Gas and electric boiler in one system: features of the assembly of a parallel circuit

The classic heating scheme with one heat generator is familiar to every owner of the house. However, combining a gas and electric boiler in one system, one can achieve a much greater practical effect. They say that such a connection is much more economical than usual. Sounds tempting, doesn't it?

With logical reasoning, doubts arise: how can electricity save the budget, because its cost is much higher than gas? And why do this from the point of view of the feasibility of strengthening the power of units? Isn’t it easier to get just one productive boiler?

In fact, the project of such a combination is justified. We will tell you in detail how to assemble heating with electric and gas appliances. You will learn about the structure of this system and its feasibility. We will help you to make a diagram and not to miss the important nuances of arranging a combined heating line.

The content of the article:

Why put two boilers at once?

The role of the leader in the “gas + electro” bundle is usually performed by the gas unit. This is logical even if only because of the lower cost of fuel used in the supply. But the word “save” was said above, and it is not clear what the cost reduction is.

The fact is that in many regions there is a tariff for electricity on a day / night system. In some cases, it turns out at least quite a bit, but more economically than paying for gas. The difference is doubtful, however, as an additional reason to the coin box of arguments for a double bond, it may also serve.

Of course, this is not such a good reason to immediately design a heating system with 2 boilers. The main advantages of the circuit are power amplification and uninterrupted operation.When choosing and installing a heat generator, it is necessary to clearly understand that any device and fuel supply are not eternal.

They turn off the power supply, they can block the gas line due to leakage, the voltage will drop in the network or a banal breakdown of the unit itself will occur. In this case, you risk being left without heat and hot water in the cold season.

This is called connecting an additional (to increase power) or backup power supply, depending on the goals and situations.

Ability to implement sharing

Designing a conventional gas-fired heating system is not so simple. That is, creating a workflow is easy, but to get it approved is problematic. Situation with electric boilers less deplorable in terms of costs, time and problems with obtaining approving papers.

And then the union of 2 different-fuel units. It would seem that you won’t end up with problems and will go on instances literally for years, for permits. But this is not so.

In fact, construction standards are quite favorable to such schemes. To be more precise, there are no prohibitions.

Meters for energy and fuel consumption are different. Consumption of resources is not exceeded, an explosive situation is not provoked - install boilers, observing standard standards, installation instructions for each. No problems should arise.

We remind you that the installation of gas boilers should be carried out in accordance with SP 402.1325800.2018 (moreover, this document is mandatory, not advisory).

How to connect 2 boilers in the system?

You can’t just take it and somehow connect 2 devices, the system will either not work, or it will work incorrectly. You must use carefully designed competently designed from an engineering point of view.

There are two main connection schemes, these are:

- Sequentialwhen all elements are connected to each other without additional nodes. In this case, one device will heat the coolant, and the second will heat it;

- Parallel, in which the devices included in the circuit have 2 connection nodes and the boilers operate independently of each other.

The series system is more suitable for low-power boiler plants and is rarely used.

Meanwhile, parallel connection in a single system of gas and electric boilers, has many advantages. Therefore, it is it that is used most often, despite the fact that with this arrangement more materials are required and it is considered more expensive.

In such a device, you can turn off one of the devices at any time and even remove it for replacement or repair, the second will continue to work as usual.

Features of parallel connection

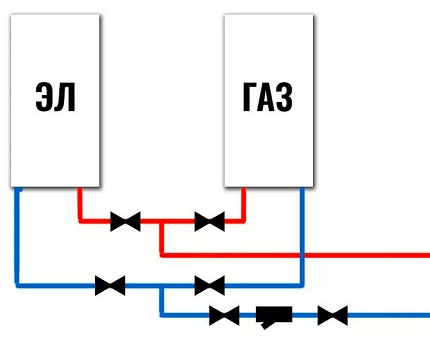

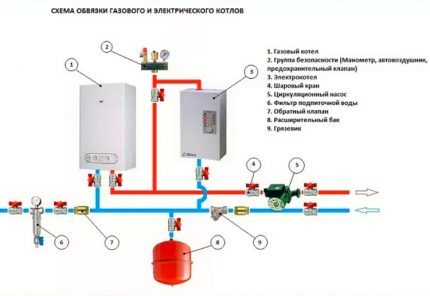

Let us consider in more detail what a standard scheme of parallel connection of gas and electric boilers looks like:

- To each unit are the coolant supply circuits. They join the common line.

- At the same time, it is imperative that safety groups and shut-off valves are installed.

- The circuits of the return lines, also equipped with shut-off valves, are connected to another line.

- On the return line (or on the supply), in front of the unit for combining the strapping loops, it is installed circulation pump.

- The lines of both heating units are connected to collectors.

- On one of the distribution manifolds is installed expansion tank. A make-up circuit is also connected to its pipe, equipped with a non-return valve and shut-off valves.

- From the distribution manifolds there are trunk branches to the underfloor heating, radiators, boiler, circulation pumps and valves for draining the coolant from the system are installed on each.

This is not a circuit diagram, but only its main features. In general, it gives an idea of how best to connect an additional electric boiler to the main gas boiler. The assembly option can be complicated and improved, for example, by an automation system and a servo drive.

Manual start / automatic control options

Management of the boiler backup system or shutdown of failed ones can be carried out manually or in automatic mode. It is not practical to leave the system working with one boiler turned off, as water will continue to circulate.

Imagine what will happen when the cooled return line goes in the opposite direction and begins to mix with the supply, cooling the coolant and forcing the pump to work in vain.

If for some reason you do not want to equip the boilers with complex devices, you will start the unit yourself. That is, everything is standard: you need to turn on the device - turn all the necessary valves and turn it on. When disconnecting, proceed in the reverse order.

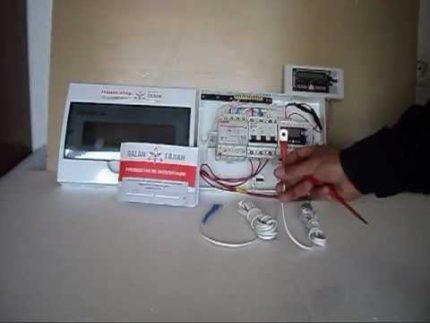

If you want the backup equipment to be launched automatically, the system is equipped with automation, temperature controllers, indoor and outdoor air temperature sensors, coolant temperature sensors, servos.

In the circuit diagram of the automatic backup start of the heating unit, all stopcocks are always in the open position. According to the counter scheme, the system is equipped check valvesto avoid parasitic circulation of the coolant through the boiler that is not working at a certain time.

However, despite the convenience, the system can cause certain problems, for example, the hydraulic resistance of check valves, causing strain on the pumps, pollution and wear of the devices themselves.

To automatically turn on the heating boiler, the system is equipped with a temperature controller, which sends commands to the control unit, depending on the temperature conditions in the house. In case of standby night use, the on-time is set on the timer. Circulation pump shuts off with a magnetic starter.

When choosing the control that will be equipped with an electric boiler installed in parallel with a gas boiler, you should opt for automation if:

- The backup boiler starts at night when it is inconvenient to start manually.

- In case of long departures from home during the heating season.

- If the gas boiler is unreliable.

In other cases, it is quite possible to use the simplest manual scheme.

Hydroarrow in parallel connection system

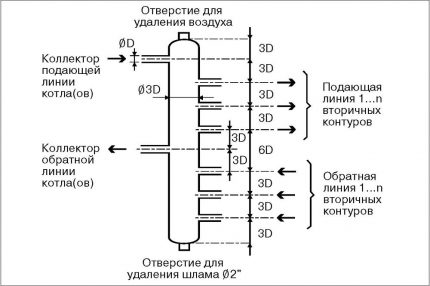

Hydroarrow is a device that provides hydraulic isolation of flows supplied to individual circuits of the heating system. It plays the role of a buffer tank, which receives the flow of coolant heated by the boilers and distributes it among consumers in a branched system.

Often, the volume of coolant required for them varies, the speed of movement of the heated water and its pressure differ. And in the situation under consideration, the movement of heated water from each of the boilers also stimulates its own circulation pump.

When you turn on a powerful pump, the coolant is unevenly distributed along the contours. So, the task water arrows is to equalize this pressure. Due to the fact that there is practically no hydraulic resistance inside it, it will freely accept and distribute the coolant flows from both boilers.

We will figure out whether it is so necessary in a parallel system for connecting 2 boilers, especially since if you buy and install a hydraulic separator using a wizard, rather than with your own hands, the total amount will unpleasantly surprise you.

In the classical wiring diagram, a hydraulic separator is usually not required, since the conflict of 2-3 pumps can be aligned without this device. Accordingly, if you have 2 boilers used exclusively as a backup and there are no more than 3-4 pumps in the system, there is no special need for it.

But if the circuits with forced circulation more or heating boilers operate simultaneously on power - it is best to install this device. Again, it is not known whether you will use the second boiler in constant or only in standby mode, so it is better to play it safe.

Conclusions and useful video on the topic

Synchronization of operation and shutdown of boilers in a parallel installation:

Installation of 2 boilers for heating, gas and electric, a wise decision to strengthen the power of heating equipment, as well as for backup heating of the building. Parallel installation of units is not as complicated as it might seem at first.

The main thing is to correctly select the arrangement scheme and calculate correctly the total or reserve capacity of the equipment. If you are not confident in your abilities and can not cope on your own, it is best to contact plumbers. They will help you quickly and efficiently install a system for reliable and comfortable heating of your home.

What is better double-circuit or single-circuit gas boiler: features of the device and operation

What is better double-circuit or single-circuit gas boiler: features of the device and operation  Installation of a gas boiler Protherm: features and main stages of installation + wiring diagrams

Installation of a gas boiler Protherm: features and main stages of installation + wiring diagrams  Electric boiler for heating a private house: an overview of the 15 best models of electric boilers

Electric boiler for heating a private house: an overview of the 15 best models of electric boilers  The principle of operation of a dual-circuit gas heating boiler and features of its connection

The principle of operation of a dual-circuit gas heating boiler and features of its connection  Why the gas boiler is noisy: why the unit is buzzing, clicking, whistling, clapping + how to fight

Why the gas boiler is noisy: why the unit is buzzing, clicking, whistling, clapping + how to fight  How to turn off the gas boiler for conservation: methods, detailed instructions and safety requirements

How to turn off the gas boiler for conservation: methods, detailed instructions and safety requirements  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements