Supply ventilation valve into the wall: features of the arrangement

In an effort to protect the house from cold, noise, dust and other negative external influences, a person seals building structures. Along with the improvement of insulating characteristics, the quality of ventilation is reduced - the intake of clean air is reduced.

The problem can be solved in many ways. One of the most affordable and effective methods is to arrange a supply valve in the wall, providing the necessary flow of fresh air. In this material we will talk about the need to install this device, weigh the pros and cons, and also reveal the secrets of installing a wall air inlet valve.

The content of the article:

The need to install a ventilation valve

The main function of the supply ventilation valve is to provide fresh air to the apartment or house.

A wall ventilator normalizes the microclimate of the room when natural ventilation does not cope with its task.

With the mass replacement of wooden window blocks with PVC products, natural ventilation has lost its effectiveness - external air flow has significantly decreased due to the tightness of modern structures. The speed of circulation of air flows in a confined space tends to zero, which extremely negatively affects the quality of the microclimate.

If measures to improve ventilation are not taken, then over time minor troubles can cause more serious consequences:

- The concentration of carbon dioxide rises, which adversely affects the well-being of a person. Fatigue, drowsiness, headache, decreased performance are the result of a lack of oxygen.

- High humidity and lack of air circulation is an excellent environment for the development of pathogens. Mold spores can cause allergic reactions or provoke the appearance of bronchial asthma. At risk are young children and people with reduced immunity.

- Exhaust ventilation works inefficiently with a low air flow - unpleasant odors, pollution, harmful substances are not eliminated naturally.

- In conditions of constant high humidity, structural elements of a building wear out faster.

The operation of the window in the ventilation mode can solve these problems, but at the same time the main advantages of the “plastic” glazing are negated: heat and noise insulation.

We also recommend reading material about other ways of arranging forced ventilation.

Design and principle of operation

The design of the ventilation valve is quite primitive. The device consists of a cylindrical body, the diameter of which is 6-14 cm. Inside the valve there is heat and noise insulation, as well as a filter.

The individual elements of a typical valve design perform the following functions:

- Air duct Through the pipe, the air masses flow outside to the room. The diameter of the duct largely determines the performance of the supply valve. As a rule, this element is made of plastic.

- Ventilation grill. It is located on the outside of the wall and is intended to protect the internal elements of the device from small animals, rain and debris. The optimal manufacturing material is aluminum. Some models have a mosquito net made of polymer threads.

- Heat and noise insulating insert. It passes through the entire duct and protects the wall from freezing, providing a reduction in street noise.

- Filter element. Cleans incoming air from dust.

- Decorative cover. Installed on the inside of the wall. The plastic head is equipped with a handle for adjusting the air flow.

Many manufacturers equip the valve with a sealing ring with a damper. Both parts are placed on the inside of the wall and inhibit gusts of wind.

The system operates on a simple principle. Air passing through the grill and filter is cleaned, moves along the heat and noise insulation channel and warms up a bit. In the confined space of the pipe, the speed of the air flow decreases, it enters the adjustable damper, and then through the technological holes into the room.

Ventilation can be carried out continuously with the windows closed. In this case, the room will not cool. If plastic windows are installed in the room, then it might be worth considering the option of installing a supply valve to the window.

However, for normal air circulation, the following conditions must be met:

- the presence of a working hood;

- the movement of air masses even with closed doors indoors - it is necessary to provide a gap between the floor and the door of 1.5 cm or arrange ventilation grilles.

The operation of the hood can be verified experimentally. Open the window and bring thin paper to the grate. With good traction, the sheet will be attracted to the ventilation duct.

Points for and against"

The wall supply valve, like any other device, has undoubted advantages and disadvantages.

Arguments in favor of the ventilator:

- The frequency of opening / closing the window is reduced. This extends the life of window fittings and saves time.

- The power of the ventilation valves installed in the wall exceeds the productivity of the window “air inlets” and can reach 60-70 cubic meters per hour.

- The device partially eliminates pollution and filters street air.

- The ability to regulate air flow based on the season and the needs of a particular house.

- The device has compact dimensions - the inner box is almost invisible on the wall, it can be hidden behind a curtain.

- Compared to conventional ventilation through a window, the operation of the wall valve is not accompanied by heat loss.

- The supply device increases the efficiency of the hood - moist exhaust air is removed faster.

The functioning of the system is carried out autonomously - the valve operates due to pressure differences in the street and indoors.

Negative moments of the use of supply equipment:

- the need to make a through hole in the wall - the integrity of the structure is in some way violated;

- non-compliance with the installation technology is fraught with freezing of the wall or duct;

- in severe frosts, fresh air ventilation can lead to lower indoor temperatures.

Some refuse to install a wall valve due to the need to drill the structure. Work requires certain skills from the performer. To ensure effective ventilation, the device filter should be regularly cleaned of accumulated debris.

Parameters for choosing a built-in ventilator

Before buying a supply valve, it is necessary to compare the main parameters of different models:

- device performance;

- permissible operating temperature;

- length and diameter of the duct;

- management method;

- sound insulation level;

- manufacturer company.

Power "inflow". On average, wall valves give out fresh air up to 40 cubic meters per hour. When determining the optimal performance, it is worth considering the volume of the room, its purpose and the number of people living.

Operating temperature. Manufacturers indicate a range of operating temperatures. The choice of model depends on the climatic conditions of a particular region. If the ventilation valve for a “warm” area is used in frosty winters, condensation may constantly form on it. The frozen liquid forms an ice plug, and the operation of the supply duct is blocked.

The dimensions of the duct. The length of the pipe is selected based on the width of the wall. The diameter of the channel determines the throughput of the valve - the larger it is, the more productive the device. When choosing the size and shape of the duct, you need to focus on the installation location of the “air intake”.

Management method. Manual and automated models are available on the market. The former are affordable, the intensity of ventilation is regulated by a manual switch.

Automated devices are equipped with a hygrostat - a device that controls humidity level in room. The user independently sets the humidity indicator (40-60%) and if this value rises above, the valve flap will open. After normalization of humidity - the air supply from the street will stop.

Noise and heat insulation level. When incorporating a ventilation valve into a thick wall, the presence of a soundproofing insert is highly desirable. Basic thermal insulation is provided in all models, however, for the northern regions it is better to choose a device with an additional insulation casing.

Company manufacturer. In the market of ventilation equipment, wall valves of foreign and domestic firms are represented. The following brands and brands received a positive assessment of consumers: Flakt Woods (Riv, Kiv125), Vents (PS100), Aereco (EHT, EFT), Helios (ZLE100, ZLA 80-160), Domvent, etc.

Installation technology of supply and wall valve

The installation process is quite simple, but specialized equipment will be required to operate. It is important to choose the right place for installation and follow the algorithm of actions.

Determining the optimal installation location

When choosing a room for installing a wall "air intake" should be guided by the following rules:

- Installation is preferably carried out in a bearing wall.

- In an apartment building, it is better to install the valve with the exterior of the balcony or loggia.

- It is undesirable to arrange forced ventilation on the wall of the building facing the road and the industrial zone.

It is not recommended to use the wall valve in rooms with a high degree of humidity - in winter there is a high risk of freezing of the device. Alternatively, it is possible to use “air inlets” with a heating function.

Having decided on the wall, you need to choose the best place to insert the valve.

The most successful sites are:

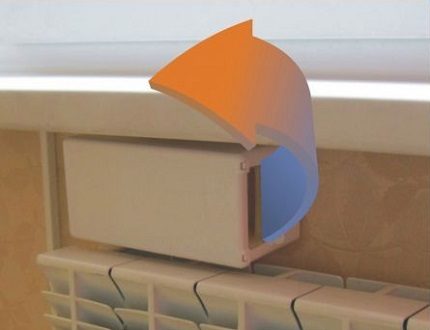

- between the windowsill and the batteries - the supply air is heated from the heating device and distributed throughout the house;

- at the top of the window opening (2-2.2 m) - air masses fall into a warm environment, warm up to a comfortable temperature and fall down.

In both cases, the wall valve will be hidden behind the curtain.

Necessary tools and materials

To insert the supply valve into the wall you will need:

- stationary drill or a powerful hammer drill with a diamond crown, the diameter of which should be slightly larger than the size of the duct;

- industrial or household vacuum cleaner - especially relevant if the installation is carried out in a “clean” area, where the repair is already completed;

- polyurethane foam;

- plaster mix;

- construction knife;

- curly screwdriver;

- marking tools: measuring tape, building level, pencil.

Ventilator installation - dusty and noisy work. Therefore, personal protective equipment should be used: gloves, glasses, construction headphones and a dust mask with a dust filter.

To install a ventilation valve with a breather, a device for cleaning and heating the air mass, diamond drilling will be required, as a conventional drill will not be able to drill a hole of sufficient diameter:

Work sequence

The whole technological process can be divided into several main stages.

Stage 1. Wall preparation. If the building is lined with hinged panels, then they must be temporarily dismantled. Mark the underside of the wall for drilling - attach the valve base and mark the contour with a pencil. It is advisable to organize dust removal.

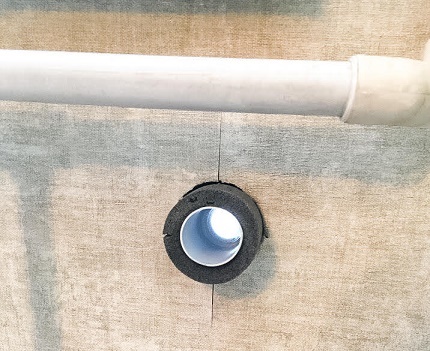

Stage 2. Drilling holes. Using a diamond crown or a drill, start drilling to a depth of 7-10 cm. Remove the broken-off concrete fragments, knock a notch in the center with a chisel for more stable positioning of the drill. The entire channel must be done with a slight slope outward to prevent moisture from getting inside the room.

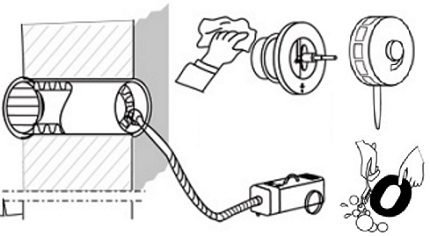

Stage 3. Channel cleaning. Insert the vacuum cleaner hose into the cut groove and remove all dust from the hole.

Stage 4. Installation of thermal insulation. To accommodate an additional layer of heat and sound insulation, expansion of the hole may be necessary. The exact dimensions of the channel depend on the type of insulation.

Stage 5. Installing the sleeve. Place the duct pipe into the channel with a heat-insulating casing, moving it with screwing movements outward.

Stage 6. Mounting the housing and cover. Fasten the protective grill on the outside of the wall.From the inside, mark out the installation of the housing, drill holes, hammer in the plastic dowels and fix the panel on the wall.

We also have material, which is described in more detail. installation process supply wall valve.

Vent valve maintenance

The supply unit must be cleaned regularly. In a metropolis, it is necessary to clean the internal elements twice a year - dust, small particles of dirt and soot from automobile gases settle on the filter of the device.

It is better to clean the valve in warm, calm weather so that cold air does not blow out through the hole in the wall. It is necessary to remove the cover from the inside of the device, remove the filter element and sound insulation.

The duct also needs to be cleaned - it must be vacuumed. If the inlet is installed on the first or ground floor, you can remove the protective grille from the side of the street and blow out the garbage out with a vacuum cleaner.

Conclusions and useful video on the topic

Video clip about the need for installation, design features and the principle of operation of the supply wall valve:

Step-by-step installation instructions for the Domvent ventilation duct:

To insert the “stitch” into the wall will have to saw the outer wall of the house. For all the complexity, the task is technically simple. Having a tool for drilling, the owner of the apartment or house will be able to install the valve yourself.

If you have any questions about installing a wall air inlet valve when reading this material, or if you have valuable information on the topic of the article, please share it with our readers. This can be done by leaving a comment at the bottom of the article.

Supply valve on plastic windows: how to choose and install a ventilation valve

Supply valve on plastic windows: how to choose and install a ventilation valve  Which supply valve to choose: varieties of valves, features of choice + overview of the best brands

Which supply valve to choose: varieties of valves, features of choice + overview of the best brands  Ventilation in the wardrobe: features of the arrangement of the hood in the dressing room and wardrobe

Ventilation in the wardrobe: features of the arrangement of the hood in the dressing room and wardrobe  Supply and exhaust ventilation: principle of operation and features of the arrangement

Supply and exhaust ventilation: principle of operation and features of the arrangement  How to make a non-return valve for ventilation with your own hands: instruction on the construction of a homemade product

How to make a non-return valve for ventilation with your own hands: instruction on the construction of a homemade product  Ventilation anemostat: design specifics + review of TOP brands on the market

Ventilation anemostat: design specifics + review of TOP brands on the market  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

In the Karelian city, she drew attention to a rather old house, it attracts attention by the fact that small holes are visible in the outer walls along the entire facade with grilles. Well done designers: they included these valves in the design of the house so that they look like a decoration of the facade. It is a pity that we do not have a law to build houses with gas stoves and columns immediately with such valves.

It is a pity that we do not have a law, so that houses with gas stoves and water heaters would not be built.