How to repair the refrigerator: finding the cause of the breakdown + repair methods

Household appliances noticeably make life easier for every busy person, but, unfortunately, it sometimes fails. And refrigerators are no exception. At one moment, which is not at all perfect, the tried and tested “white friend” suddenly breaks.

Well, if he had already served his. But if the service life is still far from complete, the best way out is to contact certified refrigeration masters with experience in repairing units. However, in some cases you can handle it yourself.

The content of the article:

Functional classification

It may seem to an inexperienced user that all refrigeration units are arranged approximately the same. However, this is not the case. According to the principle of action, three types of household refrigerators are distinguished at once.

Before you start repairing your equipment, you need to know exactly how the refrigerator works. Therefore, we consider in detail each of these types.

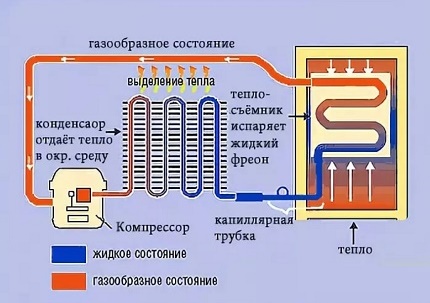

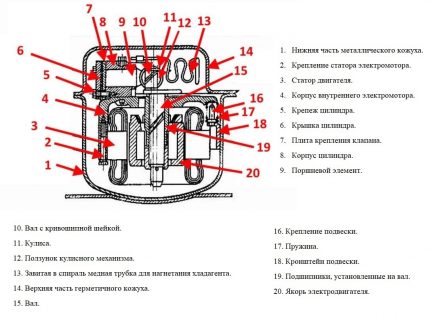

The principle of operation of compression refrigerators

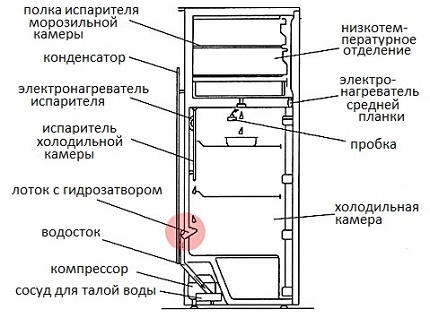

In this case, a special liquid is used to cool the chambers of the unit, which under certain conditions is capable of passing from liquid to gaseous form and back at room temperature.

This is the so-called refrigerant. It is pumped into a closed loop, moving along which it performs the cooling process. It happens as follows. First, the refrigerant in liquid form is injected under pressure into the evaporator.

It has the shape of a coil so that the cooling process takes place as efficiently as possible. The nozzle through which the refrigerant is supplied is called a die.

In household equipment, it is a small fragment of an un profiled capillary tube. In industrial models where greater productivity is required, profiled dies are used.

After the refrigerant enters the evaporator, it begins to expand rapidly, turning into gas. It takes a certain amount of heat from the air, which corresponds to its heat of vaporization. Thus, the temperature in a well-insulated refrigerator or freezer is lowered and everything inside is cooled.

The normal evaporation process will continue only until the pressure inside the evaporator rises. For this reason, the compressor continuously pumps out refrigerant vapors and delivers them to the radiator.

This is another coil inside which gaseous refrigerant is converted to liquid. In doing so, it releases heat entering the air. Next, the liquid is supplied to the die and the cycle repeats. What can be attributed to the advantages of such a design? First of all, it is an efficiency approaching 100%.

In addition, the compression equipment is economical, efficient and easy to adjust. Absolutely safe and chemically neutral compositions are used as refrigerant in such units. The main disadvantage is the presence of detachable joints, moving and rubbing parts.

In addition, the refrigeration circuit has mechanical connections with the external environment, which requires high-quality seals. There is another significant unpleasant moment.

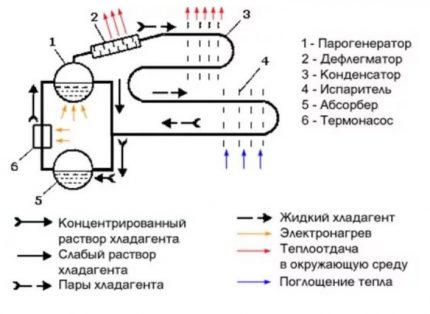

The nuances of the work of absorption units

The design of absorption-type aggregates has some similarities with compression apparatuses. However, its main difference is the absence of rubbing or moving parts.

Consider the principle of operation of such devices. As a refrigerant, a low-boiling composition is used, which dissolves well in a high-boiling liquid. The latter is called an absorber.

The container in which a certain supply of concentrated refrigerant is contained is likewise called. From here it enters a heat pump, which is a vertically mounted tube of copper, which is heated by an electric spiral.

Further, the refrigerant moves into the steam generator, basking on electric current. Here, the refrigerant vaporizes and mixes with the absorber vapor.

The resulting mixture moves into a reflux condenser. This is a specially designed radiator in which the absorber and the refrigerant are separated. The first condenses and goes to the steam generator, and gaseous refrigerant is directed first to the condenser, then by gravity to the evaporator.

Here, a cooling process takes place, similar to that in compression units. Then the heat-absorbing refrigerant is absorbed by the absorber and the process repeats.

Thus, the main advantage of absorption models is their virtually unlimited duration due to the absence of moving elements. However, at the same time they are not economical enough, because consume about 1.5 times more energy than compression ones.

In addition, such refrigerators freeze pretty badly and slowly. Another significant minus is security.

Water is used as an absorber, and ammonia is used as a refrigerant. As a result, highly concentrated ammonia is in the loop.With a possible leak, this is dangerous. Models that run on isobutane or propane are available, but this is even more dangerous.

Considering that absorption units can be kept turned off in the refilled state for any length of time, they are readily purchased for use in homes with seasonal living.

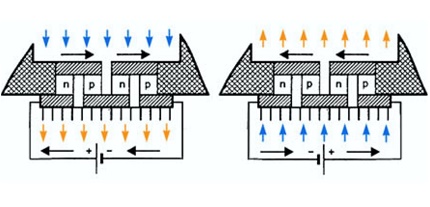

Semiconductor type cold

These are not common devices, the principle of which is based on the Peltier effect.

It consists in the fact that a junction of dissimilar conductors, when an electric current is passed through it, heats up in one direction and freezes in the other, compensating for the heating of the other side. Thus, you can get the temperature up to -40ºС and even lower.

However, the system has significant disadvantages. First of all, it is a high power consumption. It is much higher than that of low-cost absorption devices. In addition, Peltier elements have a limited resource.

At the same time, semiconductor refrigerators are insensitive to mechanical stresses and quickly and efficiently freeze foods. If necessary, it is possible to switch the current direction, which allows you to quickly defrost the system.

Self-repair: what is possible and what is not?

To repair your refrigerator, and not completely break it, you need to know exactly which parts of the system can be repaired independently and which ones are best left untouched. In any refrigeration unit, four circuits can be distinguished:

Refrigeration system. The cooling circuit itself, including coils, refers to it. This is the least suitable part of the unit for self-repair.

Masters persistently do not recommend trying to conduct independent repair work in the absence of knowledge and experience in this area. Amateur performances can be very expensive. Unskilled repairs most often result in the need to purchase a new unit.

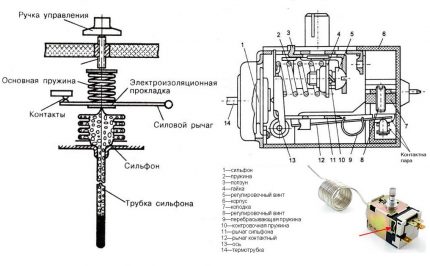

Thermoregulation system. It is here that breakdowns most often occur. Repair is most often possible, but experience in carrying out such work is desirable.

You need to understand that self-repair will require the availability of spare parts, which are not always freely available. Most likely they will have to be ordered in a specialized online store and wait for delivery for a while. For this reason, perhaps a better solution would be to call a refrigeration repair technician.

The mechanical system. Includes seals, fastenings of shelves, covers, suspension of doors and compressor and the like.

Repair itself is usually simple and can be done even by the most inexperienced home master. It usually consists in adjusting the door, seal replacementfixing shelves. Special knowledge is not required here.

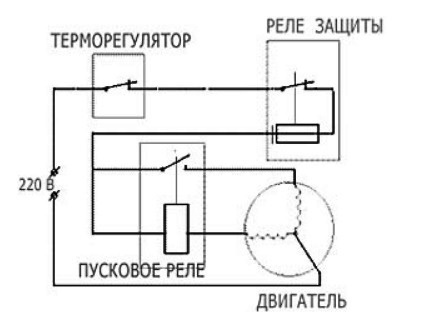

Electrics system. It is an electrical circuit that ensures the normal operation of the refrigeration unit. Includes wiring starting relay, motor compressor, etc.

It is quite maintainable. To work, you need a tester, a soldering iron and some knowledge in the field of electricity. In this system, you can fix almost any damage.

Common refrigerator problems

Before diagnosing a malfunction, you should determine the type of your refrigeration equipment.

Thermoelectric units break extremely rarely. The most common failure is the end of the life of a battery of thermocouples. Most likely, it makes no sense to replace it, since its cost is quite comparable with the price of the unit itself.

In addition, sometimes contacts are burned in such refrigerators, which even an inexperienced craftsman can fix. Much more problems with compression models. If such a refrigerator does not work, there can be many reasons. Let's talk about the most common.

If it does not work when the device is turned on, the power supply circuit may be “to blame”. It includes a socket, plug, power cord, detachable contacts in the compressor compartment. Perhaps the problem is a safety relay or thermostat. The latter should be called by the tester to find out the reasons. If there is a breakdown, there will be no signal.

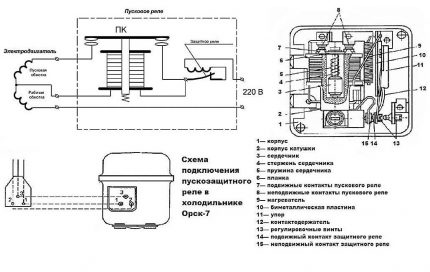

If the power supply network is fully operational, and when starting, the compressor does not turn on or starts, but stalls immediately, the problem is most likely with a start-up relay.

In an almost similar situation with a working network, it takes three to five seconds to start the compressor or it does not start the work on the first attempt to turn it on, you should look for a problem in the start relay.

The unit freezes badly, but it regularly responds to the signals of the temperature regulator. At the same time, the compressor heats up, trembles, and protection against overheating is activated. Thermal protection and start relays are fully operational.

The winding should be diagnosed. motor compressor for detection of interturn circuit. If a short-circuit occurs in the starting winding, then the compressor will not start at all. In this case, the thermal protection and start relays will be operational. In both cases, a replacement is required.

Another malfunction. The unit freezes very hard, while the compressor runs without interruption or its operation is interrupted by the operation of thermal protection. The equipment practically does not respond to the thermostat, only turning the knob to the “0” position stops the compressor.

The latter makes a lot more noise than usual. At the same time, the counter shows that the consumption of electricity far exceeds the usual volume. All this indicates a sticky start relay. This condition is quite dangerous for the compressor, since it leads to overheating and burnout.

If the unit freezes badly, refrigerator thermostat it is set correctly. By the time the compressor is turned off, the condenser has warmed up normally, so that the hand has to be pulled back.

Most often, the problem lies in the faulty thermostat. It will need to be replaced. In some cases, it is possible to repair. The temperature regulator is also broken if the unit turns on, but freezes too weakly or too much.

Does not respond to the position of the temperature control knob.In this case, the heating of the condenser and the hum of the compressor are normal.

The unit operates on a short cycle, which is characterized by frequent compressor shutdowns. At the same time, it freezes badly, and the condenser does not have time to warm up properly when the compressor is turned off. The cause of such a malfunction is a breakdown of the thermal protection relay or thermostat.

The equipment operates on a long cycle, sometimes even continuously. In the freezer, frost appears on the portion of the refrigerant supply pipe. Moreover, there is no ice on the opposite side. The situation is stable and does not change.

The cause of the breakdown in this case is a refrigerant leak. Most likely, a microcrack formed somewhere. The circuit should be diagnosed in order to detect it and the system refilled.

In some cases, it is possible topping up freon. All this is highly discouraged to do it yourself. If the refrigerator does not freeze at all, the cause may be a lack of refrigerant in the circuit. In this case, when it is turned on, it will be possible to feel a strong vibration, the compressor will begin to knock and ring when operating.

Self-repair is not amenable to. In some cases, repairs may cost more than a new unit, which must be considered.

The equipment works only on a short cycle and at the same time it freezes very much. The sound of a running compressor is alarming. It is too loud, as if champing or sobbing.

The reason most often lies in the unskilled maintenance of the unit. When filling the refrigerant, it turned out to be too much, which led to the supply to the compressor not of vapors, but of a more concentrated “fog” from freon.

This is extremely dangerous for the integrity of the tubes and compressor. Therefore, it is urgent to call the master. The unit freezes too much. So much so that you have to set the thermostat flag to a position not higher than 4.

At the same time, the compressor heats up quickly and makes a lot of noise, there may be a smell of melting insulation. This is how a weakened bimetal plate located in a heat-protective relay manifests itself.

Strong vibration, excessive compressor noise, but otherwise everything is normal. Check compressor suspension and adjust if necessary. If this does not help, then the reason is its increased wear.

Have to think about replacing the compressor. An overfreezing freezer indicates problems with the tightness of the door or poor insulation. In the latter case, repair is extremely difficult or even impossible.

Diagnostics Basics and Easy Repair

Let's analyze the simplest operations that need to be done to test the refrigerator. It’s worth starting with determining the quality of the mains voltage. It must strictly correspond to 220 V. Smaller values may well cause a failure of the unit.

You should also inspect the power plug with the cord. Bends, creases, damage should not be. If the elements are warming or sparking, this is a clear sign of trouble.

The compressor terminals are checked, which must be in working condition. After that, you need to use a tester to check whether the device receives sufficient voltage from the network.

After making sure that it is of proper quality, the device must be disconnected from the power supply. Now you need to carefully inspect the compressor located at the bottom of the unit. There should be no visible damage.

To check the winding, the tester switches to ohmmeter mode. One end of the wire is attached to the tester, after which the conclusions are checked one by one. Pair diagnostics are also carried out. A short circuit or damage to the winding will be indicated by the lack of movement of the arrow of the tester.

Next, check the control circuit. To do this, disconnect the wires from the relay and close them, and then check for contact between them and the power plug. The presence of such a contact indicates that the relay, cord and temperature sensor are working.

If a problem is detected, each block will have to be checked individually. To test the temperature sensor, it is removed and the wires are disconnected.

Next, each of the wires must be checked, if there is a circuit, a conclusion is made about the malfunction of the detector. It should be replaced. If the control circuit operates normally, there are no breaks, the protection and start relays are checked.

To get access you have to remove the cover. In older models, it is fastened to latches, in new ones - on rivets. They must be carefully drilled, and after inspection, fasten the cover to the screws.

The most frequent breakdowns of this unit are jamming of the spring or core in the coil, burning of contacts or breakage of the rod. All this is quite possible to fix. To begin with, the coil is removed from the latches, a core and a rod with contacts are removed from it.

Next, a thorough cleaning of all these elements is carried out. In the simplest cases, a soft cloth with alcohol impregnation will be sufficient. In more complex to ensure free running with the core will have to work with sandpaper or even a file. All contacts are also cleared.

If it turns out that the rod is broken, and this happens often, since it is a rod made of plastic, it can be replaced with a piece of a regular nail. After repair, the assembly is assembled in the reverse order, put in place and connected.

Conclusions and useful video on the topic

Video # 1. How to replace the temperature controller in the refrigerator:

Video # 2. Features of the “No Frost” system:

Video # 3. Compressor replacement guide roller:

Repairing your refrigerator yourself is not easy. This is a complex unit, the work with which requires special knowledge. An inexperienced master is unlikely to be able to perform all necessary repair work correctly and without errors.

Unfortunately, even small inaccuracies, not to mention major miscalculations, can completely disable the device. Then you don’t have to think about repair. It will be necessary to seek funds for the purchase of a new refrigeration unit.

Please write comments in the block below, ask questions and post photos on the topic of the article. Tell us how you restored the performance of the chiller with your own hands. It is possible that your advice and valuable information will be useful to site visitors.

Why is the refrigerator knocking: finding the causes and methods of eliminating the knock

Why is the refrigerator knocking: finding the causes and methods of eliminating the knock  Indesit Refrigerator Repair: Find and Fix Common Problems

Indesit Refrigerator Repair: Find and Fix Common Problems  Why doesn't the refrigerator work, and does the freezer work? Troubleshooting and troubleshooting

Why doesn't the refrigerator work, and does the freezer work? Troubleshooting and troubleshooting  Start relay for the refrigerator: device, how to check and repair it correctly

Start relay for the refrigerator: device, how to check and repair it correctly  Stinol Refrigerator Repair: Frequent Problems and Solutions

Stinol Refrigerator Repair: Frequent Problems and Solutions  Compressor for the refrigerator: an overview of frequent breakdowns + step-by-step instructions for replacing

Compressor for the refrigerator: an overview of frequent breakdowns + step-by-step instructions for replacing  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

For a long time, the old refrigerator, which was released in Soviet times, stood and worked perfectly in the parents' apartment. I remember how constantly a puddle formed under it, for normal operation it was necessary to periodically defrost it and drain the water. Whether it was a feature of the model, or a malfunction. Then there was no Internet, and it was not difficult to solve the problem by an ordinary drain. The new refrigerator works properly, although sometimes I notice condensation on the back wall. Set a certain temperature control mode, the problem disappeared.

Hello. Indeed, condensation on the back of the refrigerator may form for reasons:

1. Incorrectly set temperature on the thermostat (too low).

2. Deformed seal.

3. When the room is too hot.

4. When storing foods with a high moisture content without containers and lids.

5. The refrigerator is “crying”.

6. Clogged drains.

Ice often formed on the back of the freezer, and periodic condensation inside the refrigerator was also a big problem. We ourselves, of course, could not have coped, so we called the masters. Now I don’t even remember, apparently, the thermostat was broken. The refrigerator was in continuous operation, so we decided to buy a new one, and sold the old one.

Oh, there are women in Russian villages. At some bad moment, the refrigerator in our house just stopped freezing. The light inside was on, and I read that the malfunction could be a thermostat. Disconnected the wires that lead to him and closed them together. I was very surprised when the refrigerator turned on. The next day, I just put in a new thermostat. The husband now believes that I can fix any thing in the house)