Gutter heating: do-it-yourself installation of a roof and gutter heating system

In early spring and late autumn, all homeowners are faced with the problem of freezing roof slopes and freezing inside the gutters of melt water. If it is not resolved in a timely manner, the safety of people, as well as the safety of their property, will be threatened by large icicles and frozen clods of snow falling from the roof.

A good solution is the heating of the gutters, which will prevent the formation of ice. In this material we will talk about why you need to equip the drainage system with heating. We will also talk about what materials will be required for this and describe in detail the essence of the process.

The content of the article:

Is it worth it to warm the drain?

In the winter months, frost and heavy rainfall prevail in most regions of our country. As a result, large masses of snow accumulate on the roof. An increase in temperature provokes their first thawing, and later active melting.

During the day, the melted water escapes to the edges of the roof and into the gutters. At night, it freezes, which leads to the gradual destruction of the elements of the roof and gutters.

Icicles and conglomerate from frozen snow and ice accumulate on the edges of the roof. From time to time they fall down, threatening the safety of the people below and their property, the integrity of the drainage system and decoration elements of the facade.

All these troubles can be prevented only by ensuring unhindered drainage of melted water. This is possible only if the edges of the roof are heated and gutter system.

It happens that in order to reduce the cost of the heating system, it is laid only on the roof surface.The owner is fully confident that this will be enough.

However, it is not. Water will flow into gutters and pipes, where it will freeze at the end of the day, since there is no heating there. Drains will be clogged with ice, so they will not be able to take melt water. In addition, there is a danger of mechanical damage.

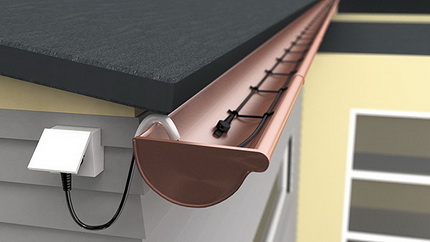

Thus, in order to get a good result, it is necessary to equip the heating of the roof and the gutters surrounding it. In most cases, the heating cable is mounted on the roof cornices, inside the gutters of the drain and in the funnels, at the joints of the roof fragments, along the lines of the valleys.

In addition, heating must be present along the entire length of the drainpipes, in the water collectors and drainage trays.

Features of arranging a heating system

Methods of heating roofs of different types may vary. We are talking about the so-called "cold" and "warm" roofs. We will analyze the features of each option.

Cold Roof Heating

This is the name of the roof without insulation along the slopes with good ventilation. Most often, such roofs are located above non-residential attic rooms. They do not let heat out, so the snow cover on them does not thaw throughout the winter.

For such structures, a gutter heating installation will suffice. The linear power of the laid cable should gradually increase. Start with 20-30 watts per meter and finish 60-70 watts for each meter of the drain.

How to warm a warm roof?

A roof with thermal insulation is considered warm. They let heat out, so that even at low temperatures on the surface of a warm roof, the snow cover can thaw. The resulting water flows onto the cold fragments of the roof and freezes, and ice forms. For this reason, it is necessary to equip the heating of the edge of the roof.

It is implemented as heating sections laid along the edge of the roof. They are put in the form of loops 0.3-0.5 m wide.In this case, the specific power of the resulting heating system should be from 200 to 250 W per square meter. Arrangement of heating gutters is implemented similarly to that used for cold roofing.

Gutter heating system device

For heating the roof and gutters, the system with a heating cable is most often used. Consider its main elements.

Distribution block and sensors

The distribution block is designed for switching power (cold) and heating cables.

The node consists of elements:

- signal cable that connects the sensors to the control unit;

- power cable;

- special couplings used to ensure the tightness of the system;

- mounting box.

The unit can be installed directly on the roof, therefore it must be well protected from moisture.

Three types of detectors can be used in the system: water, precipitation, and temperature. They are located on the roof, in gutters and drains. Their main task is to collect information for automatic heating control.

The collected data goes to the controller, which analyzes it, decides to turn off / on the equipment and selects the optimal mode of operation.

Controller and control panel

The controller is the brain of the entire system responsible for its operation. In the most simplified version, this may be some kind of thermoregulatory device. In this case, the minimum operating range of the device should be in the range from +3 to -8 degrees C. In this case, the control and switching of the system cannot be fully automated, human intervention will be required.

A more convenient option for use is the use of a sophisticated electronic control device with the possibility of programming. Such equipment is able to independently control the process of precipitation melting, their amount, monitor the temperature.

The controller quickly responds to ongoing changes and makes optimal decisions by choosing the best operating mode for heating equipment in existing conditions.

The control panel is designed to control the entire system and ensure safety during its operation.

To equip a node, the following elements are usually used:

- three-phase input automatic machine;

- RCD (it is also a residual current device);

- four-pole contactor;

- signal lamp.

In addition, it will be necessary to supply single-pole circuit breakers for each phase, as well as thermostat circuit protection.

In addition, during the installation process you will need parts for fastening: roofing nails, screws, rivets. You will need shrink tubes and a special mounting tape.

How to choose a heating cable?

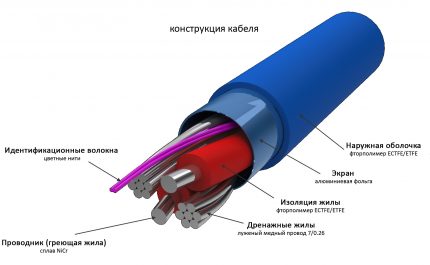

Perhaps the most important element of the system is the heating cable. In practice, choose between two types of devices: self-regulating and resistive cable. Consider all the pros and cons of using both options.

Features of resistive cable

It is characterized by the simplicity of the principle of operation. Inside such a cable is a metal conductive core with high resistance. When electricity is supplied, it begins to warm up quickly and gives off heat to the heated object. The resistive cable system is very easy to use and does not cost much.

The main advantages of using this type of cable are the absence of starting currents at startup, the low cost of the resistive wire and the presence of constant power.

The last statement can be classified as controversial.Since in some cases, constant power will be rather a disadvantage. This will happen if parts of the system need different amounts of heat. Some of them may overheat, while the rest, on the contrary, will receive less heat.

To regulate the degree of heating of a system with a resistive cable, temperature controllers or other devices are necessarily used.

The effectiveness and efficiency of the functioning of such a system depends on the correctness of their settings, so the reality is often far from desired. In this, the resistive cable is significantly inferior to the self-regulating one.

If possible, experts recommend laying a zone resistive cable. This variety is distinguished by the presence of a heating thread of nichrome. Its linear power does not depend on size; if necessary, the cable can be cut.

Also, the advantages of the heating cable include the ease of installation and long-term operation.

The cable is self-regulating and the nuances of its work

It features a more complex device. Inside such a cable there are two heating conductors, around which there is a special matrix. It “tunes” the cable resistance depending on what the ambient temperature is. The higher it is, the less the cable heats up, and vice versa, the colder it is around, the better it heats up.

The self-regulating cable has many advantages. First of all, for its normal operation, installation of a set of control devices: detectors and temperature controllers is not required. The system will configure itself, and overheating or insufficient heating, as can happen with a resistive cable, will not happen.

Self-regulating wire can be cut. The minimum length of the segment is 20 cm, its operational characteristics will not change from the length. During the installation process, if necessary, the cables can be crossed and even twisted, they will work in normal mode. Installation and operation of the self-regulating cable is very simple. It can be mounted outside or inside a heated object.

The system also has disadvantages. First of all, this is the cost. Self-regulating cable costs about 2-3 times more expensive than resistive. It should be borne in mind that it will be cheaper to operate. Another minus is the gradual aging of the self-regulating matrix, as a result of which the self-regulating cable fails over time.

Read more about the features of choosing a self-regulating cable read Further.

Calculation of the heating system

Experts advise choosing cables with a power of at least 25-30 W per meter for the heating system of the roof and gutters. You need to know that heating cables of both types are used for other purposes. For arranging warm floors, for example, but their power is much lower.

Power consumption is evaluated in active mode. This is the period when the system is operating at maximum load. It lasts in total from 11 to 33% of the entire period of cold weather, which conditionally lasts from mid-November to mid-March. These are average values, for each area they are different. System power needs to be calculated.

To determine it, you need to know the parameters of the drainage system.

We give an example of calculations for a standard design with a cross section of a vertical drain of 80-100 mm, the diameter of the chimney pipe is 120-150 mm.

- It is necessary to accurately measure the lengths of all the gutters for water flow and add up the resulting values.

- The result must be multiplied by two. This is the length of the cable that will be laid along the horizontal section of the heating system.

- The length of all vertical drains is measured. The obtained values add up.

- The length of the vertical section of the system is equal to the total length of the drains, since in this case one cable line will be enough.

- The calculated lengths of both sections of the heating system add up.

- The result is multiplied by 25. As a result, the power of electric heating in the active mode is obtained.

Such calculations are considered approximate. More precisely, everything can be calculated if you use a special calculator on one of the Internet sites. If independent calculations are difficult, it is worth inviting a specialist.

Choosing a place for cable laying

Actually, the heating system for drains is not so complicated, however, in order to work as efficiently as possible, you should lay the cable in all areas where ice forms and in places where the melted snow has melted.

In roofing valleys, the cable is mounted up and down, with a length of two-thirds of the valley. Minimum - 1 m from the beginning of the overhang. For each square meter of valley there should be 250-300 watts of power.

On the edge of the cornice, the wire is laid in the form of a snake. The snake pitch for soft roofs is 35-40 cm, on hard roofs it is made a multiple of the pattern. The length of the loops is chosen so that no cold zones appear on the heated surface, otherwise ice will form here. The cable is laid on the drip line. It can be 1-3 threads, the choice is based on the design of the system.

The heating cable is mounted inside the gutters. Usually two threads are laid here, the power is selected depending on the diameter of the gutter. Inside the gutters, one heating core is laid. Particular attention should be given to pipe outlets and funnels. Usually, additional heating is required here.

Heating system technology

We propose to study the detailed instructions for installing the roof heating system and gutters with your own hands. The process of installing a heating system for gutters includes a number of standard steps:

To begin, we outline the places where the cable will be laid. It is important to take into account all the turns and their complexity. If the angle of rotation is too steep, it is recommended to cut the cable into parts of the required length and then connect them using couplings.

When marking, carefully inspect the base. There should be no sharp ledges or corners, otherwise the integrity of the cable will be in jeopardy.

Inside the gutters, the cable is fixed with a special mounting tape. It is fixed across the wire. It is advisable to choose the tape as strong as possible.

The resistive cable is fixed with a tape every 0.25 m, self-regulating - after 0.5 m. Each strip of tape is additionally fixed with rivets. Places of their installation are treated with sealant.

Inside the gutters, the same mounting tape or heat shrink sleeve is used to secure the cable. For parts whose length exceeds 6 m, an additional metal cable is used. A cable is attached to it to remove the bearing load from the latter.

Inside the funnel, the heating cable is attached to the tape and rivets. On the roof - on a mounting tape glued to sealant, or on a mounting foam.

Important notice from experts. It may seem that the adhesion of the roofing material to the sealant or foam is not sufficient for a reliable connection. However, it is absolutely impossible to perform holes for rivets on the roofing material. Over time, this will inevitably lead to leaks, and the roof will become unusable.

We select a place for the junction boxes and install them. Then we call and accurately measure the insulation resistance of all the resulting sections. We put the thermostat sensors in place, put the power and signal wires. Each sensor is a small device with a wire, the length of the latter can be adjusted. Detectors are placed in strictly defined places.

For example, a place on the roof of a house is selected for a snow sensor, and a water detector is selected at the bottom point of the gutter. All work is carried out according to the manufacturer's instructions. We connect the detectors to the controller. If the building is large, the sensors can be combined into groups, which are subsequently connected in turn to a common controller.

Next, we prepare the place where the automatic control system will be installed. Most often this is a distribution panel located inside the building. The controller and protective group are installed here.

Depending on the type of controller, the nuances of its installation may vary slightly. However, in any case, it will have terminals for connecting detectors, heating cables and for supplying power.

We establish a protective group, after which we measure the resistance of the previously mounted cables. Now you need to test the automatic protective shutdown to find out how well it copes with its functions.

If everything is in order, we program the thermostat and start the system.

Typical system installation errors

Experienced installers highlight the typical mistakes that are often made by those who first set their own heating gutters:

- Design Errors. The most common is ignoring the features of a particular roof. When designing, one does not pay attention to cold edges, warm areas, spillway zones, etc. As a result, ice continues to form in some areas of the roof.

- Errors in fixing the heating cable: a movable wire “hanging” on the mounting tape, holes in the roof for fasteners, the use of a tape that is designed to install a warm floor on the roof.

- Installation of plastic clamps for internal use as fasteners. Under the influence of ultraviolet light, they will become brittle and will collapse in less than a year.

- Suspension of a heating cable into a drain without additional fastening on a cable. Causes wire breakage due to temperature expansions and ice severity.

- Installation of power cables that are not intended for installation on the roof. As a result, a breakdown of insulation occurs, which threatens with electric shock.

Errors include connection heating cable in areas where its use is not required. His work will be useless, and the owner will have to pay for it.

Conclusions and useful video on the topic

Interesting information about heating cables and useful tips for their installation are presented in the following videos.

Features of the self-regulating heating cable:

How to assemble the gutter heating system yourself:

Installation of a heating system for an industrial assembly:

Practice shows that in cold weather it is necessary to heat gutters. This makes it possible to get rid of ice and guarantees protection against sudden snow melting. You can arrange such a system yourself.

The most difficult thing is to calculate it and select the areas where you want to lay the heating cable. This part of the work can be entrusted to professionals. Having received the calculations and the project, the subsequent installation is easy to implement independently.

Do you want to ask a question about arranging the heating of a drain? Please write it in the box below. Here you have the opportunity to report on interesting facts on the topic of the article or share your own experience in arranging the heating of the drain.

Do-it-yourself installation of metal gutters for the roof: technology analysis + installation example

Do-it-yourself installation of metal gutters for the roof: technology analysis + installation example  Installation of a gutter system: the main stages of self-installation of gutters

Installation of a gutter system: the main stages of self-installation of gutters  Roof spill systems: existing types of systems and their arrangement + calculation and installation steps

Roof spill systems: existing types of systems and their arrangement + calculation and installation steps  How to make a blind area around the house with your own hands: rules and methods for arranging the ebb system

How to make a blind area around the house with your own hands: rules and methods for arranging the ebb system  Installation of gutters: how to properly install the gutter and attach it to the roof

Installation of gutters: how to properly install the gutter and attach it to the roof  Do-it-yourself sewerage in an apartment: rules for internal wiring and installation

Do-it-yourself sewerage in an apartment: rules for internal wiring and installation  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

At one time this topic was interesting. Even at some point I began to do, but problems arose. Living creatures took a bite of the wire, and immediately the desire was gone. Still, for your own home, the thing is not so relevant. For all winters I didn’t have much ice on the drain, mainly when spring came. A month to tolerate and everything is fine. I think it’s better to do for large buildings, it’s just right for them.

When erecting a new roof, he provided for heating the roof surface to avoid icicles and property damage. But, as it turned out, I did not fully think out the system and did not conduct heating in the gutters. As a result, the melted water drained into the gutters and iced there. Last summer I corrected the situation, this year I hope for a different result. I used a resistive cable for heating.