Baxi boiler error codes: what are the codes on the display talking about and how to eliminate typical malfunctions

Baxi brand boilers are one of the best equipment options used in the arrangement of heating systems. Various configurations of this modern thermal equipment have been developed, respectively, rather comfortable operating conditions are provided to potential users.

However, like any other electronic-mechanical devices, this type of technology is not completely immune from malfunctions. Technical documentation mentions possible failures of various types at least 99 times.

How are malfunctions expressed, what numbers are associated with the errors of the Baksi boiler, and how can the problem be eliminated at home? Consider this issue in our article.

The content of the article:

- Documented codes and their decryption

- Code E01 and E04 - flame monitoring sensor

- Code E02 - thermostat fuse against overheating

- Code E03 - traction sensor

- Codes E05-09 - DHW and burner flame control

- Code E10 - minimum pressure switch

- Codes E12 and E13 - DGP malfunction

- Codes E21-22 and E97-99 - electrical and electronics

- Codes E25-27 and E32 - temperature defects

- Codes E35-36 and E40-43 - flame control and GDC

- Codes E50 and E62 - NTC sensor and flame control

- Code E55 - gas valve malfunctions

- Conclusions and useful video on the topic

Documented codes and their decryption

Modern household appliances are notable for the fact that microcontrollers are actively used in its design. The use of these electronic elements allows you to control the equipment efficiently and rationally without human involvement.

The controllers also make the monitoring function effective, organize timely fault detection and accurately diagnose malfunctions.

All this applies to heating equipment - household gas boilers. The electronic control system is able to detect malfunctions of a Baxi domestic boiler and inform the user (mechanic) of alleged errors in the operation of the equipment.

Judging by the technical documentation, it is possible to detect almost any system error with displaying a specific number.

Further, using the error number issued by the system, the owner of the equipment or a invited mechanic will be able to quickly determine the place of failure and eliminate the emergency.

All existing error codes for Baxi domestic boilers are presented in a list with at least a hundred options. To clearly describe each of them, one article is clearly not enough. Therefore, we consider the main ones - often found in practice.

Code E01 and E04 - flame monitoring sensor

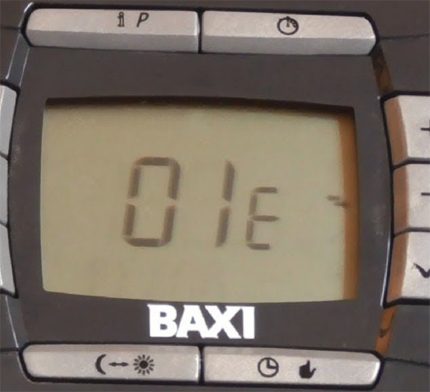

The situation, typical for most models, is connected with the functionality of locking the boiler ignition system. The classic error code for such cases - “E01” or “01E” (as well as “E04” or “04E”) is displayed on the information display.

If the design does not provide for a display, the same error is identified by the corresponding LED indicator.

Relationship of error and possible situations:

- no gas supply;

- broken contact on the flame sensor;

- flame control sensor dirty;

- malfunction of the ignition system;

- phase and zero on the supply line do not match;

- malfunctions of a gas valve, electronics, coaxial chimney.

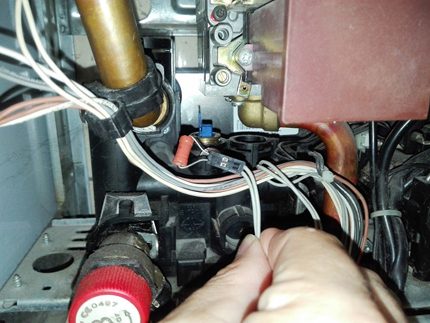

Accordingly, on the basis of possible malfunctions, it is necessary to check all the indicated components (elements) in order to verify the correct operation, and in the opposite case, to carry out repair measures.

Code E02 - thermostat fuse against overheating

The manifestation of this error, displayed as “E02” or “02E”, may also be accompanied by various variations of the defects.

In particular, the following defects may occur:

- the water temperature of the main circuit has been exceeded;

- circuit temperature sensor defective;

- no contact on the temperature sensor of the heating circuit;

- coolant circulation in the primary heat exchanger circuit is not enough;

- clogged filter, heat exchanger, air in the system;

- defect circulation pump;

- malfunction on the electronics board.

The same errors are typical for boiler models where there is no display. They are determined by the presence of an indicator glow with a temperature marker.

Code E03 - traction sensor

This error is preceded by malfunctions related to the draft sensor, thermostat or pneumatic relay. The error code is displayed as “E03” or “03E”.

The situation is typical both for equipment where a closed combustion chamber is used, and for equipment where an open combustion chamber is used.

