Insulation of a private house outside: popular technologies + material overview

The erection of the walls and roof of the house is only half the battle. It is necessary to make the built space comfortable for life. For this, insulation of the house is most often performed outside or inside, and sometimes both options are used simultaneously.

Do you want to insulate your home, but don’t know what technologies exist and where to start? We will help you deal with this problem - the article discusses the main options used for external thermal insulation. The order of the work was also considered, thematic photos and useful video recommendations on the nuances of warming were selected.

The content of the article:

Features of the building insulation process outside

The materials from which the walls of capital structures are built can be different: brick, concrete,slag- oraerated concrete blocks, wood,sandwich- panels - these are just their main types.

For some of them, insulation is not required at all: for example, forsandwichpanels. But other options need it to one degree or another.

Why is it necessary to insulate the outside? Many attribute this to the fact that in the case of the insulation layer inside the building, the usable spatial volume is stolen in the interior.

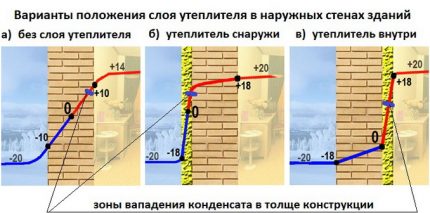

This is partly true, but that is not the main reason. The critical parameter is place of dew.

A dew point is formed on a surface where a temperature difference is observed with pressure.

And if you arrange the insulation inside the building, it means that the walls of the building themselves will be cold, since the insulation will save heat inside the space and prevent it from getting into the building envelope.

Methods and procedures for wall insulation

It turns out that the change in weather fromout will provoke a change in humidity inside.Moreover, the changes will be significant - condensation will form on the walls, which will not be able to dry. Hence a number of negative points, including development mold and mildew.

That is why it is so important to insulate the walls from the outside. In total, 3 technologies differ, with the help of which warming of capital structures is carried out. It seems reasonable to dwell on each of them in more detail.

Method number 1 - well

This is one of the oldest ways to insulate the walls of your house from the outside. Indeed, everything is logical: capital bearing walls are built, and after that, having retreated a little, they are covered with another row of bricks - a thickness, for example, of a half brick.

Between the capital and the external, let's call it decorative, a wall forms a void - a "well" that creates the effect of a thermos.

The distance from the decorative wall to the main wall is adjusted with the help of special connecting steel anchors or a reinforcing mesh is laid. It overlaps the section of the well and simultaneously serves as reinforcement for strengthening the external wall.

Dew in this case will fall on the inner surface of the decorative wall. It is more thermally conductive than air in a well, which, moreover, is heated from an internal load-bearing wall.

Thus, condensation will inevitably form on the wall cooled from a colder external environment. However, the presence of free space will allow air to circulate inside the well and the condensate will evaporate again.

The distance between the supporting and decorative walls should not be too small, because:

- Firstly, it will increase the heat transfer from the inside wall to the outside;

- and secondly, makes convection of air inside difficult, therefore, the drying of the condensate will stretch over time.

Therefore, for normal air circulation it is recommended to leave free space not less than half a brick wide.

But be that as it may, and in this case, the insulation is carried out by air, and for many this seems insufficient.

The technology allows the additional use of any type of insulation, whether extruded polystyrene foam, polyfoam, polyurethane, polyurethane foam or mineral wool.

It is important not to make a mistake, to which surface this insulation should be attached. Therefore, it is worth remembering that the insulating material should be mounted exclusively on the internal, main wall. Next, there must be an obligatory layer of air - a well, and then - a decorative wall.

In this case, the temperature difference on the inner surface of the decorative wall will be less, because the air space in the layer will receive an order of magnitude less heat from the inner wall covered with an insulator. So, the volume of condensate falling on its surface will also be less.

Well insulation technology for a private house implies the absence of purged ventilation in the air gap. That is, a microclimate should form inside, which should not exchange moisture with the environment.

Therefore, when constructing such a multilayer wall, special attention should be paid to ensure that no holes form in the decorative wall, for example, in masonry. After all, only that moisture which is contained in the blocked air will fall on its inner surface.

And if gas exchange with the environment is present, then the amount of moisture will be added, which will lead, in the end, to the wetting of the insulation.

Method number 2 - wet plaster

This technique is interesting, thanks to two features: the problem of dew loss is solved by itself, and the work of warming the house from the outside is highly economical.

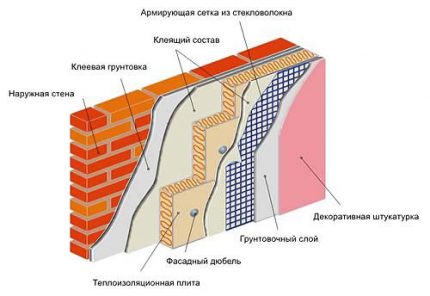

The algorithm of actions when using such technology of external thermal insulation in a house is as follows. Insulation plates are installed on the capital walls from the bottom up.

If it is decided to use expanded polystyrene orpenoplex, then this insulation requires that the main wall before this be leveled and even putty,at least, all cracks and crevices were covered.

In order for the bottom layer to stand evenly, it is initially required to install a stop bar on the wall as the bottom edge, anyway, from what material. Each insulation plate must be attached to the wall with at least five clamps on the dowels - 4 in the corners and 1 in the center.

Then, using a glue solution, a layer of a reinforcing polymer mesh is attached to the insulation. First, the insulation boards are coated with epoxy glue, then the mesh is fixed and a layer of glue is applied again.

Further, a layer of plaster is applied to the prepared surface - not more than 5 cm thick. It can be mixtures: cement or polymer-cement, cement-lime, silicate, based on epoxy resins. After drying, the plastered surface is painted.

Such a “layer cake” of warming does not imply the presence of any voids inside, where there may be air in significant volumes, as, for example, in “well" technologies. Therefore, there is simply nowhere to drop dew.

In addition to thermal insulation of the room, the technology of applying wet plaster is indispensable from an aesthetic point of view. For example, in cases where it is necessary to preserve the historical appearance of brick buildings.

Method No. 3 - ventilated facades

The installation of ventilated facades allows not only to qualitatively insulate the house from the outside, but also to give the structure a completely different appearance. As a rule, this uses tiles made of artificial stone of various textures, colors and shades, but even wooden lining can be used.

At its core, the technology of ventilated facades is very similar to well, but it has a number of significant differences. Let's analyze the algorithm in more detail.

First of all, vertical metal rails are mounted on the insulated walls of the building. The step should be chosen based on the width of the insulation plates, which, in fact, will be fastened in 5 places with holders on the dowels to the walls between the rails. This should be done as tightly as possible.

Then, the outer surface of the insulation is covered with a vapor-moisture protective membrane, which can be a regular polyethylene film.

Why in the case of well this membrane is not used by technology, and when forming ventilated facades it is extremely in demand - more on that below.

The height of the guides must be calculated so that from the membrane to the inner surface of the decorative panels there is a gap of at least 8 cm. The decorative panels are mounted on the rails using special clamps. The seams between them are not sealed at all.

Dew in this case will fall on the inside of the decorative panels. Moreover, it will be relatively many. This is because the facade is ventilated precisely through the numerous slots between the panels.

Unlike well technology, due to the gaps between the cladding, the volume of air between the panels and the wall of the structure is constantly different. This means that new humidity comes with new air.

That's it, in order to protect the insulation layer from the damaging effects of high humidity and is requiredvapor protective membrane.

AT well technologies when forming a decorative wall, it is required to deviate from the surface of the wall or insulation (if used) not lesshalf-brick -12.5 cm. So why are the standards for ventilated facades lowered - only a minimum of 8 cm indentation is required?

The answer is in the intensity of ventilation. In the well, evaporation of condensate occurs due to convection in the internal cavity of the wall. And in the case of a ventilated facade, moisture is literally blown out by a draft formed by the external environment.

A few words about suitable heaters

There are many kinds of insulating materials. However, the most popular in terms of efficiency / cost ratio are: mineral wool, polystyrene foam and polystyrene foam.

View # 1 - mineral wool

Mineral wool replaced the common, cheap glass wool. Unlike its predecessor, the insulation made, for example, from basalt, is absolutely harmless when handling it.

The use of special technologies allows turning a solid mineral into a fibrous material, which is able to effectively retain warm air between its fibers, isolating the surface from the effects of cold.

