Pipe cutter for plastic pipes: choose the best model + instruction for use

Self-installation of a water supply, sewage or heating system requires not only certain skills, but also special tools. One of them is a pipe cutter for plastic pipes, without which it is impossible to obtain subsequently high-quality welding seams.

For the optimal choice of tool model, you should familiarize yourself with the types of pipe cutters and the features of their work.

The content of the article:

Classification and types of pipe cutters

There are a huge number of designs of household and industrial pipe cutters for plastic pipes, but the principle of their action is usually reduced to two options:

- roller;

- guillotine.

Roller pipe cutters have from one to several tens of cutting elements fixed on rigid or movable bases. During their movement around the pipe, the rollers gradually deepen into the plastic wall until it is completely cut off.

Structurally, the roller models of the tool practically do not have complex mechanical elements, therefore, their price is quite low.

For guillotine devices, the cutting edge is a solid blade that is pressed into the wall of the plastic pipe using manual force. Most models have a built-in ratchet mechanism that allows you to make the cutting process smooth and relatively easy.

Naturally, the devices differ in other parameters:

- diameter of the processed pipes;

- types of materials available for work;

- the maximum wall thickness that the device is able to cut;

- the presence of an electric drive.

The maximum pipe diameter for manual cutting is 110 mm. This is the thickness of the sewer pipe for the toilet or the inside riser. But most tools are limited to a diameter of 50-63 mm.

The maximum wall thickness of a plastic pipe is limited only for roller pipe cutters, so they should be selected based on this parameter. Cutting wheels with the required blade height can be purchased separately.

A bonus of roller models is their possible versatility with respect to the processed materials. There are pipe cutters that are designed exclusively for working with plastic material. But there are those that can cut both steel, copper, stainless steel and other types of metals.

Electric drives are expensive, so they are purchased mainly by professionals. But with the sufficiency of financial resources, anyone can buy them and make it easier for themselves to install plastic wiring.

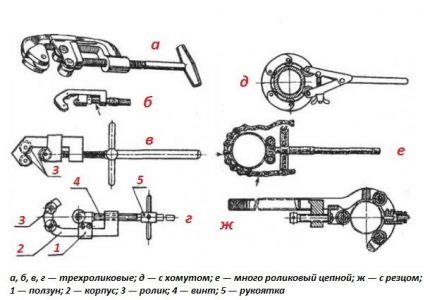

Roller Type Pipe Cutter

The roller pipe cutter works smoothly, without cutting forces across the pipe, so the cut is smooth and without nicks.

Device and specifications

Roller tool consists of the following elements:

- Clamp body to cover the pipe.

- Screw handle, acting as a clamping mechanism.

- Cutting rollers fixed to the end of the clamp.

- Carriage with support steel rollers.

- Faskosnimatel built in a bracket (more advanced models are equipped with it).

The advantages of a roller pipe cutter are its cheapness and the absence of lateral pressure on the surface during cutting. This allows him to work even with thin material without the risk of damage to the pipe by pressing force.

The disadvantage of a roller cutter is the need to rotate the tool. If the pipe is already rigidly fixed close to the wall, then cutting it off will be problematic.

The principle of operation with a roller device

For pipe segments with a roller pipe cutter, you need to perform the following list of actions:

- Insert the pipe with the marked cutting point into the center of the clamp.

- Press the roller to the mark with the handle-screw.

- Scroll the pipe cutter once around the pipe and look at the correct shape of the resulting furrow.

- Using the clamping mechanism, push the roller deeper into the pipe wall, and scroll the 2-turn tool around the pipe. Repeat until the product is completely cut.

Helpful hints:

The result of cutting with a roller pipe cutter is distinguished by the absence of burrs and the strict perpendicularity of the resulting pipe end.

Chain cutter

Chain pipe cutter is a device for cutting pipes without reference to their diameter. It is incredibly practical, but the cost of high-quality models scares off most buyers.

The device and properties of the chain mechanism

The chain pipe cutter resembles conventional tongs, at the ends of which a long chain is attached.Its links are connected using a swivel mechanism. The chain is in most cases non-separable, therefore, its complete replacement is required if one link breaks.

One end of the chain is fixed to the end of the tool handle firmly, and the other is free. At the end of the second handle there is a special hook on which, depending on the diameter of the pipe, a corresponding chain link is thrown.

The tensile force is created manually due to the information of the two handles of the tool, although there are pipe cutters with a screw clamping mechanism.

Depending on the mounting pattern of the cutting elements, the chain pipe cutter can be of two types:

- Mobile. The cutting rollers are mounted directly on the hinges and can rotate during the cutting process.

- Still. The cutting elements are rigidly attached to the links of the chain, not turning in the process.

There are chain pipe cutters in which the cutting effect is formed solely due to the clamping force, but they are practically not used for plastic pipes.

The advantages of chain pipe cutters are:

- high cutting speed due to many simultaneously working cutting elements;

- with five chain links, the angle of mutual overlap of the sections is only 72 degrees, which allows them to work in a limited space;

- minimal deformation of the pipe due to the many support points;

- the ability to cut pipes with a wide range of diameters;

- high weld quality and minimal burrs.

The only drawback of chain pipe cutters is the high cost of their purchase, repair and maintenance.

Chain Pipe Cutting Technology

Using a chain pipe cutter is quite simple. To cut the pipe, you must perform a series of sequential actions:

- Mark the location of the cut on the pipe.

- Grasp the pipe with a chain so that the cutting rollers are exactly at the mark.

- Fasten the chain link at maximum tension to the hook grip of the device handle.

- If there is a tension screw, tighten it tightly until the cutting elements stop against the pipe wall.

- Rotate the tool in both directions while cutting. As the cut is made, it is necessary to tighten the tension screw or increase the tension using the information from the pipe cutter handles.

It is necessary to rotate the tool until the pipe is completely separated.

Despite the resulting high-quality cut, it is advisable to additionally treat the pipe with a bevel cutter and a chamfer.

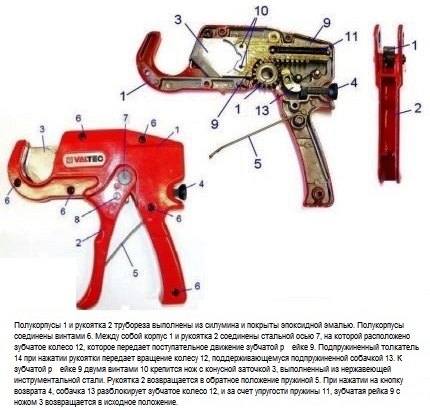

Ratchet scissors

The ratchet guillotine pipe cutter is also called scissors. It has a built-in mechanism that allows you to cut the pipe with a blade, not with a simultaneous movement, but with the repeatedly applied force, which reduces the physical load on the arm muscles.

Structure and properties of scissors

The guillotine pipe cutter looks like an adjustable wrench with two handles. It has one molded handle ending with a wide C-shaped base for fixing the pipe, and a second handle that presses the cutting blade through a ratchet mechanism.

The tool is equipped with a button to return the cutter to its original position and a lock of the closed state for easy transportation.

The working diameter of the scissors varies from 3 to 75 mm. A feature is a sharp increase in the cost of the device with an increase in the maximum possible thickness of the pipe over 42 mm.

Manufacturers are trying to make the design of the torch and the blade so as to minimize the necessary working space. Blades can be smooth or jagged. Some models are equipped with a built-in chamfer, but the pipe end is machined after cutting, and not simultaneously with it.

The advantages of a guillotine pipe cutter are:

- low cost of the tool;

- the ability to cut in a limited space;

- using only one hand at work;

- lack of chips and burrs when cutting.

Scissors also have shortcomings:

- Hand fatigue with large volumes of work.

- The need for sharpening blades.

- The high cost of interchangeable blades.

- Transverse pipe deformation during cutting.

- The likelihood of acquiring an inexpensive tool that becomes dull after a dozen cuts.

- Limited maximum pipe diameter.

Despite the shortcomings, guillotine modifications are ideal for mounting plastic pipes of small diameters with small volumes of work.

How to use pipe scissors?

The process of cutting with a guillotine turbo cutter differs little from working with ordinary scissors, but has its own characteristics.

To cut the pipe with this tool, it is necessary to carry out the following actions:

- Draw the cut location on the pipe.

- Position the pipe on the wide base of the pipe cutter so that the intended cut strip is exactly opposite the blade.

- Using a handle, push the blade onto the pipe.

- After each complete squeezing of the handles, loosen them, returning them to their original position.

Repeat rhythmic squeezing of the instrument handles until the pipe is completely cut.

A number of tools have a ratchet mechanism, each click of which notifies about the movement of the internal ratchet mechanism by one clove. The sound of a click means that it is already possible to unclench the handles of the instrument and repeat pressing from a more convenient position.

For more information on how to use scissors for cutting plastic pipes, see this stuff.

Electric pipe cutters for plastic pipes

The electric drive for pipe cutters greatly facilitates and accelerates the installation process.

There are three types of electric pipe cutters:

- tools that simply copy the principle of a guillotine or roller mechanism;

- stationary industrial equipment with a complex internal structure;

- universal tools for cutting materials.

These types of tools should be considered in more detail.

Reciprocating electric saw

Reciprocating saws resemble a jigsaw in principle. They have an electric drive with which the toothed blade makes fast reciprocating movements. The length of the files starts from 100 mm, and the width and height of the teeth varies from the material being processed. For plastic, a tooth pitch of 4 mm is used.

Additional equipment to facilitate cutting with a reciprocating saw is a chain or C-shaped clamp for the pipe. It is fixed to the body of the power tool with a special mount.

The advantages of reciprocating saws when cutting plastic pipes are:

- work safety;

- low cost of removable blades;

- high cutting speed;

- the ability to work with pipes of any diameter;

- the ability of the blade to bend and cut pipes flush with the wall;

- durability;

- the price of a household electric saw is comparable to the cost of a professional guillotine pipe saw.

