How to choose an iron for welding polypropylene pipes and how to use it correctly

Polypropylene pipes are in active demand among summer residents and owners of private houses of permanent residence. And not surprisingly, such a pipeline is able to withstand various operating conditions, including temperature differences.

In addition, the cost of pipes, low weight and ease of assembly of the structure justifiably makes them a demanded material. Moreover, you can assemble the pipeline yourself - you will need an iron for welding polypropylene pipes and skills in working with such equipment.

Mastering the welding machine is quite simple, the main thing is to adhere to safety measures and the rules for using the iron. Doubt your own strength? We will help you choose a reliable device, get ready for work and solder the pipeline.

The article sets out the basic criteria for choosing an iron, identifies popular manufacturers, and describes a step-by-step instruction for using the welding machine.

The content of the article:

How the equipment is arranged

At home, polypropylene pipes are welded using a welding machine called an iron. All of them differ in technical characteristics, color, size and cost. But their appearance and operating principle is similar for all manufacturers of such equipment.

Typical structure of a welding iron:

- a pen;

- wire for inclusion in the electrical network;

- iron operation indicator;

- indicator of the device reaching the set temperature;

- temperature regulator;

- heating plate with holes for installing nozzles;

- nozzles for heating pipes - sleeve for putting on pipes and mandrels for fitting;

- stand for installation of the device.

Depending on the model of equipment, there may be mechanical or automatic temperature control. In cheaper models, a mechanical temperature regulator is installed, which allows you to set the desired heating temperature.

A professional device can be equipped with a display that displays the temperature change in real time. When the desired heating level is reached, the appliance switches off automatically. Such a display allows you to monitor the slightest fluctuations.

How to choose the right device

The abundance of offers makes it difficult for an inexperienced user to choose - it is difficult to immediately buy the perfect iron for welding, which will be convenient and will last a long time. The choice of a suitable device should be approached carefully by comparing the necessary parameters with the model you like.

Required iron power

First you need to determine the required power of the equipment. For this, it is necessary to clearly highlight the front of the upcoming welding of polypropylene pipes. You can certainly aim at a range of 1.5-2 kW, as some masters advise. But it will be a more expensive device, which, most likely, will not be used 100%.

When it comes to a modest pipeline with a pipe diameter of 16-25 mm, a serious unit will be an extra waste of money - you can easily do with a Chinese iron for 1000 rubles, the power of which is from 350 watts.

To calculate the required power of the welding unit, proceed from the maximum diameter polypropylene pipesto be welded. This diameter must be multiplied by 10 and add 30%. This is a safety margin so that the iron does not work to the limit of its capabilities.

So, for a 25 mm pipe, the power of the device will be: 25 * 10 + 30% = 325 W. It turns out that the power of the future iron should be from 350 W - this is quite enough for welding polypropylene pipes 16, 20 and even 25 mm in diameter.

For large-scale work, it is better not to save and purchase a more powerful iron - 1.2-1.5 kW. Such power will allow reliable connection of plastic pipes with a diameter of 40, 60 and more mm. Up to 10 cm.

Complete set of the welding unit

In addition to power, you should pay attention to the device itself and its configuration. The quality of the material the iron is made of is also important. And without gloves, tape measure and pipe cutter for PP pipes it will be difficult to cope with the task to a home master who does not have experience in carrying out such work.

Therefore, before buying an iron, you should pay special attention to such points:

- Number of nozzlesgoing bundled. If there are few of them, then it is better to buy the required diameter, choosing the right ones.

- Teflon coating quality - for more expensive irons, nozzles with a good coating are included. Also, for the cheapest units, you can buy expensive nozzles where high-quality Teflon is applied.

- Lack of plastic elements - the iron body must not contain polymer parts. The handle and other elements of the case of a good device are made of heat-resistant material.

- Availability in the set of necessary equipment - gloves, scissors for cutting polypropylene pipes, the necessary nozzles, tape measure, instructions and other accessories. If you buy all this, it will be much more expensive.

- Product packaging quality - The manufacturer supplies a good iron in a metal case, where all components take their places.

As for the configuration, it directly affects the cost of the device. Here you should find the most suitable option for your wallet - how much they planned to spend on this equipment.

When you have to assemble a plastic pipe at home, at the cottage and at your mother-in-law, it’s better not to save on the tool - it’s 5-10 times more expensive to hire a specialist. If you have to replace a section of the pipeline, then you don’t have to buy an iron at all - you can rent the necessary equipment.

The cost of the service depends on the region of residence and the model of the device. On average, an iron for welding can cost 150 rubles per day.

Value for money

Choosing the right iron for welding, I want to dwell on the optimal ratio of quality and price. So, the cost of individual models can start from 800 rubles and reach 20,000 rubles. Such a range will perplex the beginner.

In order not to get confused, it is important to initially determine the task that the device will perform. If the scope of work is very modest, then you should not overpay - a suitable model of Chinese production for 1.2-1.5 thousand is quite suitable.

For instance, Foxplasticmade in China and having a perfectly acceptable configuration. Moreover, to buy separately scissors, gloves and nozzles will cost an order of magnitude more expensive.

All irons for welding polypropylene have their own characteristics depending on the country where they were produced. So, the most desired brand is Rothenberger. The devices of this German company are not cheap - their cost starts from 10 000 rubles.

The second step is occupied by Czech devices - these are various models of irons from the company Dytron. The cost depends on the technical specifications. But experts note the high cost of the brand - not every newcomer will allow himself to have such a device.

Although it’s still worth buying nozzles separately, the Teflon coating will survive more than one cheap iron for 850-1000 rubles.

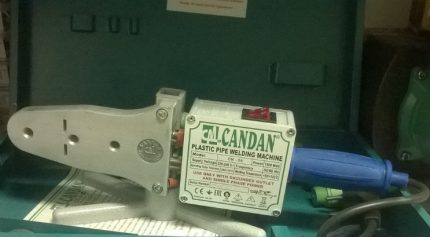

Turkish companies are in third place: Valtec, Candan, Cobra, Kalde other. They occupy a wide niche among such equipment - original irons are able to last 3 years or more.

When buying Turkish devices, you must definitely look at the manufacturer so as not to get a fake. This situation is not uncommon now, so you should carefully examine the proposed purchase before paying its cost.

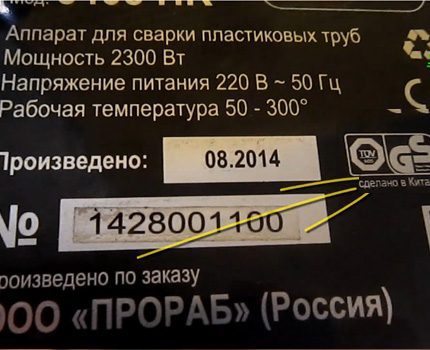

At the last step are the most budget models assembled by Chinese factories. There are many of them, moreover, often domestic brands assemble their devices in the same place - in China.

Chinese irons have a low price, but the guarantee for such products is about 1 year.And some manufacturers do not give any guarantee at all. Therefore, before buying, you should carefully study the packaging and check for a passport or instruction and warranty card.

For a modest work front, an iron for 900-1500 rubles will be just right. If the budget allows, it is more advisable to pay attention to Turkish devices, which will help to assemble more than one polypropylene pipeline.

Welding Iron Guidelines

In order for the equipment to last a long time and not bring a lot of problems, it is important to operate it correctly. Otherwise, instead of a pleasant job, there will be continuous troubles - broken equipment, an inoperative pipeline and burnt hands / feet of an inattentive craftsman engaged in welding polypropylene pipes.

Work safety measures

It is important to adhere to the basic rules for working with iron prescribed by the equipment manufacturer. Although irons are different from different companies, personal safety measures will be the same in all cases.

Firstly, you can’t touch the heated device with bare hands or feet - the temperature of the heating plate can reach 260 ° C and above.

