Expansion tank of the heating system: device, calculation and selection of the best option

A correctly selected and correctly installed expansion tank of the heating system will not allow its failure, it will maintain pressure at the required level. It is needed as a reserve for expanding water when heated. Depending on the type of system, the built-in expander can be open or closed.

We will talk about how to choose a reserve capacity depending on the heating scheme being created. The article we presented describes the design features and specifics of the installation of expanders. Recommendations are given, the observance of which will ensure the ideal operation of the heating circuit of any type.

The content of the article:

Open expansion tanks

A design feature of open type expanders is the contact of the coolant with the atmosphere. Circulation in systems with an expander of this type is convection. When heated, the volume of liquid increases, its excess is absorbed by the reservoir tank.

With a drop in temperature indicators, the liquid returns by gravity, under the influence of gravity.

Due to the zero pressure in the tank, the device does not require a solid metal structure, therefore:

- any metal is used in the manufacture of the case;

- ready-made container made of heat-resistant plastic can be used;

- not important is the shape of the tank.

In summer houses, such equipment can be assembled from improvised means. As a container, you can use a plastic canister or barrel equipped with a receiving pipe and an outlet for overflow.

Outwardly, it is an ordinary metal tank, the upper plane of which is equipped with an opening for servicing and adding liquid.An anti-clogging protection is provided by the leakproof cover. Fasteners are provided in the lower part or on the lateral plane.

Open heating systems are used in low-rise buildings, where the volume of coolant and the length of heating communications are relatively small.

Installation requirements are simple:

- the expander is placed at maximum height, on the supply line;

- the feed is connected to the tank through the pipe;

- To drain excess fluid, an overflow tapping is performed above the calculated level.

To ensure gravity circulation, it is recommended to use larger pipes for installation.

Usually they try to mount the tank in a heated room, equipped with a warmed attic, and if this is not possible, then the tank will need to be insulated. The presence of insulation will not allow freezing of liquid and loss of system performance.

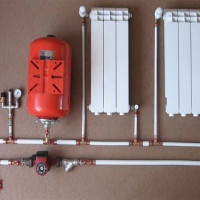

Closed expansion tanks

The structural specificity of closed tank modifications is complete tightness, which allows maintaining the pressure necessary for circulation at any point in the system.

The tank inside is divided by a membrane into air and liquid parts. Each of the compartments is completely sealed - the nitrogen-containing mixture from the air section never mixes with the coolant filling the liquid compartment.

Principle of operation closed expansion tank lies in the fact that the heated liquid from the system is pushed into the liquid part of the tank and begins to press on its part against the sealed membrane. The partition is deformed and acts on the air part, compressing it.

As a result, the volume of the air chamber of the tank decreases, and the gas in it is compressed. This situation contributes to an increase in pressure in the system. As soon as the pressure normalizes, the coolant is pushed back from the liquid compartment.

If the pressure rises rapidly, then, when a critical volume of liquid in the tank is reached, a safety valve is activated. As a result, excess coolant will be removed from the tank.

Depending on the form, all closed expanders for installation in the heating system are divided into the following types:

- Spherical - A kind of membrane design with an elastic partition. Upon receipt of the liquid, it stretches and takes up all the excess volume. The tank itself has the appearance of a spherical capsule.

- Oval - Another type of membrane hydraulic lifters. The cylinder of the expander is traditionally divided by a flexible membrane into gas and liquid chambers, but the body configuration has a slightly elongated vertical shape.

Externally, the oval extenders are a cylindrical cylinder painted in red. On the one hand, a nipple is provided for creating pressure in the gas chamber, on the other hand, a pipe through which the system is connected.

Mounting units are welded onto the case, which provide for hinged installation of equipment and are able to withstand its working weight. The spherical modification of the tank differs from the oval only in shape.

In closed systems, gravity circulation cannot provide the required pressure level. Therefore, the design includes circulation pump.