In addition, it has low thermal conductivity, so a layer 30 mm thick is enough to significantly reduce heat loss in the house.

View # 2 - expanded polystyrene

This material has a lower thermal conductivity than mineral wool - from 0.028 to 0.034 W / (m * K).

In addition, extruded polystyrene foam is completely impervious to moisture. And if the plates are carefully adjusted to each other and the joints are coated with waterproof glue, then in the technology of raw plaster you can do without a layer of vapor barrier membrane, which simplifies the technology of insulation.

View # 3 - Styrofoam

Polyfoam differs from polystyrene in that this material has vapor permeability, that is, it is hygroscopic, and therefore requires the use of a moisture barrier.

In addition, the foam is also flammable, and also requires a perfectly smooth surface of the insulated wall. Of the advantages, it can be noted its low cost and good thermal insulation properties.

We also recommend reading our other material, where we examined in detail varieties of insulation for the walls of the house from the inside. More details - go to the link.

Conclusions and useful video on the topic

Analysis of the most common errors with external insulation of the facades of private houses:

Thermal insulation of capital buildings ceases to be a separate issue, which is decided after the house is built. Now it is decisive in choosing the construction technology itself.

Over time, with the rise in price of electricity and energy, such as gas, it will be issues that come to the fore in the construction of a buildingheat saving.

Tell us what method of insulation you used to insulate your own home and what materials used for this. Are you satisfied with the result? Please leave your comments in the contact block located under the article.

How to sheathe a wooden house outside: the best types of materials and technologies for their installation

How to sheathe a wooden house outside: the best types of materials and technologies for their installation  Warming of a wooden floor: popular insulation technologies + expert advice

Warming of a wooden floor: popular insulation technologies + expert advice  Finishing the house from the outside: types of finishing materials, their advantages and disadvantages

Finishing the house from the outside: types of finishing materials, their advantages and disadvantages  Insulation for walls of the house outside: an overview of options + tips for choosing an external insulation

Insulation for walls of the house outside: an overview of options + tips for choosing an external insulation  Do-it-yourself warming the balcony: popular options and technologies for warming the balcony from the inside

Do-it-yourself warming the balcony: popular options and technologies for warming the balcony from the inside  Insulation of the ceiling in a private wooden house inside and out: choosing the best material and the nuances of installation

Insulation of the ceiling in a private wooden house inside and out: choosing the best material and the nuances of installation  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

We built our house, thought it was warm, but something did not calculate. The first winter we froze, although we turned on the boiler at full capacity. In the summer we decided to warm. The easiest way that occurred to me was to insulate with mineral wool. Expanded polystyrene was not considered in principle because of its flammability. It turned out pretty well, let's see how to winter.

We made a budget and not the most troublesome option. Over the walls of silicate brick was insulated with ordinary foam 50 mm. They write that extruded polystyrene is denser and better, but have you seen its price? Well this is unbearable money. Normal dense polystyrene is excellent. Putty on the grid, and on top of the decoration they covered 1.5 cm and painted. The only thing I regret is that I did not take the polystyrene top ten. It would be warmer.

They write for a reason. Extruded polystyrene is one level higher than conventional polystyrene in almost all respects. This applies to thermal conductivity, and mechanical strength, and hydrophobicity, and a much lower tendency to shrink. No wonder he is now enjoying such popularity. Yes, it costs more, but not too much money. Although this, of course, is individual for each family budget.

But this is if it speaks of warming in general. Specifically for the facade, in my opinion, the faculty of facade brands is still better than an extruder. To EPS, the adhesion of conventional adhesive compositions to wet facades is very low.

Of course, the price between ordinary polystyrene and extruded polystyrene will be different, the latter will be more expensive. But let's take a constructive approach to this issue. Why is extruded polystyrene more expensive than polystyrene? And here it is enough to look at the characteristics. I attach the table, pay attention to the density and thermal conductivity index. The higher the density, the lower the thermal conductivity, which means that less heat will be lost through walls insulated with extruded polystyrene foam.

The difference in price between these two heaters is not so big as to categorically contrast the foam with extruded polystyrene foam. The latter will be more expensive by 20%, not such a large amount will be, given the best indicator of thermal conductivity.