How a cesspool with overflow is arranged: schemes and construction technology

An independent sewage treatment plant in a suburban area will allow the correct way to solve the problem of waste disposal. It is relevant for settlements that are not connected to central networks. If the connection is not planned in the coming years, then a cesspool with overflow will be the best solution. The beneficial benefit of civilization will serve as an urban option. Is it comfortable, agree?

You will learn how to make a treatment plant with overflow by reading our article. It thoroughly disassembled options for the construction of systems, described the technology of construction. The advantages that an autonomous sewer system will provide are listed.

The information presented on the specifics of the construction of overflow cesspools and the features of their operation is based on regulatory documents and the experience of independent builders. A weighty and valuable addition to the text are useful photo compilations, diagrams, and video guides.

The content of the article:

The principle of operation and device

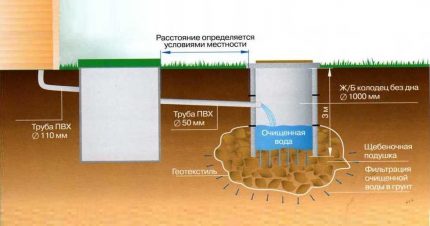

The design of a simple cesspool with an overflow well includes two objects interconnected by a pipe segment.

The first is a large hermetic container constructed according to the principle of a storage tank with impermeable walls and a bottom.

The second part of the structure is arranged exactly the same as the filter version of the sewer well. This means that it does not have an impenetrable monolithic bottom. Instead of a continuous concrete slab, a kind of filter with a capacity of 1 m or more is constructed in the zone of the conditional bottom.

The filter is made in the form of filling from materials with high filtration properties: crushed stone, slag, gravel and / or sand.

The walls can be made solid and with openings to increase the rate of removal of recycled effluents from the filtering well, otherwise called absorption.

Connect the cesspool and filter well overflow - a pipe located at an angle to the side of the absorber. Its depth depends on the climatic data of the region, i.e. like any overflow laid in the ground, the pipeline should be below the level of seasonal freezing of the soil.

A sewer pipe is brought to the drive, through which waste water will flow from the internal sewage system to the storage tank.

Over the cesspool arrange overlap with a hatch designed to pump out the contents. The ventilation pipe is mounted so that the lower edge is higher than the drain horizon at any degree of filling. The second end of the pipe is brought to the surface.

For a cesspool with one filtering well, only one ventilation duct can be built, but it is better to equip each compartment of the simplest treatment plant with its own ventilation.

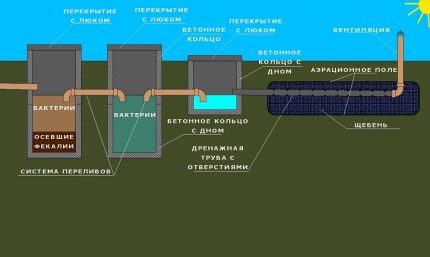

This design allows you to make the waste treatment process more efficient and faster. First, all waste enters the first pressurized chamber. Here they accumulate and decompose under the influence of bacteria. Gradually, there is more waste, the liquid level in the chamber rises and reaches overflow.

The insoluble part of the effluent settles at the bottom, and partially clarified with the participation of bacteria and the settled liquid component reaches the level of overflow installation as it is filled and by gravity moves to the absorption well, in which the sewage system is refined.

In the filtering well, the effluent passes through the drainage layer and enters the soil, again being further cleaned through a natural earthen filter. And solid waste in the form of silty sediments accumulate in the sealed compartment of the cesspool, from which it is subsequently extracted and, if desired, the hosts are used as source material for composting.

Why do we need such difficulties, because it is easier to pump out the sewer mass from the cesspool and thus get rid of it? The presence of two containers significantly increases the size of the sewage system, part of the effluent, after passing through natural cleaning, is transferred to the ground, due to which the number of calls of sewage trucks is significantly reduced.

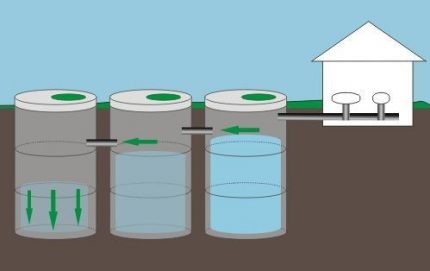

With an increase in the number of overflow wells, the scheme is somewhat more complicated. However, this increases the period from the receipt of waste in the tank to the movement of the liquid component into the soil. This improves the quality of wastewater treatment and makes them safer for the environment.

Practice shows that a sewage treatment plant of two or more wells emits significantly less unpleasant odors than the usual version of this kind of design. Usually there are no odors or they are insignificant. Improve the situation with the processing of sewer mass and the elimination of odors will help use of special bacteria.

The unpleasant squishing sounds that a crowded cesspool makes are absent in the overflow design. Owners of such a structure usually do not have to save sewer resources.They can safely use the water without worrying about overfilling their sewers.

Figures and basic standards

Before starting construction work, you should choose a suitable place for the pit with overflow. Standards for the remoteness of the structure from other objects on the site are approximately the same as for regular cesspoolbecause the problem of groundwater pollution is still relevant.

You should also consider the characteristics of the soil on the site. The higher the permeability of the soil, the greater should be the distance separatingtwo-chamber cesspool from other buildings.

Depending on the type of soil, it is recommended to locate the sewage system at a distance from the apartment building:

- not less than 15 m - for sandy, crushed, pebble and gravel soils;

- not less than 10 meters - for sandy loam.

Sink pits with an overflow effect are arranged only on soils with high filtration qualities. If the base of the absorption facility is supposed to be clay, rock or semi-rock, the construction of a treatment plant of a similar design will have to be abandoned.

A solid should be the space separating the source of drinking water and the sewer:

- not less than 50 m - for sand;

- not less than 30 meters - for sandy loam.

Since the creation of a structure consisting of two chambers takes more time and effort than with the construction of a conventional cesspool, it makes no sense to make the construction of a small volume. The minimum recommended structural capacity is 2 cubic meters. meter. Such parameters provide sewage throughput in the range of 0.2-0.5 cubic meters. m / h

When designing a structure, it is also recommended to consider some parameters. For example, the optimal distance between the cells of the cesspool is one meter. Although there are structures in which the cameras are separated simply by a thick wall. In this adjacent wall, a hole for overflow is arranged. But this option is considered less effective.

It is recommended that the overflow be given a slope standard for sewer pipelines in order to facilitate the movement of liquid effluents into the filter well. The sewer pipe leading from the house is placed at a similar slope - 1.5 cm of height for each meter of pipe is enough.

If the sewage system is arranged correctly, there will not be any problems with it. Nevertheless, it is recommended to regularly check the filling level of the structure. If filters are installed inside the structure, their condition should be monitored at least once a month.

Options for the construction of treatment facilities

When choosing a place for a cesspool, it is necessary to provide access roads for special equipment. If this is not possible, during the installation of the sewage system, it will be necessary to manually carry out bulk excavation work to dig the pit. It may turn out to be even more complicated and quite unpleasant manual cleaning procedure drive from the waste of human life.

A variety of tools can be used to make a two-chamber cesspool. Of course, it is important that they ensure tightness to the first compartment of the structure and permeability to the second. The most common version of such structures is concrete ring rake.

In the first chamber, the bottom is concreted, or a concrete slab is laid down; in the second chamber, the bottom is covered with a meter-long layer of filter material: crushed stone, gravel and / or sand.Suitable for the construction of a cesspool and brick. The bottom of the sealed brick compartment should also be concreted. On this basis, brickwork is performed.

The bottom of the second section of the cesspool is left free and, as with concrete rings, is covered with gravel or gravel. Actually, such a filter layer is used in any variant of the permeable section of the cesspool. Brickwork here can be done with gaps to make the walls permeable. This will reduce brick consumption and uptime.

Another way to equip a sealed cesspool is to pour concrete. To do this, you need to make the crate and strengthen the walls of the structure with the help of reinforcement. This is a rather time-consuming and costly method, it is used infrequently.

The possibilities of creating a filtering part of a cesspool are more diverse. Here you can install perforated plastic container or even do used tire pit. Some used for the construction of both compartments large galvanized containers installed in the pit at a distance from each other.

Using improvised materials to create a sewage system, it should be remembered that they must be in contact with a humid and aggressive environment for a long time. Only those materials that are resistant to such conditions can be considered acceptable.

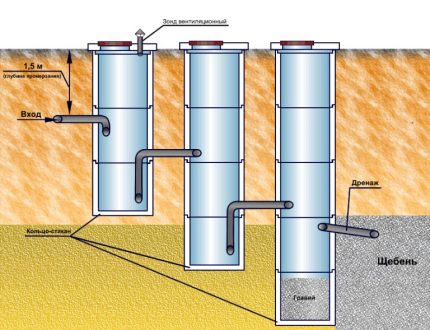

Three-chamber design

If the dimensions of the suburban possessions allow, it is better to make not two, but three overflow wells for the treatment of effluents from one cesspool. All these departments, of course, are connected by overflow. At the same time, the distance between the chambers can be made smaller - only 70 cm. It is recommended that the size of each chamber, for example, the diameter of concrete rings, be at least one meter.

The first two wells are designed for wastewater treatment, and the last is for filtering the last two degrees of purification of the liquid component of the sewer. Its bottom and / or walls are permeable, as in the construction of a two-chamber sewer.

The treated effluents can be redistributed not only to the underlying layers, but also discharged into sewer ditches or non-operational reservoirs. Sewage from the treatment plant can be transported to the filtration fields through drains - pipes with openings for the release of the refined liquid component.

Drains are laid in sedimentary incoherent soils of different densities, preferably without loam layers. The drainage system is constructed at a depth, the mark of which is below the level of freezing of the soil by the actual thickness of the pipe. Drains are wrapped with a layer of geotextile, and then covered with gravel or sand gravel.

The presence of three chambers increases the volume of sewage and significantly improves the treatment of effluents. The liquid obtained at the outlet can be used for various technical needs, usually for irrigation.

Stages of building a monolithic system

Those who wish to fill monolithic concrete septic tank They will significantly save on costs, but they will build much longer than those who decide to purchase ready-made concrete rings. Briefly about the process of the device in the photo selection:

Installation procedure for a two-chamber pit

Work on the construction of a two-chamber sewage system begins with marking. It is necessary to determine the location and configuration of both pits. You can dig one large pit, install containers in it, and then fill up the space between them with soil, but usually this only increases the cost and time of construction work.

Usually they dig a pit using an excavator. If you decide to dig manually, use a shovel and a bucket on a rope, with which they take out the earth. When using concrete rings, digging a pit can be done as follows: first, a ring is installed in the right place, then they begin to dig inside, gradually undermining the soil under the walls of the ring.

Gradually, the ring will descend down the cylindrical shaft.This method is especially appropriate on light soils, as it prevents the walls of the pit from shedding. In all other cases, it is recommended that the walls of the pit be given a slight slope so that they do not crumble and collapse.

After the pits are dug, you need to equip the bottom, i.e. pour it with concrete screed. Crushed stone is added to the solution to make the bottom more solid. If concrete rings are already laid, then concreting is performed inside the circle.

If it is decided to use a plastic container as an airtight chamber, the base is concreted for its installation. The container is lowered into the foundation pit on a frozen concrete slab and gently filled with earth.

As you backfill inside the tank, it is recommended to gradually pour water so that a large amount of soil does not crush the structure. Water will balance internal and external pressure.

In the second chamber, as already mentioned, instead of a concrete mortar, a layer of filter material is poured. The technology for erecting this part of the structure is practically no different from the construction of a conventional absorption sewer well and depends on the type of material: brick, tires, wood, etc.

Now it is necessary to bring a sewer pipe to the first chamber of the pit, as well as to install an overflow. The pipe is placed in a trench so that it is below the level of freezing of the soil.

As an additional protection against freezing, it is recommended to use insulating materials.

Overflow is also set with a slope. It is made from a piece of plastic pipe with a diameter of 100 mm. The overflow is set so that the parts of the pipe protrude into the containers.

On them, you can install perpendicular vertical sections of the same pipe to improve the sewage system.

At the same stage, strainers are installed, which, as mentioned above, must be regularly inspected and, if necessary, cleaned. However, pits with overflow in the form of a simple pipe segment also function quite successfully.

If water drainage through an additional drainage is provided from the filtering well, this pipe should also be laid in the ground on a crushed stone layer. Both cesspool chambers must be tightly closed. Often, concrete slabs with round or square holes for maintenance are used for this.

The holes are closed with special covers, produced for the arrangement of sewage. Now you need to solve the issue of ventilation. For a traditional accumulative-type cesspool, it is mandatory in order to divert a significant part of fetid gases from the tank.

The method for removing methane gases generated during the processing of effluents depends on the type involved in the construction of bacteria. Some of them are already present in the sewage due to natural reasons, but the processing process is much more effective if special bacterial preparations are added to the accumulation department of the sewer construction.

There are aerobic and anaerobic microorganisms. The former need a constant influx of fresh air, i.e.they function only in the presence of oxygen. Anaerobic bacteria do not need access to air. It is such microorganisms that can carry out the process of processing wastewater in a sealed container.

If it is nevertheless necessary to provide the sewage system with ventilation, a special hole is made in the compartment lid for its arrangement. A pipe with a diameter of about 100 mm should be installed in it. The top of the pipe is closed with a special conical cap to prevent precipitation from entering the cesspool.

The process of creating a cesspool consisting of three compartments is not much different from the technology described above. Just instead of two wells make three. Accordingly, three pits will be needed, and not two. Both first compartments are sealed and the last compartment is left permeable.

Issued industrial septic tanks also work on the principle of multi-stage wastewater treatment using microorganisms. But they are considered more efficient, productive, and at the output they allow to obtain a significant amount of purified liquid suitable for technical use.

Installation of a septic tank is carried out by specialists and takes relatively little time. But given the cost of the structure, it should be supplemented by payment for the installation services of the structure in order to have a complete picture.

Conclusions and useful video on the topic

The quick installation diagram of the cesspool is clearly presented in the following video:

A cesspool with overflow is, of course, a more modern and convenient option for a conventional cesspool. Of course, the creation of a two-chamber or even three-chamber structure requires more material costs, time and effort. But all this will more than pay off in the future, when the residents of the house will feel the effect of using a reliable sewer that requires minimal maintenance.

If you have experience in constructing cesspools with overflow or have already encountered this issue and have something to share with our readers, please leave your questions or valuable tips in the comments below.

How a cesspool is constructed without a bottom: schemes and arrangement rules

How a cesspool is constructed without a bottom: schemes and arrangement rules  How to construct a cesspool of concrete rings: schemes + step-by-step guide

How to construct a cesspool of concrete rings: schemes + step-by-step guide  How a cesspool is constructed in a private house: a review of structures + rules for their arrangement

How a cesspool is constructed in a private house: a review of structures + rules for their arrangement  Barrel pit: step-by-step master-class on arrangement

Barrel pit: step-by-step master-class on arrangement  How to build a cesspool of tires: step-by-step technology of self-construction

How to build a cesspool of tires: step-by-step technology of self-construction  Do-it-yourself cesspool: analysis of popular options for arranging

Do-it-yourself cesspool: analysis of popular options for arranging  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Hello! I appeal to those who have already managed to successfully independently make a cesspool with overflow. I plan to start building it on a summer cottage, but I'm afraid that it will fly a pretty penny. How much money can be spent on the necessary materials and the work itself? P.S. Timing is not compressed.

Basil, in general, your question, unfortunately, has no answer, since you have not indicated what materials you want to use, depth and so on.

I can tell you how to save money on the example of my friend. The septic tank cost "turnkey" 40 thousand. The local tractor driver was digging for them and he also found a manipulator, to go for the rings purchased under the ad. Again, other materials, pipes, they bought there. The result is 20 thousand. But regionally, prices for everything sometimes differ very much.

But, again, it’s possible to dig a hole itself, a trench ... You can throw wheels, a plastic container. Then it’s true, five thousand - it will be budgetary.My friends simply did it thoroughly, for a large family, and for a permanent, and not country, as you use.

You can meet two thousand rubles, from which you will need to buy a cylindrical metal container with a diameter of 1.5 meters and a depth of 2.5 meters and a plastic pipe - drain. In the container, it is necessary to make a lot of holes in the grinder for leaking fluid into the soil, and throw rubble into the bottom of a 2x2 meter pit almost to the bottom, and a pebble or stone from the top - a boot, the second pit will never be filled. This type of sewage system itself: I pump it out every 7 years, only from the first hole!

Hello. Not always relevant. If the groundwater level throughout the site is high, as, for example, in our country house, the filling of the second pit will be frequent seasonally, and pebbles will prevent the pump from being used.

Last year, it was necessary to expand the cesspool. For a long time I had to suffer, as everything was done manually and from improvised materials. I dug a hole, in the construction of the chamber I used large old tires. The maximum of problems was that the pit was digging about 7 meters from the existing one, since there was no place. And the main difficulty was connecting the pipe. It was not easy, but still coped with the task.

Is there not much 7m for overflow? I have a similar problem, I am considering an overflow option, but the distance from the existing pit (old) will also be about 7-8m, is it not much?

Good day, Sergey. No it's a bit. The distance is determined based on the terrain. The main thing is to withstand the slope, see Figure 1. Pay attention to the change in parameters depending on the diameter of the pipes.

Since the distance is planned to be rather big, you should not neglect the standards. Too strong a slope can lead to blockages, because the water flow will move at a faster speed, not having time to entrain the feces / large waste washed into the sewer.

The exit point of the pipe from the first tank will most likely be above the freezing point of the soil, so it is advisable to insulate at least the first 4 meters.

Do not forget also about the preparation of the sand cushion under the pipe along its entire length.

Hello. In general, it is desirable that the distance be minimum from 0.5 m. Since the drains, containing fat and other substances in their composition, can settle on the walls of pipes, which will not be easy to clean. In addition, a more thorough insulation of the pipe will be required, freezing in winter time with a small drain of water is not excluded. But if space does not allow anything, there is nothing to be done.

Hello! Tell me, on some schemes I saw this ... Why do they arrange overflow at the bottom of two or three chamber septic tanks? It’s clear from above, but why below?

Dinara, I suppose that the overflow in the lower part is done to save on filling silty fecal waste, which, as a rule, settles to the bottom. It turns out that they are poured into another barrel and go to the filter bottom.

Good afternoon, Dinara. Look, any septic tank requires maintenance, but it consists primarily in pumping out silty sediments that accumulate at the bottom.

The overflow in the lower part is designed to increase the usable area, thereby reducing the frequency of sediment pumping. This scheme allows you to less often call the scavenger machine saving your family budget.