Corrugation for hoods: how to choose and install a corrugated pipe for ventilation

Many types of repair work can be done on their own. And connecting the hood to the ventilation system is one such case. Agree that even an inexperienced home master can cope with this crucial stage.

Especially when an aluminum corrugation is used as an air duct for drawing. This type of building material during installation does not require many years of experience and special knowledge.

But you do not know where to start and how to choose the corrugated pipe? We will help you determine the type of material and cope with this type of installation work - the article discusses the variety of corrugations, its features and scope.

The subtleties of choosing a corrugated duct for connecting the hood are highlighted and step-by-step installation instructions are given. The material is supplemented by visual photos of the individual stages of installation of the corrugation and video recommendations from specialists.

The content of the article:

Classification and use of corrugation

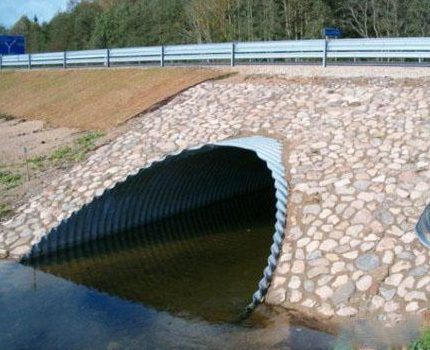

Corrugated pipe is presented on the building materials market in a wide variety of options - these are color models of small diameter made of plastic and a serious culvert corrugation made of stainless steel. Material, size, color, price - all this for any buyer.

It is difficult for a novice home master to choose exactly what is ideal for solving the arisen problems.

Varieties of corrugated pipes

One of the convenient and simple solutions for the kitchen is the use of corrugated pipes for connecting the hood to the ventilation system.

To buy exactly what is required, not to get lost among a large number of offers and not to overpay for the duct, you need to understand a little about the main types and purpose of the corrugation.

Corrugation is actively used by builders and home craftsmen as an important element in arranging communications.

Its popularity is due to its high strength, a variety of sizes and materials, and a long service life.

In appearance, the corrugation is rectangular and round. For a kitchen hood, buy a round duct.

Often you can find corrugated pipes made of such materials:

- galvanized steel;

- stainless steel;

- aluminum;

- textile;

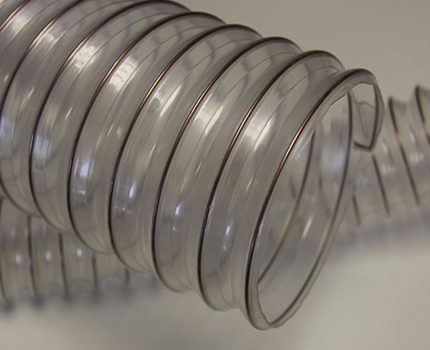

- high and low pressure polyethylene;

- polyvinyl chloride.

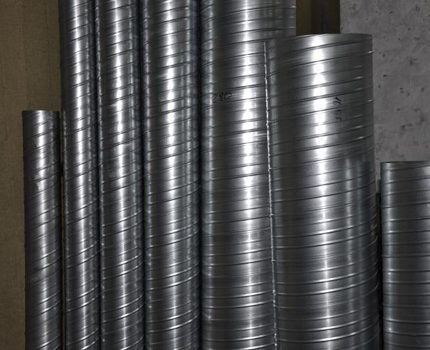

The scope depends on the type of material and the diameter of the finished product. To equip household ventilation, they often buy corrugation made of aluminum and stainless steel.

According to the method of manufacturing corrugated pipes are:

- wireframe;

- spiral-wound.

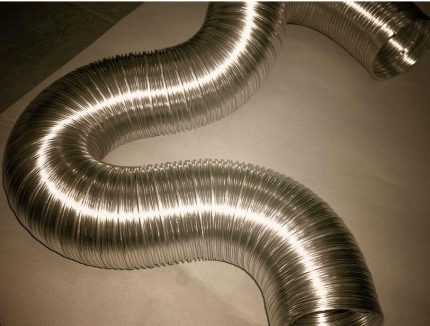

The first type of product is a metal frame covered with aluminum foil or polymer film.

These are flexible ducts. They have the ability to return to their original form without deformation after stretching the corrugation in full length.

The second type of duct is made of metal bands. The finished product is half flexible - it can stretch 2-3 times, but cannot return to its original state.

You will have to make an effort to give such a pipe the desired shape, and traces of deformation will be clearly visible.

Many manufacturers offer flexible corrugation with and without thermal insulation. The first option allows you to expand the scope of use of products.

So, using four-layer flexible pipes, it is possible to lay ventilation ducts both inside and outside the premises. And the distance will not matter.

Scope and nuances of application

A wide variety of corrugated pipes, significantly differing in their size and type of material, eloquently testifies to the various areas of use of this building material.

Half-flexible pipes of small diameter, made of plastic and polymers, are actively used when laying electric cables.

It can be a channel for telephone, computer, power and other wires. Most often, electricians use corrugation with a diameter of 1.6 to 4 cm.

A half-flexible corrugation made of galvanized or stainless steel has become one of the most relevant options for arranging a heating system. In practice, this type of pipe is easier to install.

The ability, if necessary, to bend any segment without violating the internal diameter of the product helps to easily bend around corners and other difficult sections during installation.

For ventilation systems, flexible types of corrugated pipes are used. The diameter, most often used for household ventilation, is from 10 to 15 cm. There are times when a pipe with a diameter of 20, 30 or more cm is required. Although this is not a running size, it will not be difficult to find the required option.

As for the material of the products, the corrugation, bought by craftsmen for arranging ventilation in the kitchen, is flexible and made of aluminum foil. Options with plastic material and stainless steel are less commonly used in everyday life.

Textile ventilation ducts are used for arranging communications in industrial premises. They do not interfere with the very fast transfer of indoor air.

It is this feature that contributes to their use in meat processing enterprises, in public catering and in other types of premises.

Plastic and polyethylene corrugation is used to connect plumbing, supply water to washing machines, dishwashers and other equipment.

When arranging the sewage system, a corrugated pipe is also indispensable. Especially in complex areas where the use of a rigid structure can be difficult.

Guidelines for choosing the right pipe

A large selection of plastic ducts offered by sellers can be difficult choosing the right pipe option when arranging ventilation.

Therefore, in order to buy the right product, you should be guided by the following parameters:

- diameter and length;

- product material;

- quality;

- price.

The diameter must comply with the recommendations given in the instructions for the purchased hood model.

If you dwell on a larger or smaller option, then expensive equipment may in the best case not cope with its functions to remove odors from the kitchen, and in the worst - burn out from overvoltage.

No need to ignore the recommendations provided by the manufacturer. Sometimes an air duct is supplied with the hood. It's great if it fits in a particular case - the length will be sufficient and the material will suit.

Otherwise, you will have to independently visit the building materials market and purchase a more suitable option.

Another situation where, along with the hood, they immediately offer to buy corrugation. Here you need to be extremely careful, because the seller does not always care about the comfort of the client.

He may offer stale or too expensive goods. In this case, the length must be measured in advance so as not to buy extra meters, trusting the seller’s experience.

The length of the corrugation required to connect the hood to the ventilation duct is measured with a tape measure. Measurement must be done from the entrance to the exhaust pipe to the entrance to the wall. The path should be chosen exactly the one to be repeated by the pipe.

Please note that the corrugation can bend, depending on the technical parameters specified by the manufacturer. For example, 180 degrees.

The ability to bend at the right angle allows you to pave the most optimal path. The pipe will be mounted in a stretched condition. This point should be taken into account.

The second parameter that affects the choice is the material of the product. Sometimes the color suits the plastic version. In this case, you need to remember about the greater noise created by the duct. If this issue is not fundamental, then the range of models can be expanded.

So that the purchase does not disappoint, do not forget about the documents confirming the quality of the purchased goods. Do not be shy to ask the seller for a certificate of quality and manufacturer's warranty.

In addition to the document, you should carefully examine the corrugation - there should be no dents or suspicious scratches.

No need to be afraid to stretch the flexible pipe to its full length and check for gaps or holes - they should not be. If the corrugation is of dubious quality, then it is better to refuse from its purchase.

Price also matters. It is good to study similar offers from other manufacturers before buying, so as not to overpay. Also, it will significantly help to save knowledge of the desired duct length.

When choosing, you should consider where exactly the corrugation will be used. If you plan to install it on the street or in the ventilation systems, where there will be heating / cooling, then you should pay attention to the models with thermal insulation.

It is more convenient to buy a finished product than to insulate a flexible pipe on your own.

In domestic conditions, the corrugation is most often used in the installation of ventilation ducts that exhaust exhaust air from the kitchen, and in the connection of exhaust devices.

With steps kitchen exhaust hoods using a corrugated pipe introduces the following selection:

You may also be interested in material on varieties. plastic pipes for cooker hoods.

Subtleties of installation and installation

Process connecting the corrugation to the hood and ventilation system will be able to home master.

To complete this work, you have to take:

- flexible pipe;

- clamps;

- aluminum tape;

- check valve grille;

- silicone sealant;

- adapters from round to square.

The last item is useful in the case when the hood has a square or rectangular pipe, and the corrugation is acquired round.

It is good to buy all the necessary parts with a corrugated pipe.

This will allow you to make the right number of spare parts.

If you need to connect 2 or more flexible pipes, you can use aluminum tape.

It well connects the material of metal ducts, provided that it is carefully glued to the surface.

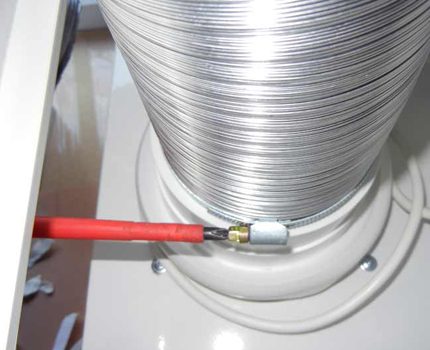

The corrugated pipe has to be stretched to its full length. In this state, one end must be attached to the exhaust outlet pipe.

For fastening it is necessary to use a metal branch pipe and sealant.

Then, every 1.0 meter vertically or 1.5 meters horizontally, laying the corrugation needs to put additional clamps. These devices will ensure that the duct is properly secured.

If the ventilation hole is only 0.5-0.8 meters, then no additional clamps will be required.

If before entering the ventilation more than 3 meters, then you need to choose a more powerful model of the hood or stretch the corrugated pipe in a straight line under the ceiling to shorten the path. Indeed, the longer the channel, the more powerful the equipment should be.

Having put additional clamps, it remains to connect the corrugation with the ventilation hole, inserting its second end into the corresponding hole in the wall grill.

The joints of the grill with the pipe should also be properly treated using sealant. Now you have to check the quality of the installation. To do this, turn on the hood and attach a sheet of paper - if it is attracted, then everything is mounted perfectly. So you can proceed to the decor.

As a decor, a decorative casing of the hood itself can be used.

Sometimes this is clearly not enough. Then the owners connect the imagination, choosing the most optimal option, for example, hide the pipe in the hanging cabinets. Which is especially true for built-in type hoods.

Depending on the style of the kitchen, the corrugated pipe can be hidden under a false ceiling. If the furniture in the room is in high-tech style, then the metal corrugation will organically fit into the overall picture.

It happens that the duct fits perfectly into the interior of the kitchen, being a logical continuation and not breaking out of the general composition.

Good reasons to replace a pipe

Corrugation is an inexpensive and very worthy solution to the problem of arranging ventilation at home. If it is installed correctly, then there will be no problems with use. The main thing is to adhere to the recommendations specified by the manufacturer of the product.

There is no particular need to take care of the corrugated duct. One thing is unpleasant - getting dust from the walls is very inconvenient. Over time, after 8-10 years, a rather thick coating of particles of fat, burning, dust forms inside the pipe. It will not be possible to clean it. The only way out is to put in a new corrugation.

If we compare the service life of 10 years with the cost of a new ventilation duct, the replacement does not look like a problem at all.

When dismantling, it is necessary to perform all actions that during installation, only in the reverse order.

After removing the pipe, you need to thoroughly clean the joints, clean the ventilation grill or even replace it. Then carry out all the installation of the new corrugation.

Conclusions and useful video on the topic

Video clip on how to connect an air duct in the kitchen - features of using a corrugated pipe:

The metallized corrugation used as an air duct in a cooker hood can be hidden behind a decorative casing.

This video instruction will help to correctly connect it to the hood:

Visual video about additional details used when connecting a corrugated pipe to a hood:

Video review of flexible corrugated aluminum pipe:

An interesting video clip about how air ducts are made of aluminum foil:

Having figured out the features of choosing and installing corrugations, you can save money by doing everything yourself. These works do not require special skills and professional tools, which allows you to do without calling specialists.

A high-quality corrugated pipe, correctly connected to the hood, can provide ventilation to the kitchen for at least the next 10 years.

If you yourself installed a corrugated duct in your kitchen, mounted a decorative box for masking it or have the knowledge to choose the best duct for a kitchen hood, please share your experience in the comments under the article.

How to connect a kitchen hood to ventilation: a work guide

How to connect a kitchen hood to ventilation: a work guide  How and how to insulate the ventilation pipe: rules and regulations for insulation of ducts

How and how to insulate the ventilation pipe: rules and regulations for insulation of ducts  How to choose and install a fan in the bathroom + how to connect a fan to a switch

How to choose and install a fan in the bathroom + how to connect a fan to a switch  How ventilation is built in the kitchen: rules and diagrams of the hood

How ventilation is built in the kitchen: rules and diagrams of the hood  How to install a hood above a gas stove: step-by-step installation instructions

How to install a hood above a gas stove: step-by-step installation instructions  Installing the built-in hood: location options and installation instructions

Installing the built-in hood: location options and installation instructions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Corrugation, of course, saves. You just need to immediately warn against the mistakes that many make. Do not connect your hood above the stove to the ventilation in the kitchen with the corrugation. The point is not only that ventilation should remain unoccupied, but also that they are improperly designed in our houses and they work from a natural influx. By the way, as an option, the corrugation can be replaced with plastic boxes with corners and adapters. It looks more aesthetically pleasing, and it is easier to hide such structures in niches.

In vain, Igor writes that you can’t borrow a vent. a hole in the kitchen hood.A connected hood, even with the fan turned off, perfectly ventilates the room. And even vice versa - a draft is created in the hood, which is only for the benefit. By the way, gas columns are connected with the same sleeve. The aluminum sleeve perfectly withstands high temperatures from a 20-kilowatt heating pad.

Why are you ‘pouring water’ about some kind of appearance and beauty. But what about fire safety standards, material properties. SNIPs for whom exist?

Of course, water! How can you sacrifice the performance of a ventilation system with a hood and safety standards in favor of aesthetics? This is stupid and irresponsible!

But for cases when it is necessary to make a hidden installation of the corrugation, there are ready-made practical solutions. For example, built-in hoods, bezel for corrugation, etc. I generally am silent about geysers, since in this case there is definitely a corrugation and no plastic joints even, not like plastic ventilation ducts. Plastic air ducts are suitable for a kitchen hood, but I would recommend choosing aluminum solutions.

To extract, especially hot gases, you always need to use only metal pipes and metal corrugations, this is so that the pursuit of economy and aesthetics does not turn into a fire. There are some nuances in the use of house ventilation for supplying a corrugated pipe from the hood, first you need to check whether the house ventilation works well and how it changes with wind changes (because it happens that when you change the direction of the wind, it blows from the ventilation hole breeze). This is so as not to frustrate users.

Ventilation of the boiler to the street also needs to be wisely, because in multi-storey buildings, it happens that carbon monoxide from the boiler exhaust is blown into the windows by the neighbors a floor above. SNiPs and GOSTs - this is not something that can be “circumvented" in case of inconvenience, because these rules are the result of thinking through safety or a bitter experience.