Rules for checking gas analyzers: frequency and methodology of work

It is likely that you have encountered state control of gas appliances. Perhaps you are an entrepreneur, and even the most insignificant aspects related to expenses matter to you? We believe that a very small number of people know the rules of calibration of gas analyzers, and meanwhile, an unsuccessfully selected device will ultimately cost tens of thousands of overpayments.

We tried to gather all the useful information together. We are talking about all the key points: standards, periodicity, verification stages. You will thoroughly approach the choice of a gas analyzer if you read the material presented by us.

Gas analyzers are subject to state regulation, as they ensure safety at facilities from different fields of human activity. This is primarily true of calibrations that are performed to ensure compliance with metrological characteristics. Let's see how verification activities are held together.

The content of the article:

Features of gas analysis instruments

A gas analyzer is a device for determining the quantitative and qualitative composition of a gas mixture. So says science. Manual absorption analyzers are widely used, in which reagents gradually absorb gas components. Automatic devices in a continuous mode determine the physical and physicochemical values of mixtures and their components.

Gas analyzers are divided into 3 groups. All devices operate on physical methods of analysis, and the difference is expressed in the ability to take into account chemical processes.

Type 1 devices monitor, among other things, related chemical reactions.Analyzers determine changes in the pressure of the fuel mixture and its volume after chemical interaction between the components.

Type 2 gas analyzers provide indicators of physical analysis, which applies to chromatographic, photoionization, electrochemical, thermochemical and other physical and physicochemical processes.

Type 3 devices only work on the principle of physical analysis. The measurement methods they have are magnetic, densimetric, thermoconductometric and optical.

Instruments for the analysis of gas mixtures also classify:

- by appointment;

- by the number of measuring channels;

- by the number of measured components;

- by design;

- by functionality.

It is worth knowing more about devices that differ in the last sign. Gas analyzers perform the functions of conventional measuring instruments, as well as signaling devices, leak detectors, indicators.

Scopes of gas analyzers

Gas meters are used in explosive facilities, boilers of thermal power plants, chemical industry enterprises, and vehicles. Analyzers are also used before firing work in wells and basements.

Devices benefit owners of gas, vacuum and refrigeration equipment: thanks to meters, they determine leaks, leaks, and the concentration of combustible gases. Doctors use gas analyzers to monitor concentrations in the respiratory circuit during painkillers. In the field of nature conservation, these devices have also found useful applications.

Read more about the principle of operation of a gas analyzer in this stuff.

Calibration of gas analyzers in Russia

Measuring instruments subject to state supervision are inspected for compliance with metrological characteristics. Ordinary citizens and entrepreneurs should be aware that since 2008, activities in this area have been regulated Federal law No. 102 "On ensuring the uniformity of measurements". A gas analyzer or other metering device is checked with a certain frequency, usually 1 time per year.

Preparation for calibration of a gas meter

Verification gas mixtures (ASG) in cylinders can withstand during the day in the room for verification. The gas analyzer itself is stored there for at least 2 hours. At the same time preparing inspection tools, as discussed in the operational documentation.

Based on the documents and operating instructions for a particular product, the analyzer is checked for completeness, after which the device is prepared for operation. Preparatory measures are a component of the verification procedure for any type of gas analyzer, in the technical documentation it corresponds to paragraph 5.

The essence of verification is that ASGs are passed through gas analysis equipment at the desired speed. When the number of cylinders is more than 1, a multi-way valve is used. The composition is switched by a simple turn of the crane.

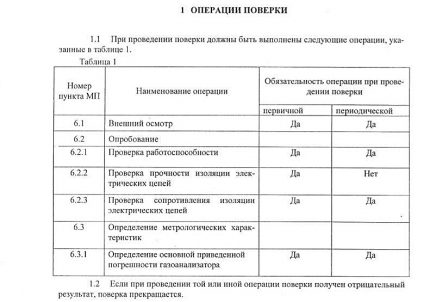

Equipment Inspection Sequence

Verification begins with an external inspection, and take into account visible problems and damage. They also look at the clarity of the inscriptions on the front panel, the condition of the thread on the fittings. According to the instructions for a specific gas analyzer, a functional check is carried out.

In the process, the gas mixture will pass through the gearbox and fall into line with the sensor. The test will come to a logical conclusion when the specialist determines the main indicators of metrological characteristics: measurement errors, as well as variations in indicators for different gas contents.

The trusting organization will issue a certificate or leave a stamp on the device.Due to the design features of some gas analyzers, the mark is sometimes put directly on a paper document.

There are 5 types of verification:

- primary;

- periodic;

- extraordinary;

- inspection;

- expert.

The primary implementation before the operation of the analyzer. Also, after the repair, the owners will have to repeat the procedure.

Periodic checks are performed as planned. Charts are indicated in the documentation, and metrological services of enterprises make up these schedules. After the plan is approved by Rosstandart, it must still be approved by the head of the company.

Extraordinary verification will be necessary in case of loss of a document on inspection of equipment, damage or a long downtime of the device.

Also, gas analyzers are subject to inspection inspection. This means a visit within the framework of state metrological supervision.

In case of disagreement on metrological characteristics, they resort to expert verification. It can be appointed by the prosecutor's office or court, but sometimes the desire of the consumer is enough.

Guidelines for the calibration of gas analyzers

Devices should work correctly with radio interference with values within the limits of Norm 1-72-9-72. As for the indicators of the gas analyzers themselves, then not only the flow rate, but also the flow rate instead of it can be subject to rationing if necessary. The main error, in which case, is replaced by random and systematic components.

Metrological standards are established in technical or standard conditions for a specific gas analyzer, depending on the scope and indicating the conditions for verification work on GOST 8.401-80. Under normal conditions, the difference between the extreme values of the measurements for the permissible basic error is allocated within 25%.

Conditions for work

First of all, they provide security. Only those rooms where there are supply and exhaust ventilation. After fulfilling this requirement, the content of harmful substances in the working area of the enterprise is checked, and the norm is indicated in GOST 12.1.005.

Employees are protected from electric shocks - based on GOST 12.2.007.0 and for other requirements from safety regulations. Using gas mixtures in cylinders standardize PB 03-576-03, they are - Rules for the design and safe operation of vessels operating under pressure.

For verification, you will have to comply with such requirements and restrictions:

- voltage of 220 V;

- consumption of ASG at the level of 0.18-0.35 dm³ / min;

- atmospheric pressure not lower than 84 kPa and not higher than 106;

- relative humidity in the range of 30–80%;

- ambient temperature from +15 to +25 ° C.

Verification is carried out only by certified employees by means of measuring PR 50.2.012-94. Before doing their job, they must read the manual for the gas analyzer, and also work with the instruments.

In the process, the specialist will record and enter the following data:

- Document Number;

- Date

- name of the owner of the gas analyzer;

- number of the device to be verified;

- instrument readings and error parameters.

As a result, the owner of the meter will receive a signed certificate with the mark “Suitable”, but if the quality of the device is not lucky, then a notice with the record “Not suitable”.

Representatives of the Center for Standardization and Metrology will immediately stop checking if they receive an unsatisfactory result by varying the readings, the main or absolute error, the alarm response time.

The fuel metering equipment must have an information unit, a charger and a passport before verification. The same applies to the act of the last verification, if carried out, as well as removable cartridges and remote probes, if any.

What do you need to know about frequency?

Legislators at the state level obliged all organizations that own gas analyzers to provide these devices for verification. The work is carried out by representatives of the State Metrological Service and certified services of private organizations. The frequency indicator for checking the sensor depends on the model of the gas analyzer, but the law says about a period of 6 to 12 months, but at least 1 time per year. However, some devices require inspection at least once every 6 months.

The period for inspection of equipment may be established by local metrological service structures. Employees of the Centers of Standardization and Metrology sometimes abuse their position and increase the frequency of examinations. The FMC can establish a six-month verification period without significant reasons.

Calibration is also distinguished - a set of measures for gas analyzers that are used outside the scope of state regulation. The interval between calibrations is not clearly set. At the same time, the methodology sometimes indicates technically sound recommendations regarding the timing for the next such procedure.

What is the essence of the verification work methodology?

The verification procedure is a document with detailed operations to confirm the validity of the gas analyzer. For different brands and models, the approach is different.

The document usually includes 7 points:

- Verification operations. We are talking about the main indicators, including errors.

- Facilities. These include instruments and gas mixtures for testing and determining metrological characteristics.

- Safety requirements.

- Conditions for holding.

- Training.

- Holding.

- Presentation of verification results. At this stage, the believer draws up a protocol and issues a document-certificate.

Direct verification begins with the fact that they attach the test gas cylinder to the control valve. Then the rotameter is brought to the exit. The latter is attached with an adapter for calibration work. The mixture is then allowed to enter the gas analyzer, and when the instrument gives evidence, they are fixed.

The specialist will calculate the error and determine the time it took to establish the testimony. The believer will compare the indicators with the standards and draw up the results.

Conclusions and useful video on the topic

Overview of a domestic gas analyzer, connection, operating principle, testing:

Verification of gas analyzers and gas detectors using modern equipment:

Verifications themselves will not cause organizational difficulties, especially if security issues have been given due attention. A device for determining the composition of the gas is considered valid after the main and absolute errors are acceptable. It is possible that the timing for calibration of the gas analyzer will become a problem. The consumer should seek a one-year interval instead of an unreasonably short period. An unsatisfactory metrological result can also be challenged.

Leave your comments, ask questions about the topic of the article, share experiences and share useful information. The contact form is located under the article.

Rules for the operation of gas equipment in residential buildings: measures and standards for safe use

Rules for the operation of gas equipment in residential buildings: measures and standards for safe use  Gas analyzer: principle of work, what to look at when choosing + manufacturers review

Gas analyzer: principle of work, what to look at when choosing + manufacturers review  Natural gas odorant: features of odorants, norms and rules for their entry

Natural gas odorant: features of odorants, norms and rules for their entry  Distance from gas equipment to electrical wiring: technical regulations

Distance from gas equipment to electrical wiring: technical regulations  Safety rules when using a gas boiler: requirements for installation, connection, operation

Safety rules when using a gas boiler: requirements for installation, connection, operation  Fire safety of gas equipment: rules and regulations for the operation of gas appliances

Fire safety of gas equipment: rules and regulations for the operation of gas appliances  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements