Thermostat for heating boiler: operating principle, types, connection diagrams

Automation in the heating system allows you to more accurately control the temperature in heated rooms and save on fuel. By installing a thermostat for a heating boiler, the owner of the cottage increases the efficiency of the boiler equipment by 20-30% and greatly simplifies its maintenance.

We will talk about the types of temperature regulators used in practice, about the rules for their location and the features of the connection. In the article we proposed, options and schemes for connecting devices are described in detail. Based on our tips, you can correctly select the device and, if you wish, install it.

The content of the article:

How does a heating thermostat work?

A conventional heating system with water as a heat carrier consists of heating equipment or a central connection unit, internal pipes and radiators.

To regulate the volume of heat coming from it into the rooms, you have to either constantly monitor the boiler, or regularly close / open the valves on the batteries.

Moreover, the inertness of such a system does not allow maintaining the desired temperature throughout the day at a set level. If more wood is put in the stove or gas is supplied to the boiler, the heat carrier in the pipes will heat up more, and it will also give more heat through radiators.

At low temperatures outside the window is good. But with a sharp warming on the street in the house, the heat becomes unbearable. The fuel is already in the furnace, and the water has already warmed up, there is no way to get rid of the heat. Plus, the boiler also continues to work.

Without a thermostat in the system, you have to turn it off manually. You can, of course, open the windows for ventilation and release heat, but then the fuel bills for home boiler definitely ruin. The conclusion suggests itself: a thermostat for heating simplifies living, making it as comfortable as possible.

The thermostat for the heating system consists of:

- thermosensitive sensor (element);

- setting block;

- control module;

- electromagnetic relay or mechanical valve.

In the simplest models, there is no control unit. Everything happens due to pure mechanics and changes in the physical properties of the heat-sensitive element.

These thermostats do not need power. They are inferior to electronic devices in efficiency and accuracy of adjustment of the system, but they are non-volatile. If there are problems with the voltage in the network, they definitely will not stop working.

The principle of operation of the thermostat is as follows:

- Using the control unit, the desired temperature is set.

- Upon reaching the required parameters, the sensor is triggered, which leads to the shutdown of the boiler or shutoff of the shut-off valve in the heating pipes.

- After the air temperature drops in the room, the boiler equipment or heaters are turned back on.

The electronic control module allows you to set not one temperature indicator, but several for each time of the day separately. Plus, if there is such a unit, it is possible to install an additional temperature sensor on the street and bind the thermostat to data from it.

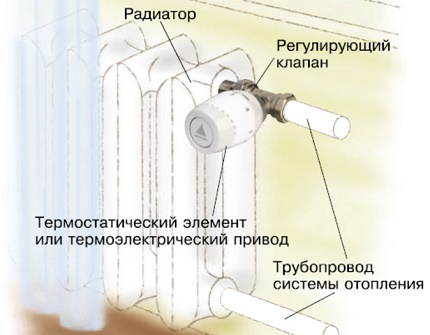

The simplest thermostat is a shut-off valve with a temperature sensor, standing on a pipe near the battery. When reaching the desired temperature thermostatic valve closes and reduces the coolant current. And when cooling the room air, it opens again, as a result of which the volumes of incoming heat increase.

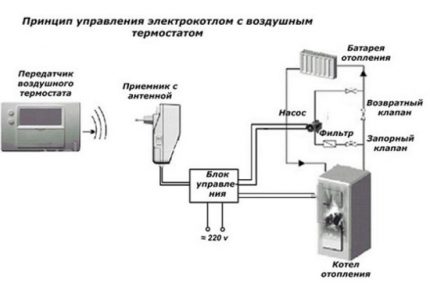

More sophisticated and advanced models require wireless sensors and control units. All communication between the individual elements occurs through the radio channel. In this case, wires are not laid, which positively affects the aesthetic side of the placement of such temperature controllers in the room.

Types of temperature regulators for boilers

The main difference between thermostats is the heterogeneous heat-sensitive sensors. Some are installed on the heating pipe, others inside it, and others are mounted on the wall. Some are designed to measure air temperature, and the second - coolant.

The choice of temperature controller model depends on:

- type of boiler;

- heating system wiring diagrams;

- availability of free space;

- required functionality.

Many modern boilers are designed in advance to connect thermostats to them. Moreover, the manufacturer of boiler equipment immediately in the data sheet prescribes all the nuances of this installation.

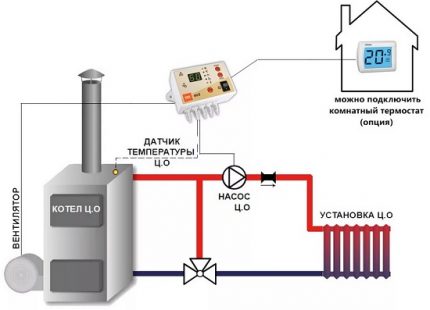

Ideally, the thermostat should regulate the operation of the heating device itself, that is, the supply of fuel to it. This is the most efficient connection scheme for fuel economy. The energy source in this case will be burned exactly as much as heat is required.

But such a thermostat can only be installed on gas or electric heating unit. If solid fuel boiler, then adjust the room temperature will help the thermostat with a mechanical valve, which is already mounted on the pipe.

Battery-mounted controls are designed to shut off the water supply at too high a temperature in the room or near the coolant. The boiler in this case ceases to work a little later, when it has its own internal temperature sensor that prevents overheating of the equipment.

Group # 1: mechanical

The basis of the mechanical temperature sensor is a change in the characteristics of the material with a change in its temperature.This is an easy-to-execute, low-cost, quite efficient and completely independent from power supply option. It is designed for installation on pipes. water heating system to adjust the flow coolant.

As a substance that reacts to temperature changes in mechanical thermostats, the following are used:

- gas;

- liquid.

When the liquid is heated, the gases expand, which leads to their pressure on the valve stem. When the temperature decreases, they are compressed, the constipation returns back by the spring, and the heated water again flows through the pipes into the heating radiators.

For thermostats per battery weak sensitivity and a large adjustment error are characteristic. They work only when the temperature rises by 2 or more degrees. Plus, over time, the bellows filler loses its characteristics, the numbers on the knob for setting the required temperature parameters and real degrees begin to diverge.

These temperature controllers are quite large. The vast majority of them are designed to measure the temperature of the water in the batteries, and not the air in the room. Often it’s difficult to precisely adjust them the way the owner wants.

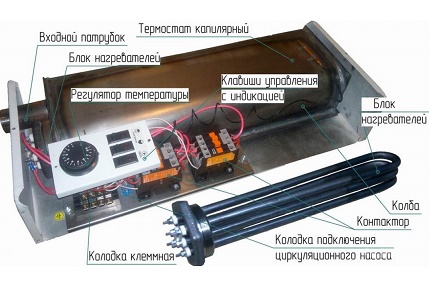

Group # 2: Electromechanical

These thermostats operate on principles similar to purely mechanical counterparts. Only as a heat-sensitive element is a metal plate used here.

When heated, it bends and closes the contact, and when cooled, it returns to its original position and opens the circuit. And already through this circuit, a signal is supplied to the burner control unit.

Another version of an electromechanical thermostat is a device with a sensor in the form of two plates of different metals. In this case, the heat-sensitive element is installed directly in the furnace of the solid fuel boiler.

At high temperatures, a potential difference occurs between the plates, affecting the electromagnetic relay. The contacts in the latter open and close. As a result, the boost is turned on / off in the combustion chamber.

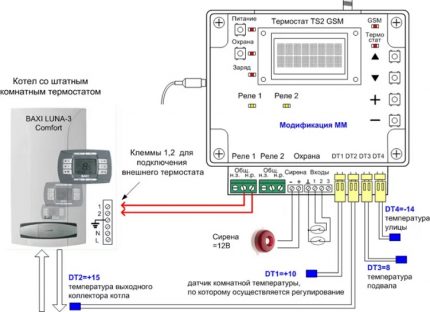

Group # 3: electronic

This type of thermostats for boilers belongs to the volatile category. Such devices have a remote temperature sensor that monitors the temperature in the room, and a full-fledged control unit with a display.

For electric boilers, these thermostats are a mandatory addition. Without them, electric heaters will work without stopping, heating the air or coolant too much.

There are two main elements in an electronic temperature controller:

- Temperature sensor.

- Microcontroller

The first measures the temperature, and the second monitors it and gives signals to increase / decrease the supply of thermal energy to the room. The sensor can send an analog or digital signal to the controller. In the first case, the thermostat is similar in capabilities to the mechanical analogue, only to greatly exceed it in the accuracy of measuring temperature indicators.

Digital thermostats are the pinnacle of the development of these devices. They allow you to adjust the heat supply according to a predetermined algorithm. Plus, you can connect to them much more sensors located both in rooms and on the street.

Many electronic thermostats have the ability to remotely control via infrared or cellular. This allows you to adjust the room temperature not only using the remote control in the room, but also from anywhere outside it.

For example, while still leaving work, you can send a signal to heat room air to comfortable parameters, and by your arrival the house will delight you with comfort and warmth.

Electronic devices designed to automatically adjust the qualitative and quantitative characteristics of the coolant are an essential component heating systems in smart homes. We recommend that you familiarize yourself with their device.

Connection diagrams

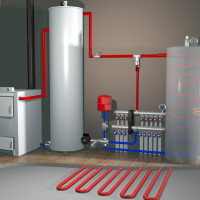

All methods of incorporating a thermostat into a heating system are divided into three connection options:

- Directly to the boiler.

- To the circulation pump.

- On the pipe supplying coolant to the radiator.

The first two schemes eliminate the deterioration in the throughput of the heating pipeline. No additional locks are placed in it, the hydraulic resistance of the entire system does not change. Here the thermostat controls the operation of only the pump or boiler, it “does not come into contact” with water.

When installing the thermostat on a battery or a common pipe with several radiators, the hydraulic resistance, on the contrary, increases. Even in the fully open state, the thermostat valve slows down the movement of the coolant slightly.

Ideally, the boiler strapping project should be carried out immediately, taking into account all thermostatic and other devices.

If the water heating system in the house is made according to single pipe pattern, then it is better to refuse the third option right away. When the temperature sensor is triggered, the valve will immediately block the entire branch of radiators in several rooms, and then you can immediately forget about comfort in rooms far from the boiler.

Connect the thermostat to the radiator input through bypass. So when it is triggered, it redirects the flow of coolant to bypass the battery. In this case, the water will return uncooled back to the boiler. The latter will stop heating it, thereby reducing the consumption of gas fuel or electricity.

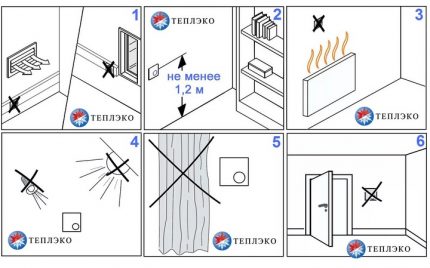

The temperature sensor must be mounted:

- in a place where direct sunlight does not fall;

- away from bridges of cold, drafts and rising heat flows from radiators;

- so that it is not covered by decorative screens or curtains;

- at a height of from the floor within 1.2–1.5 meters.

If the sensor is installed incorrectly, the thermostat will give false signals. This can lead to overheating of not only the air in the room, but also the coolant in the system. And in the second case, not long before the problems with the boiler.

Conclusions and useful video on the topic

There should not be any special difficulties with the installation of the thermostat. It only needs to be selected correctly for a specific heating system. And the selected videos will definitely help you with this.

Video # 1. Connecting a room thermostat to a gas boiler in all the nuances:

Video # 2. Overview of wall thermostat:

Video # 3. Technology for incorporating a contact thermostat into a system with a circulation pump:

The addition to a heating boiler in the form of a thermostat is a great way to save on heating, increase the comfort of living and reduce the wear of heating equipment. The money spent on thermostats pays off for one winter season.

In this case, you can choose as a simple mechanical option with manual control, as well as a more advanced device with a programmer.

Want to tell how a boiler with a thermostat works in your country house? Do you have information that will be useful to site visitors? Please write comments, ask questions, publish photos on the topic of the article in the block below.

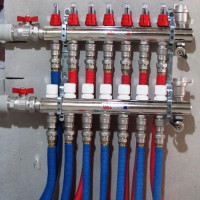

Distribution comb of the heating system: purpose, principle of operation, connection rules

Distribution comb of the heating system: purpose, principle of operation, connection rules  Voltage stabilizer for a gas heating boiler: types, selection criteria + overview of popular models

Voltage stabilizer for a gas heating boiler: types, selection criteria + overview of popular models  Temperature sensors for heating: purpose, types, installation instructions

Temperature sensors for heating: purpose, types, installation instructions  Types of heating systems for a private house: a comparative overview + the pros and cons of each type

Types of heating systems for a private house: a comparative overview + the pros and cons of each type  Pipes for heating boilers: which pipes are better for tying the boiler + installation tips

Pipes for heating boilers: which pipes are better for tying the boiler + installation tips  Connecting a room thermostat to a gas boiler: installation manual for a thermostat

Connecting a room thermostat to a gas boiler: installation manual for a thermostat  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I agree that in order to save energy, the thermostat must control the boiler directly. In large houses, two or even three heating circuits are used, and here additional devices are needed to control the temperature. And we implemented a scheme where the first thermostat controlled the boiler, and the second and third - shut-off valves with servos. They tracked teams of electronic devices installed on each floor of the house. The temperature was set on these devices with digital displays and clearly maintained within specified limits.

Generally speaking, the topic is very cool! I have a house heated by a gas boiler. Spent in the winter months somewhere around 2500 rubles for gas. I bought a thermostat and was surprised how much it saves fuel. With a thermostat, he began to pay 1400-1500 rubles.