How to make the right chimney for a do-it-yourself stove: a step-by-step instruction

To heat temporary buildings, garages, greenhouses, utility rooms, a potbelly stove is often used. But it also emits combustion products, a lot of smoke from burned wood or other fuel.

Therefore, you will need to decide how to make a chimney for a potbelly stove and where it is better to install it so that it is inexpensive and efficient. Moreover, this can be done with your own hands. Moreover, everything is not as complicated as it might seem at first glance.

To make it easier for you to understand the assembly and installation of the chimney, in this article we examined a step-by-step process, starting with the choice of material and assembly and ending with a test of the operability of an already mounted system.

The content of the article:

What can a chimney be made of?

To use a potbelly stove, you will need to take care of the removal of smoke. To do this, you have to build a chimney, choosing the optimal material.

To carry out work, you can invite specialists, but you can do everything on your own - especially since the amount of work is small.

Types of chimney pipes

Various materials are used to make the smoke exhaust pipe.

Initially, depending on the material of manufacture, there are 2 options:

- Take finished pipes manufactured at the factory;

- To make pipes from sheets of stainless steel or other sheet metal.

The cheapest way is to make pipes yourself. Here, the undoubted advantage lies in the fact that the pipe will be the right diameter, which is especially important for homemade stove bourgeois.

The second advantage of homemade pipes is cost. For their manufacture, you can use improvised material, or purchase metal sheets with a thickness of 0.6 mm or more. And better in 1 mm.

Moreover, it is possible to make an insulated pipe for the chimney by making 2 pipes of various diameters from sheets 2. Or take finished metal of different diameters. In addition to self-production of pipes for the chimney, you can stop at a simpler and faster option - buy finished pipes from the right material.

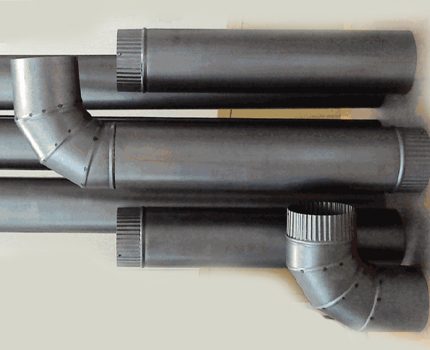

An elementary version of the assembly of the chimney for a potbelly stove involves the use of finished steel pipes and a corner element. A smoke channel is collected from them and welded to a makeshift stove:

Among the most common materials are the following:

- Brick. This is the cheapest material. From it lay a chimney on the spot, but this will require skill;

- Steel. Stainless, galvanized, alloyed (carbon) pipe can be used as a chimney;

- Ceramics. Ceramic products are of high cost, which excludes installation ceramic chimney in the garage or utility room;

- Asbestos cement. Asbestos-cement products are affordable, but not suitable as a material for the construction of the chimney. Although often they can be seen in this role;

- Vermiculite. These pipes are made of stainless steel with a 5-cm layer of vermiculite deposited on the inner surface of the pipe.

In addition to such options, the market offers many other products. So, you can meet pipes made of heat-resistant glass, from which it is quite possible to build an exotic chimney. But this is done extremely rarely - you need skill to install and connect individual structural elements to each other.

Recommendations for choosing a pipe for a stove

To make a chimney for a stove, it is not necessary to build pipes from metal sheets with your own hands. This will require some skill and time.

After all, the sheets will first need to be rolled into a tube of the desired diameter, and then tightly fasten the seam using rivets and heat-resistant sealant. It is much easier and faster to buy the necessary products manufactured at the factory.

As for the material, you should not take cheap asbestos-cement pipes for these purposes - this material will not stand if the temperature during the furnace rises above 300 degrees Celsius. And the pipe itself is quite heavy.

It will also absorb condensate. And to make a hole for cleaning from soot or removing condensate will be problematic.

To make a chimney for a stove from brick is unreasonably high costs. Firstly, rarely do any of the home masters know how to make the correct masonry. And secondly, it is a bulky design that requires additional reinforcement of the foundation. A potbelly stove is a temporary heating equipment.

A metallized corrugation can serve as a temporary substitute for a stationary metal pipe, but for constant use it must be replaced with a metal pipe:

It is optimal to take metal pipes from stainless steel, and preferably from alloy steel. A design made of such material can serve as a chimney for 7-10 years. This is provided that the pipes of sufficient thickness are 6-10 mm or more. And the build quality of all elements of the smoke exhaust system plays an important role.

Another undoubted advantage of metal pipes is their lightness. Light weight allows you to single-handedly perform all the work on the construction of a chimney for a stove.

We also recommend that you read more complete information on choosing a chimney pipe.

Having decided on the material of the future chimney, you can proceed with the purchase of all components and the construction of a correct and workable design.

Chimney construction briefing

The complexity of constructing a chimney for a stove is dependent on where the stove will be installed. After all, cutting a hole in the roof is more difficult than passing a pipe through a window.

Therefore, the complexity and time of manufacturing the correct chimney for a stove is completely dependent on the individual characteristics of a particular home ownership.

Stage # 1 - chimney assembly

The easiest option for constructing a chimney is if you have to use a potbelly stove on the street. It is important to choose the best place to install the stove so that flammable objects do not come into contact with it. Yes, and the pipes themselves must be heat resistant.

If the smoke removal pipeline is to be built indoors, then a number of safety rules must be observed that will help protect yourself and your loved ones from the fire.

Firstly, the pipes must withstand high temperatures - preferably 1000 degrees Celsius and above. After all, the smoke emitted during the combustion of fuel in a potbelly stove can have a rather high temperature.

Secondly, it is important to position the stove itself so that it does not come into contact with surfaces that may catch fire. If the walls are finished with lining or plastic, then additional work remains to be done to protect themselves from the occurrence of a fire hazard.

Thirdly, the place of entry of the pipe into the ceiling or wall should be properly framed.

To do this, it is important to maintain a distance to nearby objects and walls - during the operation of the stove, the temperature of the pipe will increase and objects nearby can flare up.

Fourth, only one potbelly stove can be attached to one chimney. For a second stove in an adjacent room, it is better to lay a separate smoke exhaust pipe.

Stage # 2 - taking measurements

At the preparatory stage, it is necessary to determine the desired diameter of the pipes and their total length. First, calculate the diameter of the pipe. Correctly, if it will be 2.7 times larger than the volume of the combustion chamber.

So, if a potbelly stove is 50 liters, then the diameter of the chimney should be: 50 * 2.7 = 135 mm. So, if you take a pipe with a diameter of 100 mm, it will not cope with the smoke emitted. As a result, there will be weak traction and effective work from such a potbelly stove to wait is useless.

In addition, the length of the future smoke removal pipeline is to be measured. To do this, it is important to choose a permanent location of the potbelly stove in the room.

Then determine where the pipe will go outside. An important point - during the removal of smoke in the chimney passing on the street, condensate will accumulate. It is worth taking care of its removal.

Now we have to measure the distance of the pipeline on the street and not forget that the chimney will rise, on average, 1.5 meters above the ridge of the roof.

It should also be provided that during the installation process you will need elbows, tees, a through hole, butt joints, heat-resistant sealant, asbestos cord, pipes of the desired diameter, pipe clamps or welding to connect all components into a single chimney design.

All this must be acquired on time, when all measurements are taken. The availability of the necessary materials will allow you to proceed with the installation of the chimney for the stove.

It remains to be decided in advance exactly where the pipe will go out:

- through the window;

- through the wall;

- through the ceiling.

It will depend on where to make a hole. Most often, a pipe is let through a wall or ceiling. To ensure security in this place you have to buy a special passage unit - a glass. It is made of heat resistant material that will protect from fire.

Stage # 3 - installation of all components of the structure

When it comes to a potbelly stove that works on the street, it is important here to take a pipe of the right diameter corresponding to the pipe branching from the potbelly stove.

The chimney must be put on the pipe. This is important, because if it is inserted into the nozzle, then smoke can seep out at the junction. You don’t have to install anything else - a potbelly stove can be used for cooking or heating food.

If we are talking about arranging a chimney in a utility room, in a garage or a greenhouse, then the procedure for carrying out the work will be more complicated. First you need to take a piece of pipe and carefully fix it on the chimney hole / pipe nozzle. It is important to put the pipe on this pipe.

Then you have to lengthen the pipeline using an elbow. The goal is to reach the wall / ceiling. A passing glass is already waiting here, through which a chimney will pass.

Further, the pipeline goes into the under-roof space and onto the roof or through the wall to the street. It is important that the outdoor pipe is insulated. Also, when the pipe goes outside, it is necessary to provide for the removal of condensate. To do this, put a tee and make an inspection window to simplify the cleaning of the chimney.

It is important to securely fix all connections, maintain a distance to walls and other objects that can easily catch fire.

Using a flash master to equip and seal the passage of the chimney through the roof greatly facilitates and speeds up the work:

Stage # 4 - System Check

When all the components of the chimney are assembled and firmly interconnected, you can proceed to the final stage - the installation of the hood and checking the operability of the structure.

So, sparks can fly out of a stove in the process of burning fuel.

As spark arrestor You can use a grid with small cells up to 5 mm in size. This is especially true if the roof or nearby structures are made of flammable materials.

If there is no danger of a fire, then you can do with a simple cap that is worn on the end of the chimney and fixed there with a clamp or carefully fixed with rivets.

To increase traction, you can use the deflector by choosing one of the options on the market, or by assembling it yourself. We offer you to read the detailed instructions for self-manufacturing chimney vent.

When the hood is installed, you can begin to check the operability of the entire chimney structure. To do this, you need to load fuel, set it on fire and see how it will burn and how smoke will escape.

If it begins to seep through some connection, then it is not hermetic. This problem needs to be fixed using heat-resistant sealant or welding.

Features of the chimney service

The chimney of the potbelly stove needs maintenance - inspection of the external state of the structure and cleaning of the pipe's interior. The frequency of maintenance is completely dependent on the material.

If this is an asbestos-cement chimney, then it will have to be cleaned more often. This is all due to the rough inner surface of the pipe, where soot accumulates with a vengeance.

