Error E4 in a gas boiler: decryption of code E04 + steps to solve the problem

Regardless of the degree of complexity and build quality of technical devices, any of them may fail during operation. The cause of violations is trivial wear and tear, factory defects or incorrect operation. Let's look at what the E4 error in a gas boiler means and what threatens it, and we will analyze typical ways to fix it.

In our article you will find tips for diagnosing a gas heater and a step-by-step description of troubleshooting methods with the indicated alphanumeric designation.

Our recommendations will help you choose the right way to restore the boiler. You will be able to decide: it is worth correcting the situation yourself or it is better to call gas workers.

The content of the article:

Violations in the work with the E4 code

Household gas equipment requires owners to regularly inspect and pay close attention. After all, the slightest malfunction can turn into a serious disaster. From irretrievably lost equipment to poisoning of various degrees and explosions with fires - all these are consequences of seemingly insignificant breakdowns.

Manufacturers of units for servicing private heating and domestic hot water circuits were well aware that not all of the owners of the equipment would be prepared for their operation at a professional level. Therefore, a warning system was developed, displayed on the displays of boilers.

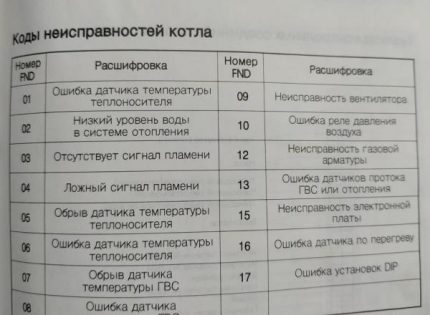

One thing is bad: the alphanumeric designation of a boiler breakdown in almost all brands has its own. In some ways, decryption systems overlap, but mostly differ. Error codes for equipment with the Bosch logo, for example, are completely unacceptable for diagnosis boiler failures Viessmann or Ariston appliances.

What to do in a difficult situation, if your gas column is stubbornly honking, highlighting the error E4? It’s simpler than that to disassemble all the typical types of malfunctions in the operation of heating equipment, most often acquired by our compatriots.

Correction of the situation in the Electrolux boilers

As an example, consider Swedish-made wall-mounted models with the Elektrolux logo. More precisely, we will analyze violations in the functionality of units with the indicated type of error.

The renowned supplier of high-quality and reliable equipment has developed a unified error reporting system for single-circuit devices with a closed combustion chamber (Basic S Fi), for dual-circuit models with a closed (Basic Space Fi, Basic X Fi) and open (Basic Space i) combustion chamber.

Similar codes are used in warning and decoding errors of units of the Electrolux series Magnum, Basic Duo, Quantum.

The reasons for displaying the E4 code on the electronic scoreboard in the listed models include:

- Low pressure in the heating circuit connected to the boiler.

- Lack of contact between the pressure sensor and the internal wiring of the boiler.

- Breakdown of the circulation pump.

In all these cases, the pressure sensor gave a command to block the operation of the boiler. There are two options: either the coolant circulates weakly on the circuit, or he himself incorrectly took readings. We start the search for the cause with the most common violation - we check the pressure in the heating circuit served by the boiler.

Diagnostic restart

If the pressure on the electronic display of the boiler is 0.5 bar, we will try to restart the boiler first. It is possible that there is no pressure sufficient for the normal movement of the coolant through the heat exchanger due to a violation of the electrical circuit or breakdown of the pump.

The fact that the pump or the wiring connected to it deserves attention, repair / replacement will be indicated by an increase in the pressure value after restarting by at least 0.1 bar. In both cases, you should contact the gas workers with whom contract signed for the supply of gaseous fuel and maintenance of the unit.

Search for leaks

If the restart did not give the above results, we will continue to diagnose it by inspecting the heating circuit.The most common reason for the appearance of an error with the code E04 on the electronic display of a gas boiler is the pressure drop of the coolant due to elementary leakage.

To detect leaks, examine:

- Pipe connection units with radiators and fittings. Visually examine the floor under the system, look for drops and puddles.

- Installation area of the safety valve. It is mounted in the wall-mounted models of the Electrolux, located in the lower part behind the circulation pump. Dripping water will tell about the presence of a leak in the area of its location, this is from the bottom of the case closer to the back wall.

We eliminate the external circuit leaks in an accessible plumbing way: we tighten the joints, change the seal or pipes, if the need for their replacement has matured. With leaks in the area of the safety valve, everything is somewhat more complicated.

To accurately determine the cause of the pressure drop, we call the master from GORGAZ, who must check the pressure in the expansion tank. For this, the coolant from the system will have to be drained completely. Without it, in the cooled state, the pressure in the expander must be at least 1 bar.

If everything is wrong, then:

- Blame or safety valve that will have to be changed.

- The membrane of the expansion tank is damaged. It will be necessary to change it, but most often they just put a new tank together with a new membrane. Especially if the warranty period has not yet been exhausted.

- The spool of the expansion tank nipple is leaking. In such situations, completely assembled the spool-nipple assembly.

After all the manipulations with the expansion tank, the master is simply obligated to pump a mixture of nitrogen with air into it to the operating values.

All the operations described above were carried out with an empty heating circuit. Therefore, after repair, the pipeline, heating radiators and the unit itself must again be filled with coolant. The pressure in a ready-to-use system should be in the range of 0.8 to 1.2 bar.

If the pressure in the circuit filled after repair is not enough for the normal functionality of the system, we supplement the volume of the coolant through the make-up valve located at the base of the housing.

By the way, through the make-up valve, the coolant volume is replenished if the pressure drop occurs due to the presence of air jams in the circuit. They need to be pitted, using a Maevsky crane.

