How to properly analyze the water from the well and disinfect it after checking

When using well water, the key issue is its quality. After all, it may contain chemical elements and pathogenic microorganisms that can harm human health.

To be sure of the safety of households is possible only after conducting research on its composition. How to properly analyze the water from the well and disinfect it after verification, we will consider in more detail.

The content of the article:

Where to go for analysis?

Water quality analysis services are provided by both state and private organizations. Each federal district has accredited laboratories that have the authority to conduct such studies.

These include:

- sanitary epidemiological station;

- geological laboratories;

- laboratories in regional branches of Vodokanal;

- in organizations related to exploration;

- laboratories at research institutes;

- accredited laboratories of Rospotrebnadzor.

The price depends on the type of study. The analysis can be shortened, aimed at identifying a specific group of substances, or complex, including chemical and microbiological research.

Checking the biological group will cost about one and a half thousand rubles. A full assessment of the state will be released about three thousand. In private laboratories, the cost of the service can be more expensive.

When choosing a laboratory, you should be guided by two parameters, these are:

- Location and remoteness of the organization - because the key to the reliability of the results is the speed of delivery of the sample to the laboratory.

- Positive reputation - It is a guarantee of the quality of research.Copies of certificates and certificates can be requested from the manager of the selected organization.

Having decided on the choice of the laboratory, it remains only to coordinate the day of sample delivery with the staff so that the analysis is carried out as soon as possible.

Sampling for analysis

To take a sample from the source and determine the quality of the water, choose the off-season period. In the spring and autumn months, surface waters are most polluted. If they have the opportunity to penetrate into the mine, then they will certainly affect the composition.

Water control is performed only after a 3-week period of operation of the hydraulic structure. During this period, the mine pollution that has arisen during the course of construction work will settle down, and the water will be partially purified.

To obtain reliable results from checking water from a well, it is important to properly sample.

To do this, you must adhere to a number of simple rules:

- The liquid collection tank must be made of clear, colorless glass or plastic. This can be a bottle of mineral or distilled water with a volume of 2 liters, or a glass two-liter bottle. It is unacceptable to use eggplants for sweet and low alcohol drinks for these purposes if they have not been previously washed without the use of detergents.

- When taking water from a well with a bucket, try to empty it a little lower than usual. This decision is explained by the fact that closer to the surface the water may become stagnant, and include sludge impurities at the bottom. Therefore, the best option would be the "golden mean."

- Before filling the dishes, they are rinsed with selected water. Well water is poured into the bottle in a thin stream so that it flows smoothly along the inner wall of the container. A pressureless flow will prevent the saturation of water with oxygen from the air, thereby preventing the occurrence of chemical processes.

- The bottle is filled with liquid at the very neck so that no air plug forms in the container. If you use a plastic bottle, gently squeeze the walls of the container, squeezing air, before closing it tightly with a lid.

- Water taken from the well should be delivered to the laboratory within the next 2-3 hours. The faster the fluid enters the laboratory, the more reliable the results. If this is not possible, place the container on a shelf in the refrigerator - this will reduce the reaction rate.

The maximum shelf life of the sample is up to two days. During the storage period, temperature fluctuations should be avoided.

The biochemical processes taking place in the selected sample can affect the change in the composition of the liquid. To prevent this, the bottle with the selected liquid should be wrapped with a piece of dark cloth or polyethylene, which will not let in the sun.

An accompanying note should be attached to the well water bottle. In it indicate the place (address), the type of source and the exact date of water withdrawal.

Key Quality Indicators

To get a complete picture and determine how well water from a well is suitable for eating, you can perform a comprehensive analysis, which consists of two parts - a chemical and microbiological study.

General chemical analysis

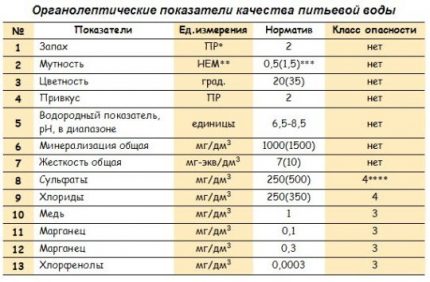

Chemical analysis allows you to determine whether the water complies with current sanitary rules and regulations (SanPiN 2.1.4.1074-01) Well water quality standards establish the maximum allowable amount of substances, as well as its sanitary and organoleptic characteristics.

In sanitary rules and regulations, three groups of requirements are imposed on the surface waters "feeding" the well: physicochemical, organoleptic, and sanitary-parasitological.

During the chemical analysis, the following indicators are determined:

- PH - hydrogen indicator. The development and vital activity of microorganisms depends on it, as well as the more aggressive effect of water on concrete and metals. Normally, the concentration of hydrogen should be 6-9 units.

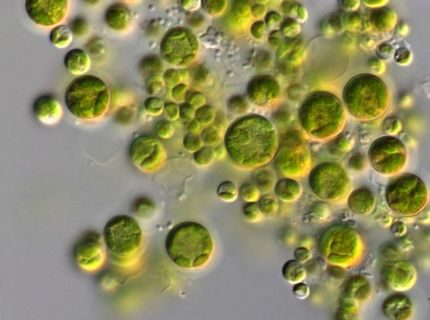

- Turbidity - characteristic of relative transparency of water. It depends on the presence of mechanical impurities in the form of suspended particles of silt sediment, algae, clay and microorganisms. Read more about the causes of turbidity and methods for their elimination in this stuff.

- Color. The color of water is associated with its content of humic substances and iron compounds. The color intensity of the sample is determined based on the color scale. It can vary from several units to tens of thousands of degrees.

- Rigidity - the concentration of salt particles of magnesium and calcium in the liquid. An environment with increased rigidity provokes the formation of scale on domestic heating appliances.

- Total mineralization. It indicates the total content of mineral substances found in the sample. Mineralization is characterized by an indicator such as solids.

- Permanganate Index - oxidizability of water. It is a measure of the pollution of the aquatic environment with organic and oxidizable inorganic substances.

The basic research methodology involves an assessment of 16 indicators, an expanded one - includes more than 30.

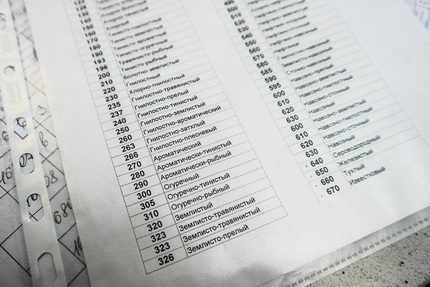

One of the main indicators of water in the study of organoleptic qualities is its smell.

The smell and taste of surface water directly depends on the chemical composition of the impurities, as well as the concentration of decaying plant residues and dead microorganisms dissolved in the water.

Microbiological components in the composition

In addition to a significant amount of chemical elements, well water contains a huge number of both safe and harmful microorganisms. Microbiological analysis helps to determine bacteriological and parasitological parameters.

The suitability of well water is determined by three main parameters:

- Total microbial number - per unit volume should be no more than 50.

- Thermo-tolerant coliform bacteria - reveals the content of microorganisms hazardous to health. The indicator must be zero.

- Common coliform bacteria - an indicator of fecal contamination. It must also be zero.

Conducting microbiological research is especially important if the well has a depth of 10 meters.This is due to the fact that protozoa and various bacteria multiply much faster in surface waters.

In addition, well water should be checked for the concentration of fertilizers, surface detergent components and oil products. These substances often penetrate the mine during heavy rainfall.

Methods for purifying water from impurities

Having received the protocol with the research parameters and indicating the maximum permissible values in accordance with SanPiN, they proceed to the choice of the method of how to properly disinfect the water in the well and clean it of impurities. The choice of method depends on the cause of contamination.

But in any case, before carrying out chemical treatment and installing filters, they perform mechanical cleaning of the well.

Shaft cleaning

The method involves cleaning the bottom and walls of the well by scraping off accumulated layers with subsequent washing of the structure.

Mechanical cleaning of a well shaft includes a number of basic steps:

- Pump out water from the well. This can be done manually by scooping out a bucket or using drainage pump. But it is worth considering that it will not work to completely empty the mine - at its bottom there will always be a small layer of water.

- Clean the walls of the structure. It is better to do the work together: the first worker, dressed in a protective suit, descends into the mine, and the second - insures it on the surface and accepts filled buckets. It is convenient to clean the walls of the well from mud or silt deposits with a wire brush or scraper.

- Replace the bottom filter. To do this, remove the layer-by-layer silt stones of the bottom filter layer by layer and remove them from the mine. Instead of the old bottom filter, a new layer of finely grained gravel is lined with neutral materials such as jadeite or river pebbles.

- Strengthen shaft rings and seal the seams. In the case of cracks, eliminate defects by coating them with cement mortar. When displacement of the rings relative to each other is detected, the structure is strengthened by tightening the elements with metal brackets.

At replacing the bottom filter instead of ordinary crushed stone, you can use natural sorbents. Petrified oil or shungite has proven itself in water purification systems.

Carbon-containing material helps to eliminate not only organic pollution, but also compounds of heavy metals, including iron. In addition, a natural mineralizer in the process of ion exchange enriches water with potassium, sodium, silicon and sulfur.

Disinfection of walls of a hydraulic structure

After the completion of mechanical cleaning and elimination of leaks, the structure is disinfected. It is performed by applying a disinfectant solution to the inner walls of the mine with subsequent treatment of well water.

The solution is prepared in a glass or enameled container and insist it under a tightly closed lid for 1-2 hours. For disinfection use only a layer of the mixture that has emerged closer to the surface. In the case of using pure chlorine to obtain a 2% solution, the powder is diluted at the rate of 3-5 grams per 1 liter of liquid.

For applying the solution it is convenient to use a wide brush and a fur roller. It should cover the entire surface evenly. The remainder of the solution is treated with a bottom filter.

Well water disinfection

If the fluid analysis showed infection with bacteria, after mechanical cleaning and disinfection of the walls of the hydraulic structure, it is necessary to disinfect the water. The easiest way is to disinfect bleach.

For this, the treated shaft is again filled with water. Then a more concentrated solution obtained by diluting 200 grams of powder per liter of water is poured into it. To disinfect water, one cubic meter of liquid on average takes 500 ml of solution.

Chlorine-treated water cannot be consumed. Before putting the mine into operation, it will have to be emptied again and filled from scratch.

The neck of the well with the solution introduced into the water is covered with a lid wrapped in plastic wrap and left for a day. Such measures will help keep the mine cool, preventing the escape of chlorine.

If, after filling the well, the smell of chlorine is still present in the water, it is better to re-pump the liquid and wait until the structure is filled with a new portion of groundwater.

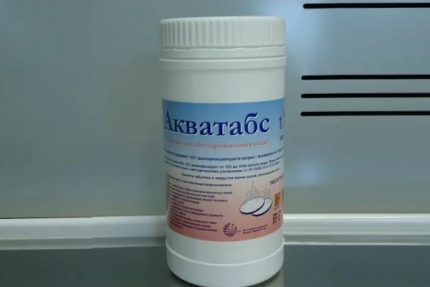

Disinfection of the building can also be performed with the help of special preparations such as Ecobriz-Oxy or Aquatabs.

Concentrated preparations for the preparation of disinfectant solutions are simply diluted with water and used according to the same technology as in the treatment with bleach.

In the first 5-7 days after disinfection, it is advisable to boil well water before eating it.

To get a solution of the required dosage, half a bottle of "White" is bred in a ten-liter bucket of cold water. The volume of solution required to process the contents of the entire mine is determined at the rate of 1 liter of fluid obtained per 1 ring of the well.

The resulting solution in quality and effectiveness will not be inferior to its more expensive counterparts.

There is an entire article on our site that is dedicated to water disinfection methods from the well, we recommend that you familiarize yourself.

Iron reduction

There are many ways to defer water. But all of them are based on the acceleration of oxidative processes, aimed at ensuring that iron goes into a trivalent state. In this form, iron-containing products precipitate in solid particles, which can only be filtered.

The easiest way to iron removal is the use of potent oxidizing agents. They destroy iron compounds, translating them into a trivalent state. Most often, chlorine is used as an oxidizing reagent. A toxic reagent can destroy not only iron compounds, but also divalent manganese, hydrogen sulfide, as well as many other substances of organic origin.

For deferrization, special filters are used, the inner walls of which are covered with a layer of oxidizing agent. In contact with the surface, iron enters into a reaction, as a result of which it becomes a precipitate and is easily cleaned with filter material.

Installation helps to solve the problem successfully reverse osmosis.

The aeration method has also proven itself. It is carried out by introducing air into the water using a compressor, which creates atmospheric pressure differences. To do this, water in the well is sprayed with special installations through gushing or showering.

Removal of hydrogen sulfide from a liquid

Hydrogen sulfide is a waste product of anaerobic bacteria. Sulfur bacteria live at the bottom of the well, where oxygen does not enter.

Experts offer two ways to solve the problem:

- Physical - assumes the saturation of the liquid with air. Forced aeration helps destroy serobacteria and additionally saturate the water with oxygen, making it more healthy. To implement this method will have to purchase expensive equipment.

- Chemical - involves the use of disinfectants and oxidizing agents: sodium hydrochloride, hydrogen peroxide or ozone. It provides the most complete degassing. Under the influence of oxidizing agents, hydrogen sulfide compounds transform into less active forms.

The liquid that has been chemically cleaned must undergo further additional filtration through activated carbon. For water purification, both carbon filters equipped with activated carbon and granular filters are used.

Water treatment with a solution of potassium permanganate helps to fix the problem. The potassium permanganate powder is first diluted in a three-liter jar to obtain a concentrated solution of a saturated violet color, and then poured into the well.

Subsequently, to prevent the formation of colonies of bacteria producing hydrogen sulfide, it is recommended to periodically perform a “purge” with compressed air.

Conclusions and useful video on the topic

How to make an analysis of water for the content of harmful impurities in it:

Non-reagent water treatment method:

Which filter to choose for cleaning dirty water:

In the future, in order to maintain proper water quality in the well, an analysis of its aquatic environment should be carried out annually. This will make it possible to control the quality of the water used, and if it worsens, take timely measures to improve the situation.

Have questions about the topic of the article? Found any flaws in the material or want to give valuable advice to visitors to our site? Please leave your comments in the block under the article.

Water seal for a well: how to close up cracks in concrete rings

Water seal for a well: how to close up cracks in concrete rings  Water purification from a well: an overview of the best and most effective ways

Water purification from a well: an overview of the best and most effective ways  How to make water supply in the country from the well with your own hands: we carry water into the house

How to make water supply in the country from the well with your own hands: we carry water into the house  How to swing a well: methods for pumping after drilling and during operation

How to swing a well: methods for pumping after drilling and during operation  DIY Abyssinian well construction: how to make an igloo-well on a site

DIY Abyssinian well construction: how to make an igloo-well on a site  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I generally had an interesting case. I decided to take water samples for a full analysis, I went to the city of SanEpidemstantsiya, where this service turned out to be paid, and even time-consuming. A friend turned up, he is the director of the restaurant, they, within the framework of agreements, give water samples for free several times a month. So I gave my samples through it. The results are given to them quickly, within a week they are ready. Water turned out to be normal both in iron content and in the quantitative composition of other elements. So we are calm now.

In our region, the water in the bowels is clean, but I still would not risk trusting the advice of the OBS (one grandmother said). Before using the well for drinking and cooking, I also performed a water analysis. Private traders repeatedly offered their services, but still I trust the Sanitary and Epidemiological Supervision somehow more. But the fact that he took the sample in the summer, after reading it, he thought ... Now it’s too late, probably in the spring it is worth going again. God protects the safe, as they say.

I understand that water for analysis needs to be taken to the laboratory, but how much will it cost? And questions about cleaning the well itself: what time of year is it better to do than clean plastic rings?

Hello. You should look for offers in a specific region.From 100 rubles (for minimal research) and up to more than 5000 (for the full range of checks). It also depends on the validity of the check - selective or complete. Application execution time is on average 5 business days for a full check on all indicators. But then again, I note that these are not critical prices / deadlines. Find out on offers in your city.

Cleaning should be done on a planned basis 1-2 times a year - in the fall in mid-September or in spring at the beginning / end of May, when the snow with talins has already disappeared and the groundwater level is quite low. There is an opinion that this should be done in the winter, but this is a misinterpretation of the words of digging specialists. If the well is the only source of water supply and you notice that the water has acquired a strange color / aroma / consistency, then we do the cleaning immediately.

Also see the helpful video for cleaning. here. Good luck