Types of cables and wires and their purpose: description and classification + decoding of marking

The existing variety of cables and wires for the most part are calculated in three-digit numbers. Therefore, it is not possible to describe the entire range in one article.

Meanwhile, it is not necessary to paint all types of cables and wires and their purpose. It is enough to have an idea of the marking standards and be able to extract the necessary information from the characteristics in order to select the suitable option according to the purpose from the variety of cable products.

Consider the main points of how you can learn to distinguish electric wires among an array of such products, as well as provide descriptions of the most popular wires and cables.

The content of the article:

- The structural basis of the cable product

- Insulation component of wires and cable

- Cable Features and Conducting

- The main types of electrical wires

- Type # 1 - PBPP wire (flat shape)

- Type # 2 - PBPG modification

- Type # 3 - APUNP aluminum core

- Type # 4 - two-three-conductor PPV

- Type # 5 - a variety under the brand name APPV

- Type # 6 - PVC aluminum with PVC insulation

- Type # 7 - modification PV1 - PV5

- Type # 8 - PVC connection cable with PVC insulation

- Type # 9 - Flat ShVVP cord in PVC sheath

- Varieties of electrical cables

- Conclusions and useful video on the topic

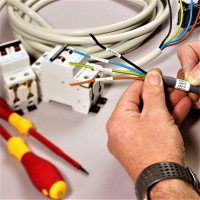

The structural basis of the cable product

The performance of the cable or electrical wires determines the technical and operational characteristics of the product. Actually, the execution of cable or wire products is, in most design variations, a fairly simple technological approach.

Classic performance:

- Cable insulation.

- Core insulation.

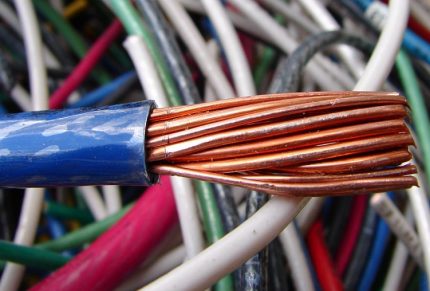

- The metal core is solid / bundled.

A metal core is the base of a cable / wire through which an electric current flows. The main characteristic, in this case, is the capacity determined by the transverse cross section. This parameter is influenced by the structure - solid or beam.

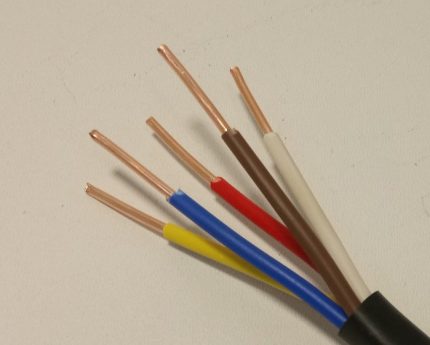

A property such as flexibility also depends on the structure. Stranded (bundled) conductors are characterized by better properties in terms of “softness” of bending than single-core conductors.

Veins of cables and wires in electrical practice, as a rule, have a cylindrical shape. At the same time, rarely, but there are several modified forms: square, oval.

The main material for the manufacture of conductive metal cores are copper and aluminum. However, electrical practice does not exclude conductors in the structure of which there are steel conductors, for example, a “field” wire.

If a single electrical wire is traditionally built on a single conductive core, the cable is the product where several such conductors are concentrated.

Insulation component of wires and cable

An integral part of cable and wire products is the insulation of a metal current-carrying base. The purpose of the insulation is quite understandable - providing an isolated state for each current-carrying core, preventing the effect of a short circuit.

Depending on the purpose of the cable (wire) products, the insulating part may have different designs.

The dielectric material may be:

- ceramics;

- glass;

- polyvinyl chloride;

- celluloid;

- polymers and others

In addition to the protection of a purely electric plan, the insulating material also provides mechanical protection, protects the electric wire (cable) from moisture and other destructive factors.

There is also a special insulating construction applied to electric wires and cables, endowing products with “armored” or “anti-chemical” properties.

Cable Features and Conducting

Often in unprofessional practice, the term “cable” is equated to any type of electrical wire. Meanwhile, the concepts of “cable” and “wire” should be separated. And, above all, the separation provides for the transmit power factor.

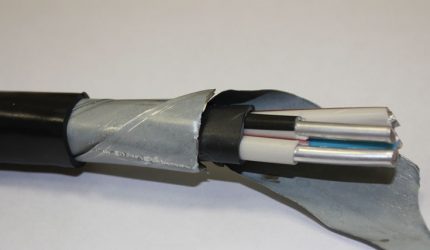

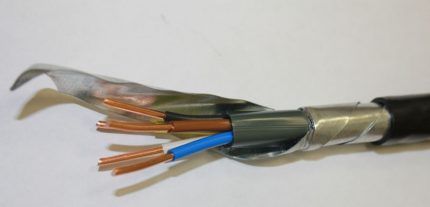

Cable - a product whose structure combines at least three conductors in insulation, additionally protected inside the shell with a special material - parchment, rubber, lead, etc.

The wire - a product consisting of one, maximum, five conductors (cord), for the latter case united by a common casing.

The priority use of cables is for industrial purposes. Wires are actively used in everyday life, as well as in other areas.

Separately, highlight bare wires that do not have insulation. The main application for such products is in the arrangement of centralized power lines.

The main types of electrical wires

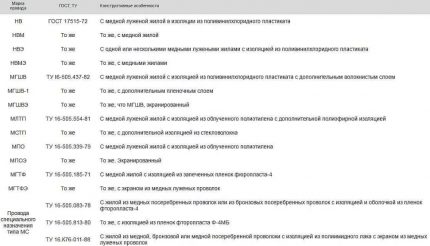

Wires of electrical networks are classified based on load power and application conditions. For everyday life, the following types of wires are typical: PBPP, PBPPg, APUNP, PPV, APPV, APV, PV1 - PV3, PVS, ShVVP.

Type # 1 - PBPP wire (flat shape)

A product with a polyvinyl chloride insulating sheath, under which a solid cast copper core is hidden. This electrical material is made with conductors with a cross section of 1.5 - 6.0 mm2.

It is allowed to use the PBPP wire in ambient temperature conditions from -15 ° С to + 50 ° С. The wire is designed for the installation of networks with a voltage of no higher than 250 V. The traditional use of PBPP is the installation of outlet lines for the household sector. Such a wire is often used for organization of wiring in the apartment.

Type # 2 - PBPG modification

In fact, the product is presented in the same version that is described for the PBPP, with the exception of one nuance indicated by the letter "g" of the standard marking.

This nuance lies in the more pronounced properties of flexibility. In turn, the improved properties of flexibility are formed by the structure of the core of this brand of wire, which is “bundled” and not solid.

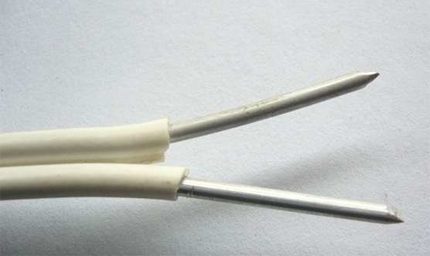

Type # 3 - APUNP aluminum core

The presence of an aluminum core under the insulation is indicated directly by the product labeling - the first “A” symbol. Such a product is produced in a cross-sectional range of conductors 2.5-6.0 mm2.

Such a conductor is not recommended for use by professional electricians. The only advantage of this brand is its low cost. However, for the construction of temporary light-load circuits it is quite acceptable for use.

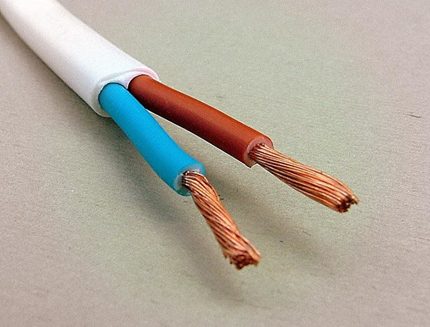

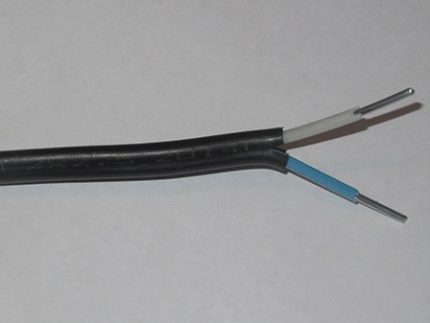

Type # 4 - two-three-conductor PPV

The product is a two-three-conductor configuration, where current-carrying conductors are placed under PVC insulation and are held next to each other by means of an insulating jumper based on the same polyvinyl chloride.

Core wires (copper) can have a cross section in the range of 0.75-6.0 mm.

According to the technical characteristics, operability is maintained at frequencies up to 400 Hz at voltages up to 450 V. The temperature limit is -50 / + 70 ° С.

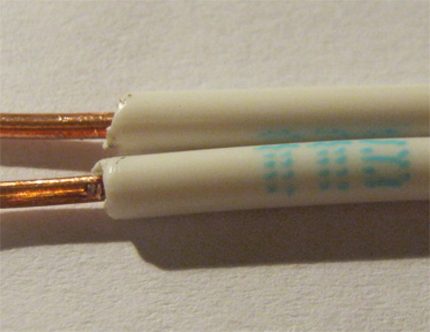

Type # 5 - a variety under the brand name APPV

In fact, the same type of performance that the PPV brand demonstrates, with the exception of the presence of aluminum cores instead of copper cores. It is made in different sections, starting from 2.5 mm2.

This type of electrical wire is widely used in a variety of installation cases. Allowed to use APPV for the device open wiring.

Type # 6 - PVC aluminum with PVC insulation

It is made in two options of a configuration of veins - solid-cast single or bundle (multicore).

In this case, a single version is represented by products where the range of cross sections is 2.5-16 mm2and the multi-core version is available in the range of 25-95 mm2.

This is one of those modifications that can be used in high humidity conditions. A wide temperature range is supported - from -50 ° C to + 70 ° C.

Type # 7 - modification PV1 - PV5

In fact, an analogue reclosure, but is available exclusively with copper conductors. The difference between indices 1 and 5 is that the first option is a solid-cast product, and the second option, respectively, is multi-core.

This variety is often used in the assembly of control cabinet circuits. Comes with multi-colored insulation.

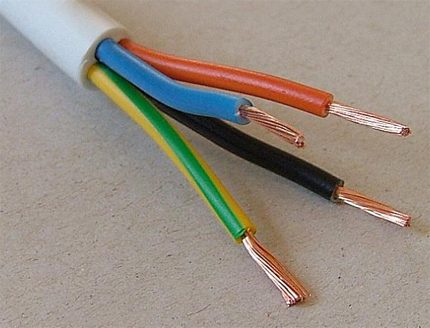

Type # 8 - PVC connection cable with PVC insulation

A view of a conductor representing the configuration of an electrical cord. It is produced with the number of cores 2-5 in the range of cross sections 0.75 - 16 mm. The structure of the wires is multiwire (beam).

Designed for operation in networks with voltage up to 380 V at a frequency of 50 Hz.

Feature of the execution of PVA is a high degree of flexibility. However, the temperature regime is somewhat limited - from -25 ° C to + 40 ° C.

Type # 9 - Flat ShVVP cord in PVC sheath

Another variety in the "cord" version. A variation in the number of wires connected by a PVC sheath in the amount of two or three is supported.

The main application is the domestic sphere, outdoor wiring. Operating voltage up to 380 V, core structure - beam, maximum cross section 0.75 mm2.

Varieties of electrical cables

If we consider exclusively cables for power electrical circuits, the main power cables are the following:

- VVG;

- KG;

- VBBSHV.

Of course, this is not a complete list of all existing cable products. Nevertheless, on the example of technical characteristics, a general idea of the cable for electrical purposes can be formed.

Execution under the VVG brand

Widely used, popular and reliable brand. The VVG cable is designed to transmit current with a voltage of 600 - 1000 volts (maximum 3000 V).

The product is made in two versions, with current-carrying conductors of a solid structure or a beam structure.

According to the product specification, the core cross-section range is 1.5 - 50 mm. PVC insulation allows the cable to be used at temperatures of -40 ... + 50 ° C.

There are several modifications of this type of cable products:

- AVVG

- VVGng

- VVGp

- VVGz

Modifications are distinguished by a slightly different insulation performance, the use of aluminum conductors instead of copper conductors, the shape of the cable.

KG type power cable

The design of another popular cable, characterized by a high degree of flexibility, thanks to the use of a bundle structure of current-carrying conductors.

The execution of this type provides for the presence of up to six current-carrying conductors inside the shell. Operating temperature range -60 ... + 50 ° С. Mostly, a type of KG is used to connect power equipment.

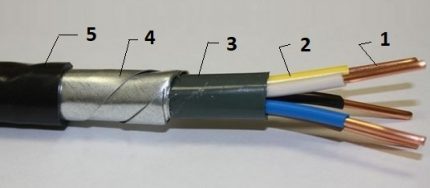

Armored cable VBBSHV

An example of the design of special cable products in the image of a product under the brand name VBBSHV. Conductive elements can be bundled or solid conductors. In the first case, the cross-sectional range is 50-240 mm2in the second 16-50 mm2.

Cable insulation is built with a complex structure, including belt insulation, tape screen, steel armor, bitumen and PVC.

There are several modifications of this type:

- VBbShvng - non-combustible insulation;

- VBBSHVNG-LS - when burning does not emit harmful substances;

- AVBBSHV - the presence of aluminum conductors.

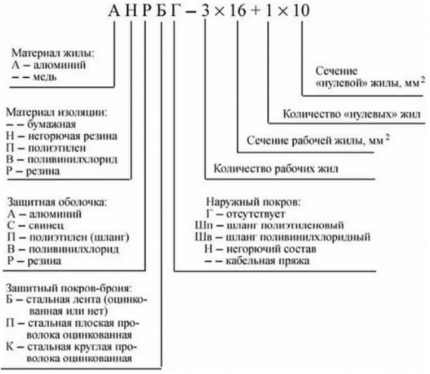

The ability to read the labeling of cable products is useful when choosing products and wiring electrical networks.

Features of the type of core material - Letter 1: "AND" –Aluminium core. In any other case, copper lived.

As for the purpose (Letter 2), here the decryption is as follows:

- "M" - for installation;

- "P (U)", MG - flexible for mounting;

- "Sh" - installation; "TO" - for control.

The designation of isolation (Letter 3) and its interpretation are as follows:

- "In (BP)" - PVC;

- "D" - double winding;

- "N (HP)" - non-combustible rubber;

- "P" - polyethylene;

- "R" - rubber;

- "WITH" - fiberglass;

- "TO" - nylon;

- "Sh" - silk polyamide;

- "E" - shielded.

The features that Literature 4 testifies to have their own decoding:

- "B" - armored;

- "G" - flexible;

- "TO" - wire braid;

- "ABOUT" - another braid;

- "T" - for pipe laying.

Also, the classification provides for the use of lowercase letters and letters indicated by the Latin alphabet:

- "Ng" - non-combustible

- "H" - filled

- "LS" - without chem. discharge during combustion,

- "HF" - no smoke when burning.

Markings, as a rule, are applied directly to the outer shell, and along the entire length of the product at regular intervals.

On our site there are articles on the selection of cable products for arranging electrical networks in an apartment and a house, we recommend that you read:

- What cable to use for wiring in the apartment: a review of the wires and choosing the best option

- Which wire to use for wiring in the house: recommendations for selection

- What cable to do wiring in a wooden house: types of non-combustible cable and its safe installation

Conclusions and useful video on the topic

The video below demonstrates the “novice electrician” lesson.

A rather useful video material is shown, which is recommended for viewing as an acquisition of generalizing knowledge on wires and cables:

Given the existence of an extensive range of wire and cable products, a potential electrician gets many options to solve any problems in the field of electrical.

However, even with such diversity, it is quite difficult to choose the right product for specific purposes, if there is no relevant knowledge. Hopefully this article will help you make the right choice.

Have something to supplement, or have questions about choosing electrical cables and wires? You can leave comments on the publication, participate in discussions and share your own experience in using cable products. The contact form is located in the lower block.

Colors of wires in electrics: standards and labeling rules + methods for determining the conductor

Colors of wires in electrics: standards and labeling rules + methods for determining the conductor  Clips for wires: existing types of clamps + detailed connection instructions

Clips for wires: existing types of clamps + detailed connection instructions  What is a vvg cable: decryption, characteristics + subtleties of cable selection

What is a vvg cable: decryption, characteristics + subtleties of cable selection  Wire stripping tool: all about cable strippers

Wire stripping tool: all about cable strippers  What cable to do wiring in a wooden house: types of non-combustible cable and its safe installation

What cable to do wiring in a wooden house: types of non-combustible cable and its safe installation  How to determine the cross-section of a wire by diameter and vice versa: ready-made tables and calculation formulas

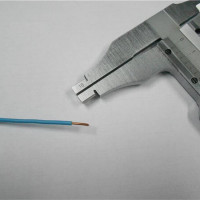

How to determine the cross-section of a wire by diameter and vice versa: ready-made tables and calculation formulas  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements