How to make a blacksmith forge on gas with your own hands: tips + drawings to help home craftsmen

Equipment for the heat treatment of metals is an expensive pleasure. Not every novice master is ready to pay a substantial amount for its acquisition. But there are technologies according to which you can build a blacksmith forge with gas yourself without any difficulties and expenses.

In our article, you will find a detailed description of the assembly of the main attribute of the blacksmith's craft. We will talk about how the hearth works and its structural components. We will show you how to achieve the temperature necessary for melting and forging workpieces.

For independent home craftsmen, we suggest that you familiarize yourself with homemade products that have been tested by blacksmithing. You will find out what materials, finished devices and tools will be required in the manufacture of the hearth. Get an insight into the difficult process and valuable advice.

The content of the article:

Principle of work and design specifics

Forge forge is necessary for a series of operations to prepare the metal for subsequent processing. The preform warmed up in it is given the designed form. With its help, they are making now-forged jewelery popular today, household items, utensils, furnishings, etc.

Mining is used in all areas of heat treatment. It can be quite miniature, installed literally on the table, and stationary, resembling a traditional brick stove. Regardless of size, all models operate on a single principle.

How does the blacksmith forge work?

To prepare the metal for subsequent forging, it must be heated and literally “softened” in temperature conditions to 1100-1200ºС. The conditions are achieved thanks to the specific features of the design, which ensures the supply of fuel and oxygen to the combustion zone in the proportions necessary for the process.

A characteristic chemical reaction occurs inside a gas or solid fuel blacksmith furnace: hydrocarbon is processed. The carbon obtained by burning both gaseous and solid hydrocarbons captures and appropriates oxygen from the heated metal. The result is steel without oxidizing impurities.

The features of the blacksmith hearth make it possible to use partially the carbon reduction potential. All oxygen is not burned from the heated preform. Due to partial reduction, the metal does not burn completely and does not become brittle, as is the case with cast iron.

By the way, cast iron products in industry after heat treatment are saturated with oxygen in order to get rid of this drawback or at least minimize it.

In an industrial horn equipped with a control system, the air needed for combustion is pumped so that it is slightly missed. It is difficult to equip a home-made device with such a device unless you install, of course, a finished gas burner with automatic equipment on it.

Due to the impossibility of a controlled air supply, or rather the oxygen contained in it, man-made forged products are often burned. This happens in the first stages. However, with experience comes the ability of the master to feel when it is necessary to stop heating, as well as the knowledge of what needs to be done in order to avoid a complete loss of oxygen.

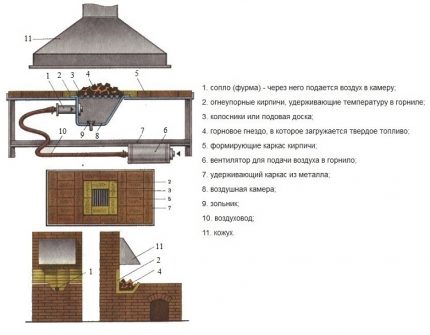

The device and working components

There are a great many options for making home-made models, tested by blacksmiths in practice. We give only a small part of them. Before deciding which gas furnace it is better to do it yourself, we will deal with typical features of the device.

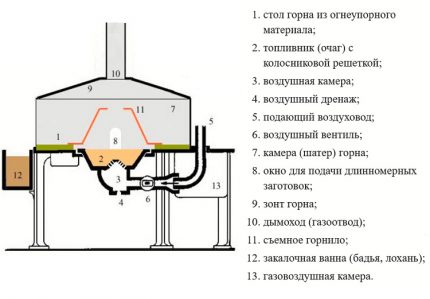

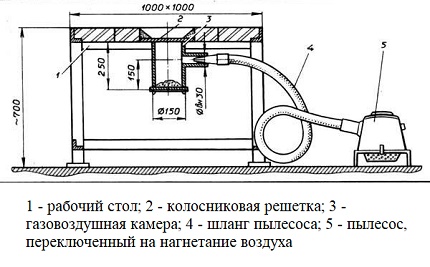

In technical essence, any forge forge is a kind of furnace with characteristic accessories: a firebox, a grate, an air chamber, referred to in Russian heating units blower. Unlike a conventional stove, the air chamber is equipped with a drain for adjusting the air supply and a nozzle with a valve.

The grate is reinforced so that it is able to resist considerable thermomechanical effects. An ordinary lattice of metal rods or scraps of a corner will not work. Need a reinforced device.Ideally, it would be better if it was a thick metal panel mounted on the desktop with evenly drilled holes.

The totality of these components is called a lance. There are several of them in the configuration of industrial furnaces so that it can be changed depending on the required conditions for performing a certain operation and on the size of the heated workpiece.

The lance is most often installed not in a closed case, but mounted on a table. He needs to be sufficiently stable and protected from thermal effects, for which a lining is used. In some designs, a grate is mounted in the table or a perforated metal panel is installed instead.

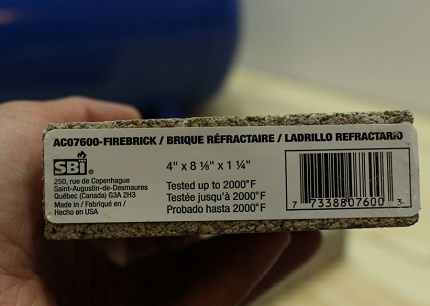

Refractory quartz bricks are used in the lining of the table for the stationary furnace, which they are going to actively exploit. Homemade products for one-time work lined with fireclay bricks. Finding it for sale is easier, and the price is lower.

To fully collect and remove flue gases, a tent or umbrella is placed above the table with a perforated panel or above the lance. They are connected to the smoke channel, which is constructed on the principle of chimney for gas boiler. It should work flawlessly, as The gases released when the metal is heated are extremely toxic.

In addition to the main structural components, there are still additional devices. Usually, blacksmiths put a quenching bath next to the mountain so that the finished product is immediately dipped into the cooling and tempering medium. This is in case heat shock hardening is required.

Even artisans on an industrial scale use a gas chamber. In it, the products are dried from condensate, introduced into the composition of the additive, which can be added only in the gaseous state. Air is dried there to obtain certain technological conditions.

To increase the area of extremely high temperature, a crucible is used - a cap expanding to the base. It is needed mainly when working with non-ferrous and precious metals. Handicraftsmen often do not need any additions, unless a bathtub under which any metal container of sufficient volume can be adapted.

The choice of blue fuel for work

It is believed that for the work of the blacksmith hearth, both main and LPG balloon. Disappoint: it is impractical to use an untreated natural option.

There are two good reasons for abandoning fossil fuels:

- From the pipe we receive blue fuel, which is a kind of mixture of gaseous hydrocarbons. Their abilities for calorific value and oxygen retention vary. Therefore, it is virtually impossible to tune in to an optimal air supply.

- In a gas mixture for domestic use, there is always an albeit insignificant but affecting the result. The presence of phosphorus with silicon may not be noticed, but sulfur will definitely render the result of labor efforts unusable. Only remelting can save.

In addition, household gas is odorized - they give it a characteristic odor so that a leak can be detected immediately. These substances will also negatively affect quality.

Industrial liquefied gases would be excellent: propane or butane supplied in cylinders. But only if it will be monogas without accompanying impurities in general.

If it is not possible to buy purified blue fuel, you can carry out the cleaning yourself. A tank with naphthalene will help to get rid of sulfur-containing compounds, through which gas must be passed before being fed into the burner.

By the way, if you use a factory-made burner, the construction of the hearth will be much faster. Yes, and for the result, you can’t worry about working, everything will be flawless and safe. In addition, air and gas in the burner can be mixed in advance in the proportions necessary for operation.

Blacksmith Horn Construction Technology

Immediately make a reservation that a homemade gas furnace, with the drawings and assembly methods of which we will introduce you, is not suitable for production purposes. However, unique decorations, interesting interior gizmos, original metal products with its help can very easily be made.

Let's start with the simplest options that do not require skills in welding and other construction areas from the contractor.

Elementary construction with gas burner

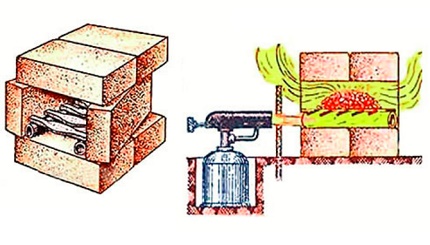

The simplest blacksmith hearth for forming beautiful tips at a metal bar, from which it is planned to weld a pretty fence in the country, or for forging jewelry can be made of six fireclay bricks.

The grate in this model is brewed on the basis of two pieces of VGP steel pipe of arbitrary diameter, but not too large. To them cross-sectional welding of a profile pipe, corner or strip twisted as a screw is welded across. So it is necessary to capture the blast stream.

From fireclay bricks they make up a firebox, which has only a base, an upper ceiling, and two walls on the sides. This horn is installed only on the street, since a smoke removal system is not provided. From the side of the boost, a small pit is dug in the ground for the body of the gas burner or blowtorch.

In order to prevent an explosion from the gas burner during operation, it is better to put a partition made of asbestos cardboard before entering the firebox. After all, the heat coming from an open firebox can return and heat the tank with gas.

In general, in this device, heating is carried out on coals or coke (small coke, produced specifically for blacksmiths). A gas burner or blowtorch is used only to activate the process. They will ignite and create a blast jet.

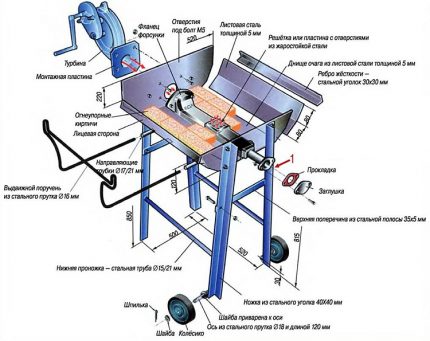

Mobile version of the goose

For the device of this model you need a used goose body. At its ends, holes are cut through to enter a homemade or purchased gas burner. Two holes are cut out above the holes. This model as well as the previous type can be operated exclusively in the fresh air.

The lining of a home-made hearth is made with a mixture of fireclay sand with brick fireclay battle. You can buy a ready-made mixture for this. After application, it is not necessary to bake anything specifically. Hardening of the lining composition will occur during use of the device.

For pressurization, a fan suitable in appearance and power is installed, for example, from a manual siren.A blast gas burner is ideal, which can be removed from an old turbocharged boiler, if it is, of course, in working condition.

This solution has a significant drawback - you can work with it only on the street, and if you use a blower, you will need power. Those. you will have to stock up either with a good extension cord of sufficient power, or take risks by placing the device near the house.

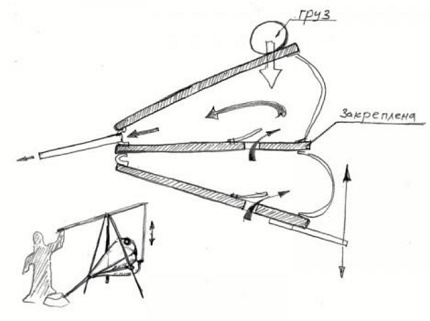

There is another option - the blacksmith's furs, which were used by blacksmiths for several centuries. However, note that manually injecting air into the firebox of the furnace is not at all safe. And with performance it will be all problematic and ambiguous.

Stationary workshop equipment

Models installed in workshops for continuous work should not only be functional, but also ergonomic. It is important to consider both convenience and safety, because a red-hot metal blank is a potential threat. And getting serious injuries is not included in the plans of any normal master.

The dimensions of the equipment in this case should not be taken as standard, because we are all folded and arranged individually. The blacksmith horn should be convenient for you and those who will use your workshop, if it is taken on a joint lease. Of particular importance is the height of the desktop and its dimensions.

To determine the size of the future hearth, we proceed as follows:

- We will choose a place in the workshop that allows us to arrange all the main and additional equipment in places convenient for carrying out the whole spectrum of work on heating, forging and hardening.

- Define your place. We stand, spreading the feet shoulder-width apart. We bend the working (right / left) hand at the elbow.

- We measure the distance from the elbow of the bent arm to the floor plane. This is more convenient to make a partner. Then we also get the second result, if not only you forge. We add 5-7 cm to the arithmetic average of two distances - we get the height of the desktop.

- We take the largest ticks in dimensions to measure the distance from the abdomen to their extreme point. We add 10-12 cm to the measured distance - we get half the diagonal of the desktop.

- We calculate the length of the side of the square desktop, given the previously received half of the diagonal.

The forge table is usually not made round, because it is inconvenient in work, especially if you have to work with an assistant.

The stationary blacksmith forge presented in the system is a universal equipment that can be adapted for both solid and gaseous fuels. In the case of loading coal from the burned firewood or coke into the firebox, the fan blows air from the stove out of the car, as the vacuum cleaner will blow the coals.

In the center of the desktop is a mounted grate. This option is needed so that when the holes are clogged with burns, there is no uneven heat distribution. When using gas, you need to equip the installation with an injection torch, which is better to buy, but you can also do it yourself.

Based on the heritage of cavalrymen

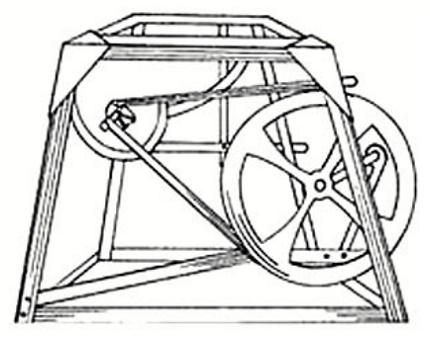

Horsemen at all times needed horseshoes and nails for their fastening. Even the hussar and ulan squadrons in their arsenal had portable horns that moved along with military units. At the heart of mobile forging machines was a crank mechanism.

An analogue of the crank mechanism is now easy to find. It is enough to recall where the grandmother’s foot sewing machine of the Singer company is stored. With some alterations, Singer followers of the Seagull brand will do.

It is advisable to give preference to the old versions with a cast-iron frame. It will withstand any thermal and mechanical effects. The ideal solution is a construction on wheels, which can easily be moved to a place convenient for work.

Propane burner horn

We’ll immediately warn you that this model of a blacksmith hearth is suitable only for those who have considerable experience working with propane. The gas chamber of this option is quite large, therefore, with the slightest violation of the rules, an explosion can be a destructive force. The consequences are unpredictable, but in most cases catastrophic.

The master, who decided to make a hearth from an oxygen cylinder, will need this empty tank with a diameter of 25 cm or more. Refractory materials will be needed: a plate, cement, paint, kaolin wool. It will require fasteners, ceramic coating, a steel barrel with a thread to equip the burner connection point.

Still need fasteners and other materials that we list in the text. For work, you need to stock up on a grinder, a set of taps 10-32 in size, a spatula, a brush for coating, a drill and files. And also protective equipment will be needed: an effective respirator, working cotton gloves, glasses.

The following photo selection will familiarize with the assembly of a homemade hearth from an oxygen cylinder:

If the container did not initially have support legs and a handle at the top for carrying, they should be welded.By the way, if there is no experience in welding, work on joining parts can be done with bolts or by soldering.

Next, you need to arrange a pipe to enter the burner in our homemade blacksmith forge:

Now you need to fix the pipe and build a device for fixing the propane burner in the pipe:

Now is the time to start arranging the bottom of a homemade hearth. To do this, we will need fireclay bricks, from which we will build a kind of desktop. At the same time, we separate the high temperature zone from contact with the metal wall of the housing.

The bottom, it’s the working refractory table of the forge, is ready. Now we are starting to arrange the back wall:

With the back of the deal, now the most difficult and time-consuming - assembling a removable cover for the front end. It is removed to periodically change the burned-out insulation and the brick stand, because this often happens during active use.

We can assume that we successfully completed the work, only the final stages remained:

We want to warn home craftsmen: blacksmithing is a very interesting, but traumatic, occupation. You need to protect your eyes, if possible, close all parts of the body, despite the high temperature in the work area.

In order to protect against burns, you need to stock up on shoes with metal-reinforced socks. It is advisable to purchase a long canvas apron and mittens. It is absolutely impossible to work with heated metal in synthetic clothing - it will momentarily flare up from a random spark.

Conclusions and useful video on the topic

Original tips for independent masters on arranging horns for a private forge:

How to make a small stove for hardening metal billets:

Detailed instruction on the manufacture of stationary equipment for heating metal with gas:

We have examined and disassembled only a small fraction of the designs and patterns of the construction of horns. In fact, there are much more. However, the information we offer will help you get an idea of the types of equipment so that you can choose the best.

Want to share your own experience in assembling a homemade blacksmith forge and in arranging a forge? Please leave comments in the form below the block, ask questions, publish photos on the topic of the article. It is possible that your recommendations will be very useful to site visitors.

Do-it-yourself Injection Gas Burner: Blacksmithing Manual

Do-it-yourself Injection Gas Burner: Blacksmithing Manual  How to make a wood-based gas generator with your own hands: homemade wood and sawdust

How to make a wood-based gas generator with your own hands: homemade wood and sawdust  How to make a gas generator with your own hands: features of manufacturing a homemade device

How to make a gas generator with your own hands: features of manufacturing a homemade device  DIY propane gas burner: step-by-step instructions for assembling home-made burners

DIY propane gas burner: step-by-step instructions for assembling home-made burners  DIY do-it-yourself gas burner repair with piezo ignition: common failures and their elimination

DIY do-it-yourself gas burner repair with piezo ignition: common failures and their elimination  DIY gas stove: the best options for homemade tiles from improvised materials

DIY gas stove: the best options for homemade tiles from improvised materials  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements