Do-it-yourself gas stove from a gas cylinder: diagrams, drawings + step-by-step guide

Many private households have an old LPG bottle. Many useful things can be made from this object, for example, a simple heating device.

If there is a desire and a welding machine, then a potbelly stove from a gas cylinder with your own hands can be made without any problems. Of course, some additional materials will be needed.

The content of the article:

The principle of operation of the stove-potbelly stove

Potbelly stove - a primitive version of the metal wood stove. Such a device works extremely simply: firewood is laid in the furnace, they burn, the furnace body heats up and gives off heat to the surrounding air. Smoky gases are removed through the chimney, and ash is poured through the grate to the ash pan, which should be periodically cleaned.

One of the main advantages of a potbelly stove is its simplicity of design. There are no strict sizes, the main thing is that the body can withstand heat and the chimney works properly. An experienced master will make such a stove in just a couple of hours. And you can burn almost any dry tree in it: both logs and sawdust. There is an article on our site with a detailed description of the manufacturing process DIY potbelly stoves.

They also heat a potbelly stove with other combustible materials: diesel fuel, coal, peat, household waste, etc. If desired, you can cook quite successfully on such a stove. This point should be considered even before the start of the manufacture of the structure in order to make a smooth cooking surface.

But it should be reckoned with the disadvantages of such a heating solution. For starters, this is a high risk of burns and fires.

For a potbelly stove, you need to choose a special place, trimmed with fire-resistant materials. It is advisable that she stand on the side where no one accidentally touches the body and burns herself.

Such a metal construction weighs a lot, so there is no question of any mobility of the device. Moving a potbelly stove to heat different rooms will be difficult.

Utility rooms in which there is no electricity or where it is intermittently supplied with heat: a garage, a barn, a workshop, etc.

Another problem is the low efficiency, since part of the thermal energy during the combustion of wood literally flies into the chimney. There are various ways to keep heat and slightly modify a potbelly stove so that it works more efficiently.

Finally, you need to take care of the good ventilation of the room in which the potbelly stove is installed, since such a device burns a large amount of oxygen during operation.

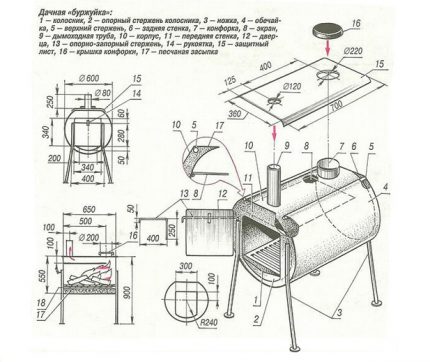

So, the potbelly stove consists of a metal case, the role of which is usually “invited” to the old gas cylinder. In the case it is necessary to make two doors: large and small. The first serves to load fuel, the second is needed as a blower, through which air enters from the combustion chamber to ensure the combustion process and traction.

Below, at some distance from the bottom of the structure, the grate should be welded. It can be made of thick wire or just take a sheet of thick metal and cut long slits in it. The distance between the rods of the grate should be such that the flue material does not wake up in the ash pan.

If the potbelly stove is heated only with wood, the grate gaps are made large, but when it is supposed to use wood chips, the grate should be made more frequent.

The ash box can be welded from sheet metal or you can take a finished metal container of a suitable size and resistant to strong heat. Some people prefer to dispense with an ashpit altogether; they simply remove ash from the lower section as necessary, although this is not very convenient. Usually, chimney for a stove lead up to provide the necessary traction.

The standard design of the gas cylinder stove can be improved by increasing productivity, turning a solid fuel heater into a heater or hob:

Manufacturing recommendations

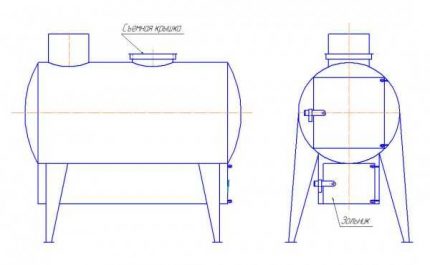

A potbelly stove from a cylinder can be different: the container can be placed horizontally or vertically. You need to choose a case of suitable size, and then use it correctly.

You will need a sheet of steel that is resistant to prolonged heating, a thick wire for the grate, a corner for the legs, etc. In the manufacturing process, a number of nuances should be taken into account to make the stove convenient and efficient.

Stage No. 1 - selection and preparation of the cylinder

Gas cylinders are very different. For potbelly stoves, a container for liquefied gas of 50 or 40 liters is best suited. If you need a small oven, you can take a cylinder of 12 or 27 liters.

But this will be a device for heating small utility rooms. Similar containers of five liters are practically useless. Such a small potbelly stove will heat up quickly, but will soon cool down, so the heating effect from it will be very insignificant.

An interesting option for a homemade potbelly stove is a container from under freon. Such a cylinder has thick walls and an elongated body. The container must be cut so that the body length is about 70 cm. Thick walls, of course, make the structure heavier, but they retain heat better. The potbelly stove will warm up for a long time, but at the same time it will warm longer.

When the cylinder is selected, you need to prepare the welding machine and remember the safety rules. Even in a very old cylinder there are always some remnants of combustible gas. If you immediately start cutting it by welding, a life-threatening explosion is almost guaranteed. For those who have not used the welding machine, we recommend reading this article.

To begin with, it is recommended to open the cylinder and vent the remaining gas. Of course, this should be done on the street, and not indoors. Then you need to drain the remaining liquid condensed inside from the balloon. This substance usually has a pungent and unpleasant odor, so it’s best to prepare in advance a small container with a lid for it to immediately pack and discard it gently.

If condensation is accidentally spilled on the floor of a room, a specific aroma can persist for a very long time. After all these operations, the cylinder is still not ready for contact with the welding machine, because the residual gas vapor remains inside.

It is necessary to fill the cylinder with water to the very top in order to completely displace all gas from it. After this, the water is drained, now the cylinder can be cut without problems.

Stage No. 2 - production and filling of the body

Next, you need to select the type of potbelly stove from the balloon, whether the cylindrical body will be located horizontally or vertically.

All other operations are carried out taking into account this orientation. If a horizontal position is selected, then one of the ends of the cylinder will serve as the back wall, and on the other you need to install a loading door and a blower.

A thick reinforcing wire can be used for the grate. In order not to cook the grate from it, you can bend it with a frequent zigzag, “snake”. This design is welded to the inner walls of the metal casing.

The front wall is made of metal sheet as follows:

- Metal must be applied to the front of the stove to mark it.

- According to the marking, a round part should be cut.

- Put another marking on it: for a rectangular door and a blower.

- Cut holes according to the marking.

- Make doors.

- Weld hinges, locks to the front wall and hang the doors.

- Weld the wall with doors to the body.

Both doors should be sealed with an asbestos-cement cord along the contour so that they fit snugly against the case. The back wall in such a stove is usually not necessary; its role is played by the bottom of the cylinder. In the upper part of the body, close to the back wall, you need to make a hole for the chimney.

The pipe must be taken from thick metal, since the lower part of the chimney will come into contact with heated flue gases. Thin metal in this place will quickly burn out. Now, solid legs of reinforcement, pieces of metal or pieces of a metal corner are welded to the bottom of the stove. They must withstand both the weight of the structure itself and the fuel that will be loaded into it.

About the same technology is used to make a vertical potbelly stove from a balloon. The bottom of the cylinder will become the lower part of the structure, at the top you need to make a cylindrical “roof” with a hole for the chimney. Usually the top of the balloon is cut off. At the end of the installation, it will be possible to weld it back. Doors - for loading and blowing - are made in front of the cylinder body.

Such a potbelly stove will take up less space than the horizontal version, and it will also be higher. If it is supposed not only to heat the room, but also to cook food, then it will be necessary to adjust the height of the stove taking this into account and ensure a smooth cooking surface.

But usually the diameter of the container is not large enough to provide a full cooking opportunity. Although boiling the kettle is a doable task.

The grate can be made in the same way as described above: from reinforcement bent by a snake along the diameter of the pipe. It is welded between the holes for loading and blowing.

Some are trying to reduce the amount of welding work, leaving the top of the tank virtually untouched. But then all other work will be more difficult.

For example, the grate will have to be inserted not from above, but pushed into the furnace door and somehow held in the correct position. Now you need to make the doors with hinges and locks and weld them to the body of the potbelly stove, previously sealing with an asbestos-cement cord. It remains to install a chimney at the top, and weld the legs below.

Stage No. 3 - manufacture of a door and an ash pan

Doors for potbelly stoves can be made from those parts of the body that remain after cutting holes. Hinges and latches are welded to them. These are simple elements. Loops can even be made from links in a thick chain. The second, more expensive option is to purchase finished cast metal structures.

You can choose two separate doors: a large one for the loading hole and a narrow one for the blower. But there are also sets in which such doors are combined into a single design.

The holes for such doors must be cut exactly to size. After that, you need to weld the frame from the corner to the edges of the openings.

The frame of cast doors is attached to the resulting frame with bolts. It is recommended to pre-weld a small side so that there are no cracks, and the furnace closes tightly.

In small potbelly stoves, if you wish, you can completely do without a grate.

It is difficult to find a place for it if you make a stove of small size or low, for example, a horizontal option. In such a device, no blowing is done, air is provided with the help of a loading door, which is simply opened. It is easy to make grate from the armature, but they are not particularly reliable.

Over time, the valve burns out, it has to be replaced. An alternative would be a piece of sheet metal in which slits or openings of a round shape are cut. To collect ash, you can use a special box - an ash pan.

In the horizontal version, stoves from the cylinder can be installed in the lower part complete with an ash pan, since the lower part of the case will have to be cut to facilitate installation.

Step-by-step photo guide

To make a home-made stove, you need one annealed empty gas cylinder, a Ø 108 mm pipe for a chimney (the meter depends on specific specifications), trimming a steel strip and corner, three hinges for hanging doors.

The construction of the body of the future stove is carried out in the following sequence:

The stove-potbelly stove from an empty gas cylinder is almost ready: the finishing touches remain:

The height of the chimney depends on the shape of the roof and the presence of a number of objects that can interfere with traction. It should be at least 0.5 m above the flat and low pitched roof. If there are tall trees or buildings nearby, then the mouth of the pipe must be arranged above them.

How to increase efficiency?

To make a potbelly stove work more efficient, there are several simple ways. First, you should insulate the chimney to save some of the heat that goes with the flue gases. Various methods can be used to increase the contact area of the heated metal with the surrounding air.

Significantly improve the heat engineering qualities of a potbelly stove constructed from a gas cylinder, a device of a kind of cap from an additional gas cylinder will help:

Some masters recommend making the chimney not strictly vertical, but curved. This will increase the path of the passage of combustion waste and allow part of their heat to return to the room. But it should be remembered that the complicated design of the chimney can adversely affect draft, so do not get carried away with excessive bends.

Sometimes metal wings are welded to the body of the stove, for example, made of a corner or any suitable strip of metal. If the dimensions of the stove allow, you can weld a horizontal sheet of metal on top and make an additional hole in it not for the chimney, but for a pot or teapot.

The hole is closed with a special compound cover of several concentric circles. By removing or adding circles, you can adjust the degree of heating.

Another option for modernizing a potbelly stove is a brick case. Masonry is performed around the stove, while leaving a small gap between the metal body and the brick. The brick will absorb some of the thermal energy, and then gradually give it to the surrounding air.

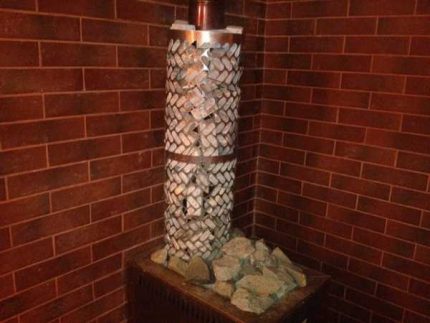

An alternative version of this modernization is a metal mesh around the chimney, in which pieces of brick or stone are laid. This is a popular solution for stoves installed in the bath, a variation of the stove. But it should be remembered that only river “naked” fish of a uniform color and without inclusions are suitable for this. If a stone consists of layers of different types, it can burst under the influence of high temperatures.

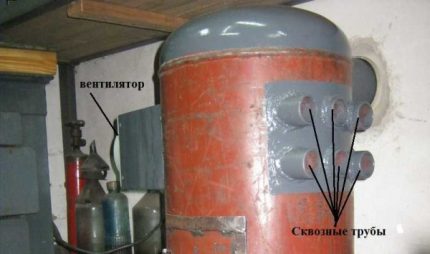

If you need a solid-sized furnace, the master has two gas cylinders at his disposal, you can combine them into one design. One of them is installed horizontally, and the second is placed vertically as a pipe for a chimney. The heating area is increasing, such a stove will work more efficiently.

Finally, you can insert inside the upper part of the pipe body through which air will circulate. If you put a fan at the end of these pipes, the air will move faster. Such an equivalent fan heater will allow you to warm up the entire room in a few minutes and more efficiently distribute thermal energy.

Conclusions and useful video on the topic

Here are recommendations for safely disassembling an old gas cylinder:

This video tells about the manufacturing procedure of a gas cylinder stove:

An original potbelly stove with the function of pyrolysis afterburning of fuel can be made of two gas cylinders:

A potbelly stove is a simple device that is not difficult to build and can be used quite widely. If the order of work is thought out in advance and correctly performed, such a stove can last quite a long time.

Please write comments on the article, ask questions, share your experience, if you already had to collect a potbelly stove from improvised materials.

Do-it-yourself stove stove: a scheme of a home-made stove for a summer house and garage

Do-it-yourself stove stove: a scheme of a home-made stove for a summer house and garage  Do-it-yourself gas bath stove: manual for the installation and installation of a gas stove

Do-it-yourself gas bath stove: manual for the installation and installation of a gas stove  How to make heating on waste oil with your own hands: schemes and principles of arrangement

How to make heating on waste oil with your own hands: schemes and principles of arrangement  How to make a potbelly stove on waste oil with your own hands: a review of the best homemade products

How to make a potbelly stove on waste oil with your own hands: a review of the best homemade products  DIY masonry: a detailed guide + orders with diagrams and drawings

DIY masonry: a detailed guide + orders with diagrams and drawings  DIY miracle oven for a garage in a diesel fuel: step-by-step instructions for the construction

DIY miracle oven for a garage in a diesel fuel: step-by-step instructions for the construction  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Great idea, I have these cylinders in the barn ..! Although it is full of heaters, the networks in our village are weak, and now, in the fall, all of their heaters were cut down, as well as kettles and microwave ovens, so the current is cut off every hour.

I already went and watched stoves, but I wanted it to boil the kettle, but what is on sale does not provide for this. Or provides, but the appearance is not like. And here you can do as your heart desires. Plus a cool idea - to overlay with stones, beautifully and functionally. You can do everything for yourself. I will embody, in short.

For 20 years I have been engaged in minor car repairs in my garage, in which there is no special heating. To heat the workplace in the winter, I use a similar stove and do not intend to change it, since its maintenance is very cheap. Only two car trailers are needed. Moisten firewood with waste oil, which increases their life by 30%, and the heat in the room! Friends are now asking me to make the same oven for them.

I confirm at the expense of stones. He bricked his potbelly stove and built a grid with stones on top. The duration of heating increased by 20-30 percent - purely by sensations.