Glue for PVC pipes: an overview of the best compositions and instructions for use

Metal and ceramic pipes are being replaced by polymer products. They are becoming more popular due to their obvious advantages - durability, lightness, corrosion resistance and aggressive substances. With careful handling, the plastic pipeline can last at least half a century.

The main thing is to ensure high-quality, tight docking of elements. To assemble parts, use special glue for PVC pipes. The so-called “cold welding” allows you to build a water supply system with minimal labor. However, the use of glue has a number of nuances that must be studied before starting work.

The article outlines the advantages of the adhesive method of joining plastic pipes, provides an overview of the best manufacturers, and also gives recommendations on choosing the right composition. Step-by-step instructions for gluing PVC products will help you assemble the pipeline yourself and avoid possible errors.

The content of the article:

Advantages of adhesive pipe joints

Pipes made of polymers are welded, glued or mechanically interconnected. The first method is the most popular. For welding use special equipment and nozzles, selected according to the diameter of the pipeline.

It is better to entrust such work to professional masters. Option - rent or buy welding machine. It is expensive, but it will help to master another useful skill.

Adhesive bonding is less common, but no less effective. It is commonly called “cold welding”. Glue joints are as reliable (and sometimes even more) as welded.

The only caveat: almost all types of adhesives for plastic pipes are designed for cold water supply systems and can quickly lose their properties under the influence of high temperatures.

Advantages of bonding PVC pipes using special compositions:

- Leak Risk Reduction. When gluing pipe sections, the parts are connected at the molecular level. The seams are absolutely leakproof, and they can start to leak only under the influence of high temperature or pressure.

- Minimum labor costs. For gluing pipes do not need any additional complex processes. This is a simple method that does not require special skills.

- Fast and cheap installation. All operations can be done with your own hands. It is enough to buy materials and choose the right adhesive composition. No need to look for a welding machine.

- Low energy consumption. The apparatus for welding polymer pipes works from the mains, and equipment is not required for gluing parts. This is an additional saving on materials and energy.

- Versatility. The method is suitable for connecting pipe parts of any diameter - from 6 to 400 mm. It can be used in the installation of plumbing and sewer systems.

Cold welding is a cheap and convenient way to install a pipeline. To use it, you do not need anything that can lead to more expensive work: you do not have to spend money on additional connecting elements or special equipment.

The principle of operation of all types of adhesive for polypropylene pipes is approximately the same. The compositions partially dissolve the polyvinyl chloride and firmly bind the particles.

The composition includes additives that improve adhesion. When bonding, the solvent evaporates quickly, and the composition hardens and gains strength. The result is a high-strength connection.

On the market you can find products for creating high-strength compounds from both foreign and domestic manufacturers.

Review of the best brands

Trademarks lead in all ratings of adhesives for PVC pipes Tangit (Germany), Genova (USA), Griffon (Netherlands), Gebsoplast (France). Buyers speak well about adhesives "Phoenix", “Vinylite”, “Mars” and others, but they are not so in demand and popular.

All types of adhesive for polymer pipes operate on the same principle, are available in packs of various volumes, and the appropriate composition should be selected depending on the purpose and technical characteristics.

Rules for working with adhesives

When working with glue, you should always read the recommendations of the manufacturers. Many compounds cannot be left open for more than a few minutes, as they quickly set, which makes their further use difficult. The average time that an adhesive can remain open is 4-5 minutes.

When buying a particular brand of glue, you should pay attention to its preparation for work. Some types are quite simple to mix, but two-component compounds have to be properly combined, to monitor their consistency.

There is a risk of improper mixing, which leads to a loss or change in adhesive properties.

Color and viscosity matter. Experienced plumbers prefer medium viscosity formulations. They are easy to apply, and when connecting parts such glue does not spread, it does not have to be removed once again with napkins.

As for color, the colorless composition is suitable for white and colored pipes. It is not visible, even if the drops protruded beyond the bonded area and froze.

Criteria for choosing pipes and type of glue

When buying pipes and fittings, they pay attention to the purpose of the products, the diameter, wall thickness of the products. Of fundamental importance is the brand.

A good brand is not only money invested in advertising, but also real quality, thanks to which the products do not lose market positions. It is always better to choose reliable manufacturers, even if their products cost a little more than the unknown counterparts.

When choosing components, it is worth reading the technical documentation, which indicates the purpose of the product, the temperature regime at which it remains functional, safety factor and service life, manufacturer's warranty.

Carefully consider pipes and fittings. Their internal and external surfaces should be smooth, and the structure should be homogeneous, without signs of delamination, sagging, cracks and other defects.

When buying glue, consider not only the characteristics of the composition itself, but also such nuances:

- Place of installation of the pipeline. Working conditions at different sites can be very different in terms of degree of contamination, fluid temperature in pipes or the environment, and other important parameters. It is possible that for different zones adhesive compositions will have to be selected separately.

- Fluid pressure. All manufacturers take care that they do not have unnecessary claims from customers, therefore they must indicate what pressure the pipe glued by their composition can withstand. The higher this characteristic, the more reliable and more expensive glue. Saving irrationally. Must match water pressure with the value indicated on the adhesive packaging.

- Load Features. Often pipelines can move due to mechanical stress from the outside or due to pressure from the inside. If serious shear loads are possible at the joint, a more reliable adhesive should be selected.

- Temperature mode. Some types of glue are perfect for arranging an HVS system, but will be ineffective for a sewer pipe, as the temperature of the effluent is different.

When choosing glue, it is important to consider the characteristics of the compositions. Usually they include volatile toxic substances. People who are prone to allergies, it is better not to work with toxins: you will either have to entrust the installation of the pipeline to specialists, or choose a different method of connecting parts.

Pipes, fittings, adhesives should be bought only at specialized retail outlets. You should not save, choosing the "same" products in the spontaneous market.

Popular products are often faked, so it is best to contact sellers with a good reputation who monitor the reliability of their suppliers, are ready to provide guarantees or exchange low-quality goods.

Step-by-step instructions for using the composition

Before you start gluing plastic pipes, you should make sure that the room provides normal air circulation, and the temperature is in the range of 5-35 ° C.

In addition to materials, some tools will be required to work:

- for marking - marker and measuring tools;

- for cutting pipes - pipe shearsjigsaw or hacksaw;

- for cleaning surfaces - sandpaper;

- for degreasing - solvent;

- for applying the composition - the glue itself, a brush made of natural bristles (some adhesives, including Tangit, are immediately equipped with a suitable brush) or a glue gun.

Surface preparation - an important step in gluing parts. They should be perfectly smooth and fat free. If contaminants remain on the pipe, glue will be taken only on top of them, form a film, but there will be poor contact with the surface itself. This can lead to leaks over time.

PVC pipes are prepared for the upcoming gluing in several steps:

Piping bonding technology:

- Pipe marking. Before starting installation of the pipeline, a project and a detailed diagram should be prepared. Pipes are measured and marked on them.

- Pipe cutting. The next stage is the preparation of segments of the desired length. Pipe cutters are best used, but other tools will do. The main thing is that the cutting points are even. The edges are cleaned with sandpaper.

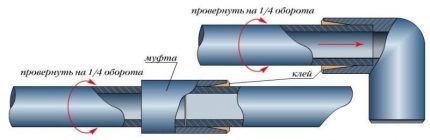

- Bonding system elements. The most convenient is a glue gun.With it, you can evenly and accurately distribute the composition on the surface. If there is no gun, use a brush. The glue is applied so that in the selected area there are no free areas left from it.

- Connection parts. To connect, the elements of the system are pressed against each other for at least 20-30 seconds. During this time, the composition thickens, becomes more viscous. Then the item can be postponed for a day. It is important that the compression force is sufficient, otherwise the joint may leak during operation.

- Pipe cleaning. No matter how neatly the adhesive is applied, it may protrude beyond the intended area. It is removed immediately until it has frozen. To do this, a wet towel, rag or sponge is suitable.

- The polymerization of the composition. It takes 20-24 hours to harden the glue, so it is better not to touch the system earlier. It is impossible to shift, disconnect and reconnect parts, to let water through pipes.

When the glue polymerization process is completed, you should check the efficiency of the system. It is launched in operating mode and carefully examined all the joints.

If it doesn’t leak anywhere, everything is in order. If leaks are detected, the connections are additionally sealed.

An important nuance: when gluing parts you need to work very clearly. A piece of pipe is inserted into the fitting in one motion. It should not be sharp, but fast. When the pipe is inserted, it must not be rocked or twisted so as not to reduce the strength of the connection.

Conclusions and useful video on the topic

Using cold welding, truly high-quality water and sewer pipelines are assembled. Moreover, the method can be equally effectively used when laying communications in a private and multi-story building.

If there is no self-confidence, it makes sense to hire professionals. But for house owners who can handle tools, it will not be difficult to independently perform the work. To help craftsmen, we offer useful video materials.

Why is it better to stick PVC pipes together? An experienced master answers:

How and how to cut polymer pipes is described in the following video:

The ideal choice is a multifunctional tool that evenly cuts pipes and immediately chamfers:

The choice of glue directly depends on the type of pipe, so they should pay attention to:

A simpler technology for joining polymer pipes than gluing does not exist. The method is cheap, convenient, and not inferior to welding in efficiency. Almost anyone can handle the installation of the pipeline with glue, ashe does not need any special skills.

The main thing is to choose the right pipes, glue and tools, and when working, be careful and accurate.

Share your experience with gluing PVC pipes with readers, tell us what kind of glue you used in your work. Please leave comments on the article and ask questions of interest. The feedback form is located below.

Scissors for cutting polypropylene pipes: species overview + instructions for use

Scissors for cutting polypropylene pipes: species overview + instructions for use  A cable for cleaning pipes: types, how to choose the right + instructions for use

A cable for cleaning pipes: types, how to choose the right + instructions for use  Fittings for plastic pipes: types, applications, an overview of the best manufacturers

Fittings for plastic pipes: types, applications, an overview of the best manufacturers  Sealant for the bathroom: types, selection tips and instructions for use

Sealant for the bathroom: types, selection tips and instructions for use  Hidden wiring indicator: principle of operation and instructions for use

Hidden wiring indicator: principle of operation and instructions for use  Pipe cutter for plastic pipes: choose the best model + instruction for use

Pipe cutter for plastic pipes: choose the best model + instruction for use  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I am looking for high-quality glue for repairing heating systems and tools, a degreaser. Tell me.

And why are you not satisfied with the recommendations for glue for PVC pipes from the article? Or do you need advice from personal experience? If so, then from experience of personal use I can recommend several options:

- Glue for PVC pipes Griffon UNI-100;

- Strong Seam (Durable seam).

The first option does not need to be introduced, the second is Ukrainian-made glue. At a price much lower, but the quality is in no way inferior (I will attach the photo). As for the degreaser, I use a cleaner for PVC pipes ERA 500 ml (primer). As for me, the optimal price / quality ratio (attached photo).

As for the tools, everything is standard here: sandpaper, pipe cutter, adjustable spanner, pliers. This is often enough in 80% of cases.

It was the case, once they called me to an accident, to eliminate the leak on the water supply. I arrived, and they had adhesive plastic everywhere, put it about 15 years ago, it broke at the connection.

I went to look for glue, it turned out to be not so easy, now very few people are interested. Found, of course, a set, glue + degreaser.

The first time I encountered this technology was the beginning of the 2000s. Well, the instruction was, I degreased both parts, and smeared with glue, put it together after a while, nothing complicated.