Fault Options:

- the length of the chimney is large;

- the chimney is narrowed or closed by a foreign object;

- Venturi injector defective;

- There is no connection between electronics and pneumorelays;

- fan malfunction or no contact;

- incorrect connection of the pneumatic relay.

The control of the same error on models equipped with LED indicators is carried out taking into account the markers "asterisk" or "house".

Codes E05-09 - DHW and burner flame control

The group of marked sensors actually performs related operations related to the control of the DHW temperature or the control of the flame of a gas burner.

Errors "E05", "E06" (coolant temperature), "E07", "E08", "E09" (flame and flue gas control) are typical for boilers of the "Main5" and "ECO-5" models, as well as others.

Malfunctions can manifest various:

- malfunction of the DHW temperature sensor;

- there is no sensor contact from the electronic board;

- overstatement or underestimation of boundary temperatures;

- malfunction of electronics;

- defective heating circuit sensor;

- flue gas sensor defect;

- open circuit ground circuit of the electronic board.

Most of the problems noted are eliminated by simply testing the circuits with a meter or by replacing the suspected faulty element with another, working.

Code E10 - minimum pressure switch

The functional component of the system - the minimum pressure switch - is used in almost all Baxi boiler designs, including EcoFour, Fourtech, Main Four, Navola, etc.

True, for some models, this functional component may be referred to as a differential pressure switch micro-switch (TIR).

The error “E10” (“10E”) traditionally appears on the display or is displayed by an LED when:

- too low water pressure KO;

- no relay contact with the electronic board;

- defect of the minimum pressure switch;

- non-working TIR;

- jammed TIR stock;

- malfunctioning pump;

- circulation of KO or primary heat exchanger (PT) is disturbed;

- water outlet pipe contamination;

- membrane defect (no pressure differential).

Elimination of the E10 error is carried out by checking all the components marked in the list and eliminating the detected defects. The units are being cleaned, individual parts or all units are replaced.

Codes E12 and E13 - DGP malfunction

The appearance of the code “E12” (“12E”) or “E13” (“13E”) on the boiler display clearly indicates malfunctions associated with the operation of the DGP - differential hydraulic pressure switch.

The reasons for the appearance of the marked code may be:

- pump shutdown;

- the presence of air in the DHW system;

- low speed of circulation;

- no contact on the TIR or “stuck” contact;

- membrane damage or clogged filter;

- impulse tube clogging.

Accordingly, to determine the malfunction of a particular element, a technical check should be carried out.

And in order to eliminate the problem, it is necessary to replace the faulty element or carry out preventive restoration work.

Codes E21-22 and E97-99 - electrical and electronics

Both codes - “E21” and “E22” - indicate malfunctions associated with the electronic board. Code “E22” may occur if the supply voltage drops below the reference value (162V).

The same code is displayed if the quality of the energy supplied to the boiler does not meet the declared standards.

For the code “E21”, a characteristic moment is the scatter of the controller parameters and the violation of normal gas combustion. In the absence of experience and relevant knowledge, it is better to entrust the repair of the board to the master.

Errors "E97", "E98", "E99" - all three codes are usually associated with defects in the electronics - the electronic board.

Code "E97" indicates the frequency of the supply voltage that does not comply with the standard. The defects present precisely on the electronic board are indicated by the code “E98”.

The simplest defect is the loss of electrical contact on the gas valve relay. In other cases, a replacement board is usually required.

Codes E25-27 and E32 - temperature defects

The appearance of any of these codes - “E25”, “E26”, “E27”, “E32” - is usually preceded by temperature changes in the heating circuit that occur at a faster rate than specified by the control system.

For example, if the temperature of the heating circuit (KO) rises by more than 1 degree per second, the code “E25” (“25E”) is displayed on the boiler display. For the code “E26” (“26E”) to appear, it is usually sufficient to exceed the temperature above the set value by 20 ° C.

Reasons traditionally causing such codes:

- circulation pump lock;

- clogged filter;

- air inside the system;

- defect in the temperature sensor;

- malfunctions of electronics;

- incorrect installation of the dhw sensor.

To eliminate it, it is necessary to carry out preventive measures aimed at checking and testing the units of hot water supply and CO. Air in the system is removed by a standard technique used by plumbing practice.

The efficiency of the circulation pump is checked on the electrical and mechanical parts.

Codes E35-36 and E40-43 - flame control and GDC

This set of codes mainly indicates malfunctions of gas burner flame control systems and flue gas control systems. So, the code “E35” (“35E”) indicates a mismatch in the arrival of the flame signal.

The code “E36” (“36E”), as a rule, indicates a malfunction of the NTC sensor. Codes “E40”, “E41” and “E42”, “E43” remind the user of the failure of the GDC test for flue gases and ionization current.

