How to sheathe a wooden house outside: the best types of materials and technologies for their installation

The outer cladding of a wooden house performs several important functions - it protects the walls from atmospheric influences, insulates the building, gives it a more aesthetic appearance. Even at the design stage, you should think about how to sheathe a wooden house from the outside, so that the finish meets the technical requirements and financial capabilities.

Consider the popular cladding options and find out which ones are better suited for cladding houses made of wood.

The content of the article:

What is the outer skin for?

Wooden houses to this day remain the most environmentally friendly, “breathing”, useful and comfortable for living. However, wood belongs to short-lived materials, therefore, it requires mandatory protection.

In addition, due to its softness and friability, wood is attractive for rodents, bugs and other animals.

But the protection becomes more effective if the top of the facade of a wooden house is covered with sheathing - reliable, beautiful, heat-insulating.

There are no universal rules for choosing a facing material, but preference is given to decoration, which has the following characteristics:

- is a heater;

- has vapor permeability;

- easy to install;

- has a low cost;

- does not require constant painting.

Of course, the wooden types of cladding win - lining, block house, planken, imitation of timber. They have the same characteristics as the main building material, and preserve the naturalness and environmental friendliness of the building.

But often they use other materials that are more practical and do not need constant care - for example, vinyl siding.

It is also worth taking care of the choice of insulation for the home. About which material is better to give preference, you can read in this stuff.

Overview of materials for home decoration

Often, when buying, they focus only on the cost of the facing material. This is the wrong approach, as cheap finishes require additional investment.

Acquiring expensive, but not suitable for technical parameters material is also wrong. Therefore, it is necessary to take into account all parties - cost, characteristics, compliance with the climate zone.

The modern market provides the opportunity to choose exactly the skin that fits perfectly in all respects. Popular types of finishes include four types of wood, and another four - from other natural and synthetic materials.

In addition to the above materials, for the finishing of log and timber houses, professional sheets are used - steel sheets coated with a polymer layer. Most often, they are decorated and imitate stone, wood or brick cladding.

Each material for finishing wooden houses is distinguished by its technical characteristics, conditions and installation method, cost. Polymeric materials that do not allow air and steam to pass through require the installation of a ventilated facade.

And now - in more detail about the materials themselves and the technology of their installation.

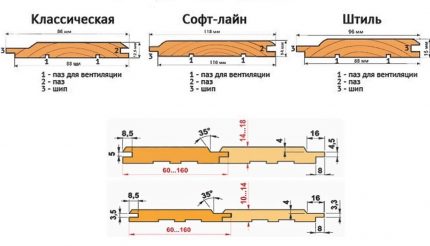

Option # 1 - wooden lining

An ordinary lining is notable for its low cost, availability, simple installation. This is one of those materials that you can use for self house cladding.

When choosing a material, you can rely on the standards specified in GOST 8242-88. There are more stringent regulations - DIN 68126/86, which sets out the requirements for the so-called "Euro lining".

Before use, the slats are dried to a certain extent - 10-15%. This provides additional protection against deformation, as well as from the effects of excessive moisture - rot, mold.

For home decoration, more expensive wooden cladding is often used, and ordinary lining is used for interior work or facing seasonal dachas.

There are many technologies for installing lining, then we will consider one of them in more detail.

Materials are attached to the wall of a wooden house in the sequence:

- lathing for insulation;

- thermal insulation layer;

- wind protection;

- counter lath;

- lining.

Sometimes the first layer is vapor barrier, which is attached to the beam directly on the brackets. But wooden lining is a natural material, so there is no need for vapor barrier.

Option # 2 - Block House

Many consider the block house a subspecies of the lining, but this is a completely different material - more durable, reliable and warm. It is made mainly of spruce and pine. Sold already in processed form.

To give the wood a particular shade, it is treated with azure, stain and glaze. You can change the color with a protective varnish or impregnation.

Before installing the casing from the block house, the logs are treated with antiseptic impregnation, reinforce the logs crowns, caulked caulk.

Work order:

- Fixing a roll or sheet vapor barrier with an overlap of 10-15 cm.

- Fastening of the vertical crate with a step of 0.4-0.6 m.

- Installation in the crate of insulation plates with dowels and nails.

- Thermal insulation coating with a windproof membrane.

- Installation of the second layer of the crate.

- Covering with a block house.

Lamels are fixed with clamps, self-tapping screws or nails. To avoid corrosion, it is better to use galvanized or anodized fasteners.

The block house belongs to those types of cladding that require processing once every 3-4 years. In order for the wood to maintain its original appearance and characteristics, it is coated with an antiseptic or acrylic varnish.

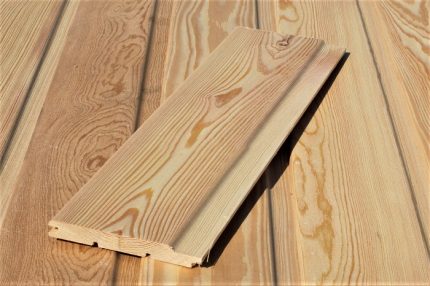

Option # 3 - imitation timber

Wooden boards imitating timber also belong to the prefabricated paneling and resemble lining. If you finish with quality material, then the exterior of the house will look like it was built from timber.

When buying material, you can choose the slats of the desired length - from 2 to 4 m. Also, the boards differ in thickness - 2.0-3.5 mm, in width - 10.5-17.5 cm.

By the method of production there are solid lamellas, and there are glued from several rails. Prefabricated parts practically do not differ from integral parts according to their characteristics.

The technology for installing a false beam is the same as for a lining or block house.

Option # 4 - planken

Compared to the skins listed, plank is a relatively new prefabricated material. It is installed in different ways, but more often - with an overlap or in a spike.

There are several types of planken: straight, beveled, with grooves. Installation methods are different. The straight line is fixed with gaps between the lamellas using spacers, the beveled one is overlapped, and with grooves it is connected like a lining. Before installation, it is necessary to make the crate from the profile.

Installation procedure for direct planken:

- We fix a vertical crate of timber.

- We fix the first element at the bottom, using self-tapping screws with a countersunk head.

- We install the PlanFix fastener - with one screw in the lath of the crate, the second in the lamella.

- We put a couple of spacers on the board to align the gap.

- We mount the next element - we hammer it on the PlanFix spikes.

- We continue to install lamellas in the same way.

- We fix the last board with screws.

- We take out the spacers.

The straight planken is not intended for insulation - it performs only a decorative function, therefore, thermal insulation should be taken care of additionally.

Option # 5 - vinyl siding

The siding was created specifically to make the lining of wooden, brick, panel, block houses. Lamels have special locks and holes for self-tapping screws, with which they are connected to each other and attached to the base.

To install vinyl siding, you need to erect a frame. Light lamellas do not require serious supports, enough rack battens. Vinyl does not let steam through; therefore, the facade must be ventilated.

The installation procedure for the various types of siding is the same, so the instruction applies to other types: metal, fiber cement.

Operating procedure:

- Assembly and installation of a frame made of wooden bars or a metal profile. If it is planned to make thermal insulation, then plates or rolls are fixed under the crate.

- Installation of the starting profile in the lower part of the facade, at the foundation.

- Installation of external and internal corner profiles.

- Installation of profiles for framing door and window openings.

- Installation of siding, starting from the start profile.

Lastly, we sheathe the area under the roof and pediment. Holes for self-tapping screws are not specially punched, we use only factory ones.

Option # 6 - metal siding

The main distinguishing feature of siding made of metal is its long service life, up to 50 years.

It is produced from rolled steel, the thickness of the sheets is 0.40-0.65 mm. Finished parts have a complex configuration, made by bending on special equipment.

When buying, you can choose the panels of the desired length - from 0.5 m to 6 m. The standard width is 20-25 cm. To circulate air, produce lamellas with perforation, which are usually located on the gables, for finishing slopes and cornices.

The color scheme is wide. In addition to plain siding, the products are “imitation stone” or “imitation wood”. Metal siding can be produced both in winter and summer, regardless of temperature and other weather conditions.

Option # 7 - fiber cement panels

No less popular are panels or siding made of cement and synthetic fibers - fiber, which plays the role of a reinforcing component. From the outside, the panels resemble masonry or brickwork, trim with boards.

The material for cement-based cladding does not fade in the sun, is not subject to fire, has a lighter weight than the metal counterpart, wear resistance and low hygroscopicity.

However, working with fiber cement parts is more complicated than with polymer parts and requires special drilling and cutting skills.

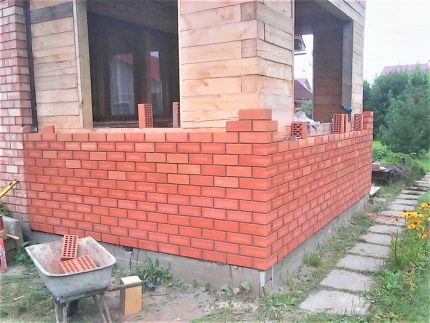

Option # 8 - facing brick

Sheathing of wooden buildings with stone, clinker or brick is very rare, as this is due to the complexity of installation. However, such a facing method is practiced due to the outstanding decorative effect. And the house after such "sheathing" becomes much warmer.

One of the conditions for using stone or brick cladding is a strong cement foundation that can withstand the weight of the finishing material.

It is also necessary to provide a gap between the wooden wall and the cladding - at least 5 mm. Finishing can only begin after the house shrinks.

Conclusions and useful video on the topic

Recommendations for choosing a casing:

The practical application of imitation timber:

Tips for installing siding:

When choosing a cladding for a wooden house, try to consider everything: from the nuances of installation to the rules for subsequent operation.

Do not forget that saving on material can result in subsequent regular expenses for caring for it. Try to find a compromise between the technical and aesthetic side, so that living in the house was comfortable and pleasant.

And what material for cladding a wooden house did you choose? What was guided by this and are you satisfied with the result? Please tell other visitors to our site about this. Leave your comments in the box below. There you can ask questions of interest on the topic of the article.

Finishing the house from the outside: types of finishing materials, their advantages and disadvantages

Finishing the house from the outside: types of finishing materials, their advantages and disadvantages  Insulation of a private house outside: popular technologies + material overview

Insulation of a private house outside: popular technologies + material overview  How to insulate the wall in the apartment from the inside: the best technology + workflow

How to insulate the wall in the apartment from the inside: the best technology + workflow  Insulation of the ceiling in a private wooden house inside and out: choosing the best material and the nuances of installation

Insulation of the ceiling in a private wooden house inside and out: choosing the best material and the nuances of installation  Insulation for the ceiling in a private house: types of materials used + how to choose the right

Insulation for the ceiling in a private house: types of materials used + how to choose the right  Insulation for walls of the house outside: an overview of options + tips for choosing an external insulation

Insulation for walls of the house outside: an overview of options + tips for choosing an external insulation  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

One of the most budget options is siding the house. This material can be selected for every taste and budget. For example, for my summer residence, I chose imitation of natural wood. The house at the parents completely lost sight, but due to redecoration found a second life. Only a true professional can distinguish siding from natural wood. And if you want, you can always change the material.

Of all the listed options for cladding a wooden (and not only wooden) house, the best option is vinyl siding. Sheathing with this material allows you to do work once and forget about the problem for a long time. All other options require periodic work on painting, gluing, fire treatment and other work, depending on the material.

Vinyl siding is cheap, but we were tormented when we started decorating the house in the fall. The material is such that it changes, albeit slightly, in size at different temperatures. It is better to cut in the heat, at first we tried on the spot, but the siding was not cut, but broke. The problem was not a jigsaw. When building materials were brought into the garage, things went better. And I had to drill ourselves. Only this must be done at low speeds.

Compared to wood paneling, siding has the advantage of being maintenance free. From time to time, it is enough to simply wash it with clean water or any household detergent without abrasive additives. When considering what material to sheathe a wooden house from the outside, this feature must be paid attention to. Varnishes and paints are not required. Once you pay for the material and installation, you can be calm for the appearance and condition of the facades for 15 to 20 years.