Clips for wires: existing types of clamps + detailed connection instructions

Electrical work related to electrical networks is inevitably accompanied by the execution of installation, maintenance, repair. In turn, the above service forces the use of clamps for wires of various configurations.

These are, as a rule, relatively small parts, designed to work with different types and sizes of conductors. The base of existing clamps is large and it is quite difficult to cover the entire range of such accessories. However, there is the so-called "popular" set, which is used most often.

Consider the most popular types of clamps, designate the scope and specifics of their application, as well as provide detailed instructions for connecting wires through such technical accessories.

The content of the article:

Popular types of electrical clamps

In practice, the installation of electrical circuits uses special technical accessories - clamps of various designs. The specific application is determined by many criteria, ranging from the purpose of the network to the technical and operational parameters of the connections.

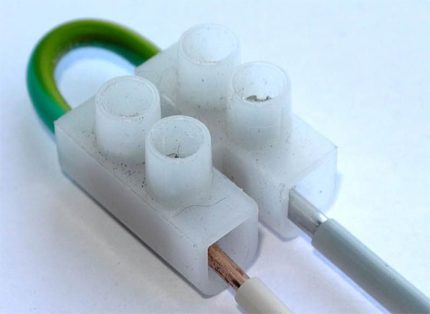

View # 1 - simple screw terminals

What is remarkable for such an option of a variety of accessories - the terminal allows you to make a reliable connection without obvious violation of the structure of conductors. In this case, it is permissible to junction conductors based on different metals, for example, copper and aluminum.

Widespread in everyday practice are considered one-way terminals on a polypropylene (polyethylene) basis.

The design is a metal, usually brass or bronze, short channel of small diameter, equipped with two threaded holes for fixing screws.

Such a metal channel is embedded inside a polyethylene sheath, which has good insulator properties. In order to joint two separate conductors, the end parts of these conductors are placed in the channel from two sides, after which they are securely fixed (pressed) with screws.

There is a different channel configuration terminal clampsbased on installation parameters such as:

- diameter of conductors

- current characteristics

- insulation class

- number of contact points.

In fact, the selection of such accessories is possible for any technical conditions, especially those that are relevant for the domestic sector.

View # 2 - self-tightening and lever clamps

This variety of connecting accessories is characterized by increased user convenience. For example, if you use self-tightening clamps for single use, it is enough to insert the stripped end part of the wire all the way into the hole in the clamp.

Inside the structure there is a springy plate, which is installed by the cutting part in the "countercurrent" conductor. When the wire is inserted into the channel all the way, the plate is pressed by a metal core and cuts into the “counter-current” part into the body of the wire.

To release the conductor, you need to squeeze the plate with a screwdriver through the hole in the second row. This type of clamp does not support reuse. They are enough for 3-4 times re-connections.

Numerous repeatability of joints is supported by similar designs, but complemented by a press lever. The practical application of such accessories is simple.

It is enough to raise the lever perpendicular to the channel, insert a stripped conductor and lower the lever until it clicks. The wire will be securely fastened. Accordingly, the reverse operation is performed in case of release of the wire from the channel.

View # 3 - connecting insulating clamps

Accessories of this kind provide a connection of conductors that are relatively small in diameter. In fact, connecting insulating clamps (technical abbreviation - PPE) represent a hand tool of the same twist.

Two or more previously stripped ends of the conductors are formed into a group and are “covered” with a connecting insulating cap until they stop. Then the cap is rotated several times.

Inside such a system, a spring spiral having a conical shape is introduced. As the cap is wound, the spiral wraps around the group of ends of the conductors and tightens it into a single unit, clamping them inside.

Cap connectors are used, as a rule, on electrical wiring of relatively low power. Very often this type of clamp is chosen during installation household home electrical networks.

There are two types of caps:

- conical straight form without persistent ledges;

- conical straight shape with persistent protrusions.

The second configuration, as a rule, has a slightly larger diameter and is intended for fastening larger conductors.

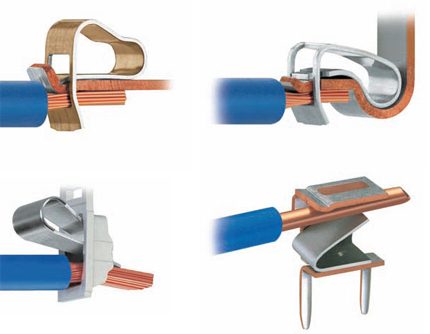

View # 4 - piercing clamping element

On electric lines with power up to 1 kV, piercing type clamps are often used.This type of accessories allows work with conductors with a cross section of 1.5 - 10 mm2 on branch lines or work with conductors 16 - 95 mm2 on the main trunk lines.

The design is a metal plate girth coated with insulation, which is compressed by pressure from the stop bolt.

The plates covering the conductor are equipped with sharp metal teeth, which, under pressure, pierce the insulation of the wire and bite directly into the body of the conductor.

The advantages of such designs are obvious. Working with them allows you to abandon the time-consuming operations of removing insulation. In addition, the design of the piercing clamps is designed in such a way that allows you to perform work without turning off the supply of electricity to the line.

Puncture type clamps provide a high degree of sealing against atmospheric influences.

The polymer insulation, resistant to ultraviolet radiation, is reinforced with fiberglass to strengthen the strength. There is an insulating rubber cap for the tip.

View # 5 - clamp between bolt and nut

Often, on power networks, installers use a simple, but quite reliable method of fastening through an ordinary bolt clamp.

To organize a connection of this kind, always available parts are needed:

- a bolt of suitable diameter;

- nut to bolt;

- two washers in size;

- lock-nut.

In a similar way, it is permissible to connect dissimilar electrical conductors, for example, copper and aluminum.

However, theoretically, such a combination is not recommended in electrical practice due to the different chemical properties of metals.

Other clamps

In addition to clamp designs for connections electrical conductors, there is a variety of this kind of accessories for other purposes.

Anchor clamps for mounting

Designs of clamps for fastening (suspension) of wires with a cross section of 2 - 25 mm2 in an amount of two to four cores. Structurally, the anchor accessory consists of a polymer body endowed with a self-adjustable clamping wedge.

Two configurations of anchor clamps are available:

- under self-supporting systems;

- under the isolated neutral carrier.

The mechanism has an easily opening handle, which makes it convenient and simple to install the clamp on brackets, hooks, hooks, and then securing the electric wires to the clamp body.

Clips for wires for test needs

Often the practice of electronics and electricians involves the use of clamps of the so-called "test" purpose. Traditionally, such accessories are "crocodiles" - gear sliding (push) metal structures.

The toothed part of such a clamp remains open, while the part under pressure is insulated with PVC material.

Such accessories are used for temporary fastening (meshing) to the wires, for example, in order to measure current or network voltage.

This type of clamps can be conditionally divided into two categories - for low-voltage electronics and for high-voltage electrical networks.Both categories differ from each other in boundary technical parameters for current.

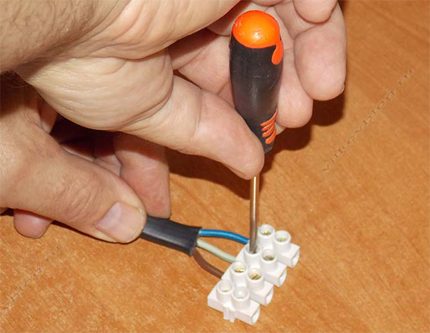

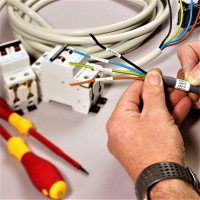

Clamp Wiring Instructions

Actually, the order of execution of work, in this case, is the connection of wires using various types of clamps, simple and straightforward. It is quite possible to do it yourself.

The first step is to bring the working conductors to the interface. AND remove insulation at the input to the clamp sleeve.

Then carefully strip the bare end part to a characteristic shine - for work it is better choose stripper.

Now you have to insert the prepared ends into the sleeve of the clamp and secure.

If necessary, such a connection can be further insulated.

Even easier is the work of connecting the conductors when the piercing type clamp is used or the type of self-aligning spring VAGO clamp.

Conclusions and useful video on the topic

How to connect wires and what accessories to use in one or another version of a paper clip? The video tells about this in detail and shows:

A variety of mechanical elements that play the role of a reliable clamp significantly facilitates the installation and commissioning. Thanks to the use of such elements, the level of safe operation of electric networks is increased.

The only caveat is the correct use of such accessories, since the mismatch of technical capabilities threatens to negate all the advantages of clamps.

Have experience selecting and using wire clamps? Or want to ask questions on the topic? Please comment on the publication and participate in the discussions. The feedback block is located below.

Types of cables and wires and their purpose: description and classification + decoding of marking

Types of cables and wires and their purpose: description and classification + decoding of marking  Wire stripping tool: all about cable strippers

Wire stripping tool: all about cable strippers  Colors of wires in electrics: standards and labeling rules + methods for determining the conductor

Colors of wires in electrics: standards and labeling rules + methods for determining the conductor  What cable to do wiring in a wooden house: types of non-combustible cable and its safe installation

What cable to do wiring in a wooden house: types of non-combustible cable and its safe installation  Pinout of different types of USB connectors: pinout of micro and mini usb contacts + nuances of desoldering

Pinout of different types of USB connectors: pinout of micro and mini usb contacts + nuances of desoldering  How to determine the cross-section of a wire by diameter and vice versa: ready-made tables and calculation formulas

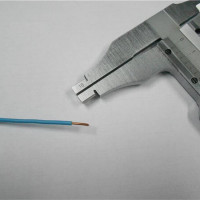

How to determine the cross-section of a wire by diameter and vice versa: ready-made tables and calculation formulas  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Recently discovered a new type of wire clip - adhesive tape. It’s convenient - you don’t even need to strip the wires, quickly - put it into the clip and squeezed it with pliers, cheap - there are real pennies. True connectors are disposable. The pluses also include the presence of moisture protection, inside the connector is a special hydrophobic gel. The only minus is the scope: adhesive tapes are suitable only for low-voltage and low-voltage circuits, for example, telephony, computer networks, many connections in the car, etc.

Good afternoon, Gleb.

I’ll add my own invention to your collection of clamps - once after closing in a junction box, I had to upgrade it.

In the old box, the wires “phase”, “zero” went under the “single bolt”. I decided to apply such “Zero tires with the DIN rack insulator“ Rack ”- a screenshot below.

Very convenient reusable design, powerful clamping screws, strong thread. Each wire is securely fixed - phase / zero input, phase / zero output, outgoing wires. The result in the second screenshot.

By the way, the convenience was tested after a year - through one of the switchboxes without hassle, the outdoor lamp was powered.

All these devices are quite convenient, but they will need a considerable amount of time for people to get used to them and begin to actively use them. All the same, twisting, at best wrapped with electrical tape on top, will continue to be popular with the layman for a long time and will terrify more advanced and understanding people. Moreover, the clamps from the material above are not without their drawbacks.