Autonomous gas heating of a private house: device options and an overview of the best solutions

Heating systems using gas as a fuel are highly efficient and reliable. Generators of thermal energy in them have impressive efficiency, are safe to operate. There are several ways to arrange gas heating for a private house.

There are solutions both budgetary in execution, and more expensive with maximum efficiency and stability in work. We are ready to share with you proven in practice options for installing a gas heating system. Using our recommendations guarantees the construction of a reliable and reliable network.

The information we provide is based on building codes. The information offered for acquaintance supplement visual photo-illustrations, diagrams and video manuals.

The content of the article:

Centralized or autonomous gas supply?

Without a combustible fuel, there will be zero use of any version of a home heating system in an autonomous version. Gas is the first thing you need to think about when planning gas heating in a country house.

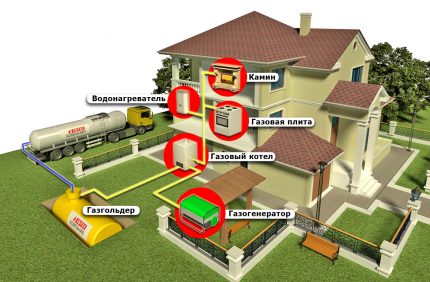

Not all settlements in Russia are gasified. However, “blue fuel” can be obtained not only from a pipe or cylinder with liquefied fuel, but also from a gas tank.

Natural gas, consisting mainly of methane, is piped to private homes. Its liquefied analogue is a propane-butane mixture, which is pumped into containers for transportation and storage. The pressure in such cylinders and gas holders is about 15-18 atmospheres.

When organizing heating in a private house using balloon containers of 50 liters, the latter will have to be changed every 2-3 days in winter. If autonomous gas supply is selected for a country cottage, then it is best prefer gas holder, which can be up to 20 cubic meters.

The choice of capacity per cubic meter depends on the level of consumption of liquefied petroleum gases (LPG). Here it is necessary to take into account not only the boiler, but also the fireplace and gas stove, if they are used in the house.

For a cottage of 150 sq.m. It is recommended to install a gas tank with a volume of 2000–3000 liters. And for a country house of 300 sq.m. you will need an option for 8000–9000 liters.

According to the cost of connection, a gas pipeline is in most cases more advantageous than a reservoir in the ground. But only when the locality is already gasified.

There are also possible situations in which the installation of a gas holder will cost less than connecting to a main pipeline. It all depends on the specific connection conditions in the region and the remoteness of the village from a large gas pipeline.

When using a gas holder, you don’t have to worry about the pressure in the pipe. It is extremely easy to operate. It is only necessary to regularly call specialists to check it for safety, and also do not forget to refuel. Installation of the entire system will take no more than three days.

If an autonomous gasification option is selected, then gas boiler should be purchased one that is designed to work on LPG. There are models on sale that are designed to operate solely on main natural gas.

But most gas heat generators are adapted to burn both varieties of this fuel. You only have to change the nozzles, as well as reconfigure the valve and electronics to a different mode.

The rules and specifics of gasification of country houses are described in detail in one of popular articles our site.

Choosing a heating gas boiler

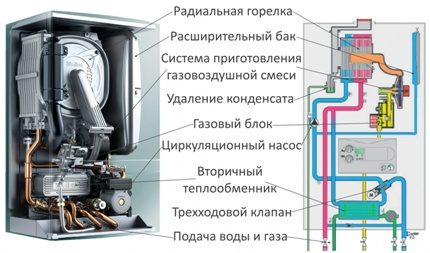

Modern gas-fired heat-generating equipment has a variety of automation and is able to work in several modes. It can be floor and wall.

The second option is more compact, but has power limitations. If the model is chosen for a large-sized private house, then you will have to purchase a powerful unit in the floor design.

The principle of functioning of a gas boiler is extremely simple - the fuel is ignited in the burner using piezoelectric elements or electronic ignition, then as a result of burning fuel, thermal energy is generated, which is transferred to the water through a heat exchanger.