Protective gloves should be used for safety. They can go in the kit and lie in the suitcase in which the manufacturer supplies his device. Otherwise, it is better to purchase a heat-resistant pair of gloves in advance and carry out all the welding of polypropylene pipes in them.

Secondly, when carrying out welding of polypropylene pipes, it is necessary to timely clean the working surface of the nozzles from adhered plastic. This is right to do immediately after connecting another section of the pipeline.

Do not wait until the unit cools down - just take a soft cloth or a special tool for cleaning Teflon surfaces and carefully remove the remaining polypropylene from the sleeve and mandrel.

Carefully choose a tool for cleaning Teflon nozzles.

It is strictly forbidden to use the following:

- cleaning products containing abrasive substances;

- metal scrapers and sponges;

- liquids that can damage the Teflon coating.

Thirdly, Do not drop the iron or fill it with water. If it falls, it may become damaged and stop working. And to cool the iron, just unplug it from the outlet and wait a couple of hours - the device will completely cool down by itself.

Fourth, from the room where the installation of the pipeline is carried out, it is necessary to remove animals and children. Do not forget about the high temperature of the working parts of the welding iron.

First start-up

Separately, it is worth noting the first launch of the purchased equipment - this should be done outdoors. The fact is that in the new welding machine, the internal parts are coated with a special lubricant, which will begin to smoke when the iron is first heated.

A rather unpleasant odor and thick smoke will appear - it is better when the device is tested outdoors.

No need to be scared if the first time you turn on the iron there will be an unpleasant smell - this is quite acceptable. To calm down, you should read the instructions for the device provided by the manufacturer in advance.Often, the seller does not warn about this feature of a naive buyer who does not have experience in using such equipment.

After the first start-up of the apparatus, it is advisable to practice before proceeding with the welding of a real pipeline. Especially if there is no experience in carrying out such work. It is also advisable to get used to the features of the iron when a very cheap Chinese device is purchased.

Often you can find reviews of real users who are advised to set the temperature in the range of 220-230 ° C. This is fundamentally contrary to the rules for welding polypropylene pipes, where required temperature equal to 260 ° C.

Everything is right here - the problem is that many cheap irons made by the Chinese simply do not know how to maintain a stable temperature in a given range.

Therefore, when the user set 230 ° C, then after 10 minutes the actual operating temperature may well reach 255-265 ° C. It is not surprising that at a specified temperature of 260 ° C, an inexperienced welder receives burned parts or a connection that is completely unusable.

In such cases, you need to practice making the right connection and get used to your iron. Moreover, for training you need a couple of hours of free time, 5-7 pieces of pipe and the same number of fittings. This is an inexpensive pleasure - one fitting costs around 10 rubles.

How to use an iron for polypropylene

For the proper use of the apparatus for welding polypropylene, it is necessary to study the instructions supplied by the manufacturer. Then you have to open the package, preferably it was a suitcase, and assemble the device by installing a sleeve and mandrel of the desired diameter.

The soldering iron itself has to be firmly fixed by installing it on a special stand. For more comfortable work, the masters advise screwing the stand to the board or sheet of plywood, and then put the iron on. This ensures greater stability when working with equipment

When the necessary nozzles are fixed, it is necessary to turn on the device in the socket and set the temperature using the temperature controller. It can be a wheel to be turned, indicating the desired number or an electronic display - the subtleties of the settings depend on the model of the device.

The operating temperature for welding polypropylene pipes is 260 ° C. This parameter should be indicated.

The warm-up time of the device depends on the power and features of the model - it can be 5 minutes, like with irons Wellner, and 20-30 minutes with Chinese devices.

When the indicator has signaled that the operating temperature has been reached, the pipe welding process can begin.

It is important in the welding process to adhere to the time indicated in the special table going to the specific device.

There, the manufacturer indicates:

- the heating time of the pipe and fitting in seconds;

- the time in which you need to have time to connect 2 parts is from 3 to 5-6 seconds;

- the time it takes to fix and create a reliable seam is from 10 to 20 seconds.

All these parameters may differ from different manufacturers of irons, so you should act according to the information given in the iron passport.

If all succeeds, then you can continue to work on welding polypropylene pipes. At the end of work, unplug the equipment from the outlet and wait for it to cool. Then remove the nozzles and put all the accessories in a suitcase.

In addition to the iron for soldering polypropylene pipes use cylindrical soldering irons and other devices. More information about different welding machines is written in this article.

Conclusions and useful video on the topic

More expensive models of irons have their own advantages, allowing to simplify the process of soldering polypropylene pipes, especially in the absence of practical experience at home craftsmen. About this in the video clip:

The main mistakes of beginners made when soldering pipes with iron are clearly shown in the video:

The rules for soldering polypropylene pipes are demonstrated in detail in the video clip:

In addition to a good soldering iron, the kit will include all the necessary accessories for welding polypropylene pipes. About the rules for buying the optimal set in the video:

The video clip gives an overview of the iron for welding by a Turkish manufacturer:

Having studied the basic rules for choosing irons for welding polypropylene, you can choose a device for personal use at an affordable price for your wallet. It is not difficult to use an iron - if you wish, you can weld a polypropylene pipeline on your own by buying a welding machine.

This will help to significantly save on the call of masters specializing in welding polypropylene pipes.

Looking for an iron to assemble a polypropylene pipeline? Or have skills with such a device? Please share your experiences with readers, ask questions and participate in discussions. The comment form is located below.

Pipe cutter for plastic pipes: types, which is better to choose and how to use it correctly

Pipe cutter for plastic pipes: types, which is better to choose and how to use it correctly  How to choose a soldering iron for polypropylene pipes: tips from professional plumbers

How to choose a soldering iron for polypropylene pipes: tips from professional plumbers  A cable for cleaning pipes: types, how to choose the right + instructions for use

A cable for cleaning pipes: types, how to choose the right + instructions for use  Pipe cutter for polypropylene pipes: an overview of the types of tools and features of working with it

Pipe cutter for polypropylene pipes: an overview of the types of tools and features of working with it  Scissors for cutting polypropylene pipes: species overview + instructions for use

Scissors for cutting polypropylene pipes: species overview + instructions for use  Press pliers for plastic pipes: how to choose + instruction on use

Press pliers for plastic pipes: how to choose + instruction on use  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I really had no choice: take a Chinese soldering iron or Turkish. I figured that with the Turkish in the set there are still scissors for polypropylene, and took it. Good iron, nozzles are smooth, well-ground. I’ve plowed with me for more than 5 years, I changed only the cord, and the scissors have already broken.

Once I had to work on someone else's soldering iron, so I noticed that it was necessary to get used to it, an iron, but another completely.

You know, there is such a muscle memory - when movements are already brought to automatism, and you know how much time to hold on to the subconscious. And on an unfamiliar instrument I still had to adapt to soldering.

For work at home I used the cheapest Chinese iron. The calculation was this - a one-time job, the goal is to save exclusively. Those. Do not hire a craftsman, but change the pipes in the apartment yourself. As I understand it, they are warming more or less normally, the accuracy (or rather, inaccuracy) of the mechanical temperature controller is compensated by choosing the right time for heating. Everything went OK, the cost of a soldering iron is 700 rubles.

By technology, everything is clear. But who will tell me about the vapor from plastic? I don’t think it is harmless. Do I need to wear respirators or something else when soldering pipes?

Hello, Nikolai. In fact, not many people wonder about the means of protection when welding plastic pipes. Some do not even wear protective gloves until they are seriously burned with hot plastic.

As for the vapors during the soldering of plastic pipes, they are present. In order not to bring the concentration to critical, it is necessary to ensure good ventilation of the room in which work is carried out.

If working indoors, then use a respirator. From personal experience I can recommend 3M 9928 (molded cup-shaped, protection class FFP) and NORTH 7190N99 (half mask in a plastic frame with a filter in the kit).