment.

A sensor that controls the operation of the pump is installed, as a rule, in water supply systems with a hydraulic accumulator. The device is always mounted in front of the storage tank. Its function is to continuously measure the water pressure in the system. The sensor compares these readings with the given indicators.

As soon as the pressure becomes lower than specified by the settings, the contacts close and the pump turns on, starting water intake. It fills the accumulator, which helps to create the required pressure.

When the sensor fixes the upper pressure limit set by the owner of the house, the electrical contacts open - the pump stops working.

The on / off frequency depends on accumulator volumepressure in the system and the number of water consumers. For example, if the hostess of the cottage takes a bath, her husband enjoys a hydromassage in the shower, and a dishwasher works in the kitchen, then the sensor will turn on the pump at some point.

First, when you turn on the taps and shower heads, water will come from the storage tank. As soon as its amount decreases, the capacitance membrane will also reduce the resistance.

Accordingly, the pressure in the system will become less. The tank membrane will immediately respond to this change and, as soon as the readings reach the lower pressure limit set by the user, the pressure switch contacts will close.

At this moment, the pump will turn on and begin to pump water into the system, at the same time filling the vacated space in the accumulator. If the taps are still open, then water will flow from the well until the pressure in the system reaches the upper limit of the range specified by the owner.

If in the house an electronic controller with additional functions is used as a sensor, then at the moment when the pressure drops, the water pressure does not become weaker. The built-in regulator helps maintain the desired pressure, and the user does not notice anything, unlike the situation using a simple pressure sensor.

Principles of Adjustment

The device that monitors the pressure and controls the operation of the pump in automatic mode is very convenient to use. He almost does not need attention and maintenance. Is 1-2 times a year to clean from debris and check how the sensor copes with the control of a given range of water pressure.

What you need to know before starting work?

Initially, the owner who bought such a device has 2 options:

- leave the settings set at the factory;

- set the desired response range yourself.

The first option is convenient when the parameters of the pump and pressure in the system correspond to the factory parameters. For simple domestic models, they are 1.4 and 2.8 atmospheres, respectively, for the lower and upper limits. Depending on the device and the manufacturer's company, these figures may differ.

If the specified range is suitable for the owner of the house, then it remains only to put the sensor, following the installation instructions. Otherwise, an independent adjustment of the sensor that controls the water pressure in the private water supply system will be necessary.

It is more convenient to adjust the desired range in models that have a built-in pressure gauge and a more sensitive graduation scale.But the cost of such a decision will cost a tidy sum.

Before proceeding instrument adjustment, you need to look at the passport for the maximum permissible operating range and compare this data with the pump capacity. It is important to leave a small margin - you must not allow the operation of the equipment to the maximum. This gap is about 0.5 atmospheres.

Also, it should be remembered that the optimal response range of the pump is 1-1.5 atm. More is not worth it - water shocks may occur that cause irreparable damage to the equipment. The minimum threshold for turning the pump on must be at least 1.4 atm.

Even before setting up the sensor, you definitely need to find out what pressure in the accumulator. To do this, it is disconnected from the network, the water is drained, the pressure is checked with a manometer.

If the readings are 1.4 atmospheres or less, then you need to pump up to 1.5 atm. Otherwise, bleed excess air to this value by pressing on the nipple.

Step-by-step setup of the pressure sensor

Depending on the model of the sensor, the steps for adjusting it will differ slightly. Each device has its own parts that are responsible for setting the pump response range. For example, the German FF4-8 has a division scale, where everything is extremely simple to adjust. And you do not need to remove the cover for adjusting - it is transparent.

If this is a complex electronic pressure controller with additional functions, then carefully read the details of the operating pressure indication for the system in the passport. Moreover, it should be at least 0.5 atm less than the maximum permissible values.

Regardless of the make and model of the pressure monitoring device, you must first check the lower limit at which the pump is triggered. To do this, you have to drain the water by opening the tap. As soon as water injection starts, it is necessary to record the pressure gauge.

When the pump shuts down, this value should also be written down - this is the upper limit of the maximum allowable system pressure. Moreover, these readings should not differ from each other by more than 1.5 atmospheres.

Knowing the initial response range of the equipment, it remains to adjust the upper limit and its difference with the lower. If this is a model with two springs, then the adjustment will occur using a wrench.

First you have to remove the protective cover to see 2 springs under it. Big is responsible for changing the upper limit of the limit. To reduce or increase the boundary value, you have to turn the nut. Moreover, it is better to do this slowly, turning 0.5 - 1 revolution.

Having twisted it once, you need to open the tap and check the pressure value obtained to turn on the pump using a manometer. If the indicator does not suit, continue to turn the nut.

A small spring is responsible for changing the difference between the upper and lower pressure. When twisting it, it is important to remember that this difference should not be more than 1.5 atm. When the nut in front of the big spring is tightened, and the nut of the small one is also adjusted, it is worth opening the tap again and starting to drain the water.

As soon as the pump starts, you need to remember the value indicated by the pressure gauge - this will be the lower limit.After that, you have to wait until the pressure in the system rises. As soon as it reaches the upper limit, the pump will shut off. This indication also needs to be remembered and compared with the bottom.

If the numbers differ by 1.5-1 atm, do not intersect with the minimum and maximum permissible operating values, then everything worked out. Otherwise, drain the water again and start the adjustment again.

Conclusions and useful video on the topic

Video # 1. An overview of the models of sensors that monitor the pressure in the water supply system:

Video # 2. A detailed video clip about an electronic relay for monitoring water pressure:

Video # 3. Information in the video format about the features of adjusting the domestic water pressure sensor:

Video # 4. About the features of the maintenance of the pressure sensor, which worked for 2 years. Initially, the task was to change the previous pump response range:

Having become acquainted with the specifics of operation and adjustment of water pressure sensors in private water systems, you can do it yourself.

If you have doubts about your own abilities, then it is better to call a specialist who enjoys a good reputation. It is important that the sensor works correctly, then there will not be any problems with the entire water supply system of the cottage / country house.

We invite you to comment on the information we have provided for review. Please write comments in the block below, ask questions, share personal experience and knowledge.

Pressure in the water supply system of a private house: the specifics of autonomous systems + ways to normalize pressure

Pressure in the water supply system of a private house: the specifics of autonomous systems + ways to normalize pressure  How a pressure switch for a pumping station works + rules and features of its adjustment

How a pressure switch for a pumping station works + rules and features of its adjustment  Hydraulic accumulator: device and principle of operation of a hydraulic tank in a water supply system

Hydraulic accumulator: device and principle of operation of a hydraulic tank in a water supply system  Water pressure switch: what it is, how it works + how it is adjusted

Water pressure switch: what it is, how it works + how it is adjusted  Pumps to increase water pressure: types, how to choose, installation technology + wiring diagrams

Pumps to increase water pressure: types, how to choose, installation technology + wiring diagrams  A pumping station without a hydraulic accumulator: features of action and a water supply device without a hydraulic tank

A pumping station without a hydraulic accumulator: features of action and a water supply device without a hydraulic tank  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

When installing a water pressure sensor in the system, you must always remember that you should not climb into it and try to adjust it yourself. Even if you consider yourself a jack of all trades. In my carelessness and self-confidence I took such a rash step. The result is a breakthrough in the pipe (and this is still easy, it could also ruin the pump). If you are already starting to regulate yourself, then constantly monitor its first start-up, so that in case of an accident you can turn off the power to the pump.

At first, we had a mechanical pressure regulator on the water supply, but then we switched to an electronic and a frequency-controlled pump. On the mechanics, when washing in the shower, the water temperature nevertheless jumped sensitively; the dimensions of the room did not allow replacing the storage tank with a larger accumulator. With electronic comfort control, much more.