Chiller-fan coil system: operating principle and arrangement of the thermoregulation system

The multi-zone climate system of the chiller-fan coil is designed to create comfortable conditions inside a large area building. It works constantly - in the summer it supplies with cold, and in winter with heat, warming the air to a predetermined temperature. Is it worth getting acquainted with her device?

In our proposed article, the construction and components of the climate system are described in detail. Methods for connecting equipment are given and analyzed in detail. We will describe how this system of thermoregulation is arranged and functions.

The content of the article:

Components of the chiller-fan coil circuit

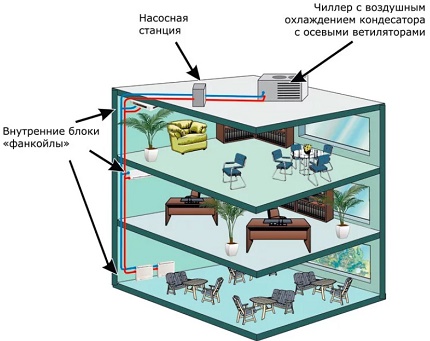

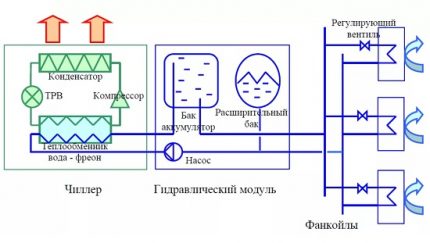

The role of the cooling device is assigned to the chiller - an external unit that produces and delivers cold through pipelines with water or ethylene glycol circulating through them. This is what distinguishes it from other split systems, where freon is pumped as a coolant.

For the movement and transfer of freon, refrigerant, expensive copper pipes are needed. Here, water pipes with thermal insulation are perfectly able to cope with this task. Its work is not affected by the outside temperature, while split systems with freon lose their functionality even at -10⁰. The internal heat exchange unit is a fan coil.

It receives a liquid with a low temperature, then transfers the cold to the air in the room, and the heated liquid returns to the chiller. Fancoils are installed in all rooms. Each of them works according to an individual program.

Typically, such systems are used in hypermarkets ‚shopping malls‚ structures ‚erected underground‚ hotels. Sometimes they are used as heating.Then, heated water is supplied to the fan coil along the second circuit or the system is switched to a heating boiler.

System design

According to the design of the chiller-fan coil system, there are 2-pipe and 4-pipe. By the type of installation, wall-mounted, floor-mounted, and built-in devices are distinguished.

Evaluate the system by such key parameters:

- power or cooling capacity of the chiller;

- fan coil performance;

- air mass movement efficiency;

- length of highways.

The last parameter depends on the strength of the pumping unit and the quality of the pipe insulation.

Connection of chiller and fan coil

The smooth functioning of the system occurs by connecting chiller with one or more fan coil units via heat-insulated pipelines. In the absence of the latter, the value of the system efficiency drops significantly.

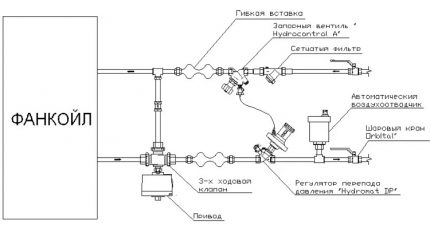

Each file coil has an individual strapping unit, through which it is possible to adjust its performance both in the case of heat production ‚and cold. The flow rate of the refrigerant in a separate unit is regulated by means of special valves - shutoff and regulating.

If it is impossible to allow mixing of the heat carrier with the refrigerant. water is heated in a separate heat exchanger and complement the circuit with a circulation pump. To ensure smooth adjustment of the flow of the working fluid through the heat exchanger, a 3-way valve is used when mounting the piping scheme.

If a two-pipe system is installed in the building, then both cooling and heating are due to the cooler - chiller. To increase heating efficiency with fan coils in the cold season, in addition to the chiller, a boiler is included in the system.

Unlike a two-pipe system with one heat exchanger, two of these nodes are embedded in the four-pipe system. In this case, the fan coil can work both for heating ‚and for cold‚ using in the first case the liquid circulating in the heating system.

One of the heat exchangers is connected to a pipeline with a refrigerant, and the second to a pipe with a coolant.Each heat exchanger has an individual valve controlled by a special remote control. If such a scheme is applied, the refrigerant is never mixed with the coolant.

Since the temperature of the coolant in the system during the heating season ranges from 70 to 95⁰ and for most fan coil units it exceeds the permissible ‚it is previously reduced. therefore hot water‚Coming from the central heating network to fan coils‚ passes a special heat point.

The main classes of chillers

The conditional division of chillers into classes occurs depending on the type of refrigeration cycle. On this basis, all chillers can be conditionally assigned to two classes - absorption and vapor compressor.

The device of the absorption unit

An absorption chiller or ABCM uses a binary solution with water and lithium bromide present in it — an absorber. The principle of operation is the absorption of heat by the refrigerant in the phase of the conversion of steam into a liquid state.

Such units use heat generated during the operation of industrial equipment. At the same time, an absorbent absorber with a boiling point significantly higher than the corresponding refrigerant parameter dissolves the latter well.

The operation scheme of the chiller of this class is as follows:

- Heat from an external source is led to a generator, where it heats a mixture of lithium bromide and water. When the working mixture boils, the refrigerant (water) completely evaporates.

- Steam is transferred to the condenser and becomes liquid.

- Liquid refrigerant enters the throttle. Here it cools, and the pressure drops.

- The liquid enters the evaporator, where water evaporates and its vapors are absorbed by a lithium bromide solution - an absorber. The air in the room is cooled.

- The diluted absorbent is again heated in the generator, and the cycle starts again.

Such an air conditioning system has not yet become widespread, but it is completely in tune with current trends ‚regarding energy conservation, and therefore has good prospects.

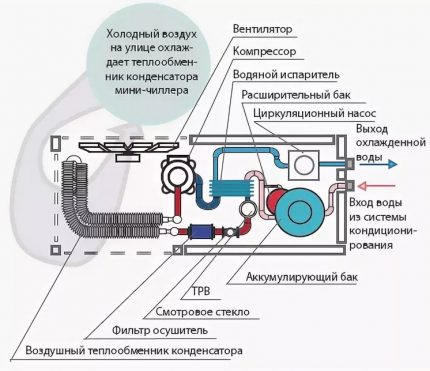

Design of steam compression units

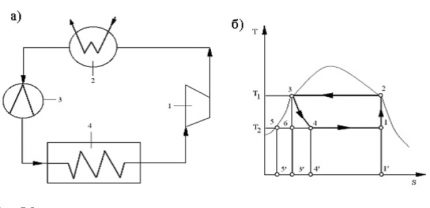

Most refrigeration units operate on the basis of compression cooling. Cooling occurs due to the continuous circulation, boiling at low temperature, pressure and condensation of the coolant in a closed system.

The design of this class of chiller includes:

- compressor;

- evaporator;

- capacitor;

- pipelines;

- flow regulator.

The refrigerant circulates in a closed system. This process is controlled by a compressor in which a gaseous substance with a low temperature (-5⁰) and a pressure of 7 atm is compressible when the temperature is brought to 80 до.

Dry saturated steam in a compressed state goes to a condenser, where it is cooled to 45 ° at a constant pressure and converted into a liquid.

The next point on the road is a throttle (pressure reducing valve). At this stage, the pressure decreases from the value of the corresponding condensation to the limit at which evaporation occurs. At the same time, the temperature drops to about 0⁰. The liquid partially evaporates and moist steam forms.

Having entered the heat exchanger-evaporator, the working substance, the mixture of steam and liquid, gives off the heat to the coolant and takes the heat from the refrigerant, drying at the same time. The process occurs at constant pressure and temperature. Pumps supply low temperature fluid to fan coil units.Having passed this path, the refrigerant returns to the compressor ‚to repeat the entire vapor compression cycle again.

Steam Compression Chiller Specifics

In cold weather, the chiller can operate in natural cooling mode - this is called freecooling. In this case, the coolant cools the street air. Theoretically, free cooling can be used at an external temperature of less than 7 ° C. In practice, the optimum temperature for this is 0⁰.

When setting in the “heat pump” mode, the chiller works for heating. The cycle undergoes changes, in particular, the condenser and the evaporator exchange their functions. In this case, the coolant must not be subjected to cooling, but to heat.

This mode is most often used in large offices ‚public buildings‚ in warehouses. The chiller is a refrigeration unit, which gives cold 3 times more than it consumes. Its efficiency as a heater is even higher - it consumes 4 times less electricity than it gives heat.

What is the difference between a refrigerant and a coolant?

The refrigerant is a working substance, which during the refrigeration cycle can stay in different states of aggregation at different pressure values. The coolant does not change phase states. Its function is the transfer of cold or heat to a specific distance.

The compressor controls the transport of refrigerant and the pump controls the coolant. The temperature of the refrigerant can drop both below the boiling point and rise beyond it. The heat transfer medium, unlike the refrigerant, constantly works in conditions of temperatures not rising above the boiling point at the current pressure.

The role of fan coil in the air conditioning system

Fancoil is an important element of a centralized climate system. The second name is the fan coil. If the term fan-coil is translated literally from English, then it sounds ‚like a fan-heat exchanger‚ which most accurately conveys the principle of its action.

The purpose of the device is to receive media with a low temperature. The list of its functions also includes both recirculation and air cooling in the room where it is installed ‚without air intake from the outside. The main elements of the fan-coil are located in its housing.

These include:

- centrifugal or diametrical fan;

- a heat exchanger in the form of a coil, consisting of a copper tube and aluminum fins, mounted on it;

- dust filter;

- Control block.

In addition to the main components and assemblies, the fan coil design includes a condensate trap, a pump for pumping out the latter, an electric motor, through which the air dampers are rotated.

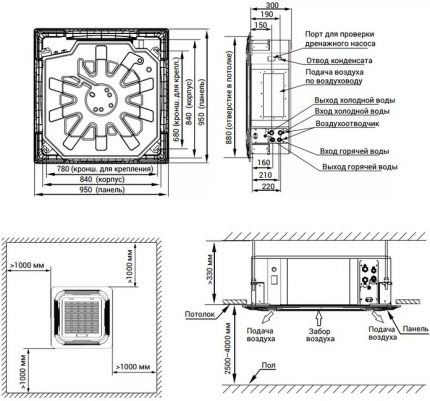

Depending on the installation method, there are ceiling fan coil units, channel, mounted in channels, through which air is supplied, unpacked, where all elements are mounted on a frame, wall or cantilever.

Ceiling units are the most popular and have 2 versions: cassette and channel. The first are mounted in voluminous rooms with suspended ceilings. Behind the suspended structure, a housing is arranged. The bottom panel remains visible.They can disperse air currents on two or all four sides.

The need for cooling does not always exist, therefore, as seen in the diagram that transmits the principle of operation of the chiller-oil coil system, a capacity is built into the hydraulic module, which acts as a battery for the refrigerant. The thermal expansion of the water is compensated by an expansion tank connected to the supply pipe.

Manage fan coils in both manual and automatic modes. If the fan coil operates for heating, then in the manual mode, the cold water supply is cut off. When it is used for cooling, they block off hot water and open the way for the supply of cooling working fluid.

To work in automatic mode, the panel sets the temperature necessary for a particular room. Support for a given parameter is carried out through thermostats, which adjust the circulation of coolants - cold and hot.

Since any large building has zones with different temperature requirements, each of them must be serviced by a separate fan coil or their group with identical settings.

The number of units is determined at the design stage of the system by calculation. The cost of individual units of the chiller-fan coil system is quite high ‚therefore, both calculation‚ and system design must be performed as accurately as possible.

Conclusions and useful video on the topic

Video # 1. Everything about the device ‚work and the principle of operation of the thermoregulation system:

Video # 2. About how to install and commission a chiller:

Installation of the chiller-fan coil system is advisable in medium and large buildings with an area exceeding 300 m². For a private house, even a huge one, installing such a thermoregulation system is expensive. On the other hand, such financial investments will provide comfort and well-being, and this is a lot.

Please write comments in the block below. Ask questions about interesting moments, share your own opinions and impressions. Perhaps you have experience in building a chiller-fan coil climate system or a photo on the topic of an article?

What is fan coil: principle of operation and installation rules for a fan coil

What is fan coil: principle of operation and installation rules for a fan coil  What is a split system: device and principle of operation of typical air conditioning systems

What is a split system: device and principle of operation of typical air conditioning systems  What is a chiller: device features, selection and installation rules

What is a chiller: device features, selection and installation rules  What is a multi split system: principle of operation + installation and connection rules

What is a multi split system: principle of operation + installation and connection rules  How to turn on the air conditioner for heating: the specifics of setting the system to heat

How to turn on the air conditioner for heating: the specifics of setting the system to heat  How a fanless fan is arranged: the device and the principle of operation of the device

How a fanless fan is arranged: the device and the principle of operation of the device  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements