How to make a controller for a wind generator with your own hands: device, principle of operation, assembly diagram

The mechanical design of the wind generator in its pure form is only part of a full-fledged wind power installation. The system, which is fully operational, in addition to the mechanical design, also has a number of electronic components.

So, for example, a controller for a wind generator is necessary — a device functionally designed to stabilize the battery charge parameters during the operation of a wind turbine.

We will figure out what functions the device performs, and give the assembly diagrams of the controller with our own hands. In addition, we outline the features of the work and the advisability of buying a Chinese electronic unit for a wind turbine.

The content of the article:

Wind generators and battery charge controllers

If a mechanical windmill is completely possible to make yourself, is it possible to make a windmill controller with your own hands?

In order to have some idea of the controllers of wind generators and successfully reproduce such equipment with your own hands, basic information about these devices will not be superfluous.

The controller serving the batteries is designed primarily to control the process of charging the battery. This is its main function, but it should be conditionally divided into a number of subfunctions.

For example, one functional monitors the charge current and self-discharge current. Another functional implements actions aimed at measuring temperature and pressure. The third is responsible for compensating for the difference in energy flows when the battery is charged simultaneously with the current consumption by the load.

Industrial manufacturing devices are endowed with full functionality. But this can not be said for amateur designs. Devices made on the basis of the simplest circuit solutions at home with their own hands are controllers that are far from perfect models.

Nevertheless, they work and are quite productive to operate. different types of wind generators. As a rule, in self-made structures, only one function is implemented - protection against overvoltage and from deep discharge.

Why is the introduction of a controller in a windmill system a must?

Because in the battery power-up mode without using a controller, unpleasant consequences should be expected:

- Battery structure degradation due to uncontrolled chemical processes.

- Uncontrolled pressure increase and electrolyte temperature.

- Loss of battery recharging properties in connection with the long-term discharge taking place.

The charge controller for the scheme of the wind generator is, as a rule, in the form of a separate electronic module. This module is removable and quick disconnect. Industrial-made devices are necessarily equipped with an indication of the modes and conditions - light or visually transmitted through the display.

In practice, two types of devices can be used - built directly into the case of the wind generator and connected to the battery.

DIY assembly solutions

For all the time since the first homemade windmills The number of circuit solutions for controllers has grown many times. Many of the circuit designs are far from perfect, but there are also such options that you should pay attention to.

For domestic use, of course, relevant are simple schemes that require small financial investments, effective and reliable.

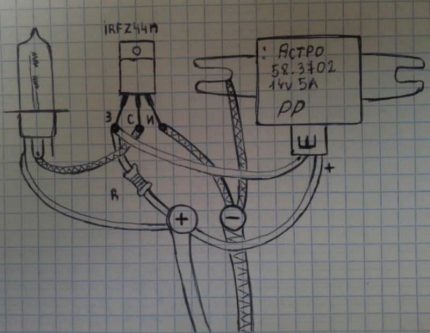

Based on these requirements, you can start with a controller for a wind generator created on the basis of automobile relay controllers.In the circuit, both relays with a negative control contact and relays with a positive control contact are applicable.

This option attracts with a small number of parts and simple installation. It will take only one relay, one power transistor (field), one resistor.

The scheme is called "ballast", since it uses an additional load in the form of a conventional incandescent bulb. Thus, the list of parts will be replenished with another element - a lamp.

A car lamp (or several lamps) of 12 volts is used, depending on the power of the system. Also, instead of this element, it is permissible to use a load resistance of a different type: a powerful resistor, an electric heater, a fan, etc.

The work of the "ballast" circuit with a minus

The action of the automobile relay-regulator is directly related to the battery level. If the voltage at the battery terminals rises above 14.2 volts, the relay trips and opens the negative circuit of the power transistor.

In turn, a junction opens on the transistor, connecting a direct incandescent lamp to the battery. As a result, the charging current is discharged through the filament of the incandescent lamp. If the voltage at the battery terminals is reduced, the reverse process. This maintains a stable battery voltage level.

How does the "ballast" scheme with a plus

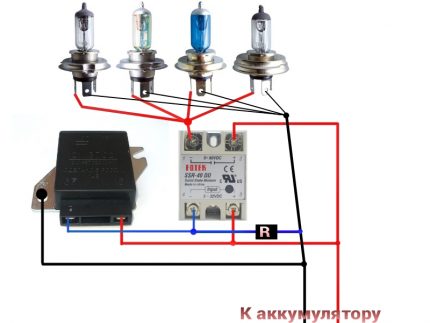

A slightly modernized version of the "ballast" charge controller for a wind turbine is the second circuit on the relay controller with a positive control contact. For example, relays from VAZ cars are suitable.

The difference from the previous circuit is the use of a solid-state relay, for example, GTH6048ZA2 at a current of 60A instead of a transistor. The advantages are obvious: the circuit looks even simpler and at the same time has greater reliability and efficiency.

Feature of this simple solution is direct connection to terminals generator windmill battery. The conductors of the charge controller are also "planted" directly on the contacts of the battery.

In fact, both of these parts of the circuit are not connected in any way. The voltage from the wind generator is supplied to the battery constantly. When the voltage at the battery terminals reaches 14.2 W, the solid-state relay connects the load to reset. So the battery is protected by the device from overcharging.

Here, not only an incandescent lamp can act as a ballast load. It is quite possible to connect any other device rated for current up to 60 A. For example, an electric tubular heater.

What is more important in this scheme - the action of a solid-state relay is characterized by a smoothly increasing amplitude. In fact, the effect of a professionally manufactured PWM controller is evident.

A complicated version of the controller circuit

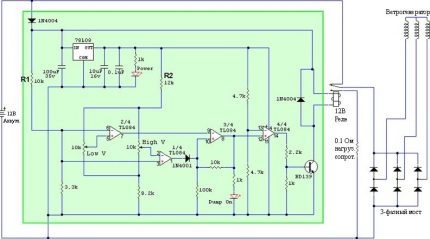

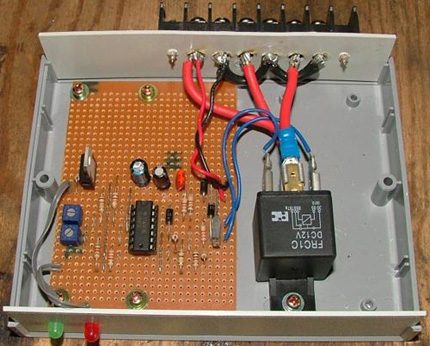

If the previous version of the circuit design of the battery charge controller only resembles a PWM device (pulse width modulation), here this principle is implemented specifically.

This controller circuit for a wind turbine with a three-phase generator differs in some difficulties, since it involves the use of microcircuits - in particular, operational amplifiers with field-effect transistors as part of the TL084 assembly.

However, on a circuit board, everything does not look as complicated as on a paper sheet.

As in previous solutions, a relay is used as a switching element for a ballast load.The relay is designed to work with a 12-volt battery, but if desired, you can choose a model for 24 watts.

The ballast is made in the form of a powerful resistance (winding on ceramics nichrome). To adjust the operating voltage range (11.5-18 W), the circuit uses variable resistors included in the TL084 microelectronic assembly control circuit.

Such a windmill battery charge controller works as follows. The three-phase current received from the wind generator is rectified by power diodes.

At the output of the diode bridge, a constant voltage is generated, which is fed to the input of the circuit through the relay contacts, an additional diode, the battery and then to the in-circuit stabilizer (78L08) and to the input of the assembly TL084.

The moment the trigger is switched to one of the states is determined by the values of the variable resistors (Low V and High V) of the lower and upper voltage thresholds.

As long as the battery voltage does not exceed 14.2 volts (satisfying the R High V setting value), a charge is performed. As soon as the values change in the direction of increase, the operational amplifier TL084 sends a signal to the base of the transistor, which is controlled by the relay.

The relay is triggered, the power circuit of the circuit breaks and closes with a ballast resistor. Ballast reset takes place until the battery discharge is close to the setting of the Low V variable resistor.

Once this value is reached, the second operational amplifier TL084 circuit switches to the reverse state. This is how the controller works.

Chinese electronic alternative

Making a do-it-yourself wind generator controller is a prestigious affair. But given the speed of development of electronic technologies, often the meaning of self-assembly loses its relevance. In addition, most of the proposed schemes are already obsolete.

It turns out cheaper to buy a finished product made professionally, with high quality installation, on modern electronic components. For example, you can purchase a suitable device at a reasonable cost on Aliexpress.

The range of offers on the Chinese site is impressive. Controllers for wind generators for various power levels are sold at a price of 1000 rubles. If you start from this amount, in terms of assembling the device with your own hands, the game is clearly not worth the candle.

So, for example, among the offers of the Chinese portal there is a model for a 600-watt wind turbine. A device worth 1070 rubles. suitable for use with 12/24 volt batteries, operating current up to 30 A.

A high-quality all-weather controller case measuring 100x90 mm is equipped with a powerful cooling radiator. The design of the housing complies with protection class IP67. The range of external temperatures is from - 35 to + 75ºС. A light indication of the state modes of the wind generator is displayed on the body.

The question is, what is the reason to spend time and effort on assembling a simple design with your own hands, if there is a real opportunity to buy something similar and technically serious?

Well, if this model is not enough, the Chinese have very cool options. So, among the new arrivals, a 2 kW model for an operating voltage of 96 volts was noted.

True, the cost of this controller is already five times more expensive than the previous development.But then again, if you measure the cost of producing something similar with your own hands, the purchase looks like a rational decision.

The only thing that confuses Chinese products is that they tend to suddenly stop working in the most inappropriate cases. Therefore, the purchased device often has to be brought to mind - naturally, with your own hands. But it is much easier and simpler than making a charge generator for a wind generator with your own hands from scratch.

For lovers of homemade products on our website there is a series of articles devoted to the manufacture of wind generators:

- DIY wind generator from a car generator: windmill assembly technology and error analysis

- How to build do-it-yourself blades for a wind generator: examples of self-made blades for a wind turbine

- Do-it-yourself wind generator from a washing machine: assembly instructions for a windmill

- How to calculate a wind generator: formulas + practical example of calculation

Conclusions and useful video on the topic

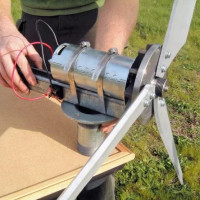

The desire to make home-made equipment for home use is sometimes stronger than a simpler solution - buying an inexpensive device. What came of this, see the video:

Assessing the prospects of manufacturing electronics on their own, regardless of its purpose, one has to come across the thought that the age of "homemade" is ending.

The market is oversaturated with ready-made electronic devices and modular components for almost every household product. Amateur electronics enthusiasts now have only one thing left to do - to assemble home designers.

Is there anything to supplement, or have questions about the assembly and use of controllers for a wind generator? You can leave comments, ask questions and add photos of your homemade products - the contact form is in the lower block.

How to make a wind generator with your own hands: device, principle of operation + best home-made

How to make a wind generator with your own hands: device, principle of operation + best home-made  DIY wind generator from a car generator: windmill assembly technology and error analysis

DIY wind generator from a car generator: windmill assembly technology and error analysis  How to build do-it-yourself blades for a wind generator: examples of self-made blades for a wind turbine

How to build do-it-yourself blades for a wind generator: examples of self-made blades for a wind turbine  Kinetic wind generator: device, principle of operation, application

Kinetic wind generator: device, principle of operation, application  How to calculate a wind generator: formulas + practical example of calculation

How to calculate a wind generator: formulas + practical example of calculation  Do-it-yourself wind generator from a washing machine: assembly instructions for a windmill

Do-it-yourself wind generator from a washing machine: assembly instructions for a windmill  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

The scheme shown is quite successful (reliable, and the details are worth a penny). But for a more difficult option, I’ll make an addition - google the controller on the Arduino platform. You can switch not only the battery charge modes, but also the power supply of the object itself. To understand this platform is not difficult, in fact, the same children's designer (datasheet in the public domain). And, most likely, this Chinese system for 10 thousand, is made on the same principle.

I revised your circuit to build the controller. But she is shown very finely. If it is possible to show it on a broader scale, I would try to do it myself. I'm a little worried about the possibility of using a 24 volt battery. Maybe it's better not to risk it, but use a 12-volt battery so that there are no failures.