Also, an asbestos chimney, if it was installed to remove smoke from a potbelly stove, may soon become stained or even burst during operation. This will lead to additional costs - you need to replace the chimney pipe.

For a metal chimney, the frequency of pipe cleaning is on average 1 time per year. It is also important to inspect the external state of the material - it is possible that some areas may burn out.

To remove soot from a metal pipe, you can:

- burn aspen wood;

- treat burned logs with a special chemical composition, which is easy to buy;

- make a hook for delicate soot removal.

The compositions for getting rid of soot are easy to use. They do not require special skills - it is enough to process firewood with a bag and burn a potbelly stove, as usual. The products of combustion will not contain harmful impurities. This is a safe way to clean a metal pipe.

In a metal pipe that removes smoke, soot most often accumulates in a horizontal section.

Experienced users of such chimneys have found a convenient solution - to drill a small hole and build a hook-shaped structure to remove soot. With this device, the pipe walls cannot be damaged, but it will be possible to clean the accumulated burnt.

A thorough examination of the external condition of the chimney will allow you to diagnose the need for replacing a particular area in time. Do not neglect this measure - because through the holes in the chimney the smoke will go into the room, and further operation of the heating device will become impossible.

Regular soot cleaning of the inner walls will help extend the life of the smoke exhaust pipe. Yes, and traction will always be at the right level, which positively affects the efficiency of the stove.

Our site also has other articles containing detailed information on the best methods for cleaning the chimney and recommendations for choosing a cleaning product. We suggest you familiarize yourself with them:

- How to clean the chimney from soot: how to properly clean the chimney

- Chimney cleaning products: the best way to clean the chimney from soot

- Chimney sweep log for chimney cleaning: composition of the product and rules of use + owner reviews

Conclusions and useful video on the topic

The subtleties of self-assembly of the chimney design are shown in the video clip:

If the draft in the chimney is too strong, you can build a device to adjust it. How to do this is shown in the video:

Inexperienced craftsmen often make mistakes during the installation of the chimney. A video clip tells about the most common problems:

If there is a problem with the release of smoke into the room, then it can be quickly and simply solved. The video demonstrates how to do this:

To service a metal chimney of a potbelly stove, you can use a simple method of delicate physical cleaning:

It is not difficult to make a chimney for a potbelly stove if you approach the task responsibly and do everything correctly. Only in this case, the compact stove will serve for a long time, without requiring additional attention to itself.

And the quality of its work will be constantly pleasing, the main thing is to timely clean the chimney from soot and other combustion products.

Do you use a potbelly stove equipped with a homemade chimney? Share your assembly experience and photos of the finished chimney in the comments section. Tell us what material you used for the chimney and how difficult it was for you to make a chimney.

How to make a spark arrestor on a chimney with your own hands: a step-by-step guide

How to make a spark arrestor on a chimney with your own hands: a step-by-step guide  How to make a gate for a chimney with your own hands: instructions for making a valve

How to make a gate for a chimney with your own hands: instructions for making a valve  How to make a chimney in a private house with your own hands: design options and their implementation

How to make a chimney in a private house with your own hands: design options and their implementation  How to put a deflector on a chimney with your own hands: step-by-step instruction

How to put a deflector on a chimney with your own hands: step-by-step instruction  How to make a chimney for a fireplace: the rules of the device of the smoke channel and a comparison of designs

How to make a chimney for a fireplace: the rules of the device of the smoke channel and a comparison of designs  Do-it-yourself garage oven: a step-by-step guide to design

Do-it-yourself garage oven: a step-by-step guide to design  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

To the very roof you need to take a stainless steel pipe 1 mm thick with a high-quality welding seam so that it does not burn out after a month, because the outlet temperatures are quite high. Further, so that all the heat is not carried out, as they say, into the pipe, you need to insulate the outer chimney. Well, here you can insulate yourself and buy insulated - although this pleasure is not cheap. With the height of the chimney, it is also better not to save, because the draft depends on this height. The material of the chimney pipe (the one on the street) is also desirable stainless steel, 0.5 mm is also possible, the main thing is not galvanizing. Many put asbestos pipes. But I think metal is better.

As for the brick chimney, it is the cheapest, most reliable and durable, unlike the same metal chimney, which is soot and resin overgrown very quickly. If we are talking about an asbestos pipe, then it can only be placed on the passage through the roof where the smoke has a temperature below 200 degrees, otherwise it will explode from heating.

A 0.5 mm thick stainless steel chimney is used only on gas heating, since the temperature of the exhaust gases is about 110 degrees, and for stoves, the output of the furnace gate can be higher than 350 degrees. Therefore, the thickness of the stainless pipe should be at least 0.8 mm and preferably 1 mm, and then you can go through the meter by 0.8 mm and through the ceiling already put a sandwich.

A potbelly stove now is a lot of garages and some outbuildings.There are exceptions, but rarely. Do you often see brick chimneys in garages? It is more important that it be collapsible, which greatly facilitates the cleaning, which is periodically necessary. So metal will work best.