The expander itself can be installed anywhere in the system, but when performing installation work, it is advisable to take into account the following recommendations:

- the best place for installation is the return line, to the point of the pump in;

- it is better to bring the coolant supply from above, which will reduce air penetration and maintain performance when the membrane is damaged;

- the lack of the main volume can be compensated by installing an additional expander with a lower capacity.

When installing, it is not forbidden to take into account the interior of the room, if necessary. To control the level pressure in the heating system the expander must be equipped with a pressure gauge.

The possibility of placement near the boiler removes the issue of the need for insulation of the tank. The equipment is located in a warm room, which ensures ease of use.

Which design is better?

Systems, depending on the device and material of the expansion tank, differ in the list of pros and cons. But, according to experts and experienced users, the advantages in functionality are on the side of closed options.

Pros and cons of an open tank

The self-flowing system requires larger pipes, which in turn directly increases costs. Settlement Budget open heating system with an unpressurized expander increases slightly, although it remains relatively small.

The main advantages of this option are simplicity, plus the low cost of components and installation work. Another positive feature is the lack of need to control the pressure level.

However, there are much more minuses:

- the use of non-freezing is dangerous due to toxic fumes;

- mounting options are limited only by the top point of the system;

- constant contact with the atmosphere increases the risk of air congestion and corrosion;

- slow warm up;

- temperature differences accompanying convection circulation accelerate equipment wear;

- used in heating low-rise buildings, a maximum of two floors;

- large heat loss and energy consumption for heating.

Another drawback of the open system is the loss from evaporation and overflow. Therefore, when installing the tank, care should be taken about the availability of the topping hole.

Pros and cons of a closed tank

If open expanders win in terms of price and ease of installation, then functionality is the strength of a closed tank, which is also called an expanometer. They are used in the construction closed heating systemsnot having direct contact with the atmosphere.

Expansomats have the following advantages:

- complete tightness allows the use of antifreeze;

- the location of the expander does not affect the performance of the system;

- insulation of the interior of the tank minimizes the likelihood of air congestion and corrosion;

- after starting, the system warms up faster, more sensitive to the adjustment of temperature conditions;

- a smaller difference between the operating conditions of the supply and return lines, which as a result increases the operational resource;

- does not require the installation of large diameter pipes, which saves on construction;

- does not require constant attention to the level and condition of the fluid;

- the possibility of application in systems designed for several floors;

- small heat losses that reduce the cost of operating the equipment.

When choosing expanders of this type, sealed cylinders with a non-separable design may occur. If the diaphragm malfunctions, the cylinder will have to be replaced with a new one.

Of the minuses, it is important to note the complexity of the design, special requirements for materials that increase the cost of equipment. To this we can add the need for constant monitoring of pressure and its recovery if necessary.

Rules for calculating tank capacity

An expander of any type will be effective only with the right choice of volume. For this, the ability of the liquid to expand during the heating period should be taken into account. Water in the heating rings expands by at least 3% of the total volume of the water system, antifreeze - by almost 5%.

Liquids are classified as incompressible media, so the tank should provide them with a sufficient reserve for thermal expansion with a certain margin. Provided that the circuit is completely filled with coolant, even thermal expansion in the calculated volumes can lead to the discharge of fluid through safety valve and coolant spill to the floor.

Therefore, so that the excess volume of the expanding coolant does not lead to accidents, closed tanks for small circuits in private homes are acquired so that their volume is 10% of the total volume of the coolant circulating through the system. This rule is valid for systems with a capacity of up to 150 liters.

If more than 150 l of coolant moves along the heating ring, then the capacity of the closed tank is calculated by multiplying the total volume of the liquid by its expansion coefficient at specific operating temperatures in the system.

To the obtained value you need to add the size of the water shutter, i.e. the volume of coolant formed in the tank as a result of standard static fluid pressure. For large heating rings, this indicator, as a rule, is equal to 0.5% of the total coolant volume, for small-sized ones with a capacity of up to 150 l, it is taken 20%.

The resulting amount is multiplied by a correction factor determined by the values of the preliminary and final pressure in the heating system. The preliminary one is taken from the calculation that 1 bar falls on 10 m of the circuit height. The final pressure is formed as a result of the system.

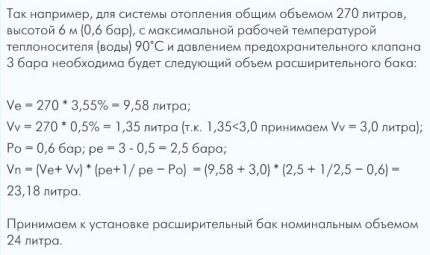

The calculation of the volume of the closed tank for large complex heating structures looks like this:

Open type capacity is not strictly regulated by standards, but there is a rule: the volume of the open tank to the overflow pipe should be 3.5 - 4% of the total volume of the coolant in the heating circuit.

Such an assessment is sufficient for a small country house, but the structure for permanent residence will require a more accurate calculation. First of all, you need to find out the total volume of the heating system.

Options for calculating the total heating capacity

This indicator can be determined with varying degrees of accuracy in three main ways. Firstly, based on the boiler data sheet. So, about 15 liters of liquid are needed per unit capacity of boiler equipment. To get the necessary data, you need 15 times the boiler capacity indicated in the data sheet.

Secondly, you can find out the volume using a water meter when filling the system. As filling takes into account the amount of fluid used. This is a more accurate and troublesome option.

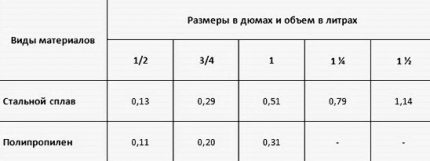

The third method involves calculating the total volume of all elements of the heating system. This is the most accurate option.The capacity of the heat exchanger of the boiler, radiators, convectors, measuring instruments can be determined by the passport characteristics. To calculate the capacity of the pipes, the data from the table are used.

The table shows the volume of pipes per meter length, made of the most popular and modern materials. The inside diameter is in inches from 0.5 to 1.5 units.

Another method that claims to be highly accurate is calculating by the formula:

Vtotal = π x D2 x L / 4,

Where:

- π is equal to 3.14;

- D - indicates the parameters of the inner diameter of the pipe;

- L - indicates the length of the pipeline system.

After obtaining the necessary data, they are summarized and the total volume of the system is obtained, which is used in further calculations.

Steps and formulas of a full cycle of calculations for the design and organization of heating a private house given here. We recommend that you familiarize yourself with useful information.

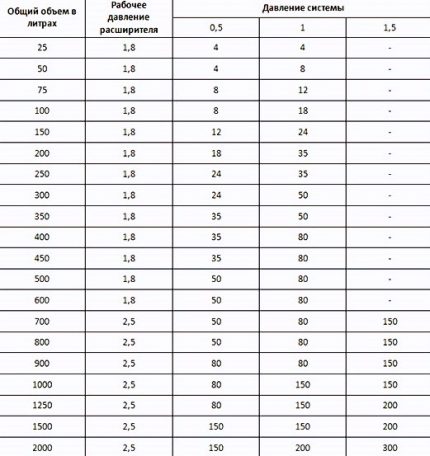

Selection of expansion tank according to the table

If you have the necessary data, the best option for the expander can be selected according to the table of volumes and design pressure.

The total volume of the system is calculated according to the specified method, the pressure parameters are relevant only for closed modifications and are indicated in the equipment data sheet.

This option does not require special calculations, except for calculating the total volume of the system. Using the table greatly facilitates and accelerates the choice of expander with the required tank capacity.

Using formulas for calculation

If the table data is not enough, it is possible to calculate the necessary indicator of the volume of the capacity yourself.

To do this, use the following formula:

Vb = Vc x k / D,

Where:

- Vb - denotes the desired capacity of the expander;

- Vc is the total capacity of the system;

- k is the coefficient of expansion of the liquid during heating;

- D is the coefficient of efficiency of the expander.

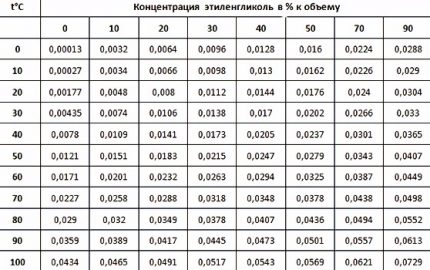

Of the data necessary for the calculation, the coefficients k and D remain unknown. The first is the tabular value, and the second is calculated by a separate formula.

A temperature expansion table also exists and is used. It allows you to determine the coefficient for systems with water or antifreeze. The value is not linear; it changes upon heating, depending on the presence and concentration of glycol in the liquid.

For water, the concentration of ethylene glycol is taken as "0", for antifreeze the concentration is determined according to the data declared by the manufacturer. The heating temperature is considered the operating temperature for a particular system.

To independently calculate the efficiency coefficient of the expansion tank, the formula is applied:

(Qm - Qb): (Qm + 1),

Where:

- Qm is the maximum pressure of the system according to the passport threshold of operation of the safety valve;

- Qb - preliminary pressure in the air chamber of the expander according to the data sheet.

If the last parameter is unknown, it is measured by pumping or by bleeding through a cylinder nipple.

Other calculation methods

In addition to independent calculations using formulas and tables, there are alternative methods. An affordable calculation option is the help of an online calculator.

Another option to get the data you need is to contact professional designers. This is the most reliable way, but the accuracy of the information received will be quite expensive.

With the rules for installing and connecting expanders closed and open type will introduce next articlededicated to these issues.

How to choose the right expansion tank?

It is recommended to determine the type of heating system at the planning stage. The choice of a tank is usually postponed for a period after the construction of the box, when the system is mounted, its volume is known.

When choosing the best option for the expansion tank, it is recommended:

- focus on the volume of the closed expansion tank that exceeds the value of the thermal expansion of the coolant;

- when buying, you should pay attention to the connection, the shape of the container and the location of the connectors for fasteners - this will avoid surprises during the installation process;

- It is important to pay attention to the instructions on the case, which contains useful installation information and technical parameters.

When buying, it is better to focus on a trusted manufacturer, even if its cylinders will cost more. This will be the key to the longevity of the heating system, however, subject to proper operation and regular maintenance.

Before connecting, the preliminary pressure in the gas compartment of the membrane tank is set to a value equal to the static pressure of the coolant column in the heating circuit. Adjustment is made by the usual automobile pump, it is controlled by the manometer.

Do not confuse expanders for heating systems and accumulators for cold water lines. They differ in appearance and design features. The first are painted red and usually not collapsible, the second are blue, equipped with a removable flange for membrane repair.

Conclusions and useful video on the topic

The video will help determine the parameters of the expander of the closed modification, to understand the differences between cylinders for heating and boiler systems:

The principle of operation and features of the choice of capacity in the video clip:

The heating system of a private house can be performed according to an open or closed scheme, which requires the installation of an expander of the appropriate design. A key factor in its performance is the volume that can be calculated independently or entrusted to professional designers.

Properly selected equipment will help to maintain the desired volume of fluid in an open system, and in sealed heating will maintain the level of working pressure.

Please write comments in the block below. Share your own experience in assembling heating circuits with an expansion tank and useful information for site visitors. Ask questions, publish photos on the topic of the article.

Expansion tank for closed heating: operating principle and device + how to choose and install in the system

Expansion tank for closed heating: operating principle and device + how to choose and install in the system  Expansion tank for open heating: device, purpose, main types + tips for calculating the tank

Expansion tank for open heating: device, purpose, main types + tips for calculating the tank  Selection of a circulation pump: device, types and rules for choosing a pump for heating

Selection of a circulation pump: device, types and rules for choosing a pump for heating  Pressure in the expansion tank of a gas boiler: norms + how to pump and adjust

Pressure in the expansion tank of a gas boiler: norms + how to pump and adjust  Heating systems in caravans: heater options for a comfortable temperature in the camper

Heating systems in caravans: heater options for a comfortable temperature in the camper  Thermal head for heating radiator: device, functioning + installation procedure

Thermal head for heating radiator: device, functioning + installation procedure  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements