Belt for a washing machine: selection tips + replacement instructions

Everyday life has long been unthinkable without technological progress that greatly simplifies life. One of such devices is a modern washing machine. The unit has a complex structural design and even the smallest details play an important role.

For example, a belt for a washing machine in the event of a malfunction may simply stop the entire washing procedure. Replacing it is not difficult if you choose the right one. We will tell you how to find the right model to restore the belt drive, explain how to restore the washing equipment.

The content of the article:

Belt Drive Specifics

All components in the washing machine are interconnected and if any element fails, the washing process will be disrupted or completely stopped.

Belt drive - a connecting link between the engine and a pulley. It is the coordinated work of this unit that reproduces the movements of the drum when performing a given washing mode. If the accessory mechanism has flown or broken, the device ceases to fulfill its purpose.

After loading the cylindrical drum and installing the necessary washing program, the process is as follows:

- The back of the drum, equipped with a friction pulley (visually this is a metal wheel), with a recess around the entire circumference, is activated by the arising frictional forces from the tension of the elastic belt.

- A pulley, however of a smaller diameter, is also mounted on the electric motor. The two-ring system is connected by a drive belt, the main purpose of which is to transmit torque from the motor to the drum.

- In the process of reproducing engine torque, a speed of 5000-10,000 rpm is achieved. This figure is quite large, therefore, subject to reduction.

- To reduce the number of revolutions, a light ring of large diameter is used, which has a rigid mount to the drum shaft.

- Due to such a rotational transition from a smaller to a larger wheel, there is a weakening to 1000-1200 rpm.

The coefficient of belt tension has a significant effect on the effective transmission of forces. Excessive pulling forces contribute to maximum torque transmission.

However, this significantly accelerates the wear of not only the belts themselves, but also the pulleys, bearings, seals and axles with which they come in contact.

If the situation is opposite and the tension is weak, the belt will slip on the pulleys. Friction interaction of surfaces entails polishing the involved moving parts. The consequence of this process is a significant deterioration in adhesion.

Only due to the high elasticity of the flexible drive are both processes compensated, and electric motor functions in the right conditions. However, for this you need to correctly select the necessary model of the rubber part.

Proper belt selection

The main task when choosing a belt drive is to find the marking of the part, for example, 1046 H7, 1100 J4, etc. In fact, these are four numeric characters and a Latin letter with a number. Accordingly, similar designations should be on the new part.

Differences between drive units

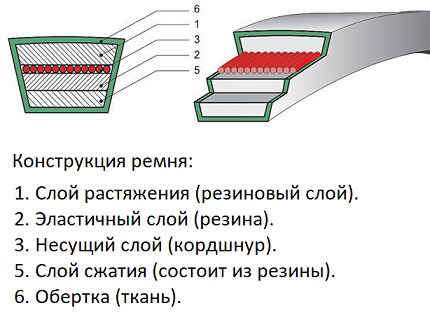

Externally, these structural elements differ not only in color, but also in tread characteristics, length, number of wedges, and also materials used in the production process.

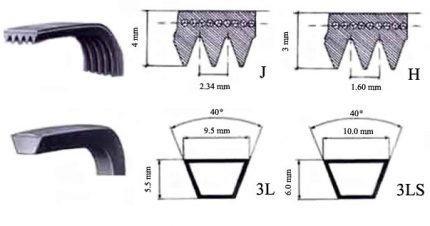

There are only two main types of belt transmission, but there are differences between the section profile:

- monoclinic for foreign-made washing machines have a section of 3 L, domestic - Z and A;

- V-ribbed (toothed) for large equipment - J, for small - H.

Visually, they can be distinguished by the depth of streams. As a rule, this kind of part allows you to transmit the greatest power, because it has the best coefficient of adhesion. The maximum broadcast power reaches 100 kW.

The number of streams in the serrated edge of the drive can vary from 3 to 8, tracks - from 3 to 9 pieces. The distance between the strips in the J-shaped profile is 2.34 mm, in the H-shaped - 1.6 mm.

Outboard belts are also classified according to the type of stiffness - elastic and rigid. The former are ideal for new models of washing units, since they have the properties of stretching.

These characteristics make it possible to achieve a firm grip between the engine and the tank. However, they do not have the ability to adjust the degree of tension.

Hard belts, on the contrary, practically do not stretch. Before installing them, you need to adjust the position of the motor relative to the tank. Such a variation is rare and can only be found on old models of technology.

The length parameter is also significant when choosing a part. In the marking, this indicator is indicated by the numbers in front of the section profile and the number of wedges.

In addition to the distinguishing characteristics described above, drive belts are made of rubber or polyurethane. The first variation has a high degree of strength, however, this affects the low coefficient of stretching in comparison with the polyurethane sample.

The second option is easy to install, however, its degree of wear is faster than that of a durable rubber product. As a rule, the type of automatic washing machine indicates the necessary type of belt drive, since the motor pin is sharpened specifically for its profile.

What to look for when choosing a replacement?

It is not always possible to read the marking of the belt, for example, with long use, the encoding can simply be erased. In such a situation, in order to select the necessary fittings, they pay attention to the main parameters, which are discussed below.

First of all, the length of the connecting element is taken into account. If the choice is made incorrectly and the purchased belt will be shorter or, conversely, longer than the previous one, it will either tear or will constantly fly off during operation. In this case, it is unlikely to fully exploit the equipment.

Also, the section profile is necessarily taken into account - the H-shaped one will not sit on a motor sharpened under a J-shaped shape. But the number of wedges does not have to be taken into account.

For example, belts with similar markings 1130 H6 and 1130 H7, 1276 J4 and 1276 J5 are almost the same. The product with more wedges will be wider. Due to this, the probability of slippage is reduced.

All Samsung washing machines use belts with the same profile and length - 1270 J. For narrow technology, three-wedge parts with a code are used 1270 J3for medium and wide - 1270 J5.

Identification of signs of breakage

If the drive belt has become unusable, soon the owner of the equipment will be able to notice this. However, to determine that the problem is precisely in the transmission unit is quite difficult, since the drive fittings are located in the equipment body. Nevertheless, you can find out the true cause by characteristic signs.

In most cases, the technique independently determines the nature of the failure and notifies the user through the display or highlighting of the corresponding buttons. Depending on the manufacturer and the modification of the device, the decryption of the error code will be indicated in the instructions.

If for some reason the unit does not give a breakdown, a flown, torn or stretched part as follows affects the operation of the washing unit:

- After choosing the washing mode, the program starts, there is a countdown, the engine is functioning, however, the loading tank does not produce reverse movements.

- The same time intervals between the audible hum of the motor and its complete stop.

- The selected washing mode is started, the engine runs continuously, then the system is completely inactive without the possibility of early termination of the process by pressing the program cancel keys.

- Manual rotation of the drum is unhindered.

All the above signs indicate the need parsing cars and replacing the belt drive. To avoid a recurrence of this kind of trouble, it is worth considering in detail the causes that contribute to the malfunction, especially if it is repeated regularly.

The main causes of failure

If the connecting link between the motor and the drum flies for the first time, this is not always the cause of a serious breakdown. This is possible with excessive load of linen. At the same time, installing the belt back is not difficult.

However, if transmission slippage is not repeated for the first time, damage may be more significant. We will understand all the malfunctions and methods for eliminating them in more detail.

Regular tank overload

Often the main reason for the rapid wear of the transmission unit is the frequent overload of linen. The washing machine, in which the tank is designed to load 7 kg, is not designed for the regular use of the maximum possible mass. During this washing mode, the load on the belt increases.

If the owner of the equipment will load the drum 25-30% less than the nominal weight specified in the instructions, then the service life of not only individual parts, but the entire unit, will be significantly higher.

With the elimination of violations in work, the consequence of which becomes non-spinning drum, will familiarize you with an article on the analysis of the causes and methods of recovery.

Unreliable mounting / breakage of the drum pulley

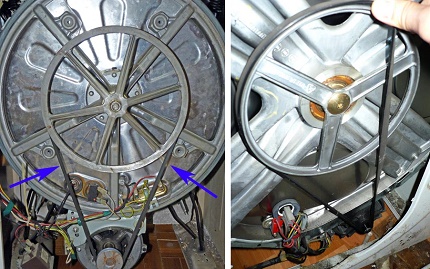

In simple terms, the pulley of the washing machine is a round cast-iron wheel with spokes located behind the drum. It is on him that a belt is worn. The whole mechanism is quite primitive, but reliable and effectively performs its functions until the moment of failure.

Since the washing process is carried out by means of an engine that transfers revolutions to the pulley through the belt, it is the broadcast unit that is the weak link in the mechanism.

However, frequent belt slippage may occur due to a malfunction of the rotary wheel. During washing / spinning, you may notice a slower rotation of the drum.

You can check the condition of the wheel without dismantling, for this you have to follow these steps:

- It is necessary to remove the back wall of the housing.

- Now remove the belt: you need to grab it with your left hand, directing the effort towards yourself, and with the right to turn the wheel, the drive itself will slip.

- With two hands, they grasp the sides of the pulley and produce slight swaying of the part. So you can check the quality of fixation.

- To eliminate the likelihood of marriage, the surface is held by hand and visually inspected for deformation.

If during the inspection any defects were found, the part will need to be replaced with a new one. If you leave everything as it is, then perhaps the belt will have to be changed more often than once every couple of months.

To replace the drive, you will first need to remove the old copy. However, this process is not the easiest - the mounting bolt on which the pulley is mounted is additionally treated with sealant, but more on that later.

At the beginning of the repair, you must disconnect the device from the power supply, the drain and water supply systems. Using a Phillips screwdriver, unscrew the screws that secure the back wall.

Next, using the method described above, remove the belt drive.Taking a small wooden wedge, it is necessary to clamp it in the spider of the wheel. This is necessary to immobilize the mechanism when loosening bolts.

To unscrew the central bolt, it will need to be heated to red with a blowtorch. Then treat this fastener with a lubricant such as WD-40 or a similar technical spray. After a short period of time, we sprinkle a wrench on the bolt and unscrew it, knocking it out with a hammer a little.

After dismantling, with obvious defects of the wheel it is replaced with a new part. To do this, put the pulley on the drum shaft, treat the screw with sealant and screw it back with the key.

Now go to the stage of replacing the belt. First we put the belt on the engine, and then we pull it onto a large circle of the drum pulley, while turning it counterclockwise and gradually laying it in the provided grooves.

At the end, we check the tightness of the fit with a few turns of the wheel - its course should be tight. After that, you need to return the back cover to its original place and fix it with bolts.

Deformation and damage to bearings

There are cases when the cause of a flown belt becomes the skew of the drum due to failure or deformation of the bearings.

There are only two reasons for the breakdown of this part:

- Wear of the oil seals, resulting in leakage and water falling on the bearing. Thus, the part is covered with a corrosion coating.

- Long term use of the washing machine. The classic factor of temporary wear.

Repair is quite complicated, but financially justified - the cost of the services of the master will cost 30-50% of the cost of the new unit.

First, the housing cover, attached by two screws to the back of the washing machine, is removed, and then the back wall. You also need to remove the detergent dispenser and control panel. After that, using a suitable tool, the front collar of the manhole cuff is removed, and the restrictive part itself is removed from the housing.

Now we unscrew the door lock and remove all the parts together with the front panel. Then we disconnect the metering hopper from the nozzle coming from the drum. In the process, you will need to remove all obstructing parts, loosen the hose clamp and remove it.

To remove the tank counterweight, just unscrew the fixing bolts with a screwdriver. In different models of washing machines, its location can be both from the front and from the back.

Reaching heating devices - TENA, you must photograph the wiring for proper connection during reassembly.

Unscrewing the mount, we remove it from the cell by prying with a screwdriver. A nozzle connected to the tank and possible wires are also disconnected.

The next step is to remove the drive belt. All wiring routed to the motor must be disconnected. Next, twisting the self-tapping screws fixing the electric motor, we take it out.

In the same way, we deal with the mounting screws of the shock absorbers. To the right and left of the tank are the springs to be removed. By disconnecting the hose tube from the tank, it can be removed.

First of all, remove the cuff - this part must be replaced. However, you must first make a marker at its location with a marker.

Remove the pulley - this process is described in detail in the previous section. After this, you must try to drown the shaft inside the tank with your hands. If the attempt is unsuccessful, repeat using a rubber cue. Now the tank is disassembled into two parts.

Having divided the tank and pulled out the drum, the condition of the cross, the sleeve and the shaft is carefully inspected. In the event that after the breakdown of the bearings the regular use of the washing machine was made, failure of these parts is also possible.

Using a hammer and a chisel, knock out the bearings. However, the entire process must be carried out with utmost care so as not to deform the tank. There should be two parts dropped out - a stuffing box and a bearing.

The place where it was installed washing machine bearingare treated with a special compound, for example, universal lithium grease “Litol 24”. Instead of a worn part, we put a new bearing and hammer it in the same way.

At the finish stage, we assemble the tank and the washing machine itself. At the same time, the connecting seam on the tank and gasket must also be lubricated, only with sealant with waterproof properties.

Conclusions and useful video on the topic

This video describes in detail the main parameters necessary for the correct selection of the belt drive to the washing machine, as well as the possible reasons for the failure of this unit:

You can even replace the belt in the washer yourself. How to do it right, the video instruction will tell you:

The most difficult problem that contributes to the falling or breaking of the transmission belt, and may be hidden in defective bearings. Find out how to replace them from the plot:

If the malfunction of the washing machine lies precisely in the link between the drum and the engine, it is necessary to responsibly approach the choice of the corresponding marking of the part.

The process of replacing a belt drive is quite simple, but the attendant serious breakdowns can significantly complicate the process. Therefore, if the tank is disassembled, it is better to photograph all the details for the subsequent correct assembly of the torque mechanism.

Want to share your own experience in replacing a washing machine belt? Do you have valuable information on the topic of the article, which is worth sharing with site visitors? Please write comments in the block form below, ask questions and post thematic photos.

Cuff for a washing machine: purpose, instruction on replacement and repair

Cuff for a washing machine: purpose, instruction on replacement and repair  Installing the washing machine: step-by-step installation instructions + professional tips

Installing the washing machine: step-by-step installation instructions + professional tips  LG Washing Machine Errors: Popular Trouble Codes and Repair Instructions

LG Washing Machine Errors: Popular Trouble Codes and Repair Instructions  DIY Samsung washing machine repair: analysis of popular breakdowns and repair tips

DIY Samsung washing machine repair: analysis of popular breakdowns and repair tips  How to properly drain your washing machine: a step-by-step guide and valuable tips

How to properly drain your washing machine: a step-by-step guide and valuable tips  Ariston Washing Machine Errors: Decoding DTCs + Repair Tips

Ariston Washing Machine Errors: Decoding DTCs + Repair Tips  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

We have an Indesit machine, an old one already, but it works steeper than new ones, only now the belt has worn out and burst. I spun it myself, I wanted to see what was the reason, and there everything is visible immediately. There was a marking on the belt, but over time it got worn and practically unreadable. I ordered it on the Internet, it looks like it. When I received it was not what I needed. The new belt is shorter than the previous one, 1.5 centimeter for sure. I tried to pull it, but so far it’s not working, hard, maybe there are some proven ways, who knows? Or throw it away and look for a new one?

Hmm ... In fact, such a big difference of 1.5 cm is not buzzing. You can try to pull, of course, but it is better to look for the same as it was. The best way is to go to some service where they fix the washing machines and ask them. You can call some master, tell the model of the washer and ask what kind of belt you need. It will come out more expensive, but in every way more reliable than buying something without knowing what.

And you, Yegor, would recommend holding the belt in hot water, it should be easier to reach. You can also try moving the engine a bit. But believe me, with such a big difference as yours (1, 5 cm or more) you won’t be able to stretch it, buy a new one, and throw this one away. Always look at the markings. She will tell a lot. Better take the old belt with you and buy exactly the same.

Can anyone tell me which belt is suitable for ATLANT 50u102 washer? Of the old markings, only J5 remained readable.

If I understand you correctly, then you need a new belt for the Atlant 50u102 washing machine. The model is not new, plus there are different assemblies, so it is difficult to say which drive belt is suitable for it.

So, for example, the belt 1173J5 PJE 908092003034 and 1165J5 EPJ 908092003035 differ by one digit at the end, but these are two completely different belts. Although your model is on both lists, but most likely the release year and whose assembly is still important. If possible, attach a photo of the belt. Or you can remove it and look for an identical one on the market.