The latter is already used as a coolant in the heating system or is consumed in domestic hot water.

The heat exchanger in a gas boiler can be made:

- from steel (stainless steel);

- copper;

- cast iron.

The most common options are steel. This metal is cheap and ductile, so cracks from constant heating / cooling appear less often in it.

But steel elements, when they constantly interact with the water of a gas heating system, arranged in a country house, quickly begin to corrode.

Cast iron is less susceptible to corrosion, but it is quite heavy. Most boiler models with cast-iron heat exchangers are floor standing. It is problematic to mount such heavy and overall equipment on the wall.

If you need a compact and lightweight heating unit, then the best option is with a copper coil. However, it costs the most among analogues of other metals.

The piping scheme and the principle of its use depend on the number of circuits in the gas-fired water boiler. One heat exchanger was originally designed to organize a gas heating system in a private house. For hot water supply, it is necessary to install another boiler or immediately select a dual-circuit model.

It is best to heat hot water for domestic use in a storage boiler. Streaming models are less economical. They will spend more gas on heating.

Which combustion chamber is better?

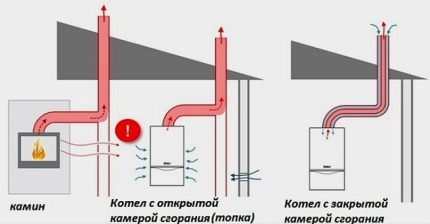

In order for the gas in the boiler furnace to burn, it needs a constant supply of oxygen. It is taken directly from the boiler room or pulled from the street. The first option involves a natural flow of air, and the second is forced by a fan.

Gas boilers are equipped with two types of combustion chambers:

- Closed - oxygen replenishment is carried out through the gap between the paired pipes of different diameters. The combustion products are discharged through the internal channel.

- Open - air enters the furnace from the room with the heating system through the supply valve. The combustion products are removed round in cross section by a smoke channel.

The first option is independent of the area of the room. Suitable for rooms of any size. The coaxial view of the chimney from the unit with a closed firebox can be displayed through a wall or an upper ceiling with a roof.

In the second case, it will be necessary to install a chimney high at 5–6 meters, otherwise the draft for suction of the required volumes of oxygen into the combustion chamber will not be enough.

But gas boilers with an atmospheric burner do not need to be connected to the mains. There is no fan in them; everything happens naturally without forced circulation.

It is recommended that gas water heaters with an open firebox be installed in special rooms with good ventilation. If you mount them in living rooms, they will greatly reduce the amount of oxygen in them.

Without a forced ventilation system there will no longer be enough. And this is an additional cost for the installation and subsequent operation of equipment for air ventilation.

Characterization of condensation models

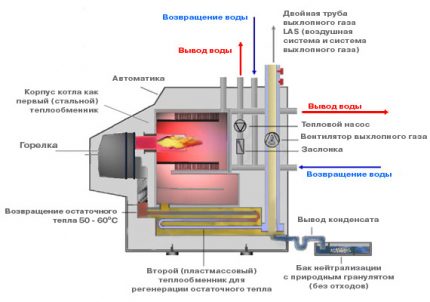

In conventional gas boilers, water vapor generated by the combustion of gas flies into the chimney. In the process of burning it forms a little, but it still carries a fairly significant amount of thermal energy. In order not to waste this heat, condensing boilers have been developed.

The principle of operation of these plants is based on the fact that when cooling the exhaust gas vapor, it transfers heat to the water from the return of the heating system. The temperature of the coolant increases slightly, but the recuperator is quite suitable as an additional source of thermal energy.

Condensed water from the condensing boiler is discharged through a special pipe into the sewer or a separate tank. It is worthwhile to clearly clarify one nuance - the condensate formed is actually a weakly concentrated acid. And in an hour it can leak up to 4-6 liters.

If this liquid is poured into a septic tank, then all the microbes living in it will be destroyed. If there is a cleaning station in a country house, condensate cannot be drained from the boiler into the sewer system. With the design of the chimney, everything is simpler, just take the one that is designed for boilers with a closed chamber.

Fireplace for gas heating at home

At the cost of equipment, gas fireplaces are comparable to electric or wood counterparts. But gas fuel is much cheaper.

And, unlike firewood, gas heating with a fireplace in a country house implies the absence of problems with ash. Plus, you do not have to constantly monitor the operation of the furnace and take care of chopping logs.

By type of installation, gas fireplaces are:

- near the wall;

- island

- recessed.

According to the general design and internal filling (burners, automation, device of combustion chambers) they completely repeat gas boilers. In both cases, the technology for connecting to networks is identical. Differences exist only in the principle of space heating.

The hot water boiler is originally designed to heat water, and a conventional fireplace - for convection of air from the body and front screen, behind which the combustion of fuel occurs.

Water heating schemes

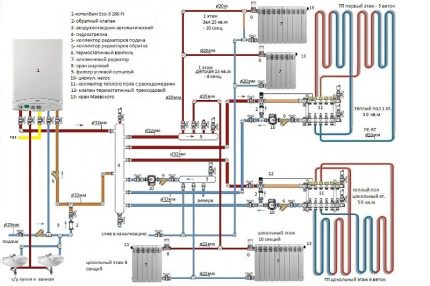

For heating cottages, heating systems with water as a coolant are equipped, consisting of:

- boiler water heating (single-circuit or double-circuit);

- piping and fittings (metal or polypropylene);

- bypassallowing disconnecting individual heaters from the network;

- of batteries (cast iron, aluminum, steel and bimetal);

- expansion tank.

Gas heating units are equipped with a specific security system, including an electromagnetic valve and a thermocouple. Devices are interconnected by wires.

If the heating unit is functioning properly, the thermocouple junction is heated by the igniter. At this time, a current flows freely through the solenoid winding, which ensures the valve is open.

When the thermocouple cools, the gas is blocked by the solenoid valve.

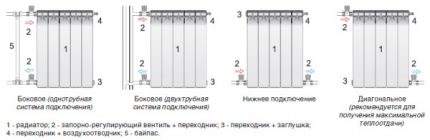

According to the scheme battery connection they are single pipe and double pipe. In the first case, water is supplied and discharged from the radiator using a single pipe. In the second, the heater is connected to two separate pipelines (supply and return).

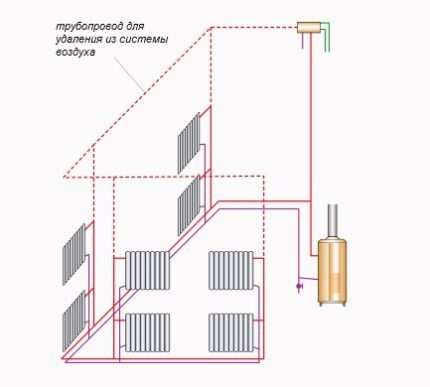

Heating circuits according to the principle of movement of water in pipes come with natural and forced circulation. With the device of the second option, the coolant circulates in the system due to convection and gravity. A forced circuit involves the installation of a circulation pump.

To ensure the normal operation of the system with two or more circuits connected to the collector, it provides for the installation of a hydraulic arrow. The hydraulic needle eliminates pressure drops and the likelihood of a water hammer.

The expansion tank can be open and closed (internally divided into two parts by a sealed membrane). For gravity heating systems, an open option will suffice. The closed tank is intended for circuits with forced circulation.

For small cottages, the natural principle of water movement will suffice. However, if a residential building has two or three floors, then you can not do without a pump. The length of the circulation circuit in the first circuit is limited to 30 meters. The boiler will not be able to “push” water over a greater distance.

With natural circulation of the coolant in the gas heating circuit of a private house, there is no pump. If the boiler is non-volatile, then the entire heating system is obtained independent of power supply. There are simply no elements that consume electricity.

On the one hand, it is more stable in operation, but on the other hand, the quality of heating in it is lower (the water reaches the coolest one that is farthest from the radiator water heater).

Especially the latter applies to pipelines and batteries made of steel or cast iron. These materials have high hydraulic resistance, which reduces the coolant current.

A variant of organizing a combined heating system is also possible. In her circulation pump connects to the trunk via bypass. If necessary, quickly warm the air in the rooms, it turns on to accelerate the water circuit.

And in other cases, it is cut off from the main pipe by shut-off valves, while the system continues to function in a natural (gravitational) mode.

Rules for arranging gas heating

Gasification and building a gas-based heating system in a private house is carried out in several stages:

- Preparation and subsequent approval by the regulatory authorities of a gas heating project.

- Purchase of consumables, boiler and other equipment.

- Connecting the house to the village gas networks.

- Installation of gas equipment and piping systems with batteries.

- Filling pipes with coolant.

- Functional test by trial run.

Independently prepare for your country house gas heating project with all schemes and calculations without the availability of a diploma in heat engineering is impossible.

In addition, the generated documentation still needs to be agreed with the gas industry. It is best to entrust all these procedures to the employees of the corresponding design and installation organization.

The arrangement scheme in a private house of gas heating should be calculated to the smallest detail. If the boiler is chosen too powerful, it will burn excess fuel. And with insufficient capacity, the unit will have to work at the limit of capabilities, as a result of which it will fail prematurely.

To obtain permission to connect to a centralized highway and to use liquefied gas equipment you need to receive a different package of documents. Before deciding on the organization of a gas system, you need to study not only them, but also weigh the pros and cons in order to determine the best option.

Conclusions and useful video on the topic

Clip # 1. The nuances of organizing a gas heating cottage:

Clip # 2. The principles of coolant circulation in the heating system of a private house:

Clip # 3. Self-assembly of various heating systems for country cottages:

Only an experienced heating engineer is competent to prepare calculations and schemes for organizing gas heating for a private house.

The preparation of project documentation and its coordination is best entrusted to professionals. But the further installation of the heating system can be done independently. Here you will only need installation skills, as well as strict adherence to instructions and the project.

Do you have any useful tips on organizing gas heating and choosing a gas boiler? Do you want to share your own experience or have you discovered controversial issues while familiarizing yourself with the material we presented? Please write comments and ask questions in the block below the text.

How to save gas when heating a private house: an overview of the best ways to save gas

How to save gas when heating a private house: an overview of the best ways to save gas  Infrared heating of a private house: an overview of modern infrared heating systems

Infrared heating of a private house: an overview of modern infrared heating systems  How to arrange heating a private house without gas: the organization of the system in a wooden building

How to arrange heating a private house without gas: the organization of the system in a wooden building  Electric heating in a private house: an overview of the best types of electric heating systems

Electric heating in a private house: an overview of the best types of electric heating systems  Heating from an electric boiler: options for organizing heating based on an electric boiler

Heating from an electric boiler: options for organizing heating based on an electric boiler  Heating systems in caravans: heater options for a comfortable temperature in the camper

Heating systems in caravans: heater options for a comfortable temperature in the camper  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

In Kaliningrad, every second one has autonomous heating, winters allow. Such heating and hot water cost, indeed, ridiculous money, especially in comparison with the central one. The boiler, of course, needs a double-circuit and better, so that with two open taps the pressure in both was normal. The need for regular maintenance is, of course, a minus, but the price still comes out much more profitable, even taking into account the cost of the boiler itself.

I left a large private house from my parents outside the city, where we spend a lot of time from late spring to autumn cold weather. But, unfortunately, in the winter it was impossible to be there.And how glad we were when we got gas there! Of course, I had to pay a considerable amount to install gas equipment in the house, but it's worth it! And if you autonomously heat them with gas cylinders, it’s really annoying to refuel them constantly.