The gas burner burns badly: popular faults and recommendations for their elimination

Your gas stove never let you down, but suddenly there were problems with burning burners? Situation, to put it mildly, unpleasant, agree? You want to try to return the equipment to working capacity on your own, but do not know where to start the diagnosis?

We will help you figure out why a gas burner does not burn well, tell you how to find a breakdown and fix it on your own. We will also talk about the most common malfunctions leading to a problem with burning a gas burner. Moreover, many of the reasons leading to abnormal operation of gas stoves can be eliminated promptly and without significant costs. Here are visual photos and thematic videos.

The content of the article:

Why do burners work poorly?

The most common cause of problems with the performance of the gas stove is dirt clogged in the nozzle of the nozzle. These structural elements are located directly below the burners. Therefore, particles of food and detergents often enter the channel intended for dosing gas.

They burn out under the influence of high temperatures, but the residues still accumulate and eventually interfere with the gas supply to the burners. Which leads to a partial, and sometimes complete loss of their performance and poor burning.

The described procedure is uneven, therefore, burning problems occur in each burner separately.

The situation with nozzle contamination is one that you can solve yourself. Since for this special knowledge and skills are not required, as well as a rare tool. Before starting repair work, we recommend that you first familiarize yourself with gas stove device.

In addition, to resolve the problem, you must perform a number of actions:

- Remove cover from burner.

- Remove the burner. This is easy to do - it is simply removed from the seat with one movement of the hand.

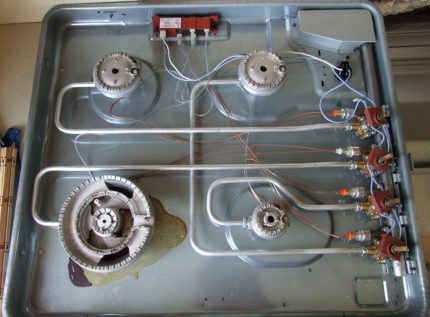

- Dismantle the gas stove table, which will allow access to the nozzle. Why sometimes it is necessary to unscrew a few screws.

- Clean the nozzle channel.

The last procedure is carried out using a pre-prepared needle or a piece of thin wire. Which, for convenience, needs to be bent at an angle of 90 °, and this will also prevent the improvised device from dropping into the nozzle channel.

For cleaning, a needle or wire is inserted into the nozzle channel and reciprocating movements are performed.

Remove crumbled dirt by opening the gas valve for a few seconds. At the same time, it is not necessary to set fire to “blue” fuel.

It is possible to check the quality of the work performed without mounting the gas stove table.

Why burner:

- set to the workplace;

- cover with a lid.

And then the usual flame ignition procedure is performed. If its parameters are not inferior to the same values of other burners, then the troubleshooting procedure is considered to be successfully completed. Then it remains only to complete the installation of the table and the installation of burners.

Rarely, but it happens that cleaning the nozzle from contamination in the installed position does not work. As a result, it will have to be dismantled. But fearing this is unnecessary, since the whole procedure, if you have the right key, will take several minutes. After that, cleaning will be easier.

In addition, after its completion, the nozzle is recommended to be washed with any ordinary detergent. Next, the device must be wiped dry and you can start assembling.

Other causes of unstable combustion

Unstable burning of burners can be caused by a number of reasons. Sometimes it happens that the burner holes that cut through the flame become clogged with combustion products. Which is the reason for the loss of a partial loss of burner performance.

Fixes an issue by cleaning holes. Which in some cases can be done with the help of improvised means and without even dismantling the contaminated burner.

But still, it is better to get it out and wash it well with detergents, as this procedure helps prevent a recurrence of the problem for a longer period.

If there is an excess amount of grease in the tap, then the gas in the right amount does not enter the burner. This leads to the blocking of the channel through which the "blue" fuel is supplied to the burner. But this happens when any work was performed with the crane or a new product was installed.

Problem # 1 - Smoked Gas Stove

The indicated reason is a sign that the energy carrier does not burn out in full. This can lead to a fire hazard. Therefore, the problem should be resolved promptly. And to do this is easy even for yourself, since in most cases the cause can be identified independently.

And the main ones are:

- clogging of the flame divider (diffuser);

- nozzle contamination.

That is, the same reasons lead to soot formation as with simply poor combustion of gas. Therefore, they are eliminated in the same ways as indicated in the previous section of the article.

In addition, deformation of the flame diffuser leads to incomplete combustion of the gas. This happens with the active use of a gas stove or the low quality of the product itself, which cannot be restored. That is, the only way out of this situation is to replace this element.

