Soldering copper tubes with a gas burner: useful tips and steps for self-soldering

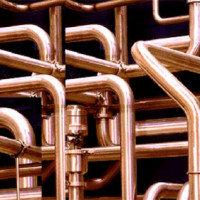

Copper pipes are used much less often than metal-plastic or polypropylene. But thanks to a complex of excellent technical characteristics - thermal conductivity, anti-corrosion and biological resistance - they are found in water supply, heating, air conditioning systems.

Long copper products are expensive, but you can save on installation costs. For example, soldering copper pipes with a gas burner is available to anyone who wants to independently improve the system or make repairs. We will talk about how soldered joints are made, we will give the rules for their implementation.

The content of the article:

Features of the process of soldering copper

The essence of soldering is the hermetic connection of two elements of a copper pipeline by heating and melting a binder material - solder.

After cooling, the tin alloy forms a reliable, non-separable structure, which will later be used to transport coolant, cold water, and refrigerant.

In everyday life, low-temperature or, in other words, soft soldering is usually used, at which the flame temperature gas burner does not exceed 450 ° C. For it, fusible solder is used, and the maximum pipe diameter is not more than 110 mm.

Soft capillary soldering is suitable for the equipment of water supply and heating systems, but is not used for gas transportation.

Necessary tools and materials

In order for the pipe-pipe or pipe-fitting connections to be airtight and not to lose their performance over time, it is necessary to use special tools and materials made by trusted manufacturers.

Tools that are planned to be used constantly in the assembly of pipelines from copper pipes, we recommend buying in specialized markets, and goods from Chinese online stores will work for one-time work.

The minimum capillary soldering kit includes a number of accessories.

For the convenience of using the burner, a vice is sometimes used if the soldering process is carried out on a table or workbench.

To quickly and efficiently clean the inside of the tube, you can use a screwdriver head instead of a hand brush.

Detailed instructions for soldering copper pipes

To fill your hand, it is recommended to practice on unnecessary pieces of pipe. Serious work should be started when all the skills have been worked out - to precisely cut the part, process it correctly, use a gas burner. The soldering process can be divided into 6 steps.

Step # 1 - cutting parts

If you need to replace a fragment of the pipeline or completely assemble the plumbing / heating system, pieces of copper pipe of various lengths will be required. Cutting material is done using pipe cutter for copper pipes, whose selection criteria will be introduced by our recommended article.

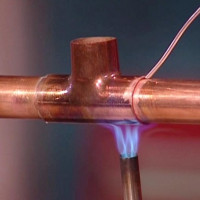

Usually they are connected using tees, angles, couplings. A bell-shaped method is also used in which one fragment is inserted into another with an expanded end.

Then we take the pipe cutter and cut the pipe into fragments of the desired length. If the work is carried out on a table, you can use an electric pipe cutter or a manual model with a large acceleration radius. For work in cramped circumstances, for example, near a wall, only a compact hand tool is suitable.

There are convenient roller options with steel blades. It is easy to use them: you need to put the pipe cutter on the side at the previously marked place of the cut, fix it with a ratchet mechanism, and then rotate the tool around the pipe.

We advise you not to cut all the fragments at once - perhaps, during the soldering process, the pipeline will shift, changing its configuration, and the length of some parts will have to be changed.

Step # 2 - stripping and expanding slices

Tight fit of metal parts and uniform spreading copper solder Guaranteed only when the connection zone is cleaned to the highest quality.

To do this, we process both fragments adjacent to each other both from the inside and from the outside:

- First, we chamfer to reduce the thickness of the metal and prepare the edge for soldering. Why use a chamfer - a small tool of a cylindrical shape.

- If two pipe sections are connected directly, we increase the diameter of the edge of one fragment with a special tool - an expander.

- Then we take a metal brush and process the inside.

- With a fine napzhachku or metal sponge we clean the outer side to shine.

The cleaned and degreased area of the part differs even visually.

If a coupling or angle is used, both ends must be prepared before soldering, all three on a tee.

Step # 3 - applying flux

To connect copper heating pipes or water supply use various types of flux and paste. Their main purpose of the solder is to ensure that the solder zone is completely filled with solder, while preparing the metal and cleaning it of oxides.

The composition of the flux may be different. The cleaning functions are usually performed by zinc chloride, hydrochloric or boric acid. Protection against oxygen is ensured by the presence of rosin, wax or resin.

Liquid solutions are sold in tubes and paste in small plastic jars. A brush for applying the composition usually comes in the kit, if it is not, then you can buy any alternative in the stationery store - for glue or for paint.

To apply a thick layer is considered a mistake - with close contact, the excess paste is squeezed out, it still has to be removed.

Step # 4 - connecting the parts

When connecting two pieces of pipe or fitting and pipe, flux is usually applied to the edge of the part, which is inserted inside. There is no point in treating the second element with flux - upon contact, it will be equally distributed on both adjacent surfaces.

We turn the parts relative to each other so that the paste is distributed over the contact area, then with a rag we remove the excess solution that protrudes outward.

Having completed the connection, you must make as soon as possible soldering copper pipes. It is not recommended to leave parts prepared for a long time so that the solder paste does not lose its qualities.

Step # 5 - soldering by capillary technology

In the assembly of heating and plumbing copper pipelines low-temperature capillary soldering is used, respectively, low-melting solder is selected.

The soldering process takes place in the following order:

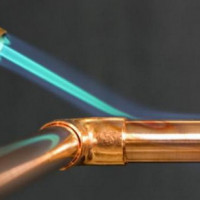

- turn on the gas burner;

- we direct the flame to the junction;

- we move the flame stream over the entire surface of the working area to ensure uniform heating;

- when the parts have warmed up to the melting point of the solder, we bring it to the gap and touch in several places so that it completely fills the space between the parts.

If all actions are performed correctly, the solder after cooling should form a strong tight connection. Outside, it looks like a seam with a different color.

The ability to use the burner, to bring it in and out on time is very important. As soon as the heated solder begins to be drawn into the gap, it is better to remove it so as not to overheat the parts.

If you feel that the solder has stopped melting and you need to raise the temperature, bring the burner up again. It is possible to check the strength and tightness of the connection only after the parts have completely cooled down.

Step # 6 - stitching

Experienced craftsmen usually master the technique perfectly. copper pipe joints and carry it out literally within one minute. At the same time, they touch the solder in only one place, after which it spreads over the connection zone and does not protrude from under the upper part.

But in practice, especially for beginners, more often the solder remains, forming scars inside and out. Internal ones can provoke deposits in the future, while external ones do not look aesthetically pleasing, therefore they must be removed.

Cleaning can be done with sandpaper, a metal brush or a brush - the same items that were used for soldering.

After finishing touches - stripping the soldering zone - the work is considered finished. You can proceed to the next connection.

Recommendations from experienced craftsmen

Each stage of soldering is accompanied by compliance with a number of rules, small but important nuances. Their observance directly affects the result of work.

Make sure that during the soldering process, the fitting or pipe is not under load - so the molten solder will spread more evenly.

After all water supply or heating from copper pipes be sure to remove flux residues from the pipes so that the copper does not begin to break down, and also immediately clean clothes and work tools.

Conclusions and useful video on the topic

Video # 1. Visual soldering master class:

Video # 2. Insertion into the pipe by soldering:

Video # 3. Features of high-temperature soldering tubes for air conditioners:

Soldering technology is available to everyone, since it does not require complex skills or baggage of special knowledge. You can achieve mastery in a few practical exercises, and materials and tools can be purchased at the nearest building market.

But when assembling heating or water supply systems, we recommend that beginners still enlist the help of more experienced installers, since soldering errors can result in an accident and additional costs.

Please write comments, ask questions, post a photo on the topic of the article in the block below. Tell us about how you soldered copper tubes with your own hands. It is possible that the technological subtleties you described are useful to site visitors.

Soldering of copper pipes: step-by-step analysis of work and practical examples

Soldering of copper pipes: step-by-step analysis of work and practical examples  Solder for brazing copper: types of solder and their characteristics + selection tips

Solder for brazing copper: types of solder and their characteristics + selection tips  DIY copper pipe installation: copper pipe installation technology

DIY copper pipe installation: copper pipe installation technology  Soldering polypropylene pipes: work rules and analysis of possible errors

Soldering polypropylene pipes: work rules and analysis of possible errors  Connecting copper pipes: instructions and comparison of various installation technologies

Connecting copper pipes: instructions and comparison of various installation technologies  Welding machine for polypropylene pipes: classification, rating of the best + selection tips

Welding machine for polypropylene pipes: classification, rating of the best + selection tips  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Once in my life I happened to solder a copper pipe. It turned out not as scary as I thought. A heat exchanger flowed on my column, the workshop did not take up repairs, I decided to come up with something myself. I studied the Internet, bought a gas bottle, the one that is tourist, 220 grams of liquefied butane, a heating pad, and solder wire.

True, he trained on an unnecessary pipe, so actively that the gas cylinder was used up. And he already made the second repair of his column, although it does not look too neat, but restored the heat exchanger.