The disadvantages of reciprocating power saws include:

- The need for a local source of electricity.

- The resulting slice requires additional processing with a bevel cutter or a chamfer.

- The difficulty of ensuring the perpendicularity of the seam without a special tube clamp.

- The difficulty of cutting without fixing the pipe in a vise.

Specially for cutting pipes made of plastic, it is not worth purchasing a reciprocating electric saw, but if it is already available, then you can use it. This tool can be useful in the household for cutting metal, wood, brick and other materials.

Roller and guillotine electric pipe cutters

This category of plastic pipe cutting tool has all the advantages and disadvantages of the corresponding manual equipment. Roller and guillotine electric pipe cutters greatly facilitate the cutting process, but their cost is several times higher than mechanical tools.

By design, the power tool resembles its manual counterparts only schematically, because it has a complex internal filling.

Pipe cutters can have two sources of electricity: a household electric network or a battery.

Cordless tools are the most expensive, but allow you to carry out work without reference to the terrain. Their cost starts at $ 150. The charge should last for 1-2 hours of continuous operation. For the installation of home water distribution, this is quite enough.

Industrial professional pipe cutters

Industrial machines can cut pipes of any size, not just large ones.

This equipment can be divided into several categories, depending on the design features:

- Electric.

- Pneumatic

- Hydraulic

- Orbital type.

- With automatic control system.

The cost of such pipe cutters starts from several hundred dollars, so they are mainly used by professional installers.

Their advantage is the automatic control of the speed of movement and the pressure parameters of the cutting element, as well as the combination of cutting with the process of chamfering and cleaning the cut from burrs.

Also on our site there are several more articles that are devoted to the selection of equipment for pipe cutting. We recommend reading them:

- types of equipment for cutting pipes;

- pipe cutters for plastic pipes;

- tool for cutting steel pipes;

- popular pipe cutters for polypropylene pipes.

Rules for choosing a pipe cutter for work

The choice of the optimal model depends on the amount of work, type of pipes, laziness of a person and his financial capabilities. The cost of similar in appearance and structure of tools may vary 3-5 times, so it is necessary to select the tool, taking into account the quality factor.

Next, a list of works and types of tools recommended for them will be considered:

- One-time installation of apartment water supply or heating: guillotine shears.

- One-time installation of apartment sewerage: roller or chain pipe cutter, reciprocating electric saw.

- Regular work with pipes in a country house: roller or guillotine devices with electric drive, reciprocating electric saw.

- Cutting plastic pipes with a diameter of less than 50 mm: guillotine pipe cutter.

- Cutting plastic pipes with a diameter of 50 mm and thin-walled pipes: chain or roller pipe cutter.

These recommendations are indicative, therefore, the final choice of model should be made, taking into account the whole complex of influencing factors.

Conclusions and useful video on the topic

The presented videos demonstrate working with pipe cutters of various types of plastic pipes. Viewing them will allow you to better understand the principle of working with these tools and make the right choice when buying a pipe cutter.

The principle of operation of the roller pipe cutter:

Overview of manual pipe cutters:

Chain Cutting:

Reciprocating Saw Review:

Pipe cutter for guillotine type pipes:

The choice of a tool for cutting pipes is not easy due to the many design options and the strong price range. For one-time homework, the cheapest models that can withstand several hundred cuts without compromising quality are suitable.

If there is enough money, it is better to immediately get a professional electric pipe cutter with automatic chamfering. The final choice is preferably done directly in the store, given the advice of sellers.

If you have experience using pipe cutters for plastic pipes, share it with visitors to our site. Tell us what tool you use, about its advantages and disadvantages that were noticed in the work. Please leave comments in the block below.

Scissors for cutting polypropylene pipes: species overview + instructions for use

Scissors for cutting polypropylene pipes: species overview + instructions for use  Pipe cutter for polypropylene pipes: an overview of the types of tools and features of working with it

Pipe cutter for polypropylene pipes: an overview of the types of tools and features of working with it  Pipe cutter for copper pipes: types, selection tips, rules and nuances of use

Pipe cutter for copper pipes: types, selection tips, rules and nuances of use  Pipe cutter for plastic pipes: types, which is better to choose and how to use it correctly

Pipe cutter for plastic pipes: types, which is better to choose and how to use it correctly  Pipe cutter for steel pipes: types, tips for choosing a model and the nuances of competent operation

Pipe cutter for steel pipes: types, tips for choosing a model and the nuances of competent operation  Glue for PVC pipes: an overview of the best compositions and instructions for use

Glue for PVC pipes: an overview of the best compositions and instructions for use  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

So I looked - there are no normally working inexpensive pipe cutters. I don’t want to give a lot of money for a situational tool. Maybe someone will advise a budget pipe cutter?

Hello. If you do not often use a pipe cutter and use it for personal purposes, it is of course best to purchase the simplest model in the form of scissors. These often come in a complete set for pipe soldering irons. It is important to look at build quality and usability. I can’t say for a specific brand, good is a relative concept. One is convenient for one modification, the other another. Another thing is that their quality, due to the simple design, is immediately apparent.