Electrolux air conditioner error codes: how to decrypt trouble codes and fix them

The climate control systems of the Swedish brand Electrolux for home or industrial use are of high quality, reliability. But sometimes errors appear on the display of the indoor unit of the air conditioner, and it is unclear what to do in such situations.

Should I immediately contact a service center? Perhaps their own knowledge, skills, tools will be enough to eliminate the breakdown. In any case, you must first decrypt the error codes of the Electrolux air conditioner, deal with the causes of their occurrence, and then make a decision.

In the article, we will consider how the self-diagnosis system of air conditioners of this brand works. We will get acquainted with common mistakes and ways to resolve them. We find out the meaning of rare malfunctions and the procedure in such situations, as well as figure out what to do to prevent the occurrence of messages about breakdowns.

The content of the article:

Self-diagnosis system of air conditioners Electrolux

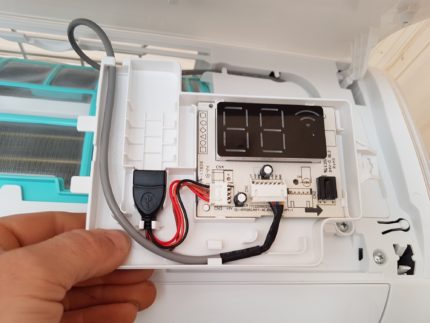

Structurally, air conditioners are quite complex devices. Inside the units there are refrigeration circuits, control boards, various sensors, valves, power inverters and other details.

The incorrect operation of individual elements and components of the equipment is intended to be reported by the self-diagnosis system - the service system, which belongs to the kind of software. It is introduced into the control unit by the “firmware” method.

An alphanumeric message can indicate that the device is not installed correctly, that it needs to be cleaned or refilled.

Failure of the main working units also happens or replacement of worn parts is needed.

But depending on the complexity of the split system, the number of controlled functions, decoding of code marks takes one or more printed pages. Each series of devices of the company can have its own “firmware”.

To activate the self-diagnosis process, you must simultaneously press on the remote control Temp and MODE.

If you need to troubleshoot onlymaintenance and cleaning without dismantling, you can handle it yourself. Complex breakdowns, when removal, disassembly of the device and replacement of parts are required, it is better to entrust the master.

Sometimes you may encounter multiple errors in the operation of Electrolux air conditioners. In such cases, codes of serious breakdowns are determined, and as they are eliminated, messages about other errors may appear.

The user can carry out a number of simple operations himself:

- clean and replace filters;

- unlock the blinds by removing foreign objects;

- restore normal power supply.

The participation of a certified specialist requires refrigerant leakage, compressor failure, an electric motor, an electronic control system.

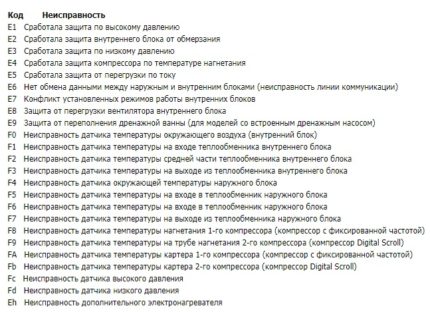

Reasons for protection operation (E1-E9)

Consumer options for all air conditioners are approximately the same, but the functions of protection against adverse environmental conditions, improper operation are different.

In this case, the protective mechanism of the Electrolux air conditioners is triggered and automatically turns off the device. Resume the device after 3 minutes. after shutdown.

Reason # 1 - high or low pressure

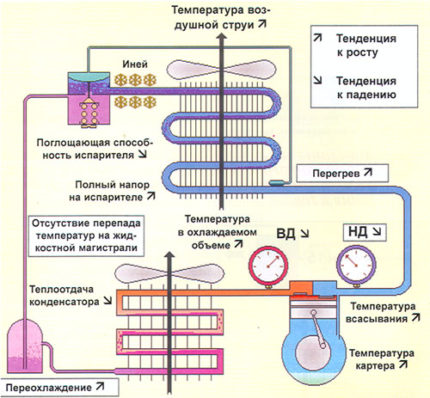

The operation of the device is supported by a certain pressure in the system. The agent is freon. The level is controlled by two sensors - high and low pressure.

Error E1 on the display means that the high pressure sensor has triggered due to refilling with freon above normal.

Message E3 signals a low pressure, i.e. an insufficient amount of freon in the system. In this case, required refrigerant air conditioning.

But the reasons may be different and only a specialist should deal with them.

If the pressure meters themselves are broken and need to be replaced, errors will appear Fc and Fd.

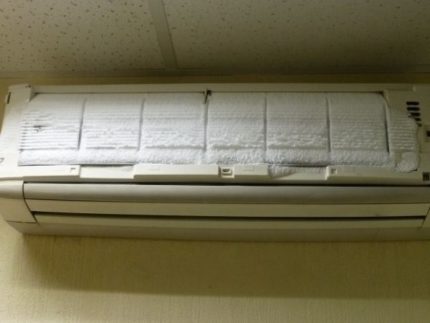

Reason # 2 - freezing the indoor unit

If the air conditioner does not have frost protection on the indoor unit, ice may appear on the valves, surfaces of the copper tubes, heat exchanger. The appliance starts blowing snow, frost.

Error E2 prevents such a development of events and turns off the device in time, but reports a problem. To get the full picture, you need to inspect the external unit.

Most often, ice formation contributes to pollution:

- filters

- fan impellers;

- heat exchanger evaporator surface.

It also helps to check for obstructions in front of the unit or in areas where air enters. This happens when the device is placed in a niche.

The air inlet must be kept clean and open. You can not cover it with decorative elements, plates.

If the problem is the contamination of parts, the presence of obstacles in the air conditioning system, it is all permissible to fix it yourself.

But freezing of the internal block is sometimes associated with:

- problems on the control board;

- breakdown of sensors, thermostatic valve;

- lack of freon;

- clogged capillary tube.

In such cases, the master will help. It is also worth paying attention to the compliance of the type of device with the operating conditions. Some models are not designed to work in cold weather if winter adaptation is not carried out.

Reason # 3 - fuse tripping

The air conditioner compressor is an expensive part, so you need to follow it even if there is a suspicion of a breakdown perform diagnosticsto discover the cause of its occurrence. A significant part of these elements is not repairable and requires replacement.

What the error indicates E4? Most often, the fact that a small amount of freon provoked a situation where an insufficient amount of oil gets into the compressor crankcase. At the same time, it overheats, the discharge temperature rises. A significant leak of freon also leads to air entering the refrigeration circuit.

What actions should the wizard perform? Analyze the condition of the oil. Check the refrigerant circuit for leaks and moisture. Perform additional system diagnostics.

Reason # 4 - overcurrent

The compressor current is an indicator of a number of system malfunctions. A reduced current indicates the compressor is running without load. This means that freon has leaked.

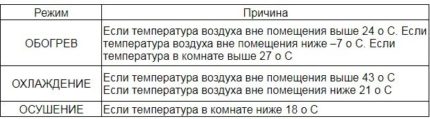

But a mistake E5 indicates an increased current. This happens when liquid refrigerant rather than gaseous refrigerant is supplied to the compressor inlet. Failure is caused by too low outside temperatures or dirty filters in the indoor unit.

To eliminate the error, it is necessary to check the correspondence of the external temperature with the minimum permissible values in the device certificate. And also clean the filters.

Reason # 5 - communication line malfunction

The code E6 signals a failure to connect system components. For example, there is no connection between the outdoor and indoor unit.

It is necessary to check all the connectors, but before that, do not forget:

- turn off the power;

- wait 3 minutes .;

- make sure that the rotation of the fan wheel is stopped.

If the error persists, disconnect the interconnect wire, to check it, connect it with a separate line and measure the voltage on the line. Then compare the obtained values with the reference. It is also advisable to check the fuses and thermal fuses.

Reason # 6 - Conflict of Installed Modes

If several indoor units are operated, one of them is determined by the main, the rest - by subordinates. When activated, MASTER / SLAVE the equipment operates according to the parameters that are installed on the main wired remote control and switching also occurs on it.

Error E7 appears when one mode is set on the main, and the subordinate is turned on in another, for example, heating and cooling or drainage; cooling and heating.

If several wired control devices are simultaneously turned on, the system determines the main unit that will give the minimum value of the number (address).

To eliminate the E7 error, it is enough to correctly coordinate the blocks with each other and set the correct modes.

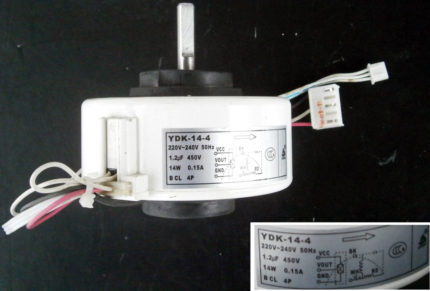

Reason # 7 - Indoor fan overload

The rotation of the fan blades creates an air stream that passes through the evaporator tubes. If there is no cold air, this may be caused by a broken fan. Error E8 reports a short, line break or part malfunction.

For diagnosis, do the following:

- remove the top cover;

- check the impeller, motor;

- inspect the blades for damage;

- make sure that there is no blockage by foreign objects.

To check the freedom and ease of rotation of the blades, rotate them manually. If the shaft with the impeller does not scroll or scrolls with difficulty, the cause of the failure is hidden in the burned stator winding.

It happens that a capacitor or other circuit element needs to be replaced. Only a specialist can carry out a full diagnosis.

Reason # 8 - overflow of the drainage bath

The drain pump serves to condensate drain to the street or to the sewer. This unit is built-in, correlates with the functions of the system and its operating conditions.

Error E9 appears when the drainage bath is full. In this case, the device stops working for cooling, the condensate must be drained manually.

The reason for this need may be the accumulation of aggressive substances, normal pollution. Useful to clean. If the problem persists, call the wizard.

Temperature sensor failures (F)

Sensors are usually semiconductor thermistors. Simple models of Electrolux air conditioners have two such elements, in smart appliances there are more of them.

According to the data obtained, an adjustment is made: the motor-compressor is active, moderately or turns off, giving an error code.

The following temperature sensors are installed in the indoor unit:

- Room air. Sets the compressor operation parameters. Error F0.

- Vaporizer (located at the midpoint of the element). Turns off the compressor if the evaporator temperature drops below zero to prevent icing of the latter. Code is displayed F2.

- At the inlet and outlet of the evaporator. Give out errors F1 and F3.

- Fan motor. Turns off the engine in case of overheating to prevent fire.

- Terminal block fuse. It opens the power supply circuit of the device and burns out when overheated more than 90 degrees.

The general rule for solving problems with temperature sensors is to find everything connected with them on the control board: there is no signal, breakage, short circuit.

In the external unit there are temperature sensors:

- Outdoor air. It limits the operation of the device if the temperature in the street is below the permissible characteristics. The device gives an error F4 and just does not turn on.

- Capacitor. There can be several such sensors in different places. The function of the element is to maintain the pressure in the desired range under changing conditions outside.

- Compressor discharge temperatures. With its help, pressure is indirectly determined. If it exceeds the norm, an error is issued F8 or F9.

- Gas main. Repeats the low pressure sensor.

The design of the air conditioner may have a different number of sensors (on the fan motor, connection block and others), but there is only one procedure for issuing an error.

To understand whether the thermistor is working or not, you need to determine its resistance.Of the tools you will need an ohmmeter or multimeter, as well as a room thermometer.

If it turns out that the sensor is faulty, to temporarily resume the device’s performance, you can install a permanent or tuning resistor in its place. At the same time, the air conditioner will operate at maximum power, so it is worthwhile to expedite the replacement of the part with a working original.

Atypical display values

If when you turn on the mode "Heat" the device starts to work, but after some time the air stops blowing, the sun indicator blinks and the inscription lights up H1, this means the appliance is in defrost mode.

It is necessary to turn off the device from the remote control, hold it simultaneously X-fan and MODE. After half an hour, the air conditioner should work in a normal rhythm.

In case of error H7 Diagnostics of the control and indication module of the device is needed. It can only be performed by a specialist.

Value H6 stands for compressor lockout trigger. This occurs in two cases: when the sensor itself is broken and its replacement is required or when there is insufficient filling with freon.

Also, with such an error, an option is possible with improper power supply to the impeller of the indoor unit, which was not taken into account during assembly. Here you need to disassemble the board to clarify the reason and eliminate it.

Rules for cleaning the air filter

According to the manufacturer's recommendation, it is necessary to clean the air filter after 100 hours of operation of the equipment.

The procedure algorithm is simple:

- Turn off the device. Open the front panel.

- Gently pull the filter lever towards you. We retrieve the item.

- We wash the filter in warm water with a washing solution.

- We dry the part in the shade, set it in place, close the device.

If the front panel is dirty, we fix it in the upper position, pull it towards you, remove, rinse.

Do not use gasoline, thinners, abrasive cleaners.

If the air conditioner is operating in a very dirty room, rinse the filter every two weeks.

Prevention of errors in the operation of the air conditioner

Quality air conditioning installation greatly affects the duration and continuity of its service. The services of professional masters are relatively inexpensive, but pay off several times.

When installing Electrolux air conditioners, specialists must consider a number of factors:

- area of the room;

- direction of sunlight;

- size and location of windows;

- number of people living;

- the presence and placement of other equipment.

It is good if the company provides documentation with engineering design for a specific apartment, house, room.

Conclusions and useful video on the topic

Video on how to clean the air conditioner yourself. Disassembly of the split system is shown in detail, recommendations and explanations are given. Before repeating the steps, it is advisable to turn on the video so that after cleaning it is easy to return all the details to their places:

Another video on disassembling the air conditioner for cleaning from the master of the service company:

Each error code on the displays of the Electrolux air conditioners makes it easy to determine the cause of the malfunction. The diagnostic system also provides automation of air conditioning control and control of the working condition of the device.The mechanism for displaying information about a malfunction on the display allows you to stop the operation of the device in a timely manner and eliminate the problem. This is a convenient feature for users and service center employees.

It is useful for owners of air conditioners to at least get the most out of trouble codes to avoid overpayments during repairs or fix the problem on their own.

Do you have an Electrolux brand air conditioner installed and want to share your own experience in finding a breakdown and the nuances of fixing it? Tell our readers about this - the feedback block is located below.

Gree air conditioner error codes: how to decipher the fault symbol and repair the unit

Gree air conditioner error codes: how to decipher the fault symbol and repair the unit  Error codes for the Daikin air conditioner: detection of malfunctions and methods for dealing with them

Error codes for the Daikin air conditioner: detection of malfunctions and methods for dealing with them  Errors of air conditioners Zanussi: codes of malfunctions and instruction on their elimination

Errors of air conditioners Zanussi: codes of malfunctions and instruction on their elimination  Errors of Samsung air conditioners: how to detect a malfunction in the code and troubleshoot

Errors of Samsung air conditioners: how to detect a malfunction in the code and troubleshoot  Errors of Artel air conditioners: decryption of fault codes and tips for resolving them

Errors of Artel air conditioners: decryption of fault codes and tips for resolving them  How to install and connect an air conditioner: detailed instruction + analysis of errors

How to install and connect an air conditioner: detailed instruction + analysis of errors  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements