Why a split system cools poorly: an overview of frequent breakdowns and how to fix them

To ensure control of the indoor climate, modern sleeping systems are increasingly being used. They help to achieve the most optimal indicators of air condition not only in summer but also in winter.

But, already in the second year of using such a technique, its performance is significantly reduced. But why does a split system cool poorly? All possible causes of such a problem, we considered in this material. They also made recommendations on how to eliminate simple damage on their own.

The content of the article:

- The principle of operation of the equipment

- The main elements of split systems

- The most common breakdowns

- Breakdown # 1 - Power Problems

- Breakdown # 2 - lack of freon in the system

- Breakdown # 3 - Fan Malfunction

- Failure # 4 - Valve Failure

- Breakage # 5 - Capillary Pipe Blockage

- Breakdown # 6 - Compressor Failure

- Failure # 7 - Sensor Failure

- Breakdown # 8 - electronic circuit board malfunction

- Breakdown # 9 - Clogged Air Purification Filters

- Conclusions and useful video on the topic

The principle of operation of the equipment

A split system is a climatic appliance for domestic or industrial use, consisting of two units: internal and outdoor. Each of the blocks has its own purpose and consists of different elements.

Inside contains in its case an air filter, a powerful fan and a coil that allows you to cool the air. Outer part consists of a compressor, capillary tube, fan and coil capacitor.

All split systems have the following classification:

- Wall mounted - their power is up to 8 kW;

- Floor and ceiling - their power is up to 13 kW;

- Cassette - their power is up to 14 kW;

- Duct and column - their power is up to 18 kW.

Less commonly used central and ruff top (roof) installations.

The compressor of the HVAC equipment contains freon - this is a working fluid that serves to cool the air. It is fed through thin copper tubes. In the indoor unit, this fluid cools the air supplied from the inside of the room or from the outside.

If the split system is switched to heating mode, then freon will already evaporate in the outdoor unit, and will be conditioned in the indoor unit.

The main elements of split systems

Fan Designed to increase heat transfer rate. The use of this part in the indoor and outdoor units can significantly reduce the dimensions of the device.

Therefore, a significant part of the energy consumption lies with these elements. Each manufacturer of HVAC equipment works to reduce the heating level of fans during rotation, to reduce their size and noise level.

Compressor Designed to move refrigerant. Freon in the state of gas is supplied to the capacitor. Since this gas has a low pressure, the compressor compresses it. From this, the gas temperature rises. The substance entering the external unit quickly gives off heat and acquires a new physical state - liquid.

In this state, it enters the evaporator in the indoor unit. Freon evaporates, which reduces the temperature in the room. Further, in gaseous form, the refrigerant again enters the compressor for a subsequent cycle of operation.

From this we can conclude that the compressor is the most loaded element of split systems of all types.

Heat exchanger there are in both blocks of the split system. It is designed to accelerate the heat transfer process. Without it, the transition of the refrigerant from a liquid to a gaseous state and vice versa would be too long.

The larger this element, the more efficient is the transfer of heat. To save useful space inside the case, manufacturers resort to the following solutions:

- lay the pipe "snake";

- develop their own chemical compositions of copper alloys, which allow to increase the temperature transfer rate;

- use additional gaskets in the gaps between the heat exchange tubes.

Since air from the street and the room passes through heat exchangers, it can clog the pipe over time. This also happens if the air filter has not been changed for a long time.

Freon pipeline is needed to move the refrigerant in the split system. It is made of copper. In this climatic technique, the freon pipeline is used in two types:

- copper pipe for gaseous refrigerant;

- copper tube for liquid freon.

The diameter of the first tube is slightly larger than the second.

More details on the device and principle of operation of the split system we reviewed in this article.

The most common breakdowns

The failure of any of the listed elements will affect the efficiency of cooling the air in the room. To understand what exactly caused the malfunction, it is necessary to consider the most common problems.

You should also consider ways to eliminate them in order to prevent the final failure of the equipment.

Breakdown # 1 - Power Problems

It often happens that the voltage in the network is too low. It may be enough, for example, to turn on fans. The sound of their operation will be heard by the user, but cooling will not occur, since the compressor will not be turned on.

To find out whether this is so, it is necessary to check the indicator of alternating voltage in the network. If it is much lower than the required 220 Volts, then you must turn off the equipment and wait for the normalization of the power state.

If the supply voltage regularly “sags”, for example, someone turns on power equipment, it is recommended to install additional devices: line voltage converters and stabilizers. This will provide climate equipment with full power.

Breakdown # 2 - lack of freon in the system

This problem is more common than others. The refrigerant evaporates from the system over time. Even if the equipment is not turned on for a long time, the gas will still evaporate slowly.

To make sure that the reason for the violation of heat transfer lies in the small amount of refrigerant, it is advisable to contact specialists. They have tools to check the amount of freon in HVAC equipment.

According to the documentation that comes with the split system, replenishment of its stock should be carried out at least once every two years for those who use the device in everyday life.

What you need to know before replacing the refrigerant:

- Freon is of different brands, the desired brand is indicated in the documentation for the equipment;

- refueling requires access to the outdoor unit;

- Before replacing it is necessary to check the level of freon in the system.

If the equipment operates in production or in conditions of a significant temperature difference between the street and the room, then the replacement is carried out once a year. By the way fill the system with freon You can do it yourself.

Among the reasons that can cause a lack of substance in the system, it is worth highlighting:

- manufacturing defects, for example, the refrigerant has been refilled due to a malfunction of automation;

- damage to the freon pipeline during installation or transportation;

- increase in the size of the track without refueling freon.

In the first case, a malfunction can be observed even with equipment just purchased. The lack of freon will not make it possible to quickly cool the room. This is due to overheating of the compressor.

The problem will be solved by replacing the equipment with serviceable or warranty service, refueling.

In the second case, self-refueling will not give a result. This is due to the fact that the refrigerant will still exit the system through damage in the copper pipe.

Before refueling, it is necessary to find the place of breakage and solder if the conductor itself is damaged. We recommend that you familiarize yourself with soldering instructions copper tubes.

In the third case, it is also necessary to refuel the equipment with cooling gas.

It is worth considering that the prolonged absence of freon in the right amount significantly reduces the life of the compressor. Repairing or replacing it will take more money and time. Therefore, it is recommended to conduct regular inspections of split systems by specialized specialists.

Breakdown # 3 - Fan Malfunction

As a rule, this malfunction occurs in split systems that have been used for more than 2-3 years. It is also possible when operating the equipment in conditions with too polluted air.

There may be several reasons for the breakdown:

- jamming of the fan bearing due to lack of lubrication and clogging;

- damage or deformation of the blades;

- violation in the operation of the control board, for example, liquid has entered or one of the strapping elements has failed;

- failure of the fan motor - jamming, shorting or power failure.

Another option is also often found: the fan is serviceable, but a layer of dust blocks the path to the air flow. Because of these reasons, cooling performance is reduced.

Unfortunately, solving this problem yourself is difficult, except for cleaning the grill. To diagnose a malfunction, you will need various tools and skills.

It often happens that a breakdown can be fixed quickly enough. For example, replace wires or repair connectors. In case of failure of the fan motor, it is replaced with a new one. This will maximize the life of the equipment.

If the control board is faulty, then the damaged elements can be dismantled and replaced with new ones. If the damage is extensive, then it is easier to replace the entire board.

Failure # 4 - Valve Failure

This part is needed to switch heating and cooling modes. If it fails, then warm air will be supplied into the room in two operating modes.

This malfunction is infrequent, but it can also be the reason that warm air comes from the split system.

To eliminate it, you will also need qualified help. This is due to the fact that revealing it is not easy: the panel will show the full operation of the device in two modes.

Breakage is solved by replacing a four-position valve. Some craftsmen completely remove this part from the structure. In this case, the cooling function will be restored, but there will be no possibility to warm the air.

Breakage # 5 - Capillary Pipe Blockage

With this malfunction, cooling may not occur at all. Less commonly, it is weak. This happens for the following reason: a partially clogged tube leads to an increase in the pressure drop at the inlet and outlet of the pipeline.

Due to the high indication of the pressure difference, freon begins to boil before it reaches the evaporator in the indoor unit. Therefore, most often there will be no cooling.

You can verify the breakdown by seeing the appearance of ice on the copper pipe (to the evaporator). Also a characteristic feature of this malfunction is the constant mode of operation of the compressor with very rare stops or without them at all.

If the tube is completely clogged, the refrigerant circulation stops. In this case, the device will work continuously, but the air will be supplied warm.

A competent specialist can fix this. Partial blockage is eliminated by blowing air. For this, special equipment is necessary, since air is supplied under pressure.

If the blockage is complete, resort to the use of hydraulic cleaning. Solvents of various grades are also used. If the blockages are multiple and they are not eliminated by the above methods, then the tube must be evaporated and replaced with a new one. More information on do-it-yourself system cleaning. brought here.

Breakdown # 6 - Compressor Failure

If only the fans are working when the electric appliance is turned on, this indicates a possible compressor failure. In this case, the refrigerant does not circulate through the capillary tubes, and the air supplied to the room has room temperature.

To solve this problem, it will not be superfluous to familiarize yourself with the methods of independent compressor diagnostics.

Repair and replacement of the compressor will cost the most. Damage can be fixed only if this element is jammed. If the master succeeds in wedging the jammed parts, then subsequent operation of the equipment is possible.

In other cases, it is replaced with a new one.Due to the fact that it fails most often after the end of the warranty period, it is most advisable to replace the external unit. This must be done then, that in this block other parts also have serious wear.

It is also worth paying attention to the fact that the compressor may not turn on for other reasons.

The main ones are:

- start capacitor malfunction;

- malfunction of the working capacitor;

- thermal relay malfunction.

A starting capacitor is used in the design of split systems to start the compressor when power is supplied to it. If it fails, then the engine will not be able to earn. Replacing a capacitor will not take much time and money.

Working capacitor serves to maintain the engine in stable condition. This element can dry out, losing its capacity. If it becomes inoperative, then the compressor can turn on, but then immediately stops working. Replacing a working capacitor is also not costly.

ANDthermal relay necessary to protect the engine from overheating. If it fails, then the mains power does not reach the compressor, and it cannot turn on. Replacing this part is also inexpensive.

Failure # 7 - Sensor Failure

Typically, sensors in a structure break rarely. But, their malfunction can affect the performance of all equipment. In case of their breakdown, there will be cooling, but it is insufficient.

The device will work unstably, turn on for a short time. The error code will be displayed on the split system display.

In the technical manual, each code means the failure of a particular sensor.

There are three of them in the design of the split system:

- indoor unit thermistor - a sensor that controls the temperature of the air in the room;

- evaporator thermistor - controls the temperature at the exit from the system;

- capacitor thermistor - controls the temperature at the entrance to the system.

Failure of any of them leads to the receipt by the control unit of invalid signals. Because of this, commands are given to the compressor to stop operation, despite the fact that the desired room temperature has not yet been reached.

Breakdown # 8 - electronic circuit board malfunction

In the indoor unit is the control unit. The board contains electronic components and a microprocessor. In the case when the cooling is not efficient enough or even absent, the problem may lie in the breakdown of this board.

In some cases, for a full repair, you only need a soldering iron and spare parts to replace damaged components.

You can fix local malfunctions: failed relays, signal amplifiers, capacitors. If liquid has been spilled on the board, for example, or there are serious mechanical damage, then it is completely replaced.

A malfunctioning board may cut off power to the internal fan. Therefore, cold air will enter the room very slowly.

Inverter-type split systems there is another board. She is near the compressor. Failure of this electronic unit may cause the power to the motor to stop. The repair method for this board is similar to that described above.

Breakdown # 9 - Clogged Air Purification Filters

There are air filters on the indoor and outdoor units.If one of them or two is clogged, the air flow is significantly reduced. The cooling efficiency is noticeably reduced. Water may drip from the split system, and ice will appear on the copper tubes.

If this problem is not resolved for a long time, then the evaporator and fan become clogged. If the filters can be cleaned quickly enough, it takes a lot of time and effort to eliminate the clogging of the evaporator and fan.

To do this, you will need to completely disassemble the indoor unit. Therefore, it is recommended to regularly monitor the status of filters in both units. In modern systems, there are filters for rough and fine air purification.

Repairing the equipment yourself is not recommended. This requires special tools. You will also need additional parts to replace those that are out of order. Also, do not forget that working with electrical devices is life threatening, since mains current can kill a person.

Conclusions and useful video on the topic

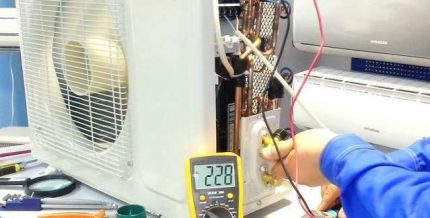

This video describes an example of servicing the internal unit of a modern split system:

Each breakdown has its own reason. In some cases, the malfunction can be eliminated by just cleaning the filters or grille from dirt. Therefore, it is advisable for each owner to know how properly maintained split system.

But, in all other cases, the skills of diagnosing and repairing such complex equipment as a split system are required. Wizards will do the job as quickly as possible and with a guarantee of operability of the device.

Do you want to supplement our publication with useful recommendations for the diagnosis and repair of split systems? Or noticed a discrepancy in the material presented? Please write your comments in the block under this article.

If you have problems with the split system and you can’t determine the cause of the malfunction, ask our experts for advice - we and other site visitors will try to help you.

Inverter or conventional split system - which is better? Comparative review and selection tips

Inverter or conventional split system - which is better? Comparative review and selection tips  TOP-12 Wi-Fi split systems: overview of popular models among customers + selection features

TOP-12 Wi-Fi split systems: overview of popular models among customers + selection features  Haier HSU-07HTM03 / R2 split system overview: budget price tag with practical filling

Haier HSU-07HTM03 / R2 split system overview: budget price tag with practical filling  Split system for the refrigerator: types + nuances of calculation and selection of the necessary equipment

Split system for the refrigerator: types + nuances of calculation and selection of the necessary equipment  Split system Electrolux EACS-07HAT / N3: technical characteristics of the model + comparison with competitors

Split system Electrolux EACS-07HAT / N3: technical characteristics of the model + comparison with competitors  Hyundai H-AR21-09H split system review: heart core with a claim for a premium class

Hyundai H-AR21-09H split system review: heart core with a claim for a premium class  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

If split - the system stopped cooling, then most likely it needs to be refilled with freon. It was so with us: literally half an hour, an hour, and the problem was solved by a specialist. It became cool again. This is probably the easiest and fastest to solve problem, which may be, everything else is worse. In general, it’s good to do annual preventive measures, for example, before the same summer season.

I had a situation. Split stopped chilling. I called the master. He says that Freon is over. OK, refuel. Everything, refueled, got his money, left. After a month (!) I understand that split will not cool again. I’m calling the master, another guy has come. He says that freon is over. I told him: did you all conspire there, or what? As a result, it turned out that in the path between the indoor unit and the outdoor, a microscopic crack formed, through which freon leaked. So there are also such reasons.