How to fix a hose for a vacuum cleaner: causes of damage + self-repair methods

A significant proportion of household vacuum cleaners in operation are structures that use a flexible corrugated hose. During the cleaning of the room, loads of a different nature affect it, which does not exclude the possibility of damage to this part of the vacuum cleaner, right?

You had a similar nuisance, and you don’t know how to fix the hose for a vacuum cleaner with your own hands? We will help you deal with this problem.

The article discusses the most probable causes of a corrugated hose defect, as well as provides detailed instructions for restoring the integrity of a part. The methods of troubleshooting we have proposed are quite simple, so any home master can perform repairs.

The content of the article:

Hose design features

Most corrugated cleaning equipment hoses are a tube made on the basis of an elastic material (polypropylene).

The tube usually has a length of not more than 1.5 meters. Due to the corrugated surface, the accessory has the ability to stretch within small limits.

One end of the elastic pipe ends with a short piece of rigid plastic tube. This part is a link to the extension rod or directly to the working nozzle of the vacuum cleaner.

The opposite end of the hose is equipped with a short nozzle-lock, through which a lock connection is formed with the vacuum cleaner module. This lock pipe is actually also a continuation of the corrugated tube.

The practice of using vacuum cleaners notes that it is precisely at the junction lines of an elastic corrugation with end rigid elements that a break occurs most often, and hose breakage is considered one of the most common vacuum cleaner breakdown.

Meanwhile, the formation of even a small rupture of the hose leads to a significant loss of efficiency of cleaning equipment.

Causes of defects

Cracks, tears, punctures on the body of the vacuum cleaner hose can occur for various reasons. However, the main reason, of course, should be considered improper handling of this part.

What user actions lead to defects on the corrugated tube body?

Take a closer look:

- Towing the vacuum cleaner from place to place through a hose.

- Bend the pipe at unacceptable angles during the cleaning process.

- Inaccurate use when cleaning objects with sharp edges.

- Storage is not according to the instructions.

The natural cause of the formation of defects should also be considered the expiration of the product’s life, wear, low quality of the material.

Towing a vacuum cleaner from place to place by pulling the unit by the working hose is a fairly common practice.

At the same time, many owners of vacuum cleaners do such “tricks” completely unaware of the impending consequences. Meanwhile, the instruction for any vacuum cleaner clearly states - you can’t do this!

The bend of the pipeline at an unacceptable angle can occur when the owner of the vacuum cleaner in the heat of cleaning strives to reach areas theoretically unattainable by the operational and technical parameters of the cleaning equipment.

Several times, such attempts can complete quite successfully. However, the strength of the material with respect to unacceptable loads is not unlimited. Therefore, at the most inopportune moment, the pipeline will simply burst in the place where there was an unacceptable bend.

Harvesting can be carried out in different conditions. For example, in conditions of cleaning furniture, the frame of which has metal parts with sharp edges. If the hose is manipulated carelessly under such conditions, there are all prerequisites for the appearance of cuts on the corrugation body.

Finally, the storage rules for cleaning equipment, specifically described in the vacuum cleaner instructions, also cannot be violated, since a violation here is one of the reasons for the malfunction of the vacuum cleaner hose.

So, storing the device together with accessories, or separately accessories, at a temperature lower than recommended leads to a decrease in the strength of the corrugated tube material.

Sudden temperature changes, loaded state, unacceptable kinks are also critical for the hose material.

DIY Repair Instructions

If the flexible sleeve of the vacuum cleaner is damaged - this is not a reason to decide on a change in household appliances.

As user practice shows, it is quite affordable to bring a defective corrugated hose of a vacuum cleaner into a normal working form. And to do it quite simply do it yourself. Consider the options.

Option # 1 - simple cut repair

Most often, gusts form at the junction of the flexible hose with hard plastic pipe ends.

It does not matter in which part the impulse formed - at the point of connection of the tube under the rod or at the point of connection of the pipe-lock. The repair principle is the same in both cases.

For repairs in such cases, you need only one tool - a sharp knife.

Progress of work:

- Run a straight section of hose slightly away from the rush.

- Carefully remove the remaining corrugation material from the inside of the trailer.

- Treat the cleaned interior with sealant.

- Screw the end cap carefully onto the cut end of the hose.

As a rule, end plastic parts have a screw landing track inside.

Therefore, the evenly cut part of the corrugation is well screwed into the inner region of the trailer, and due to the lubrication of the “thread” with a sealant, the connection is tight and quite strong.

Many modern vacuum cleaners, for example, firms Samsung, are completed with hoses with folding trailer. Inside of which a “nylon” threaded sleeve “sits” where the end of the hose is screwed. The kapron sleeve is fixed inside the end pipe by an annular plug with clamps.

The repair principle of such assemblies is similar. You only need to squeeze the clamps, remove the ring plug and kapron sleeve with a torn piece of hose.

Then remove the dangling part from the sleeve, cut the hose, screw the nylon sleeve onto the trimmed end and assemble everything in reverse order.

Option # 2 - using the overhead brace method

Such defects usually appear as a result of damage by mechanical rigid objects and often due to the fault of the owner of the equipment. Moreover, damage can take the form of cuts, tears, punctures.

Here, a rather practical and effective way to restore the performance of the corrugation of the vacuum cleaner hose seems to be to use a piece of a bicycle rubber chamber as a repair material.

Repair Instructions:

- Cut out the damaged corrugation segment evenly (perpendicularly).

- It is good to clean (degrease) the ends on the cuts.

- Take an integral piece of a bicycle chamber 80-100 mm long.

- Place a piece of the chamber on any of the corrugation segments and extend a little further than the cut-off point.

- Apply glue of the “Moment” type to the ends of the cuts and connect the hose sections.

- Treat the surface of the corrugation in the joint area with universal glue.

- Pull a piece of the chamber in the opposite direction along the hose until the rubber completely encompasses the joint.

The rubber of the bicycle chamber has good stretching properties, so pulling through the hose is not difficult.

At the same time, a slightly smaller diameter of the chamber allows a sufficiently tight fitting of the hose corrugation at the connection point. The applied adhesive enhances tensile strength.

In this way, a neat connection is obtained that does not actually violate the elastic properties of the corrugation.

Option # 3 - applying the thermal method

There is another technique that is more complicated than the methods mentioned above, but the quality result can be obtained at the factory level. This is a thermal method for repairing a defective vacuum cleaner hose using a heat-shrink tubing and a hair dryer.

It should be noted: in this option, there is no need to cut (shorten) the hose, which has its advantages.

The work instruction is as follows:

- To choose a heat-shrinkable tube according to the color and size of the diameter of the corrugation.

- Disassemble and dismantle the hose end piece.

- Put on the shrink tube through the released end and stretch to the rush point.

- Close the damaged area with a shrink tube with a margin of several centimeters on both edges.

- Heat shrink with a building hairdryer, gradually moving the tool along the entire length of the patch.

This method is also well suited for repairing punctures and cracks in any part of the corrugated pipe.

Another question is that a building hair dryer or similar tool is a rather specific technique and may not always be at hand.

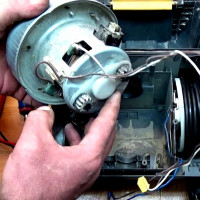

Option # 4 - Repair corrugation with internal conductors

Another, quite difficult from a technical point of view, is the repair of a vacuum hose, the design of which contains a switching electrical line.

A similar system is usually used on accessories supplemented by a handle with an airflow control panel, for example, Samsung SC6573.

The complexity of the repair lies in the fact that in order to eliminate the impulse it is necessary to cut off the defective piece, and with it inevitably it is necessary to cut the switching line consisting of two conductors. The cut off wire is subsequently re-soldered to the working contacts.

If you are the owner of a Samsung vacuum cleaner, we recommend that you familiarize yourself with the information on typical breakdowns of equipment of this brand, which is set out in this article.

The instructions in this case are as follows:

- Disassemble the body of the nozzle-lock.

- Unscrew the pipe counterclockwise from the hose.

- Cut off the defective part, taking into account the sufficient length of the wires.

- Solder the contact pins to the conductors.

- Assemble the body of the nozzle-lock.

Gusts on such systems can also appear on the opposite side, at the junction of the hose with the control handle. There may also be a defect in only wire breakage without breaking the hose.

In this state of affairs, the repair becomes even more complicated, since it is necessary to solve the problem of restoring the operability of the contact mechanism of the communication line.

Option # 5 - temporary recovery technique

Quite often, the owners of vacuum cleaners resort to the simplest ways to repair the hose when a gust, puncture or crack forms. To carry out repairs, usually use adhesive tape, insulation or plumbing tape.

In principle, these temporary measures taken during operation before replacing the corrugation with a new one are acceptable, but from the point of view of continuing the effective operation of the equipment, this is not the best option.

If you still decide to use one of the simple methods, in any case, it is recommended to adhere to the standard instructions:

- The lining area of the tape or tape must be cleaned.

- It is advisable to degrease the area to be repaired using suitable means.

- Apply the tape tightly and evenly on the principle of "turn on turn" in at least two layers.

- The end of the tape is preferably fixed to the glue.

Subject to this instruction, a temporary patch at the rush site can serve for quite a long time. But the status of "temporary" from this does not change.

Conclusions and useful video on the topic

In the video below, the wizard will demonstrate how to repair a hose that contains a communication line inside:

Repairing a vacuum cleaner hose often does not cause any particular difficulties for the user. The main criteria for self-repairing a hose is the ability to hold a metalwork tool in hand and, accordingly, a creative impulse to carry out repair work. Without both, the quality of the repair is not guaranteed.

Have something to supplement, or have questions about repairing a flexible corrugated hose? You can leave comments on the publication, participate in discussions and share your own experience in fixing this part of the vacuum cleaner. The contact form is located in the lower block.

Do-it-yourself Samsung vacuum cleaner repair: common causes of malfunctions + troubleshooting procedure

Do-it-yourself Samsung vacuum cleaner repair: common causes of malfunctions + troubleshooting procedure  How to fix a vacuum cleaner with your own hands: the most common breakdowns and their repair

How to fix a vacuum cleaner with your own hands: the most common breakdowns and their repair  How to disassemble a Samsung vacuum cleaner: typical breakdowns + detailed instructions on how to disassemble a vacuum cleaner

How to disassemble a Samsung vacuum cleaner: typical breakdowns + detailed instructions on how to disassemble a vacuum cleaner  Review of the Samsung SC4520 vacuum cleaner: the perfect assistant for summer cottages - simple, powerful and cheap

Review of the Samsung SC4520 vacuum cleaner: the perfect assistant for summer cottages - simple, powerful and cheap  Overview of the Philips FC 8472/01 PowerPro Compact Vacuum Cleaner: simple design and high power

Overview of the Philips FC 8472/01 PowerPro Compact Vacuum Cleaner: simple design and high power  Review of the Samsung SC4326 vacuum cleaner: a powerful cyclone as standard

Review of the Samsung SC4326 vacuum cleaner: a powerful cyclone as standard  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

A hose from a vacuum cleaner - this is the thing that you really can repair by yourself. I have personally repaired a couple of hoses from different vacuum cleaners. The first case is simple - the corrugated hose was torn almost at the entrance to the handle. He shortened it and anointed it with glue under the coupling for reliability. But this method was not suitable for the second situation, when the hose frayed in the bend almost in the center. There, he simply cut a tube from an old bicycle chamber, pulled it on a hose and rewound it with tape from above. It does not look very aesthetically pleasing, but the main thing works.

In our old vacuum cleaner, the hose broke at the junction with the end-pipe. Initially, the hose fell out, it was necessary to constantly push it back and hold it with your hand so that it would not fall out. After the father-in-law glued the hose to the pipe with adhesive tape, but this did not work either, since the adhesive tape has poor adhesive ability. As a result, we glued the hose with sealant, and then we began to vacuum without any problems.

In general, the methods given here are more like temporary ones. Kakby is good not to close the gap, it still will not become as tight as it was. It’s easier to buy a new hose. Although if it is torn at the junction, then you can really cut off the excess.