Why is muddy or yellow water in the well: causes of pollution and methods for their elimination

When constructing a well, we imagine how we will drink tasty, crystal and well-chilled well water directly from a galvanized bucket. But the reality is sometimes far from fantasy, and we find that the state of water does not inspire confidence. The result of quenching thirst can be unpredictable and even dangerous. Do you agree?

We will explain why muddy water in the well will explain in detail how to eliminate the causes of this phenomenon. The article submitted for consideration describes all kinds of reasons that affect the purity and chemical composition of water in a private source. Here you will learn not only about the methods of cleansing and disinfection, but also about the rules of prevention.

The content of the article:

Causes of turbidity in the well

As a rule, well owners prefer to drink water from a natural source, even if they are connected to a central water supply.

It is believed that water produced independently is akin to spring water and is healthier than that which undergoes chlorination. But over time, the water we received from the well loses its transparency. What can cause such an unpleasant phenomenon?

Well tightness

When constructing a well reinforced concrete rings, which are components of this structure, are set on top of each other. The seams between them are sealed.

But, over time, the movement of the soil can lead to a partial displacement of the rings relative to each other. At the same time, the tightness of the seams is also violated.

Spring floods, heavy rains and widespread snowmelt create an excessive load on the joints of the rings, as a result of which contaminated water begins to flow into the well. Dregs form.

I don’t want to not only drink such water, but also use it for everyday household needs. Moreover, in clouded water, hazardous chemicals may be present in dissolved form.

Change in aquifer composition

Sometimes dirt does not penetrate the well through the seams between the rings. They can poison the aquifer itself, due to which the structure is filled with water. This happens if there is an enterprise located near your site that merges its industrial effluents into a natural reservoir, ruining it and the territory adjacent to it.

In this case, the water can not only become cloudy, but also acquire an unnatural color. The shade of the liquid will depend on what type of contamination affected it. The pollution of this type is most difficult to fight: well water treatment will not bring the desired result.

Indeed, new portions of water from the supply layer will return the problem. One can only hope for a filter system that should be placed on the way of water from the source to the place of its final consumption.

Causes of excess iron

If yellow water has appeared in your well, then this may be caused by industrial effluents and high iron content. In the first case, the color of the liquid, as a rule, is strongly pronounced and may be accompanied by a chemical odor. In the second - only a shade of water will be yellowish.

To eliminate the high iron content, it is necessary to use special filters that can provide such cleaning.

Water stagnation problem

Another reason for clouding of water in a well can be stagnation. Perhaps the water source is not used as often as we would like. Water does not renew and stagnates.

Organic matter entering the well shaft from the outside begins to decompose. This process is accompanied by an unpleasant odor of hydrogen sulfide and a change in the color of the liquid.

Of course, you can’t drink such water, and you don’t want to: it has a specific aftertaste. Smell, color and taste arise due to the development of putrefactive bacteria in the water. This problem is corrected by the method of cleaning the well. That's just to clean and disinfect water source will have to be done more than once, but regularly, not forgetting to give due attention to this process and time.

Well design defects

When direct sunlight penetrates the mine unhindered, ultraviolet light creates ideal conditions for the development of bacteria and the multiplication of microorganisms. The fact that the “process has begun” will be signaled to us by a greenish tint of water and an unpleasant odor. In especially advanced cases, the walls of the structure can be covered with green mosses.

The source must be protected from direct sunlight and debris. You can do this with source arrangements, constructions over a canopy shaft or a gable house. You can just cover the shaft with a lid. As a rule, this problem is solved even in the process of choosing the shape of the future structure.

Error installing pump

Sometimes the appearance of water in the well is not a concern, and its clouding occurs only after the pump is started. It turns out that the equipment is simply improperly installed and during operation raises sludge from the bottom, which causes turbidity of the water. It happens if vibrating pump installed too close to the bottom or is very active and powerful.

If the operation of the pump became the cause of the change in the state of the liquid, it will have to be dismantled and reinstalled, having previously studied in detail the instructions for use of the equipment.

The distance from the suction part of the pump to the bottom surface should be no less than 70-80 cm. If the measures taken do not help, you should use a pump with a different type of liquid suction.

Methods for eliminating turbidity of water

If a problem arises, measures must be taken to resolve it. You will not drink and use muddy water with an unpleasant odor and taste for cooking? What can be done?

Well cleanup

The measures taken always depend on the source of the problem. If dregs are formed as a result of water pollution by pieces of silt and sand, it is necessary to install filters for mechanical cleaning, which will trap this suspension and prevent its removal from the water.

If the dirt brings with it water that seeps into the gaps between the rings of the mine, measures must be taken to eliminate the inlet openings for it. If the haze appears after heavy rains, then the reason for the pollution really lies in the lack of tightness of the seams.

When the cause of the trouble is established, you can begin to restore water quality.

To do this, you need:

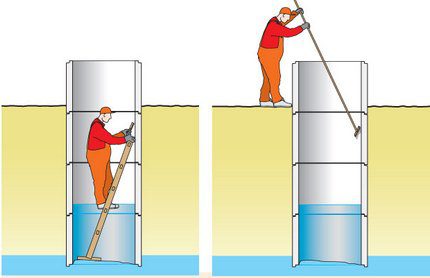

- with a pump to pump out all the water in the well from the well shaft;

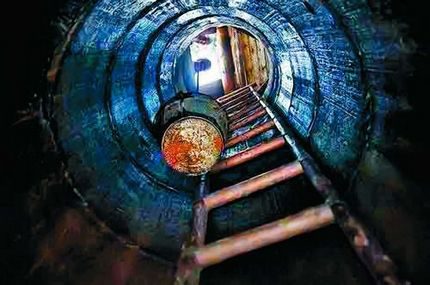

- armed with a scraper and a stiff brush, descend on the cable into the shaft in order to thoroughly clean the inner surface of its rings from deposits of any kind;

- disinfect the entire concrete surface mine;

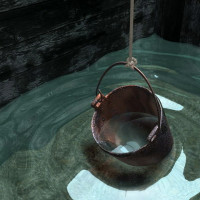

- scoop out all sludge, deposits and debris that accumulated there during operation from the bottom of the structure with buckets;

- explore the walls of the well: the joints of the rings, as well as cracks and chips found during the work, thoroughly lubricate with sealant;

- create a clay castle, if it was not provided during the construction of the well.

As a preventive measure to prevent water pollution, you can use a bottom filter from aspen.

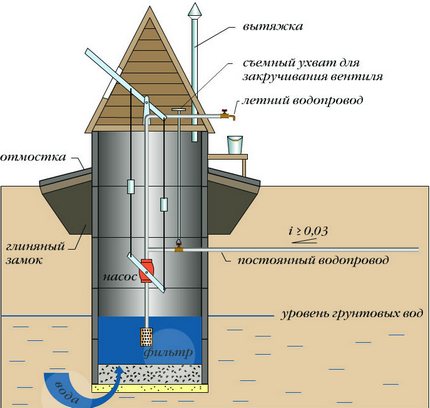

What is a clay castle

Turbid water in the well shaft may appear both during its operation and almost immediately after digging. This happens if during the installation of the well a clay castle was not built - a structure that is intended as an artificial barrier for rain and melt water to get into the well.

Perhaps the castle was made, but over time it failed or did not meet the technological requirements. In this case, the old clay protection will have to be dismantled and a new, high-quality one installed.

The manufacture of a new clay castle is carried out in the following order:

- Material preparation. Take the oily clay and add sand to it so that it makes up at least 15% of the mixture. When 20% lime is added to the working mixture, its composition will improve. Make sure that the clay does not dry out during operation.

- Digging a trench. Around the upper ring of the well, it is necessary to dig a trench approximately 2 meters deep and 50 cm wide.

- Castle formation. The resulting trench must be hammered with clay and well tamped. Do not forget to make a slight deviation from the ring to the periphery, which will not allow rain and melt water to accumulate around the mine site. Crushed stone is poured onto the clay and the castle is concreted, making it as protected as possible.

Such a clay castle will perfectly protect the contents of the well, diverting water from the exterior walls of the structure.

We make disinfection of a well

The appearance of bacteria in well water is accompanied by the appearance of an unpleasant odor. That is exactly how hydrogen sulfide smells, which occurs in the process of their life. Such water should not be drunk. It is necessary to disinfect the well and get rid of bacteria.

There are two main ways to solve the problem:

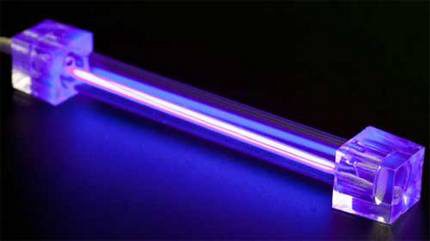

- surface treatment with ultraviolet lamps;

- cleaning the mine with chlorine.

Which method of disinfection is more effective? Let's figure it out.

UV treatment

The disadvantage of ultraviolet disinfection is the high cost of this procedure. The method has indisputable advantages: its application does not require significant preparatory work, and the taste of water treated with ultraviolet does not change after this procedure.

The source of ultraviolet radiation is special devices that must be installed in rooms, close to the place of water consumption.

It turns out that ultraviolet will not have any relation to the well itself, since the place of the radiation source is the consumer’s house. This treatment is used as a preventive measure that can prevent the appearance of bacteria.

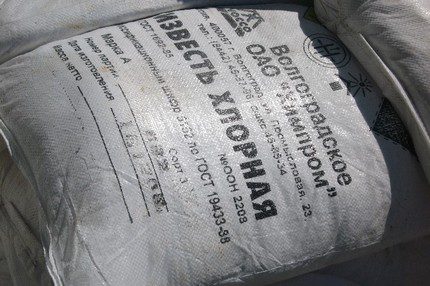

It turns out that cleaning with active chlorine is a non-alternative way to disinfect the mine. It is produced if it is believed that bacteria already exist in the water. After applying chlorine, you can also connect an ultraviolet installation.

Active chlorine stepwise purification

Unlike ultraviolet light, active chlorine can adversely affect human health. When applying it, it is necessary to carefully observe the recommended dosage.

Disinfection work is carried out by specialists equipped with protective equipment: respirators and special gloves. The procedure itself is strictly regulated by SanPiN.

It is conditionally possible to divide the entire disinfection procedure into the following stages:

- preliminary work;

- well shaft cleaning;

- final disinfection.

At the stage of preliminary disinfection, it is very important for us to calculate as accurately as possible exactly what volume of water is currently in the well. Knowing the parameters of the rings forming the walls of the structure, and the water level in it, it is not at all difficult to calculate the volume.

Now we need to calculate the total weight of active chlorine, which we will fill in the mine, based on the fact that for every liter of water we need 10 grams. powder.

We fill in the substance and agitate the resulting solution. To do this, scoop up a liquid with a bucket and immediately pour it back. We repeat this maneuver several times, after which we close the shaft with a lid, allowing chlorine to do its work for the next 2 hours.

After two hours, you can start cleaning the mine. To do this, completely free it from water. Now the mine needs to be thoroughly cleaned by removing moss and mucus from the walls, and from the day - silty layers and all kinds of garbage. All dirt must be raised to the surface and disposed of by burying away from the well.

We evaluate the condition of the walls: reveals cracks and leaky seams. Identified defects are eliminated by performing local repair work. Now the inner surface of the shaft should be disinfected. We prepare a solution at the rate of 3 gr. active chlorine or 15 gr. bleach per 1 liter of water and apply it to the surface using a control panel, roller or brush.

After completing these works, you can close the well and wait until the column is completely filled with water.

The third, final stage of processing is re-disinfection. We will again need a chlorine solution. To prepare it, you need to dissolve 200 g in 1 liter of water. bleach.

The solution must be left to infuse for an hour. We divide the resulting composition: we do not need the upper part to the sediment, and pour the lower part into the well.

We mix the water in the well with a bucket, as we already did before, and leave it for a day. After a day, you need to do the same procedure again. Another day has passed, now you need to completely pump out all the water and wipe the walls of the shaft with brushes, a mop or any other similar device. Then the walls are rinsed with clean water.

Now we have to fill the column several times with water and completely pump it out. This process will be completed only when the water ceases to smell like bleach, and in it there will be no extraneous taste. We will show reasonable caution: over the next two weeks we will drink only boiled water.

Water quality is not always determined by taste and smell. Better to confirm its characteristics laboratory analysis. How to take a sample and where to pass it for research is described in detail in our article.

Conclusions and useful video on the topic

If the process of water disinfection seems too complicated for you, you can turn to professionals for whom these works are familiar and understandable. How exactly they get down to business, look at the video:

This video presents different types of work aimed at a single result - to make the water that we get from the well tasty and safe for our health. Of course, the video is openly advertising in nature, but the overall workflow is presented in it clearly, accessible and in sufficient detail.

Clouding of water in a well is a signal that appears if the prevention of pollution in your well has failed. There are many reasons for this and we have described them in detail in this article so that you can easily find the source of your own troubles.

Most of the troubles could have been avoided if we carefully read the instructions for the pump, provide a cover and a canopy that protect the shaft from the sun and dirt, initially correctly position the well on a hill, do not forget about the clay apron around its perimeter, and so on.

Nevertheless, the situation is not fatal, and you can still fix it by following our advice or by contacting professionals who will certainly help you.

Want to share your own methods and subtle tricks in restoring the quality of well water? Please write comments in the block below. Here you can ask a question and post unique photos with the cleaning process.

Water purification from the well: what to do if the water in the well is cloudy or turns yellow

Water purification from the well: what to do if the water in the well is cloudy or turns yellow  Disinfection of water in a well: features of the disinfection procedure

Disinfection of water in a well: features of the disinfection procedure  Do-it-yourself well cleaning: a review of common clogging causes and best cleaning methods

Do-it-yourself well cleaning: a review of common clogging causes and best cleaning methods  Digging a well with your own hands: types of well structures + an overview of the best digging technologies

Digging a well with your own hands: types of well structures + an overview of the best digging technologies  A review of the best tools for cleaning wells and how to use them

A review of the best tools for cleaning wells and how to use them  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

For the second month now I’ve been trying to solve the problem with troubled water in a well. I immediately discarded some options: everything is fine with the rings, I am sure of this, and there is no defect in the design either. I thought maybe a lot of iron, but a special filter also did not help solve the problem. I think to make a clay castle, but I need help, if someone did it, then tell me how and where to start? What are the nuances? I will be glad to any information.

Yes, here, in general, there is nothing complicated. The most important task is to make water drainage from the concrete rings of the well as reliable as possible. You just dig around the perimeter of a deep trench - about 2 meters somewhere, there is no more sense to dig (through this thickness water will not leak out unambiguously), up to half a meter wide (the wider the better). Then you fill it all with clay mixture with sand and tamper well (it’s best to walk with a tamper). Then you make a small corner from the same clay (like a ramp from the rings of a well to the ground). And you strengthen this business with small rubble and a layer of concrete. Water will slide down the concrete and will not accumulate near the rings. You also make a convenient approach to the well itself for water collection. That's actually the whole science. But it’s better to take a water analysis, otherwise you may have a problem in another.

Hello. The water purification device is selected according to its intended use. This is the most effective method. To think that the water is cloudy due to iron and immediately buy such a filter is impractical. It is best to give water for analysis and find out its chemical composition, and only then choose treatment equipment. I would also like to know if there was such water in the first place, or did you just dig a well? Is there a shade of water?

I also had problems with clouding of water. At first I put it in a long box, but over time, the water quality deteriorated even more. I realized that I need to urgently decide, since the main source of water for me is just a well. First I relied on poor tightness of the rings, checked everything perfectly. Then, at random, he set filters to purify water from a large amount of iron, and the problem was solved. I am reading all the factors that could influence now and I understand that I was very lucky that my problem was solved quite easily.

On water, the causes of water pollution were clearly described, but I want to argue about cleaning, since it is better not to do it yourself. If the water has changed color, it is necessary to immediately do a professional examination, it is also recommended to do it at the very beginning of the use of a well or well. Whatever good cleaning method you have, there are elements that cannot be eliminated at home.

Laboratory chemical and bacteriological analysis of well water, which you call an examination, of course, will not be superfluous. But the cleaning methods listed in the material will be enough for most situations. Unless some plant starts to discharge into groundwater.