The appearance of these codes is usually accompanied by:

- moisture in the area of the electronic board;

- residual combustion after closing the burner;

- mismatch in the quality of the supply network;

- defective NTC sensor (flue gas sensor);

- lack of communication between the sensor and electronics;

- defects in electronics;

- lack of gas pressure;

- contamination or malfunction of the flame sensor;

- gas valve malfunction;

- too long chimney.

Some of these defects are available to the user to fix on their own.

However, other points, for example, electronic malfunctions and sensor testing, require the intervention of specialists.

Codes E50 and E62 - NTC sensor and flame control

The automation of the Baksi boilers is adjusted to certain parameters of combustion stability, as well as to a certain temperature range of flue gases.

Error E62 - burner flame monitoring sensor

If either of the two parameters (or both at once) goes beyond the limits of the settings, the automation is triggered, and the code “E62” (“62E”) appears on the control display screen.

Traditional reasons:

- faulty or dirty flame control sensor;

- faulty NTC sensor;

- defects in the electronic board.

Sensors are verified by replacing known-good instances, and electronics are tested by instruments designed for such purposes.

Error E50 - NTC temperature sensor

The manifestation of the “E50” error is typical for boilers of the ECO-5 and Main 5 models. The “E50” code is displayed on the control display, as a rule, because the sensor detects the temperature of the heating of the flue gas above 180 ° C.

In turn, a rise in the temperature above the set limit may be due to:

- low coolant circulation rate;

- clogged filters;

- the appearance of hydraulic resistance in the system;

- low concentration of antifreeze;

- defects in the circulation pump;

- contamination of the system or air.

Also, the DTC “E50” (“50E”) is displayed when the NTC sensor breaks down, due to a malfunction of the electronics, due to an incorrect gas valve setting.

Accordingly, the elimination is ensured by consistent testing of designated nodes and the production of necessary work.

Code E55 - gas valve malfunctions

Often this code - "E55" - makes itself felt due to incorrect calibration of the gas supply valve.

To eliminate the occurrence of an error, a calibration procedure should be carried out. Usually this work is done by a specialist, but if you wish, you can try to calibrate yourself by following the instructions.

Conclusions and useful video on the topic

The author of the video below parses another possible error that was not included in the list of the current publication. In particular, the video shows the malfunction marked with the code “E00”:

The electronic system for detecting errors in the operation of the Baksi boiler, followed by the output of the corresponding code to the control screen, is a very convenient service for the user.

This is a significant help for mechanics when it comes to dealing with rather complex malfunctions that require additional testing of equipment before and after repair.

If you have questions about the topic of the article or there is valuable information which you can supplement our material, please leave your comments in the block below.

Immergas gas boiler errors: error codes and solutions

Immergas gas boiler errors: error codes and solutions  Error codes for a gas boiler Viessmann: methods for troubleshooting and recovery

Error codes for a gas boiler Viessmann: methods for troubleshooting and recovery  Junkers gas boiler malfunctions: breakdown codes and troubleshooting

Junkers gas boiler malfunctions: breakdown codes and troubleshooting  Error codes for the Master Gas boiler: decoding symbols and troubleshooting guides

Error codes for the Master Gas boiler: decoding symbols and troubleshooting guides  Repair of a gas boiler "Proterm": typical malfunctions and error correction methods

Repair of a gas boiler "Proterm": typical malfunctions and error correction methods  Beretta gas boiler malfunctions: how to decrypt the code and eliminate the malfunction

Beretta gas boiler malfunctions: how to decrypt the code and eliminate the malfunction  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

That's all interesting is written here. But the error E26 may appear for another reason. In the book you definitely will not find such a breakdown. Here is how it was! I turned on hot water, began to heat up, everything was fine. The wife washed the dishes and turned the tap. Water stopped flowing, but for some reason the burner did not go out and gas continued to flow. Then some kind of protection against overheating worked and the boiler went out, error E26 appeared.

I climbed into the book, but there it was only indicated that the pump could be blocked and contact the service organization. What organisation? I thought. We have no normal masters. He got on the Internet, covered several forums, but there was no sense at all.

And then I decided to figure it out myself. I immediately threw off the pump lock, because it worked during heating. The problem was the hot water circuit. He began to slowly disassemble. He took off the tap, then on the list there was a DHW water flow sensor with a ferromagnetic ring. This is where the whole problem lurked. There is a mesh, like a filter. Here it is for some reason torn. I don’t know why, most likely due to our bad water. So the ferromagnetic ring stuck in the upper position and gave a constant signal, so the burner worked constantly. I disassembled the sensor myself, cleaned it from rusty coating and that's it! The boiler has earned as before. Perhaps my information will be useful to someone.

The organization that connected your boiler and conducts annual service. In general, it is better not to climb into the boiler yourself.

After turning off the hot water in the boiler, something clicks for 10 seconds or more. No error