Sometimes it happens that the soot appears due to the low quality of the gas. For the most part, this applies to fuel, which is supplied to consumers in cylinders. And in this case, you just need to replace the tank with another.

If gas cylinders are used, improper adjustment may be an additional cause of soot. gearbox fuel supply. The solution is to make the appropriate settings. To complete which it is better to call a specialist.

Problem # 2 - the flame changes color

Such a cause of burner malfunction indicates that the resulting gas-air mixture contains insufficient oxygen. for complete combustion of gas.

Moreover flame color change - The malfunction is more dangerous than it seems. The reason is that when a gas burns with any flame other than blue (for example, red, white, orange), it leads to mass formation carbon monoxide. And he is mortally dangerous. So, even with a small concentration of 0.1%, acute poisoning and even an accident can occur.

Therefore, identifying that the gas burner burns poorly, you need to immediately clean it from dirt, as this ensures fire safety use of equipment.

The whole procedure consists of 2 stages:

- Burner washingits covers;

- Cleaning the nozzle of the nozzle burners.

Detailed information on how to perform the above operations in a quality manner is described in the previous sections of the article.

In the case of the wrong flame color, even owners of newly purchased gas stoves should not ignore cleaning. Since on their structural elements, including jets, burners, taps, there is a protective lubricant to which dust and dirt particles stick, which can negatively affect the amount of air supplied.

If cleaning has not led to normalization of the stove, then the cause of the poor-quality process of formation of a gas-air mixture should be sought in gate settings. That is, a device that regulates the amount of air supplied to the gas. It is better to entrust the gate setting to a specialist who at the same time will check its operability.

If the owner of the stove decides to make the adjustment on his own, you should be aware that moving the shutter toward the nozzle will block the primary air intake channel. Which will lead to even greater problems with gas combustion. That is, the correct solution is to move the flapper away from the nozzle. And how much exactly is detected experimentally.

Signs of normalization of combustion are:

- blue flame color;

- the length of the flames within 2-2.5 cm;

- lack of noises, tear-offs of flames.

Rarely, but it happens that the cause of an improper combustion process is low-quality gas in the pipeline. It will be possible to identify this reason by a comparison method: if the neighbors have the same problem, then we can conclude that poor-quality energy is supplied. In this case, you need to contact the gas service. Although it is unlikely to succeed in changing such a situation.

If the color of the balloon gas changes, then you can try connect to the gas stove new cylinder.

Problem # 3 - noise and flame-off

Noise and flame detachment indicate that the gas pressure is excessive.

In this case, it is unlikely that you can fix the gas burner yourself, because the cause is one of the following problems:

- Incorrect nozzle nozzle size. The problem is solved by selecting a product whose throughput corresponds to the characteristics of the plate. The very process of disassembling / mounting the nozzle is simple, but the difficulty will cause the selection of a new product.

- Incorrect position of the gate (damper). The malfunction is eliminated by adjustment, i.e. by changing its position (the procedure is described in detail in the previous section of the article).

- Incorrect hole sizes for flame dividers. The problem is fixed by the selection of a new product. Such a malfunction is inherent exclusively in gas stoves of a new generation.

If the issue with noise and tearing of flames arises when using balloon gas, then you should pay attention to the gearbox. Since the cause, most likely, will be its breakdown. Which is most easily eliminated by purchasing a new similar device.

We have another article on our site, where possible burner noise causes gas stove and methods for their elimination.

Problem # 4 - the smell of gas when the stove is on

Such a malfunction is one of the most dangerous. Therefore, measures to eliminate it must be taken immediately after identification.

The causes of gas when the stove is on can be:

- junction leak nozzles with a gas supply tube or at the joints of these two structural elements of a cooking device;

- wrong setting - in this case, it will be possible to eliminate the problem by changing the position of the gate according to the instructions described above.

Sometimes you will need to replace the nozzle with a product with a suitable channel diameter.

It is possible to detect a gas leak yourself, since for this you need to perform just a few simple steps:

- remove burners;

- dismantle the stove plate;

- replace the burners and their covers;

- apply the previously prepared soap solution to the junction of the nozzle with the tube or at the joints of these structural elements of all burners;

- Turn on each burner in turn to check for leaks.

If after the last procedure bubbles detected, then this means that the leak assumption has been confirmed.

And then you just need to call gas company specialist to fix the problem. Which is carried out by replacing the used parts. Until the gas stove is fully restored, it is not worth using it. Since this may result in a fire or explosion.

Rarely enough, but it so happens that the cause of the depressurization of the gas tubes of the stove are o-rings and washers. Faults are caused by their defects, destruction.

Remedy: replacement with new ones, but this work should be entrusted to a specialist. This must be done at least because he knows how to replace a damaged part.

Problem # 5 - Burner Attenuation

In addition to the ones described above, a number of malfunctions of gas stoves are often found, leading to the loss of burners.

These include unstable combustion with the following symptoms:

- poor burner operation that results in flame attenuation;

- the burner does not work well, while the handle of its tap is difficult or impossible to turn;

- all burners of the stove burn poorly.

Since the listed breakdowns are considered typical, then their features need to be better understood.

When the burner damps, combustion can stop both immediately after ignition, and later, but in any case the causes will be the same.

The main causes of cessation of combustion include:

- Nozzle clogging. It is possible to fix the problem by cleaning (how to do it correctly, described above) or by replacing the product.

- The temperature sensor does not heat up when burning. As a result, a command signal is generated that the ignition has not occurred and the gas control system blocks the energy supply. The reason usually is careless handling of the temperature sensor, as a result of which it occupies an incorrect position.

- Gas control system malfunction, which leads to its incorrect operation. In this case, you will have to replace the electronic valve or temperature sensor. Sometimes it is necessary to change the entire system in the kit.

In some cases, the burner can not only work poorly, but simply can not turn on.

Damage to the electric ignition system

It is easy to identify malfunctions related to this category, since it is enough to carry out the ignition using matches. And, if the gas ignites, but not in automatic mode, then this will be proof of a malfunction of electric ignition.

And the reasons are traditionally:

- ignition button failure - this happens due to defects, resource development;

- malfunction of the ignition unit, which is responsible for generating a spark when receiving a command signal from a button.

If the gas burner with electric ignition does not ignite due to the listed malfunctions, then you should be prepared to replace the failed structural elements of the stove. And this must be entrusted to specialists.

When one burner is problematic, the first thing you should pay attention to is the spark when you press the button. If it is, but is directed to the side, and weaker than on other burners, then the cause of the breakdown in the candle. And in a hurry with its replacement is not worth it.

Since often the fault of incorrect operation is the layer of dirt that covered the specified device, due to which the spark does not correspond to the established parameters.

In this case, all that is needed is cleaning the surface of the candle from food debris, detergents, soot. The same is done if a wire adheres to its body and breaks through the insulation onto the plate body.

In addition to cleaning contaminants, you must remove traces of oxidation from the steel rod.

If it was not possible to restore operability by cleaning, then this indicates the destruction of the insulation of the candle or its wiring. In these cases, both elements are replaced. What you need to entrust to the master.

When there is no spark on all burners, this indicates a break in the wiring from the button to the electric ignition unit. This can happen due to a defect or mechanical damage to the wire. Typically, such a malfunction is characteristic of private homes.

In addition to problems with burning a burner, gas appliances also have other breakdowns. We recommend that you familiarize yourself with popular plate breakdowns and methods of their repair.

Conclusions and useful video on the topic

The roller located below will help you figure out how to change the jets, the pollution of which often leads to unstable operation of the burners:

The following video will enable you to identify and fix problems with automatic ignition:

Gas stoves are quite repairable. Therefore, in most cases, the identified malfunctions can be eliminated promptly, and without significant costs. At the same time, it is worth remembering that you can not save on repairs, as well as forget about safety measures.

Do you still have questions about identifying a breakdown or fixing a problem of weak burning of a gas burner? Ask our experts and other users for advice - the comment block is located below.

Do you know the answer to the question of one of the site visitors? Or do you want to supplement the above material with useful recommendations? Write your comments, participate in discussions - the feedback form is under the article.

Why the gas burner is noisy: analysis of the causes + valuable recommendations for resolving the problem

Why the gas burner is noisy: analysis of the causes + valuable recommendations for resolving the problem  Why a gas stove is shocking: popular reasons and recommendations for their elimination

Why a gas stove is shocking: popular reasons and recommendations for their elimination  Why does the gas pipe in the apartment vibrate and buzz: causes of noise and solutions to the problem

Why does the gas pipe in the apartment vibrate and buzz: causes of noise and solutions to the problem  What to do if a gas stove passes gas: causes of gas leakage and their elimination

What to do if a gas stove passes gas: causes of gas leakage and their elimination  Can a gas column explode: why the threat arises and how to prevent it

Can a gas column explode: why the threat arises and how to prevent it  Why a gas pipe is shocking: causes and ways to cope with a problem

Why a gas pipe is shocking: causes and ways to cope with a problem  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements