How to determine fan pressure: ways to measure and calculate the pressure in the ventilation system

If you pay enough attention to the comfort of your home, then you’ll probably agree that air quality should be one of the first places. Fresh air is good for health and thinking. It’s not a shame to invite guests into a well-smelling room. Ventilating each room ten times a day is not an easy task, is it?

Much depends on the choice of the fan and, first of all, its pressure. But before determining the fan pressure, you need to familiarize yourself with some physical parameters. Read about them in our article.

Thanks to our material, you will learn the formulas, learn the types of pressure in the ventilation system. We have provided you with information about the full pressure of the fan and the two ways in which it can be measured. As a result, you can independently measure all the parameters.

The content of the article:

Ventilation pressure

To ventilation was effective, you need to choose the right fan pressure. There are two options for self-measurement of pressure. The first method is direct, in which pressure is measured in different places. The second option is to calculate 2 types of pressure from 3 and get an unknown value from them.

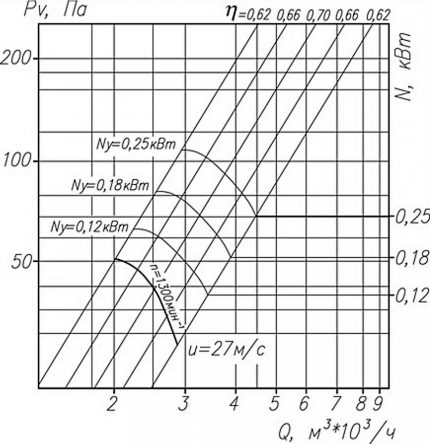

Pressure (also - pressure) is static, dynamic (speed) and full. According to the latest indicator, three categories of fans are distinguished.

The first includes devices with a pressure <1 kPa, the second - 1-3 kPa and more, the third - more than 3-12 kPa and above. In residential buildings, devices of the first and second categories are used.

The technical documentation for the fan usually indicates aerodynamic performance, including full and static pressure at a certain performance. In practice, the "factory" and actual parameters often do not coincide, and this is due to the design features of ventilation systems.

There are international and state standards aimed at improving the accuracy of measurements in the laboratory.

In Russia, methods A and C are usually used, in which the air pressure after the fan is determined indirectly, based on the installed capacity. In various methods, the impeller bushing is included or not included in the exit area.

Formulas for calculating the fan head

Pressure is the ratio of the acting forces and the area to which they are directed. In the case of the ventilation duct, we are talking about air and section.

The flow in the channel is distributed unevenly and does not pass at right angles to the transverse section. It will not be possible to find out the exact pressure from one measurement; you will have to look for the average value at several points. This must be done both for entering and leaving the ventilating device.

The total fan pressure is determined by the formula Pp = Pp (out) - Pp (in)where:

- Pп (exit.) - total pressure at the outlet of the device;

- Pп (in.) - total pressure at the inlet to the device.

For static fan pressure, the formula differs slightly.

It is written as Pst = Pst (out) - Pn (in), where:

- Pst (out) is the static pressure at the outlet of the device;

- Pп (in.) - total pressure at the inlet to the device.

The static pressure does not display the required amount of energy for its transfer to the system, but serves as an additional parameter by which the total pressure can be found. The last indicator is the main criterion when choosing a fan: both home and industrial. The decrease in total pressure indicates the loss of energy in the system.

The static pressure in the ventilation duct itself is obtained from the difference in static pressure at the inlet and outlet of the ventilation: Pst = Pst 0 - Pst 1. This is a minor parameter.

The correct choice of a ventilation device includes such nuances:

- calculation of air flow in the system (m³ / s);

- selection of a device based on such a calculation;

- determination of the outlet velocity by the selected fan (m / s);

- calculation of the device Rp;

- measurement of static and dynamic pressure for comparison with the full.

To calculate the place for measuring the pressure, they are guided by the hydraulic diameter of the duct. It is determined by the formula: D = 4F / P. F is the cross-sectional area of the pipe, and P is its perimeter. The distance to determine the measurement location at the inlet and outlet is measured by the number D.

How to calculate ventilation pressure?

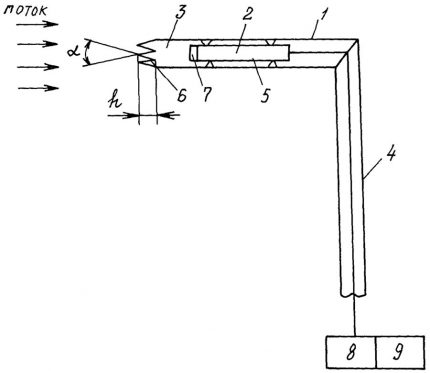

The total pressure at the inlet is measured in the cross section of the ventilation duct located at a distance of two hydraulic diameters of the duct (2D). In front of the measurement site, ideally, there should be a direct fragment of the duct with a length of 4D and undisturbed flow.

In practice, the above conditions are rare, and then a honeikomb is installed in front of the desired location, which straightens the air flow.

Then a full pressure receiver is introduced into the ventilation system: at several points in the section in turn - at least 3. The average result is calculated from the obtained values. For fans with a free input Pп, the input corresponds to the ambient pressure, and the excess pressure in this case is equal to zero.

If you measure a strong air flow, then the pressure should determine the speed, and then compare it with the size of the section. The higher the speed per unit area and the greater the area itself, the more efficient the fan.

The full pressure at the exit is a complex concept. The output stream has a heterogeneous structure, which also depends on the operating mode and type of device. The air at the outlet has return zones, which complicates the calculation of pressure and speed.

The pattern for the time of the appearance of such a movement cannot be established. The heterogeneity of the flow reaches 7–10 D, but the index can be reduced by rectifying gratings.

Sometimes at the exit of the ventilating device there is a rotary elbow or a tear-off diffuser. In this case, the flow will be even more heterogeneous.

The pressure is then measured by the following method:

- After the fan, the first section is selected and scanned with a probe. The average total head and productivity are measured at several points. The latter is then compared with the input performance.

- Then choose an additional section - in the nearest straight section after leaving the ventilating device. From the beginning of such a fragment, 4-6 D are measured, and if the length of the section is less, then a section is chosen at the most distant point. Then take a probe and determine the performance and average total pressure.

From the average total pressure at the additional section, the calculated losses in the segment after the fan are taken away. Get full outlet pressure.

Then they compare the performance at the input, as well as at the first and additional sections at the output. The input indicator should be considered correct, and one of the holidays should be considered closer in value.

A straight segment of the desired length may not be. Then choose a section that divides the plot for measurement into parts with a ratio of 3 to 1. Closer to the fan should be the largest of these parts. Measurements cannot be made in diaphragms, gates, bends and other compounds with air disturbance.

In the case of roof fans, Pp is measured only at the input, and at the output, the static is determined. The flow rate after the venting device is almost completely lost.

We also recommend reading our selection material. pipes for ventilation.

Features of the calculation of pressure

Pressure measurement in the air is complicated due to its rapidly changing parameters. Pressure gauges should be bought electronic with the function of averaging the results obtained per unit time. If the pressure jumps abruptly (pulsates), dampers that smooth out differences are useful.

Keep in mind the following patterns:

- total pressure is the sum of static and dynamic;

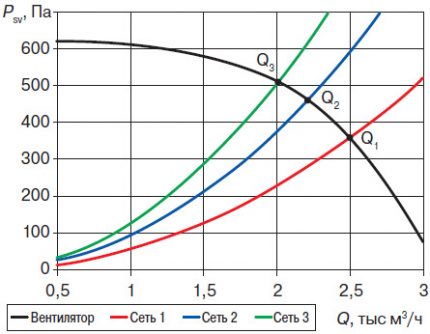

- the total pressure of the fan should equal the pressure loss in the ventilation network.

It is not difficult to measure the static pressure at the outlet. To do this, use a tube for static pressure: one end is inserted into the differential pressure gauge, and the other is sent to the section at the outlet of the fan. The static pressure calculates the flow rate at the outlet of the venting device.

The dynamic head is also measured with a differential pressure gauge. Pitot-Prandtl tubes are connected to its connections. To one contact - a tube for full pressure, and to the other - for static. The result will be equal to the dynamic pressure.

To know the pressure loss in the duct, you can control the dynamics of the flow: as soon as the air speed rises, the resistance of the ventilation network increases. Pressure is lost due to this resistance.

With increasing fan speed, the static head decreases, and the dynamic head increases in proportion to the square of the increase in air flow. The total pressure will not change.

With a correctly selected device, the dynamic head changes in direct proportion to the square of the flow, and the static one is inversely proportional. In this case, the amount of air used and the load of the electric motor, if they increase, are not significant.

Some requirements for the electric motor:

- low starting torque - due to the fact that the power consumption varies in accordance with the change in the number of revolutions supplied to the cube;

- large stock;

- working at maximum power for greater savings.

Fan power depends on the total pressure, as well as on the efficiency and air flow. The last two indicators correlate with the bandwidth of the ventilation system.

At the stage of its design will have to prioritize. Take into account costs, loss of usable space, noise level.

Conclusions and useful video on the topic

Overview of the physical indicators that are needed for measurements:

The role of pressure in the ventilation network:

The fan is a simple design in the form of a wheel with blades. At the same time, this is the main part of the ventilation system. A mechanical device affects the pressure in the duct and determines the effectiveness of ventilation.

If you want to calculate the fan pressure, deal with such values as speed, air flow, power. You will better understand the essence of measurements. The main indicator, measure the total pressure according to the schemes described by us.

If you have questions, ask them in the form under the article. Write comments and share valuable knowledge with other readers. Perhaps you have experience in the design of ventilation systems - it will be useful in someone's specific situation.

Hood in the chicken house: the best ways to equip the ventilation system in the house

Hood in the chicken house: the best ways to equip the ventilation system in the house  Calorifier calculation: how to calculate the power of a device for heating air for heating

Calorifier calculation: how to calculate the power of a device for heating air for heating  Calculation of hoods for the kitchen: how to calculate the power of the hood

Calculation of hoods for the kitchen: how to calculate the power of the hood  Ventilation in the cellar: proper ventilation system technology

Ventilation in the cellar: proper ventilation system technology  Calculation of air ducts for speed and flow rate + methods for measuring air flow in rooms

Calculation of air ducts for speed and flow rate + methods for measuring air flow in rooms  Norm of air humidity in the apartment: measurement methods + tips for normalization

Norm of air humidity in the apartment: measurement methods + tips for normalization  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements