How to make a wood-based gas generator with your own hands: homemade wood and sawdust

Over thousands of years of history, mankind has learned to extract oil and gas, invented electricity, uses wind and solar energy, but still burns wood in furnaces. Firewood, sawdust, old wood, waste products from woodworking enterprises - all this can be used if you make a wood-burning gas generator with your own hands.

Many masters successfully use this device for the home and even for the car. If you are interested in this topic, or if you have an idea to make a generator yourself, we will tell you how to put it into practice.

In our material we will talk about the principle of operation of a wood gas generator, the advantages and disadvantages of such a system, as well as how to assemble such a device yourself.

The content of the article:

The principle of operation of wood gas generators

The rapid burning of firewood in the open air gives mainly a certain amount of useful heat. But quite differently, wood behaves under the so-calledpyrolysis burning, i.e. when burning in the presence of a very small amount of oxygen.

In such a situation, there is not so much burning as the smoldering of wood. A useful product of this process is not heat, but combustible gas.

Gas generators were once actively used as a fuel supplier for cars. And now you can occasionally see cars running on the gas they produce:

When the wood is burned slowly, an output is obtained containing the following products:

- methane (CH4);

- hydrogen (N2);

- carbon monoxide (aka CO or carbon monoxide);

- various saturated carbohydrates;

- carbon dioxide (CO2);

- oxygen (O2);

- nitrogen (N);

- water vapor.

Only some of these ingredients are combustible gases, all the rest is pollution or non-combustible ballast, which is better to get rid of. Therefore, you need not only to burn the tree in a special installation, but also to clean the result, as well as cool the resulting gas mixture.

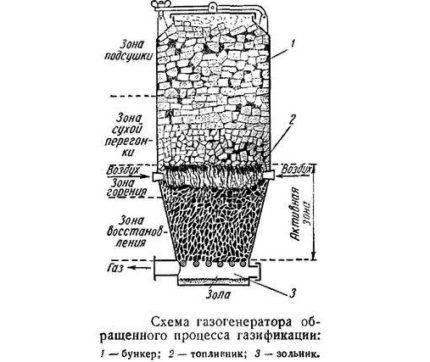

In industrial production, this process includes the following steps:

- Solid fuel combustion in the presence of a small (about 35% of normal) amount of oxygen.

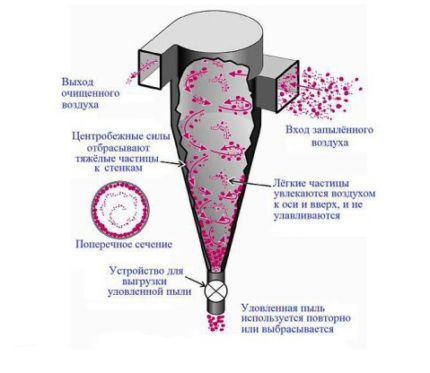

- Primary rough cleaning, i.e. separation of volatile particles in a cyclone vortex filter.

- Secondary Coarsein which the gas is cleaned with a water filter, a so-called scrubber cleaner is used.

Homemade devices for use at home look simpler and take up less space, but the principle of their work, as well as the design are very similar. Before starting the manufacture of such a device, you need to think through everything well, as well as draw up or find a design for the unit.

On the Internet there are many recommendations on how to make a homemade wood gas generator. Some of them are provided with drawings that are quite real for implementation.

Masters who have already managed to some extent carry out this fascinating process, note that a lot of time and effort can be required. You may have to perform more than one alteration and carry out a number of experiments in order to obtain an aggregate with acceptable characteristics.

Advantages and disadvantages of the system

Gas generators are extremely convenient to use. If the unit is made correctly, in compliance with all safety requirements, it is very rare to load fuel into it. For example, you can load firewood into the chamber only once a day, and if charcoal is used as fuel, once a week will be enough.

But this applies, rather, to industrial manufacturing devices. Course work homemade gas generator should be carefully monitored. The temperature of the hot gas can be very high, the risk of fire also increases significantly.

Wood is an affordable material. Firewood, wood chips, and pressed sawdust, and any waste from the wood industry, and cellulose-containing materials. Dry and light charcoal is excellently suited as fuel. If the size of the bunker allows, it is possible to load firewood into it even without preliminary splitting, in its entirety.

The product obtained as a result of combustion, combustible gas, can be used to solve various problems: heating a house, operating an internal combustion engine of a car, even for generating electricity. But it is worth recalling the “minuses" of this useful device.

To begin with, the industrial model of a gas generator, reliable, safe and convenient, is quite expensive. Not every owner of a house or cottage can afford such a unit. But the creation of a homemade gas generator even from improvised materials can result in a tidy sum.

It is not always possible to use any improvised materials for it. All parts of the unit must be very durable and able to withstand high temperatures. Without a doubt, you will need a welding machine, as well as skills in working with it. Metal will have to be cut and boiled.

Expecting what it will cost to create a homemade gas generator on sawdust, you should also consider consumables. You will need cast iron to create a grate, it is quite possible that for the manufacture of the cover you will have to find or buy a special spring.

Heat-resistant gaskets for manholes, for connecting individual elements of the device, etc. are also required. Before manufacturing a gas generator, you need to carefully calculate everything.

Another item of expenses for a gas generator is electricity, which is necessary for the forced supply of air to the combustion chamber. If for some reason the electricity is turned off, the gas generator will not be able to work.

This situation is unacceptable, since a decrease in the combustion temperature can lead to contamination of the device with tar. As a result, you have to stop the process, clean the gas generator, and then start it again.

Although it seems that you can load the gas generator with almost any fuel, you should still remember that it should gradually, as it burns, descend down the bunker. Therefore, firewood for the generator should be prepared by chopping them into more or less the same size elements.

DIY device manufacturing

First you need to decide for what purpose the gas generator will be manufactured: for home or for a car. In the latter case, priority is given to low weight and compact size. The best material for an automobile gas generator is stainless steel, expensive but durable and light. But for the home they make a large device from improvised materials, which are easier to find and are cheaper.

Let's analyze an example of manufacturing a gas generator to provide fuel for a motorcycle:

For the supply of gaseous fuel to a gasoline engine, it must be cooled, cleaned and mixed with air in suitable proportions. For this, the unit must be equipped with an ignition fan, cyclone, filter, mixer and cooler.

It remains to supplement the home-made gas generator with devices that ensure normal operation, and solve problems with installing it on a motorcycle with a sidecar.

Of course, the closer the dimensions and configuration of the homemade gas generator to the industrial model, the more efficient the device will work. It is difficult, and not necessary, to make an exact copy of a gas generator manufactured at the factory at home.

It is easier to copy a finished home-made unit, asking it from friends, acquaintances, or simply using information on the Internet.

First, the main components of the gas generator are made, then they are assembled into a single unit. To make such a device, it is necessary to prepare the following elements:

- Body.

- Hopper for fuel.

- Combustion chamber.

- The neck of the combustion chamber.

- Air distribution unit.

- Filter unit.

- The pipe of the combustion chamber.

- Grate, doors and other similar elements.

The housing, sometimes referred to as the filling chamber, can have either a cylindrical or a cubic shape. Therefore, the master has two options for its manufacture: use a suitable metal container, slightly modifying it, or make the case “from scratch” from a corner and sheet metal.

In the same way, a bunker for solid fuel is made, that is, also from a metal sheet and a corner. Later, the hopper is fixed inside the housing, so its dimensions must be appropriate. However, it is sometimes easier to turn a part of the gas generator housing into a bunker. For this, part of the space is separated using metal plates.

Suitable material for the inside of a wood gas generator is low carbon steel. The housing should be covered with a tight-fitting lid. Sealing is an important condition for the correct operation of the generator, since it is in this way that a limited amount of oxygen is supplied.

A homemade gas generator is a rather heavy device, care should be taken about its stability. To do this, strong legs are welded to the bottom of the body. The cover through which the fuel is loaded deserves special attention.

Sometimes it is difficult and lifting it yourself is not easy. To solve the problem, you can use a special cushioning spring.

A special heat-resistant steel will be needed for the combustion chamber, since it is here that the fuel burns at very high temperatures. However, for these purposes, you can successfully use an empty gas cylinder. A new container and a used one will do.

The metal neck of the combustion chamber, in which another important process is carried out - cracking resins - should be separated from the rest of the elements with special heat-resistant gaskets. Asbestos is considered to be quite suitable material for this, but it is better to use more modern and safe materials.

The air distribution unit is connected to the structure using a plug, next to which a check valve is installed. The objective of this element is to regulate the flow of air to the fuel and prevent the leakage of the resulting combustible gas, for the sake of which the creation of the generator was started.

Between the air distribution box and the middle part of the combustion chamber there must be special calibration holes-lances. After the combustion chamber, a filter system is installed to clean the resulting gas mixture from contaminants. The grate is designed to clean the combustion chamber.

It is usually made of cast iron. To facilitate the cleaning process, the middle part of the grate can be made movable or removable. Doors provide access to various sections of the gas generator and serve to load firewood, clean the combustion chamber, etc. Of course, all such doors must be airtight and sealed with heat-resistant gaskets.

A pipe is mounted below, through which the resulting gas mixture enters the filter assembly, and then into the cooler. For the manufacture of a small cyclone filter, you can use the body of an old fire extinguisher or other metal container of a suitable size and configuration.

It works this way: polluted hot gas is pumped into the upper part of the cyclone. Then, in a round case, it begins to rotate. Under the action of centrifugal forces, particles of contaminants move to the bottom of the device and leave it through the discharge hole. The purified gas leaves through another hole in the upper part of the filter.

At home, as a cooler, you can use a conventional radiator or make a special coil. Hot gas moves along such a long structure and gradually cools. If desired, water cooling can be arranged.

It is believed that a household gas generator is able to “digest” wood of any moisture content, even 50%, which is typical for a freshly cut tree. In practice, it turns out that the higher the humidity of the fuel, the lower the efficiency of the gas generator. It is not recommended to load fuel with a moisture content of more than 20%.

Correct the situation will allow a small modification of the device. An annular gas pipeline should be drawn from the nozzle of the combustion chamber, placing it in the space between the walls of the housing and the outside of the loading chamber.

As a result, part of the thermal energy will be transferred to the fuel, which will reduce its moisture content. In addition, less time will be required for cooling, and the generator efficiency will increase.

Valuable information on gas generators

Sometimes the expectations of owners of private houses, thinking about acquiring or making a gas generator on their own, are too bright in comparison with the real situation.

There is an opinion that the efficiency of the gas generator, which is about 95%, significantly exceeds the efficiency of the usual floor gas boilerwhich reaches 60-70%. These figures are generally correct, but it is incorrect to compare them.

The first indicator reflects the efficiency of the production of combustible gas, and the second - the amount of heat received during operation of the boiler. In both cases, wood burns, but the result of this process is qualitatively different. If in the future the combustible gas obtained by pyrolysis of wood is used to heat the home, such a comparison can be made.

It is also worth remembering that homemade gas generators, although they can work with high returns, are rarely as effective as industrial models. This point should be taken into account even at the stage of designing the unit and calculating the cost of the project and its expected effectiveness.

If the need to create a gas generator is due only to the desire to improve the heating system at home, you should pay attention to a similar device - pyrolysis boilerwhich works on very similar principles. Its main difference from the gas generator is that the gas obtained is immediately burned, and the energy received is used to heat the coolant in the home heating system.

In such a device, an additional combustion chamber is mounted, into which it is necessary to organize a separate air supply. If you need to heat the house with a gas generator, you will need choose convector for heating. This will increase the cost of upgrading or installing heating. It is necessary to calculate whether in this case the game is worth the candle?

An important point is the correct maintenance of the gas generator during its operation. Advertising claims that this is a universal device in which everything burns: from sawdust to freshly cut wood.

But the advertisement is silent about the fact that when loading wet raw materials, the amount of combustible gas produced can be reduced by 25% or more.

The optimal fuel for the gas generator, according to experts, is charcoal. When it is burned, the evaporation of moisture takes a minimum amount of energy, which allows to accelerate the pyrolysis processes.

Vehicle owners can rely on a gas generator not only for heating, but also for the operation of their vehicle. indeed, in Europe, many motorists quite successfully adapted their vehicles to work on wood. But most often these are compact and durable devices made of thin and durable stainless steel.

The cost of such units, even manufactured independently, is not at all small. In Russian realities, gas generators for automobiles are made from improvised means and installed on trucks.

The effect of their work is low, usually the presence of such an aggregate is accompanied by phenomena such as prolonged ignition, the need for constant engine operation at high or medium speeds, which contributes to its rapid wear.

An interesting option for using a gas generator in private households is the use of combustible gas for a home power station. Such a project is implemented using a diesel internal combustion engine.

Conclusions and useful video on the topic

This video demonstrates the operation of a homemade gas generator:

Here is an interesting experience on creating a homemade gas generator, taking into account the mistakes made:

This is a variant of a compact gas generator designed for installation on a vehicle:

Making DIY a viable gas generator is not so simple. Most often, such units are made for cars, but in homes they are quite effective. A skilled craftsman who is not afraid of difficulties and is ready for experiments, this task is quite capable.

If during the review of the information you have questions or have recommendations for the hand-made assembly of a wood gas generator, please leave your comments below.

How to make a gas generator with your own hands: features of manufacturing a homemade device

How to make a gas generator with your own hands: features of manufacturing a homemade device  DIY gas refrigerator: the principle of the propane refrigerator + an example of assembly homemade

DIY gas refrigerator: the principle of the propane refrigerator + an example of assembly homemade  DIY gas grill: step-by-step instructions for building a homemade product

DIY gas grill: step-by-step instructions for building a homemade product  How to make a blacksmith forge on gas with your own hands: tips + drawings to help home craftsmen

How to make a blacksmith forge on gas with your own hands: tips + drawings to help home craftsmen  DIY propane gas burner: step-by-step instructions for assembling home-made burners

DIY propane gas burner: step-by-step instructions for assembling home-made burners  Do-it-yourself Injection Gas Burner: Blacksmithing Manual

Do-it-yourself Injection Gas Burner: Blacksmithing Manual  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

An interesting idea, I heard many times, but here everything is described in detail. I have my own carpentry workshop and there will be no problems with fuel. I was in Europe and there motorists quite successfully adapted their vehicles to work on wood. I like to do something with my own hands. Such a gas generator will be quite difficult to assemble yourself, the more interesting.

A gas-powered motorcycle is a thing! At first glance, it looks fantastic. I think this is interesting for areas where gas stations are far away or inaccessible at certain times of the year.For the uninterrupted operation of the gas generator in the house, constant electricity is needed, that is, you need to additionally have an autonomous source of liquid fuel, which results in such a vicious circle of problems. Although, burning one portion of coal during the day is worth it.

In fact, there is absolutely nothing fantastic in such a motorcycle on firewood. The technology is quite old, it is almost a century old. Invented in France in the 1930s. During the Second World War in Sweden, 1/4 of all motorcycles were with a wood gas generator. And in Siberia, gas-generating transport was also common. The same GAZ-42 was generally mass-produced. Another question - is it relevant now? Perhaps not. But the development of civilization is such a thing - at some point oil will become scarce.

This is something from the series: “Goal for the invention of cunning.” When people are already moving to electric cars with might and main, such a miracle can only be considered as a technical curiosity. Well, yes, it's cool - a wood-burning motorcycle, but imagine that there are a lot of such motorcycles, but that could have been worse than in Beijing.

And what's so funny about that? And the production of the same electricity? This installation can be used for stationary generation of electricity, and how you will later use this electricity is no longer a gas tank problem. And coal, by the way - there is still a lot on Earth. And gas from it can be extracted with the help of the Sun, if that ...

It is clear that the car on wood or coal in the 21st century will look ridiculous. Nevertheless, there are such solutions, especially in poor countries. Of course, there are enthusiasts who put gas generators to test their developments.

As for stationary gas generators, such equipment is not difficult to remake to receive - electricity. I even helped friends in the implementation of such a project for a private house. In conditions when there is cheap raw materials (coal, firewood) or even free, then this is a profitable solution.