Installation of gutters: how to properly install the gutter and attach it to the roof

One of the key stages in arranging a roofing system at home is the drainage system. Without its organization, it is impossible to protect the facade of the building from rain and water flows during the melting snow.

How to properly install the gutters and what to consider when installing the structure, we will consider in the article.

The content of the article:

Highlights when designing gutters

The question of how the gutter system will be equipped should be decided at the construction design stage.

When making calculations, one must be guided by the requirements of the current SNiPa 2.04.01-85. This approach will allow, taking into account all the nuances, to correctly select the best design option.

The main points that should be followed when designing a drainage system:

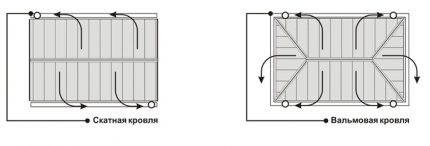

- Having made a copy of the roof drawing, draw a plan of the location of the drainage elements.

- Calculate the total area of the roof and all its slopes separately, taking into account the adjacent vertical walls.

- Based on the indication of the intensity of the rains in the area, determine the throughput of the system.

- In accordance with the obtained values, determine the diameter of the mounted downpipes, the number and cross section of the drain funnels, as well as their frequency along the wall of the building.

The result should be a system capable of collecting and draining the maximum amount of fluid.

At the design stage, it is important to determine the location of the risers so that they do not violate the exterior composition. Most often they are placed in the corners of the building, but it’s quite acceptable to equip them in a niche created by the bay window.

If the discharge of the outgoing pipe from the gutters will be carried out to the blind area, the risers should be removed as far as possible from the entrances to the basements, basement ventilation outlets and pedestrian walkways laid near the house.

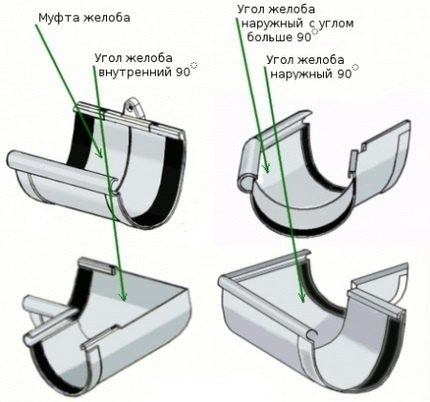

The components of the drainage system

The system includes two groups of parts - horizontal and vertical drainage parts. Together they include about a dozen types of structural elements, each of which performs the task assigned to it.

The structural elements of the drainage system are:

- drainpipes - key functional elements of the system designed to move water masses from the roof;

- gutters - narrow channels for collecting and redirecting water;

- funnels - conical sockets in the upper part of the pipe are designed to collect, delay and drain water flowing down the gutters;

- knee - structures in the form of short bent pipe sections are installed to change the direction of water flow;

- brackets - fasteners for fixing the gutter to the roof;

- seals - additional elements provide fastening strength at the joints;

- clamps - fasteners for fixing the structure to the facade of the building.

During construction gutter system on long-sloping roofs, guide rails are additionally installed. Their main purpose is to reduce the flow rate of water along the roof surface.

The shape of gutters and brackets can be any. There are products with round and semicircular sections, U-shaped and trapezoidal in shape.

The gutters differ in the way they are connected to the bracket. The easiest way to install systems that require fixation through a simple snap. The rotary latches included in the package provide an opportunity to dismantle part of the gutter without special efforts if it is necessary to replace or carry out repair work.

The drainage funnels are universal, they can be installed anywhere in the drainage system. The plugs that cover the gutters come in two versions: left and right.

The connection of drainpipes and the laying of water outlets from the base of the building cannot be performed without the use of elbows. Their number is determined on the basis of the fact that for each drain pipe it is required to install three elbows: one below and two above.

Clamps are used to fix the gutter structure to the building facade. For metal water pipes, fasteners with screw elements and a long hairpin are chosen. For PVC structures - plastic clips with two support points.

Material Type Choices

The price of the drainage system depends on several factors, one of which is the material of manufacture.The modern market offers a lot of options for the materials that you can choose when arranging a drainage system. The choice largely depends on the appearance of the building and the aesthetic ideas of its owner.

The most widely used products made of polymers and metal.

Each species has its advantages and disadvantages:

- Plastic - lightweight, durable and at the same time quite easy to process material. At a low price, it shows excellent operational parameters. Installation of PVC gutters does not cause special difficulties.

- Galvanized steel - Stronger and more durable material than polymer. To give the product a more presentable appearance, manufacturers coat the steel with a polymer coating.

- Aluminum - Lightweight and easy-to-use material, the service life of which reaches over half a century.

- Copper - beautiful, durable, but at the same time quite expensive metal. But it is vulnerable to the damaging effects of electrolytic vapors. To minimize the risk, all elements of the system should be made of one material.

The polyvinyl chloride used for the production of components is much lighter than metal. This makes it possible to install brackets having a smaller cross section, without losing mechanical strength of the structure. But when installing PVC structures, linear fluctuations in dimensions should be taken into account.

Compensating couplings enable the main elements of the system to shorten and lengthen without risk of deformation. They are also used in the installation of metal gutters, despite the fact that they have much less thermal expansion.

EPDM rubber acts as a material for the manufacture of seals. It is a modern analogue of rubber.

To further protect the rubber and simplify the installation process, the seals are additionally treated with silicone grease.

Gutters produce sections of one to four meters. They come in rectangular and round sections. On their performance, this is not displayed. The choice is limited only by the design solution of the drainage system and the design solution of the facade of the house.

When purchasing drainpipes made of polymer materials, keep in mind that they have the same diameter along the entire length. And therefore, to connect them to each other, it will be necessary to use special couplings, which entails additional costs. We also invite you to read the article in which we examined all the pros and cons plastic and metal gutters.

Calculation of the required number of elements

This rather important event is better to entrust to specialists selling drainage systems, or to masters of the company providing installation roofing services. In the absence of such an opportunity, the calculation can be performed on their own.

The main points of competent calculation:

- Gutters. The total length of the channels should correspond to the length of all the slopes of the roof used to collect water. Their docking is carried out using connectors.

- Water intake funnels. They are installed in the outer corners of the building and additionally placed every 8-12 meters so that the total slope of the channels is not too large.

- Drainpipes. The number of products corresponds to the number of funnels, and the length corresponds to the distance from the roof to the earth's surface.

- Brackets. The number of brackets is determined based on the fact that for each meter of the channel one element is required. Additional holders will be required for the funnels in the center and wall and in the corner of the house.

The number of clamps depends on the height of the building. But in any case, each individual installable pipe section is fixed with at least one clamp. When installing a drainpipe in a one-story building, often three fasteners are located at the top point, bottom and in the middle of the product.

In the calculation, the condition is taken that for 1 square meter of roof in horizontal projection there should be 1.5 square centimeters of the cross-sectional area of the drain and funnel. For example: the cross-sectional area of a pipe D 100 mm is 78.5 sq.cm. This is an average value.

Depending on whether it is necessary to install the system in regions with high rainfall, or, conversely, in arid areas, the calculations are amended.

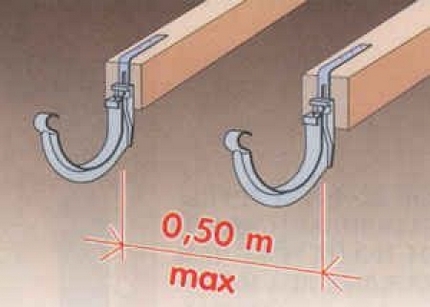

Bracket Mounting Methods

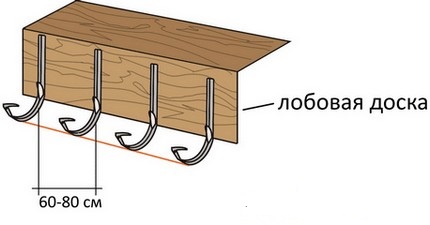

To install brackets according to the rules is still at the stage preceding the installation of the roof. If fixing is done after the coating is laid, then ordinary short hooks are used as fasteners.

Depending on the shape of the bracket, you can fix the elements in one of three ways:

- Fixing to the windshield of the roof - it is used if it is necessary to install the system on the finished roof.

- Mount on the rafter foot - used at the installation stage, preceding the laying of the roofing material.

- Bottom fixation flooring or the first battens lath - used for roofing, the step between the rafters of which exceeds the mark of 600 mm.

Brackets designed for fixation to the frontal roofing board are most often included in the package of systems made of polyvinyl chloride.

Metal brackets for attaching to the frontal roofing board are made shorter. If a windshield is not provided for in the roof structure, combined brackets are used.

They are equipped with extension cords made of steel. Due to this, it is convenient to attach them directly to the rafter leg.

In case it is impossible to provide access to the rafters, metal crutches are attached to the wall. ” They act as a support for further fastening of the metal gutter.

The fixing method, which involves attaching to the rafter leg, is effective in arranging roofs of houses in regions with heavy rainfall. Apply it and, if necessary, drain water from roofs with a large area, for the shelter of which heavy coatings are used.

With this method, the hooks are set behind the base and set at an equidistant distance in order to provide the desired slope of the gutter.

The third fixation method, which involves fastening to the crate, is most often used when arranging a roof that has an ondulin or metal tile coating. It is chosen only if the recesses cannot reduce the bearing capacity of the crate in the area of the cornice.

When choosing the third method, it is important to remember the fixation, that only strict observance of the installation rules and installation procedure can ensure the reliability and durability of the structure.

Gutter Installation Technology

Installation of equipment for gutters is carried out after the completion of the facing work. In how to prepare and install the drain, there is nothing complicated. Installation of a PVC system can be performed even by a novice master.

The assembly and installation of the drainage system includes a number of standard steps:

After installing and fixing the gutters, drainage funnels are installed in the lowest points of the drainage system, to which drain pipes are connected:

Installation of horizontal elements

A set of tools that will be needed during the work:

- marking cord;

- tape measure not less than 3 meters long;

- hacksaw for metal;

- universal screwdriver;

- hammer;

- flat bend;

- pipe tongs.

Some craftsmen are cutting metal gutters and pipes using a grinder. But this is far from the best solution, since a rotating disk heats the polymer coating during operation. And this can cause damage to the drainage elements during operation.

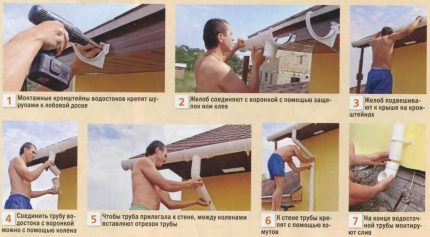

The installation of the brackets begins with the installation of the extreme elements. Then the distance between the drainpipes is divided into equal intervals of 60-80 cm long for the installation of the remaining hooks.

To simplify your task, ensuring a uniform slope of the gutters in the direction of the water intake funnels, it is better to pull the cord when marking. The boundary values of the slope are from 2 to 5 mm per linear meter. To increase the accuracy of the installation, it is better to identify several key lines by pulling a string in two or three rows for this.

During the installation of the brackets, the slope is achieved by shifting the short fasteners vertically or by bending the metal holders in the calculated place.

In order not to disturb galvanization and not damage the polymer coating, a special device is used to bend the fasteners - a pliers.

The collection of the drainage system can be performed in one of two ways:

- Lay out all the elements on the ground in a horizontal position, and then insert the assembled structure into the brackets fixed around the perimeter of the building. This method is applicable for small houses and small areas of decoration.

- The traditional version involves the phased assembly of all elements of the system directly on the building.

Installation of the gutter should be done in a “top to bottom” order: first, water inlets are installed, then the gutters are connected. This is dictated by the technological features of the drainage system.

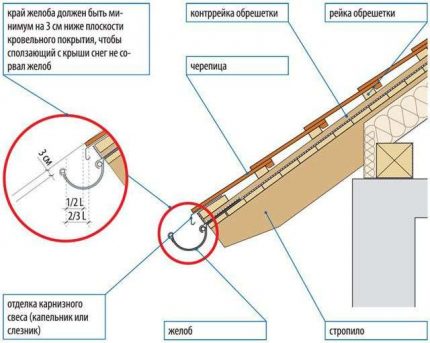

Before attaching the gutters to parts of the roof, funnels are first mounted, not forgetting to take into account possible temperature expansion. Then the gutters are installed, placing them 2 cm below the line, which conditionally acts as a continuation of the overhang. They are released in segments of 3-4 meters long. Gutters that occupy extreme positions in the line will most likely have to be cut.

When installing the gutters, it is worth remembering that they must be at least a third covered by the eaves overhang. Ideally, the overlap should be half its own diameter.

The gutter line ends with a pivoting element, connector or plug. When joining the elements, an adhesive layer of 5 mm thickness is applied to the inner surface.

An important point: the gutters made of polyvinyl chloride can not be joined in focus. This can cause cracking and damage to the structure.

Arrangement of a drain and drainpipes

To go from the funnel to the drain, use two knees and one straight section. For roofs with narrow cornices, the transition is collected by connecting only the upper and lower knees. The distance of the lower knee to the wall of the building is usually determined by the manufacturer.

The assembly of the gutter riser begins with the installation of a funnel, in the direction of which the slope of the gutters must be formed for spontaneous rainwater runoff:

Funnel - the starting element of the gutter riser, to which it is connected. To connect at the top, two angular bends are used, which can be connected to each other if the roof has a narrow ledge, or connected using a pipe segment if the ledge is wide. Further:

Installation of drains should not cause special difficulties. Four-meter segments are easily joined together using couplings. Connect parts moving from top to bottom. A drain is attached to the lower end of the pipe with glue.

If you want to collect rainwater in a storage tank for use for economic purposes, connect to the drain pipe water collector:

If the site is equipped storm system, the task is simplified - the drainpipe is simply taken out to a collection well, or placed 5-10 cm from the surface of the tray.

For the possibility of fixing the gutter riser mark the location of the clamps. The lowest point should be located directly above the drain. The riser clamps are not tightened so that the pipe at the moment of linear expansion can slightly move up or down.

In order for water to flow freely from the roof in the cold season, the gutters are equipped with a heating system. And how to do it, read in this stuff.

Conclusions and useful video on the topic

The advice of professional installers is always useful if you want to do it yourself install a drainage system on the roof.

Tips for organizing drainage:

An example of assembly and fastening of elements:

Design and install a drain using a modern modular system under the power of any owner. The main thing is to have minimal construction skills and not be afraid of heights.

Have questions about the topic of the article? Found bugs or is there valuable information that you can share with visitors to our site? Please leave comments in the block below.

Installation of a gutter system: the main stages of self-installation of gutters

Installation of a gutter system: the main stages of self-installation of gutters  Do-it-yourself installation of metal gutters for the roof: technology analysis + installation example

Do-it-yourself installation of metal gutters for the roof: technology analysis + installation example  Gutter heating: do-it-yourself installation of a roof and gutter heating system

Gutter heating: do-it-yourself installation of a roof and gutter heating system  Roof spill systems: existing types of systems and their arrangement + calculation and installation steps

Roof spill systems: existing types of systems and their arrangement + calculation and installation steps  Sewer cleaning cable: types of tools and how to use them correctly

Sewer cleaning cable: types of tools and how to use them correctly  How to mount a fan pipe: step-by-step instruction and analysis of common mistakes

How to mount a fan pipe: step-by-step instruction and analysis of common mistakes  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Helpful information! I live in a house divided into two owners: that is, on the one hand, my family, and on the other hand, the other owners. So the neighbor, the slippery type, installed the drainpipe incorrectly and everything merges under the porch. And since it is wooden, there is already something beginning to rot there. It will be necessary for him to throw off the link, let him look. But my masters did everything, there you can’t find fault.

Build your house. Hired workers. The construction is almost completed, and here the husband decided to save) He said that he would install the gutters and attach it to the roof himself. Our roof is broken, two-tier, so it became necessary to install the gutters on the ledge of each pitched plane. As the material selected aluminum. They thought it was easy, it turned out that it was better to entrust the construction to experienced roofers. After installing the gutter, her husband’s hands wet the facade of the house on one side, and rainwater poured directly from the drainpipe onto the foundation and porch. Redid. Now everything is fine!