Start off air discharge follows from the device farthest from the boiler. After air release we make up and slightly weaken the air vent in the boiler.

Is there a reason for the pressure sensor?

Assume that no leakage has been detected, the pressure reading is normal, and the display stubbornly shows E04. What now needs to be checked and changed? Look for a malfunction associated with the pressure sensor or its electrical connection.

In order to check the electrical circuit between the pressure sensor and the electronic board, a multimeter is required.If the device detects a break, reconnect by replacing the damaged wire.

If everything is in order with the wiring between the pressure sensor and the control board, check the contacts. If they are weakened, it should be tightened, if they have oxidized or rusted, remove the plaque that makes contact difficult with sandpaper.

Disturbances in the circulation pump

All of the above actions have been carried out, but the result is disappointing? What to do if your gas boiler shows an E4 error, despite all the efforts made? What is the catch?

A list of reasons to find out gas boiler repair already significantly limited due to the method of eliminating probable breakdowns. Now it remains only to examine the built-in circulation pump and the electrical wiring connected to it.

After restarting the boiler, select in the settings the rotational speed of the “compass” impeller, indicated by III. Remember that all test and repair measures for which you need to remove the unit cover must be performed by the master of GORGAZ or a similar service.

To study the technical condition of the pump, the gasman must:

- Test the pump with a magnetic identifier.

- Check the pump “manually” if there is no magnetic device. To do this, remove the end screw from the front of the pump, behind which the shaft end with a longitudinal recess is located. A screwdriver is inserted into it and the shaft is turned.

If the shaft does not turn, check the impeller integrity. It is possible that it was jammed with a breakaway blade or a cracked part. There is only one way out - replacing the entire pump.

With free rotation of the shaft of the circulation pump, you will have to continue the diagnosis, for this you need:

- Inspect and ring the wiring with a multimeter, check the wire itself and the terminals for violations / disconnections / damage. They are eliminated as they are detected.

- Check voltage in mains. If the problem is in it, all questions, including the repair of the boiler, are sent to the structure of centralized power supply. To protect equipment from power surges and similar "surprises", it is better to connect it through a voltage regulator with a minimum power of 0.4 kW.

- Perform a performance test of the pump itself. To make sure that the circulating device is working or malfunctioning, remove the terminal box and check the voltage on the windings of the device in phase and zero, changing the speed of rotation of the impeller.

If the resistance during rotation of the impeller at the first speed will be 440 Ohms, and at the second and third - 220 Ohms, it will be necessary to repeat the procedure. If the resistance indicators do not meet the standards specified by the manufacturer in the technical documentation, the device must be changed.

Variations of breakdowns with code E4

Not all manufacturers of equipment for heating coolant and water in mixers adhere to the error coding and decoding system developed by Electrolux. For example, work Baxi brand heaters are blocked for a completely different reason.

If error 04 appears on the display, boiler operation is interrupted due to a command given by the flame control electrode.If the flame responsible for this process detects a flame six times smaller than the standard size, the fuel supply to the gas burner is cut off.

The causes of a decrease in combustion intensity include:

- Violations in the smoke exhaust system. If flue gases are poorly removed from the combustion chamber, the sensor will detect a color change or a reduction in the size of the flame tongue.

- Clogged ignition device electrode. It must be regularly cleaned of carbon deposits and dust.

- Lack of contact between the sensor and its electronic circuit board.

Of course, in addition to the indicated reasons, the boiler operation can be blocked by the failure of the control board or sensor.

To the owners of the boilers Gaslux, Neva Lux, the error E4 displayed on the display will indicate that the heat exchanger is overheating. This is caused both by malfunctions of the temperature sensor, and by a reduction in the flow of water passing through the heat exchanger.

If the speed of movement and the volume of water passing through the heat exchanger fall:

- Clean the heating circuit filter. A device clogged with scale and mineral sludge significantly complicates the movement of water through a closed pipeline.

- Check the pressure in the water supply system. It is possible that these are punctures in the work of public utilities.

- Install the filter on the water supply line that supplies water to the heater.

If the above measures did not help, check the operability of the sensor and the board, and also test the electrical connections.

But the flashing of the error 04 on the display of the Navien Ace units is connected with fixing a false flame or short circuit of the electrical connection of the flame sensor with the control board. In 99% of cases, as a result, you have to change the fee.

Conclusions and useful video on the topic

Video instruction will help to visually understand the essence of the problem and understand the methods for its elimination:

Information about the decoding of a manufacturer-coded gas equipment malfunction will help prevent negative consequences in a timely manner. To know what they mean, you need all owners of units that consume gaseous fuel in their work. It is a pity that practically all boilers do not have the same error values.

However, the causes of violations are almost always identical. The main thing is to understand what is connected and choose the appropriate diagnostic path. We examined a substantial number of problems in the presented article; you can deal with most of them on your own.

Errors of a gas boiler Navien: decryption of the breakdown code and solutions

Errors of a gas boiler Navien: decryption of the breakdown code and solutions  Why pressure drops in a gas boiler: causes of instability of pressure + ways to prevent problems

Why pressure drops in a gas boiler: causes of instability of pressure + ways to prevent problems  How to check a three-way valve in a gas boiler: DIY valve check instructions

How to check a three-way valve in a gas boiler: DIY valve check instructions  What to do if condensate in a gas boiler: methods for preventing the formation of “dew” in a chimney

What to do if condensate in a gas boiler: methods for preventing the formation of “dew” in a chimney  Error codes for the Master Gas boiler: decoding symbols and troubleshooting guides

Error codes for the Master Gas boiler: decoding symbols and troubleshooting guides  Bosch gas boiler errors: decipher common errors and resolve them

Bosch gas boiler errors: decipher common errors and resolve them  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements