Centrifugal fan: device specifics and device operating principle

With the development of the industrial sector, a large number of technological processes required forced air supply. The household sphere did not stand aside. Some types of communications require a regular supply of fresh air.

An elegant solution to this problem was a centrifugal fan, which is able to autonomously pump the required amount of air mass. But how does it work and how does it work? We will analyze these issues in detail in our article.

Consider the design features of the device, its capabilities, scope, the best manufacturers, whose products are presented on the market. We also give recommendations on choosing the right fan model.

The content of the article:

The essence of fan blowing and vacuum

The fan is a mechanical structure that is capable of processing the flow of the gas-air mixture by increasing its specific energy for subsequent movement.

Such an architecture of the unit provides the ability to create the effect of injection or rarefaction of the working gas in space through an increase or decrease in pressure, respectively (energy conversion mechanism).

By gas pressure we understand the endless process of random movement of gas molecules, which, when they hit the walls of a confined space, create pressure on them.

Therefore, the higher the speed of these molecules, the more shocks and the higher the pressure. Gas pressure is one of the main characteristics of gas.

On the other hand, any gas has two more parameters: volume and temperature. Volume - the amount of space that the gas has filled. Gas temperature is a thermodynamic characteristic that relates the speed of molecules and the pressure they generate.

On these “three pillars” is the molecular-kinetic theory, which is the basis for the description of all processes associated with the processing of gases and gas mixtures.

The injection process is a forced concentration of molecules in a confined space in excess of a certain norm. For example, the generally accepted air pressure at the surface of the earth is approximately 100 kPa (105 kilo Pascals) or 760 mmHg. Art. (millimeters of mercury).

With increasing height above the surface of the Earth, pressure becomes less, air becomes rarefied.

The rarefaction is the reverse process of injection, during which the molecules leave the closed system. The volume remains the same, but the number of molecules decreases several times, therefore, the pressure decreases.

The effect of discharge is necessary for the forced movement of air. A variant of air movement through the rarefaction effect is possible: to restore the pressure balance in the entire system, molecules move from a more concentrated region of molecules to a less concentrated one.

In this way, gas molecules move.

There are various layouts of ventilation systems, but they can be conditionally divided into several classes according to certain parameters:

- By appointment. There are general and special purpose fans. Fans are used for normal gas movement. Special fans are used for pneumatic transport, transportation of aggressive and explosive gas mixtures.

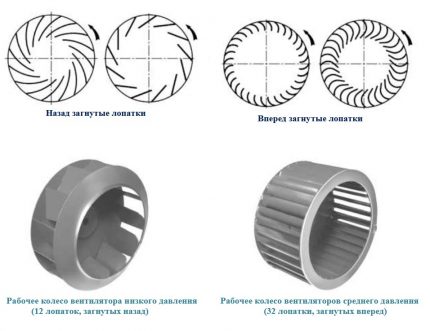

- By speed. There are small, medium and high specific speed of the wheel with blades.

- By pressure range. Known systems for generating low (up to 1 kPa), medium (1-3 kPa), high (over 3 kPa) pressure.

Some industrial and domestic processes using blowers occur in extreme environmental conditions, so the relevant requirements are put forward for the equipment.

Thus, we can talk about dust, moisture-proof, heat-resistant, corrosion-resistant, spark-proof units and devices for removing smoke and conventional fans.

Information about the types of fans is discussed in detail in another our article.

Centrifugal Fan Design

The centrifugal design system is a pressure mechanism with a radial architecture, which is able to generate pressure of any range.

It is intended for transportation of mono- and polyatomic gases, including chemically “aggressive” compounds.

The design is “clad” with a metal / plastic case, which is called a protective casing. The shell protects the inner chamber from dust, moisture and other substances that can adversely affect the operation of the unit.

A high-quality ventilation product always has a certain protection class. The degree of protection of the shell (Ingress Protection) is a single international standard for product quality, which determines the level of protection of the equipment from environmental influences.

The mechanism is driven by an electric motor or internal combustion engine (typical for industrial fans). The most common method is an electric motor that rotates a shaft with an impeller.

There are several options for transmitting rotational motion from a motor to an impeller:

- elastic coupling;

- V-belt drive

- stepless transmission (hydraulic or inductive slip clutch).

Given the existence of a huge number of manufacturing companies that create unique systems with a wide variety of dynamic parameters, a rather extensive range of fans is at the disposal of consumers.

As a result of the hard work of the developers, we have a wide range of applications for such machines, including:

- ventilation and heating systems in private and high-rise buildings;

- air supply and purification for non-residential buildings;

- filtration systems in agriculture;

- performance of technological processes in light and heavy industry of various directions.

There are also options for the use of blowers in fire extinguishing systems and ultrafast air change in confined spaces.

Such fans work with high-temperature gas mixtures, which obliges manufacturers to include information on the compliance of their equipment with international standards in the technical documentation.

The proven and simple design of the centrifugal mechanism has several distinct advantages:

- high reliability and unmatched performance;

- ease and accessibility of equipment maintenance;

- safety of integration and operation of units;

- minimum energy and repair costs in case of failure.

In addition, blowers have a fairly low noise threshold, which allows them to be used in domestic conditions. Centrifugal fans also have an exceptionally long service life due to the lack of direct contact of the working parts of the mechanism in the working chamber.

Features of the operating cycle of the device

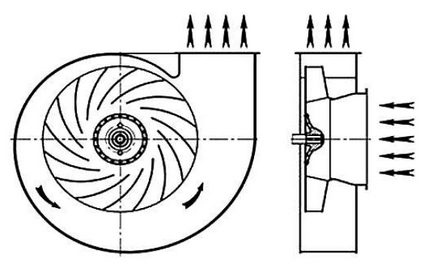

Consider the general principle of operation of a centrifugal blower of a radial design. Note that specialists distinguish between two main fan designs: with axial and radial placement of the inlet, where the air flow is sucked.

This primarily affects the option of mounting the fan in the system and practically does not affect the overall performance.

An axial inlet is characteristic of general purpose blowers. The radial arrangement of the flow inlet is characteristic of mainstream blowers.

At the first stage of the fan’s duty cycle, the air flow moves to the surface of the rapidly rotating impeller. Impeller blades divide the air into small volumes that move inside the working chamber.

Here, the air mass accumulates, that is, the air mass is directly compressed into a small volume.

The design of the unit body itself has its own characteristics.

The two most common body forms are known:

- rounded

- spiral-shaped.

The round shape of the case is typical for fans that move a huge amount of air in a short time. A spiral shape is inherent in fans, which additionally compress the air volume and generate medium and high pressure.

At the second stage, air is forced into the working chamber. As you know, with a constant volume with an increase in the total mass of gas molecules, the number of collisions of molecules increases, and hence their speed increases. Consequently, the gas pressure also increases.

At the final stage, the compressed gas is removed from the working chamber to the outlet. Further, the air passes into the central duct and moves in the indicated direction.

The rarefaction process is exactly the opposite. Air is taken in from an air pipeline or confined space where it is necessary to create a rarefied area and is discharged into the environment or other limited space.

Centrifugal Fan Specification

Compressor systems are characterized by a number of structural and dynamic differences that must be taken into account when selecting and implementing them in the ventilation system.

The specification includes:

- directly to the design of the blower;

- engine's type;

- Control block;

- placement of the impeller and transmission of rotational motion from the motor;

- the angle of the location of the inlet and outlet pipe;

- the material from which the product details are made, its dimensions and weight.

Specialists also pay attention to the compliance of products with international standards: ISO / IEC and GOST standards, IP marking, ATEX directives, etc.

Injection pressure - the maximum value that the fan is able to create during operation in nominal mode.

Pv = Psv + Pdv,

Where: Pv - total pressurePsv - static pressure Pdv - dynamic pressure.

Differential coefficient - difference between inlet and generated pressure (bar).

Volumetric air flow - the amount of gas mixture that moves per unit of time (productivity). Usually calculated in m3/ h for domestic producers, liter / min - for foreign ones.

Rotational speed - the number of full rotations of the impeller per unit time. Calculated in pcs / s or Hz. It must be remembered that the load level of the air fan should not exceed 75% of the maximum.

Working for a long time in overload mode with a high speed, the fan overheats and can quickly fail. But this process can be controlled by controlling it at your discretion. Why use speed controller a fan.

Sound pressure is the noise level from rotating parts and metal air friction. Measured at a distance of 3 meters from the source when it is operating at maximum load. Noise must be considered when choosing a constantly running fan.

One of the devices with a low noise level is bladeless fan.

The fan efficiency is a product of the following three factors:

- loss in air flow;

- leakage through gaps in the structure;

- mechanical efficiency of the product.

For centrifugal fans, the overall efficiency is in the range from 0.7 to 0.85, in axial (ducted) - not more than 0.95. When choosing a radial fan, it is necessary to take into account the safety factor of the electric motor 1.2. That is, pick up the power of the electric motor 20% more than necessary.

The power of the fan motor is determined by the formula:

N = (Q * P) / (102 * 3600 * Efficiency),

Where: Q - performance (volumetric air flow), P - generated pressure.

Fan selection according to requirements

The process of selecting ventilation equipment for an industrial facility (work shop, hangar) is quite an interesting and intricate process that a specialist should do. Features of ventilation of industrial premises in detail reviewed here.

For ordinary apartments and private houses, ready-made solutions already exist. In the general case (for a 2-3 room apartment) we have the following ventilation system architecture:

- ventilators are mounted in living rooms, the number of which depends on the size of the premises and the number of residents;

- exhaust diffusers are integrated in the kitchen and bathroom plus are laid air ducts to the supply and exhaust installation.

The centrifugal fan includes a control unit, a filter system for air purification, an electric motor and the radial fan itself.

The current market for ventilation equipment is represented by a wide range of foreign companies: Systemair, Soler & Palau, OSTBERG, Rosenberg, HELIOS, Maico, Ruck Ventilatoren GmbH, AeroStar, Blauberg, Elicent, Rhoss, Frapol, CMT CLIMA, HygroMatik GmbH, Winterwarm, Tecnair LV, AERIAL LV , MITA.

Products from these companies will be an excellent solution for ventilation tasks of any scale.

Domestic brands Vents, Elkom, Domovent and Vesa are not inferior to them in the quality of production and reliability of equipment. If there are doubts about the accuracy of the calculations or with the choice of a specific model, we recommend that you contact the support service of any of the companies.

If you are the owner of a private 1-2-storey building, industrial or commercial building of a similar size (restaurant, warehouse, dining room, cafe, office), when choosing equipment, you must take into account the volume of premises, the rate of air exchange, the length and cross-section of the main pipelines.

Be sure to pay attention to the additional functionality of centrifugal fans and the ability to integrate into a variety of air conditioning systems.

So, radial blowers can be equipped with auxiliary components:

- adjustable timers and interval switches, photosensors and humidity detectors;

- speed controllers and status indicators;

- sensors of motor overload and lack of electrical power to the network;

- spring absorbers or rubber vibration isolators.

If the fan is located inside an apartment or house, it can be closed with a removable decorative panel made of aluminum or plastic, taking into account the interior of the room.

For many users, a significant criterion when choosing a fan is the noise level. Are you picking a quiet fan in the bathroom? We recommend that you read the rating silent fans.

Conclusions and useful video on the topic

In the following video, Elcom specialists talk about centrifugal fans:

Below is a great example of installing a household fan in a bathroom:

Another option for installing a household low-power fan in an apartment:

The classic centrifugal fan is the result of many years of experience in the design and manufacture of ventilation equipment. This is not only an excellent solution for the industry, but also an optimal air transportation tool for residential and office premises.

Have you thought about purchasing a centrifugal fan? Or noticed a discrepancy in the disassembled material? Ask your questions, clarify technological aspects in the comments section.

Or maybe you already installed such a fan in the bathroom? Are you satisfied with his work? Have you chosen the right power for your room? Send a photo of your fan and leave your comments.

Types of fans: classification, purpose and principle of their operation

Types of fans: classification, purpose and principle of their operation  Supply and exhaust ventilation: principle of operation and features of the arrangement

Supply and exhaust ventilation: principle of operation and features of the arrangement  How to connect a fan with a humidity sensor: subtleties of connection and installation + selection rules

How to connect a fan with a humidity sensor: subtleties of connection and installation + selection rules  Turbo deflector for ventilation: principle of operation and comparison of types of rotational deflectors

Turbo deflector for ventilation: principle of operation and comparison of types of rotational deflectors  Exhaust hood for the kitchen: operating principle, device, types of units

Exhaust hood for the kitchen: operating principle, device, types of units  Charcoal filter for hood: device, principle of operation and replacement technology

Charcoal filter for hood: device, principle of operation and replacement technology  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements