Start relay for the refrigerator: device, how to check and repair it correctly

The most necessary device, both in an apartment and in a private house, is a refrigerator. And it’s hard to disagree with this statement, right? It is difficult to find a home where it is not. Like any appliances, refrigerators can break. But there are situations when a breakdown can be diagnosed independently.

Almost all domestic refrigeration equipment is equipped with a single-phase motor. To start it, you have to use a starting device. If this simple but important part fails, then the compressor will stop starting. But, knowing the principles of the device, you can identify the problem and fix it.

This article will discuss how the starting relay for the refrigerator works and the signs of a malfunction. We’ll show you how to troubleshoot your refrigeration equipment. The videos presented by us will help to understand the principle of operation of the starting device, and also, if necessary, to identify its malfunction.

The content of the article:

Starting a single-phase asynchronous motor

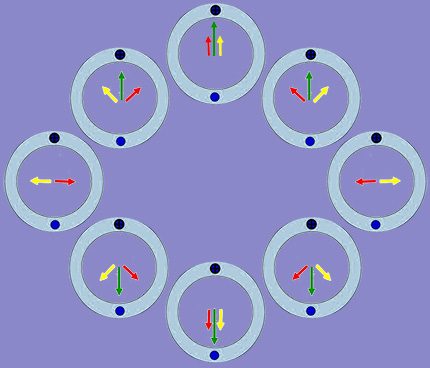

At its core, the motors of compressors installed in modern refrigerators are single-phase asynchronous motors with a starting winding. Their main components are a rotating rotor and a stationary stator.

The rotor is a hollow cylinder made of conductive material or containing short-circuited wiring.

The stator includes two windings: working (main) and launcher (start). They are mutually arranged at an angle of 90 degrees, or have the opposite direction of winding - the so-called “bifilar”. An alternating current passing through the main winding creates a magnetic field with a changing vector.

If the rotor is not static, then according to the law of electromagnetic induction, the engine will develop or slow down the torque, since the slip relative to the forward and reverse magnetic flux is different. Therefore, to maintain movement, an alternating current passing through the working winding is sufficient.

If the rotor is stationary, then with the same slip relative to magnetic fluxes, the resulting electromagnetic moment will be zero. In this case, it is necessary to create a starting torque. For this, we need a starting winding.

The currents in the windings must be phase shifted, therefore, a phase-shifting element is introduced into the motor - a register, inductor or capacitor. After the rotor reaches the necessary rotation, the supply of electricity to the starting winding is stopped.

Thus, to start a single-phase asynchronous electric motor, it is necessary to pass current through two windings, and to maintain rotation of the rotor - only along the working one. To regulate this process, a start relay is installed in the circuit in front of the compressor of the refrigerator.

The principle of operation of the start relay

Despite the large number of patented products from various manufacturers, the schemes refrigerator work and the principles of operation of the starting relays are almost the same. Having figured out in principle their actions, you can independently find and fix the malfunction.

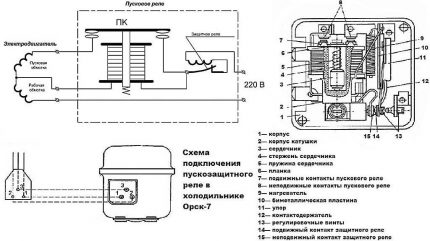

Device diagram and compressor connection

The relay circuitry has two inputs from a power source and three outputs to a compressor. One input (conditionally - zero) goes directly.

Another input (conditionally phase) inside the device is split into two:

- the first goes directly to the working winding;

- the second passes through the disconnecting contacts to the starting winding.

If the relay does not have a seat, then when connecting to the compressor, you must not make a mistake with the order of connection of the contacts. Widespread on the Internet methods for determining the types of windings using resistance measurements are not true in the general case, since some motors have the same starting and working windings.

Therefore, it is necessary to find documentation or disassemble refrigerator compressor to understand the location of the through contacts.

This can also be done if there are symbolic identifiers near the outputs:

- “S” - starting winding;

- “R” - working winding;

- “C” - general exit.

Relays differ in the way they are mounted on the frame of refrigerators or on the compressor. They also have their current characteristics, so when replacing it is necessary to choose a completely identical device, or better, the same model.

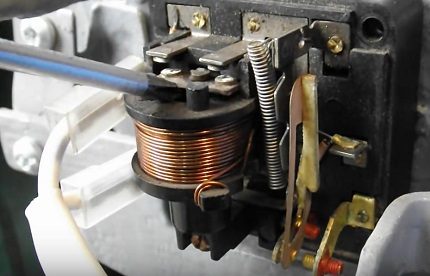

Contact closure by induction coil

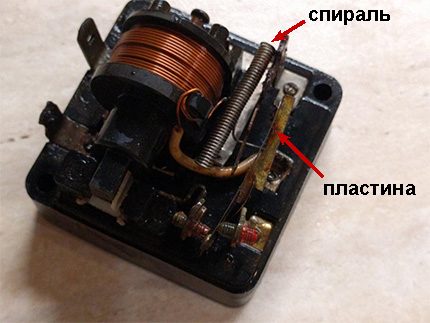

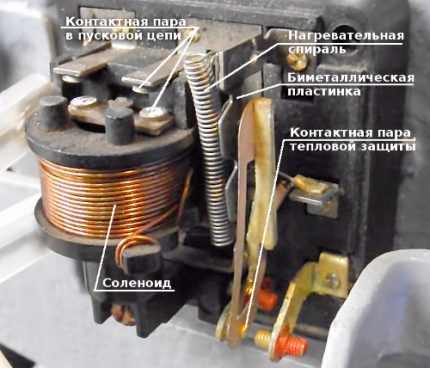

The electromagnetic starting relay operates on the principle of closing a contact to pass current through the starting winding. The main active element of the device is a solenoid coil, connected in series with the main motor winding.

At the moment the compressor starts, with a static rotor, a large starting current passes through the solenoid. As a result of this, a magnetic field is created that moves the core (anchor) with a conductive strip installed on it, which closes the contact of the starting winding. The acceleration of the rotor begins.

With an increase in the number of revolutions of the rotor, the current passing through the coil decreases, as a result of which the magnetic field voltage decreases. Under the influence of a compensating spring or gravity, the core returns to its original position and the contact opens.

The compressor motor continues to work in the mode of maintaining the rotation of the rotor, passing current through the working winding. The next time the relay trips only after the rotor stops.

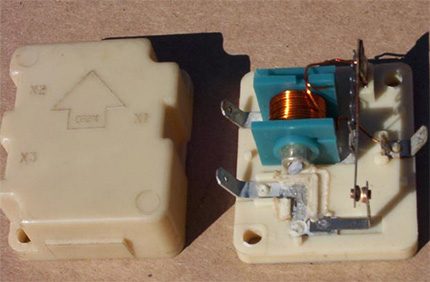

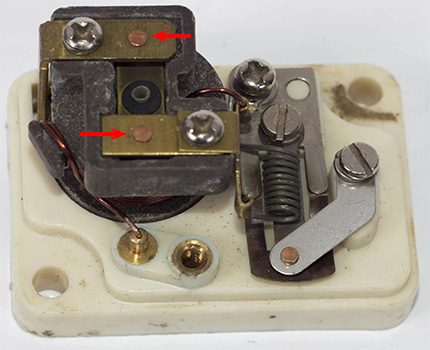

Posistor current control

Relays manufactured for modern refrigerators often use a posistor, a type of thermal resistor. For this device, there is a temperature range below which it transmits current with negligible resistance, and above it, the resistance increases sharply and the circuit opens.

In the start relay, the posistor is integrated into the circuit leading to the start winding. At room temperature, the resistance of this element is negligible, therefore, at the start of compressor operation, the current flows unhindered.

Due to the presence of resistance, the posistor gradually heats up and, upon reaching a certain temperature, the circuit opens. It cools down only after the current supply to the compressor is cut off and again responds to a pass when the engine is turned on again.

Realization of protection of current type

An induction motor is a complex electrical device that is prone to breakdowns. If a short circuit occurs, it will work. circuit breakerestablished in switchboard.

If a fan fails, which cools the winding and mechanical moving elements, the built-in thermal protection of the compressor will react.

However, a situation may arise when the motor for a long time (more than 1 second) begins to consume current 2-5 times more than the rated current. Most often this occurs when an unplanned load on the shaft occurs due to jamming of the engine.

The current strength increases, but does not reach the short circuit values, therefore load matched machine will not work. Thermal protection also does not have a shutdown reason, since the temperature will not change in such a short period of time.

The only way to quickly respond to a situation that has arisen and to avoid fusion of the working winding is to trip the current protection, which can be installed in different places:

- inside the compressor;

- in a separate current-protective relay;

- inside the start relay.

A device that combines the functions of turning on the starting winding and current protection of the motor is called a start-up relay. Most refrigeration compressors are equipped with just such a mechanism.

The effect of current protection is based on three principles:

- with increasing current strength, resistance increases, which leads to heating of the conductive material;

- under the influence of temperature, the metal expands;

- thermal expansion coefficient for different metals is different.

Therefore, a bimetallic plate is used, which is welded from metal sheets with different expansion coefficients. Such a plate bends when heated. One end is fixed, and the second, deviating, opens the contact.

The plate is designed for temperature response with the passage of current of a certain force. Therefore, when replacing the start-up relay, it is necessary to check its compatibility with the installed compressor model.

Troubleshooting

Given the small number of relay elements, you can consistently test them for operability. To do this, you need a flat screwdriver and a multimeter.

No. 1 - malfunctioning relay

From a structural point of view, a relay with a coil is a device with normally open contacts, and a posistor version with normally closed contacts. Although in that and in the other case, there are possible variants when at the start there will be no current supply to the starting winding or, on the contrary, its shutdown will not work.

If the compressor is serviceable, but does not turn on according to the command given from the refrigerator control unit, then this indicates a lack of voltage on the stator starting winding.

The reason for this may be:

- open circuit;

- contact strip problem;

- overheating of the posistor;

- operation of the electrical protection system and its non-return to normal position.

If the refrigerator turns on for 5-20 seconds, and then turns off, then most often this is a consequence of the relay's protective mechanism tripping.

The reasons may be the following:

- the protective mechanism is operational, and the operation occurs due to problems in the working winding of the motor;

- the protective mechanism is operational, but the relay does not open the contacts in the starting winding circuit;

- the protective mechanism is defective, a false alarm occurs with slight heating.

Since there may be several causes of the malfunction, it is necessary to conduct a complete diagnosis of the fridge start-up relay.

No. 2 - electrical circuit faults

A malfunction of the start-up relay can be detected with a multimeter.

To do this, you need to ring three sections of the electrical circuit:

- If there is an open circuit in the section from the input to the output to the working winding, it is necessary to check the place of opening of the contacts by the protective mechanism. It is possible that it worked and did not return to its original state or open contacts were oxidized.

- If there is no contact in the area from the entrance to the output to the starting winding, then in addition to the banal rupture of the conductive core, two options are possible: opening the circuit with a protective mechanism or lack of contact through the bar.

- A break in a straight (zero) section means mechanical damage to the circuit - it is easiest to find and fix it.

If the relay is based on the use of an induction coil, then it is necessary to forcibly raise the bar - otherwise there will be no contact.

No. 3 - incorrect operation of the posistor

To make sure that the posistor is working properly, it is necessary to check it in a cold and heated state.

First of all, you need to wait until the posistor cools down (2-3 minutes in the idle state are enough) and ring it with a multimeter. If there is no current or a large resistance is detected, the posistor is defective and needs to be replaced.

To test the disconnect ability, you need to connect a power consumer incandescent lamp, for example, to a posistor. To do this, you need an electric plug with two terminals that connect to the input to the device. The wires from the lamp are connected to the connectors leading to zero and the starting winding.

When the plug is plugged in, the light will come on. Since the rating of the passing current in the experiment is much less than when starting the compressor, the posistor will heat up for a long time - for a 100-watt lamp, the response time will be 20-40 seconds.

If after some time the light goes out, the device is working properly. If the consumer is not de-energized, then this means that the posistor is not working. At home, it is impossible to repair, it is inexpensive, so you need to purchase an element similar in parameters.

No. 4 - problems with the contact strip

There are two types of contact strip problems:

- there is no current skipping when the contacts are closed;

- The bar sticks and does not fall.

The first problem may arise due to oxidation of the contacts. In this case, it is necessary to clean them with sandpaper. Also, the cause may be the curvature of the position of the bar, then you must install it horizontally.

A more complex problem is the joint between the bar and the pin, which is affected by the magnetic field of the solenoid. The solution to the problem is individual and depends on the type of malfunction.

Sticking the strap is expressed in the fact that it does not move away with the core. To do this, it is necessary to clean the contacts in order to remove the adhesive and make them smooth.

No. 5 - emergency operation of current protection

If during dialing there is a lack of contact from the input to both windings, then most likely the breakage occurred in the protection zone.

In most cases, this is either a contact waste, which opens the bimetallic plate, or damage in the area of the heating coil.

If the damage is not corrected otherwise, you will have to purchase a new relay.

Conclusions and useful video on the topic

Video # 1. Overview of the principle of operation, types and basic faults of the start-up relay:

Video # 2. Signs of breakdowns of a common RCT starting relay. Connecting an external capacitor to compensate for unstable voltage:

The simple design of the start relay allows you to independently find faults and easily eliminate them. For this, you do not need in-depth knowledge of electrics or a special tool.

However, punctuality must be observed, since the functionality of expensive equipment depends on the quality of the work performed.

Want to talk about how you selected a start relay to restore the operation of the refrigeration unit? Do you have useful information on the topic of the article, which is worth sharing with visitors to the site? Please write comments in the block below, post pictures, ask questions.

Temperature regulator for the refrigerator: device, check + subtleties of replacement if necessary

Temperature regulator for the refrigerator: device, check + subtleties of replacement if necessary  How to repair the refrigerator: finding the cause of the breakdown + repair methods

How to repair the refrigerator: finding the cause of the breakdown + repair methods  Indesit Refrigerator Repair: Find and Fix Common Problems

Indesit Refrigerator Repair: Find and Fix Common Problems  Voltage stabilizer for the refrigerator: how to choose the right protection

Voltage stabilizer for the refrigerator: how to choose the right protection  Compressor for the refrigerator: an overview of frequent breakdowns + step-by-step instructions for replacing

Compressor for the refrigerator: an overview of frequent breakdowns + step-by-step instructions for replacing  Bulb for the refrigerator: characteristics, types, selection rules + how to replace it yourself

Bulb for the refrigerator: characteristics, types, selection rules + how to replace it yourself  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I have two refrigerators at home. One new, modern, another was purchased under King Peas. Everything is in order with the new one: it has been working for a couple of years, there are no problems, and the old relay has failed several times. I wanted to throw it in a landfill, my wife does not, says “rarity”. I myself am not a connoisseur of repairs, I called the master to the house.And he takes a decent repair money for half an hour of repair. Here I looked, read and thought that I could fix it myself, there is nothing tricky.

Thank you for the article. Dismantled, it turned out to be a posistor. Went to look for a new one.

Great article! It helped me deal with the repair of the refrigerator. Thank!!!

The article is very useful, thanks. I have a new refrigerator, it works very quietly, but when it is turned off, quite loud clicks occur periodically. This is probably due to the operation of the start-up protective relay, but at the same time, time clicks are not related to the direct on or off of the compressor. Is this normal and should it be? This does not follow from the article. In the ten-year-old Indesit, I did not notice these clicks at all.

Hello. Of course, it is difficult to identify a problem of this nature without diagnosing the system, but in general, these are characteristic clicks.

During the compressor’s rest, a temperature difference occurs, the “crying” evaporator system, as well as the refrigerator case, may make a crack. Nothing to worry about, usually, manufacturers calculate this fact without harm to the system. If in doubt, call the after-sales service and consult their model with them. The service number must be in the documents that accompany the device.

Thank! It helped to figure it out!

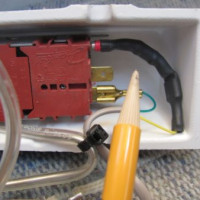

Greetings! He also ran into a bang in the fridge, a thing in the photo cracking. The crack is not connected in any way with the beam or the unit stops.

Refrigerator LG no frost began to leak, the tubes are clean, checked. Can this relay be responsible for defrost? Those. on defrost heating element?

Hello. The gizmo in the photo is called - the defrost timer. And yes, “Bingo!” 🙂 It controls the defrost cycle. Call

Hello! I have an Ardo refrigerator. I plug into the outlet, it takes 50-60 minutes, and only then the compressor starts. After a set temperature has been set, it works for 2-3 hours, turns off and then does not start. Even turning off the power and after 3 hours does not start. Is this also a problem in the relay?

When I accidentally moved the refrigerator, I unsuccessfully pulled out a junction box from the motor-compressor, that is, where the relay with terminals is located. Now I'm wondering which and where of the three wires to pick up.

I can’t remove the cover and relay to see where the starting, main and working contacts are. I slightly pressed the relay about the MK and looked that there were two at the top, one at the bottom. And as I know, most MKs have the opposite. But the trouble is, but how to do something with wires?

What model of the refrigerator though? They didn’t even write a brand ... It would be even easier if you took a photo and attached it here, since it is very difficult to visualize which wires you have torn off and which ones are in place. And given the fact that the manufacturer is not named, the task is complicated at times.

True, the connection diagram of the compressor and the start relay is almost the same for all refrigerators, in general terms, of course. Therefore, I will attach the diagram for reference.

In general, the color wires in the junction box are located. Or drive in the search model of your refrigerator and find the exact scheme. If this is difficult, then discard the photo of the problem, I will try to help.