Supply valve on plastic windows: how to choose and install a ventilation valve

Installation of sealed window structures entails a deterioration in the microclimate of the room: humidity rises, a lack of oxygen and air staleness appear. Problems can be easily solved by placing a supply valve on plastic windows - the device normalizes natural ventilation and stabilizes air exchange.

We will tell you how to choose the right ventilator to ensure the supply of fresh air to rooms with plastic window frames. We have described in detail proven practical models of the device. For independent home masters, we provide detailed installation instructions.

The content of the article:

Do I need to install a supply valve?

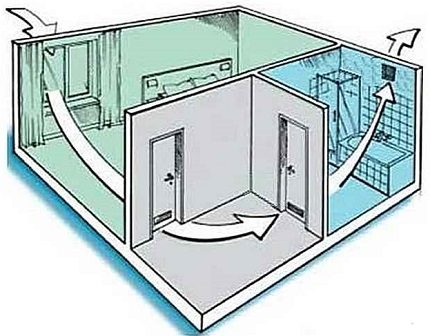

The basis of a normal indoor microclimate is the availability of an effective ventilation systems.

The air must constantly circulate - contaminated with excess carbon dioxide is removed through the hood, and clean comes from the outside.

When designing Soviet-built houses, special attention was paid to exhaust ducts, and supply air ducts were not equipped. The intake of fresh air occurred naturally - through the cracks in the wooden window frames.

Metal-plastic analogues are equipped with air chambers in sashes and frames, sealed double-glazed windows and perimeter seals.

Modern designs isolate the room from street noise and retain heat, but paralyze the normal functioning of ventilation. As a result, the microclimate worsens - the air becomes stale, humidity rises, people experience a lack of oxygen, appears black mold.

An attempt to restore air circulation by opening a window in the airing mode cannot be considered a good solution for the following reasons:

- the advantages of "plastic" are reduced to zero - the effectiveness of the thermal insulation of the room is reduced;

- ventilation works only with the window open, which is especially problematic to organize in the cold season or in windy weather;

- the air flow is uneven and uncontrolled - drafts appear.

Some manufacturers of window systems took into account the consequences of complete tightness and improved metal-plastic constructions.

Special ventilation fittings:

- ventilated profiles;

- opening limiters;

- partially breathable seals;

- glazing beads with regulating valve.

To ensure the flow of air through a previously installed window, a supply valve is used.

Principle of operation of the supply valve

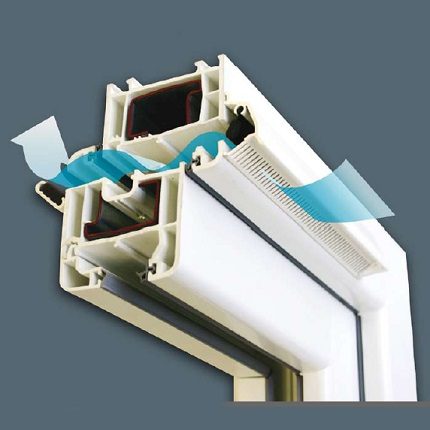

In fact, the supply valve is a slit with shutters in the window structure. The ventilator is part of the natural air exchange.

The device works due to the difference between the pressures inside and outside the room. For the effective functioning of the “air inlet”, an exhaust ventilation system is needed.

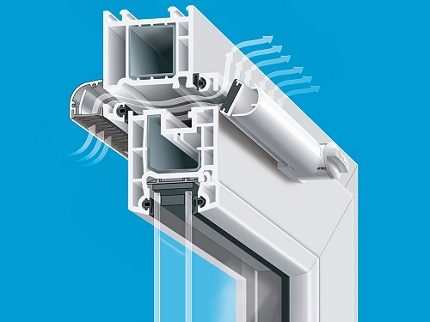

Standard equipment of the ventilation valve for plastic windows:

- Air intake - the outer part of the device mounted on the outside of the frame. The inlet block has an anti-insect grille and a visor that prevents snow and rain.

- Through gap - a telescopic channel through which air flows. The element crashes into the window frame.

- Inside - is installed from the inside of the room.The exhaust block is equipped with a nozzle, a throughput adjustment valve and a filter.

Street air enters the air intake hole, moves along the telescopic channel and exits through the nozzles. Further, under the action of convective flow from the heating radiator, the air rushes to the ceiling and warms up.

In general, according to building rules, the installation of plastic windows in houses not equipped with mechanical ventilation should be accompanied by modernization of ventilation. For example, by setting wall supply valve, with the features of which we recommend that you familiarize yourself.

Which valve to choose?

To choose the optimal model of ventilator for installation on plastic windows, you need to determine the method of installation and the type of adjustment. The quality of the device largely depends on the company of the manufacturer, and the performance on the technical characteristics of the device.

Types of ventilators by type of construction

Supply valves for PVC windows according to their design features are divided into three main groups:

- folded;

- slotted;

- waybills.

Folded models

Microventilation of the room in this case is carried out due to a slot in the frame. The window can be equipped with such a device without dismantling the double-glazed window.

Advantages of folding valves:

- affordable cost;

- preservation of heat and sound insulation qualities of the window;

- simplicity and speed of installation;

- possibility of automation.

Minus - low throughput (up to 5 cubic meters / h). To increase the flow of air, experts recommend installing two valves on one window.

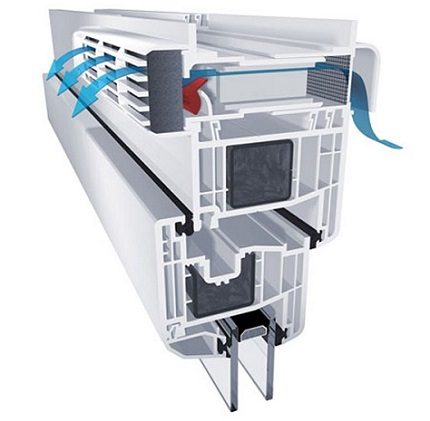

Slit climate devices

Fresh air here enters through a slot with a width of 17-40 cm and a height of 12-16 mm. The valve has an inlet and control unit. Advanced models consist of one universal box.

Advantages of slotted models:

- sufficient throughput (about 20 cubic meters / h);

- protection against external factors;

- the ability to install without removing the glass.

The disadvantage is the difficulty of installing two-block models that require milling of the window block. This minus is deprived of cheaper analogues. Simple “air inlets” allow air to flow through the space between the sash and the frame.

Overhead valve models

Such valves are similar in principle to slotted models. The main plus of the device is high productivity (up to 100 cubic meters / h). “Pritochniki” are placed both in blind and open windows. However, the installation is carried out before the installation of the double-glazed window.

Overhead type devices are usually used in industrial and office premises, installation in a house or apartment is impractical. In addition, such valves allow street noise and degrade the thermal insulation of the window.

Ways to control the window "air intake"

Depending on the valve device for plastic windows, the intensity of the supply ventilation can be constant or adjustable. The optimum microclimate parameters can be achieved with the help of a ventilator with the possibility of regulation, which can be automatic or manual.

The operation of an automatic valve is based on one of the principles:

- Air supply stabilization due to pressure difference between the room and the street. The owner sets the allowable range of air flow, which is maintained by the device under various atmospheric conditions.

- Air circulation adjustment with polyamide sensor. The valve cross-section increases with excess moisture, and when optimal microclimate is achieved, it decreases.

Minus automatic devices - high cost. In addition, in some models it is not possible to completely block ventilation.

The air flow in the mechanical device is adjusted by changing the position of the valve or curtain.

The manual setting method allows you to independently choose the time for airing the room. Such a method is more crude - unconsciously, a person alone, can allow the occurrence of drafts and overcooling of the room.

Selection of the main characteristics of the valve

When choosing a ventilation valve, special attention should be paid to the following parameters:

No. 1 - Performance Range

The value of the indicator depends on the pressure drop at the outlet and inlet, as well as on the flow area of the “air inlet”. When evaluating the models, it should be borne in mind that in the technical characteristics the throughput is always indicated with reference to the pressure difference.

It is not necessary that a device with a capacity of 15 cubic meters. m / h at 10 Pa will allow a greater air flow than the analogue with an indicator of 12 cubic meters / h at 5 Pa.

No. 2 - Soundproofing

Most metal-plastic windows have a sound insulation index of 30-35 dB. The supply device must meet such characteristics that after installing the valve, the noise level in the room remains the same.

No. 3 - Temperature Operating

Water vapor escapes through the ventilation device. In winter, this is fraught with complete icing and equipment failure.

In modern systems, the principle of "thermal break" is used - a plastic insert is placed between the metal inner and outer parts.

No. 4 - Possibility of adjustment

For residential premises, it is undesirable to choose devices without the ability to control air exchange. Constantly there is a need to change the intensity or completely block the ventilation duct.

It should be remembered that the window inlet is only an addition to the ventilation system of the apartment. If it does not work, required restore ductwork. We recommend reading about how restoration measures are carried out in our article.

Overview of popular ventilator models

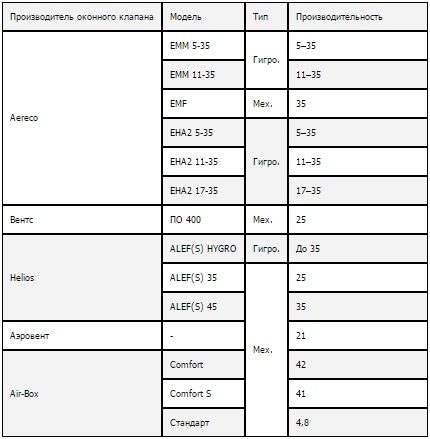

There are a lot of models of ventilation valves from different manufacturers on the market. As in every industry, there are leaders: Aereco, Air-Box, Helios, Vents and Siegenia.

Aereco (France) offers various modifications of ventilators. Automatic valves are equipped with a V8 sensor and operate on the principle of hygroregulation. The sensor actuator is located away from the air stream.

Popular models Aereco:

- ENA2 - Available in three variations of various capacities. The manufacturing material is plastic, the maximum throughput of the model range is 35 cubic meters. m / h, sound insulation - 37 dB.

- EMM - The main difference from previous products is a mobile outdoor unit.

- EMF - lack of hygro-regulation system. The model is equipped with a manual mode switch.

Air box (Russia) produces plastic “stitches” of manual regulation. The main advantage of the models is the ease of installation, the disadvantage is the lack of automatic control of the humidity level.

Series Air box:

- Standart - the valve is mounted without milling. The main purpose of the valve is to prevent condensation on the PVC windows. The volume of incoming air is 4.8 cubic meters per hour with a pressure drop of 10 Pa, sound insulation - 32 dB.

- Comfort - Two installation methods are possible. Inserting the ventilator into the frame increases its productivity from 31 to 42 cubic meters per hour. The inlet can be used in any swivel and tilt-and-turn constructions.

- Comfort s - it is mounted only on milled holes. A feature of the model is the two-sided direction of air flow, providing better ventilation of the room. The valve capacity is 40-42 cubic meters per hour.

Reenson (Belgium) produces slotted ventilation Aerovent. The valve is equipped with a filter and mosquito net. Manual control with a cord is provided - operation is carried out in two modes: “closed” and “open up”.

Installation example of a perforated ventilator

It is advisable to mount the valve for perforation in the upper part of the window. The complexity of the work lies in the need for frame milling - here you can not do without special equipment and skills with a power tool.

Preparatory work

When planning a valve insert, some points must be considered:

- installation of the ventilation device is best done on the removed sash;

- installation is carried out in the warm season;

- when cutting holes, it is necessary to work carefully so as not to damage the seal on the sash.

The shutter is removed from the hinges, installed in an inclined or vertical position.

List of required tools

For the installation of the “supply air” you will need:

- electric drill and drill (diameter - 5 mm and 10 mm);

- fine-grained file;

- jigsaw;

- pattern for marking holes;

- silicone sealant.

It will be possible to prepare a groove without a template, however it is easier to work with it. You can make a template yourself from plywood or hardboard.

Phased installation and mounting progress

The whole process of installing the supply valve is divided into several stages:

Stage 1. Markup. To put on a template on a vertical ledge and to mark the place of insert of the device.

Stage 2. Sash milling. Drill a large diameter drill a few holes in a row and connect them using a jigsaw. Repeat surfacing the frame.

Stage 3. Installation of the mounting plate and valve. Treat the back side of the strip with sealant, attach the part to the sash and fix it with self-tapping screws.

Stage 4. Installation of a peak. On the outside of the frame, secure the protective visor with screws. Seal the joint between parts. When installing, it is advisable to use insurance.

Stage 5. Installation completion. Fit the furniture harness back into place and hang the sash on the hinges. Set the ventilation mode on the ventilation device.

Valve installation example without milling

Installation of fresh air ventilation without perforation of the sash takes a little time and does not require special skills.

Of the tools you will need:

- stationery knife;

- screwdriver or screwdriver;

- ruler.

The necessary valve components are supplied complete with a “supply air”.

The standard set includes:

- valve;

- one long and two short seals;

- plugs for fixing the device;

- self-tapping screws.

First you need to determine the location of the valve and mark it with a pencil. Optimal - install the device in the center of the sash.

Make cuts at the marked points with a sharp knife and remove the seal from the groove.

To install the valve in an open groove, place fixing dowels - one in the middle and two at the edges. Remove the protective film from the adhesive tape and attach the device in the desired position.

On the frame, it will also be necessary to replace the seal with a narrower one, so that the valve can let the air flow through. Changes made will not affect the sash's performance.

If the installation of the supply device on a plastic window did not lead to the expected results, ventilation in the apartment requires serious modernization. We recommend that you familiarize yourself with the methods of regularly providing the apartment with fresh air.

Conclusions and useful video on the topic

Video materials will help to better understand the installation technology of different types of ventilation valves.

Video # 1. The installation procedure of the slotted valve without milling the window frame:

Video # 2. Supply valve insert technology:

Ventilation valves do not replace air conditioning systems that refresh and change the temperature of the room. At the same time, “air inlets” are an excellent alternative to open air vents and sashes. The installation scheme of the valve can be done by any home master.

We are interested in your opinion and your stories about the hand-mounted installation of inlets on plastic windows. Please write comments in the block below. Ask questions here, post photos with purchased devices or installation steps.

Supply ventilation valve into the wall: features of the arrangement

Supply ventilation valve into the wall: features of the arrangement  Which supply valve to choose: varieties of valves, features of choice + overview of the best brands

Which supply valve to choose: varieties of valves, features of choice + overview of the best brands  How to make a non-return valve for ventilation with your own hands: instruction on the construction of a homemade product

How to make a non-return valve for ventilation with your own hands: instruction on the construction of a homemade product  Ventilation anemostat: design specifics + review of TOP brands on the market

Ventilation anemostat: design specifics + review of TOP brands on the market  Plastic ducts for hoods: overview of types + installation rules

Plastic ducts for hoods: overview of types + installation rules  Check valve for ventilation: how to arrange ventilation with a check valve on the hood

Check valve for ventilation: how to arrange ventilation with a check valve on the hood  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Last year, we bought an apartment in a new building, and there in the kitchen and in the large room, the supply air valves were already installed.Given that the house is new, the brick is damp, then constant air circulation is very convenient and necessary. True, in winter we had a problem, the whole hole froze, ice constantly formed. When it melted, it was all on the windowsill. As a result, for the remaining months of winter, we sealed these valves and insulated. So in winter we were not able to fully use the “prichachniki”.

That's it, I also heard that in the cold, the valves on the air inlet freeze. In addition, they deprive plastic windows of one of their advantages - sound insulation. I doubt to bet or not.

Good afternoon, Tamara. You can install accessories with micro-ventilation, the second name is micro-slotted. When opening the sash, it becomes possible to open the sash by 5 mm. This is sufficient to remove minimal condensation.

A step-by-step opening option is also available, there are two types - three and five positions. The first, as in the case of micro-ventilation, reclines by 5 mm., Each subsequent one comes in increments of 5-7 cm, depending on the manufacturer of the fittings. Convenient is the moment of fixation of the sash in the selected position, that is, it will not slam from the draft.

I have heard about supply valves for a long time, but did not know how they look. Their device seemed to me very simple. Only an inconspicuous hole was visible, which is regulated by pressing a button, but I was mistaken. Nevertheless, I consider this method of ventilation a real breakthrough in the field of ventilation due to the natural flow of air. It is a pity that this system has a number of disadvantages.

I like this option much more than drilling a wall. Here it’s easier to regulate and the window is easier to replace if something happens.

The main thing is that dust does not leak through the air intake along with fresh air. We stood like that. And nothing had to be drilled. But firstly, in the summer the dust passed into the house, and secondly, the noise insulation was damaged.

How will window manufacturers react if I install such valves? I will not lose the guarantee?

If your plastic windows are still under warranty, then it is better to involve a specialist from the company to install the supply ventilation valve. The installation of such a valve involves making technological holes in the profile of the window frame. You can consult with company representatives about whether such an installation would result in voiding the warranty.

If there is a problem with this, then you can mount the supply valve into the wall.